Bakewell STW – Activated Sludge Plant (2016)

The site discharges clean water into the River Wye - Courtesy of MWH Treatment

Bakewell is located in the heart of the Peak District National Park and as such attracts thousands of visitors each year. Bakewell is a thriving town with a cattle market that trades every Tuesday, a showground that hosts numerous national events each year and is a great base to explore the surrounding National Park. Bakewell grew up around a cluster of thermal springs and wells that attracted Iron Age settlers and, in Anglo-Saxon times, gave the place its name. The town has a long and fascinating history; and the clear, sparkling waters of the River Wye attract lots of visitors as well as Bakewell’s famous pudding.

Bakewell STW and the need for change

Bakewell STW is a traditional works comprising an inlet works, primary tanks, trickling filters, humus tanks and tertiary clarifier. In 2011, Severn Trent Water identified the need to update the original plant in order to meet the future 2020 discharge consent and address a significant number of capital maintenance issues.

The site outputs clean water into the River Wye – Courtesy of MWH Treatment

The existing works was built in the 1960s and treats wastewater from a population of just under 10,000 before discharging into the River Wye. The river is located over a half mile to the north of the site boundary and a few miles outside Bakewell.

The site has been modified in most areas over the last 55 years and the current assets were mostly life expired. The site had a number of health and safety issues and regular maintenance of existing plant was required to maintain a good quality final effluent.

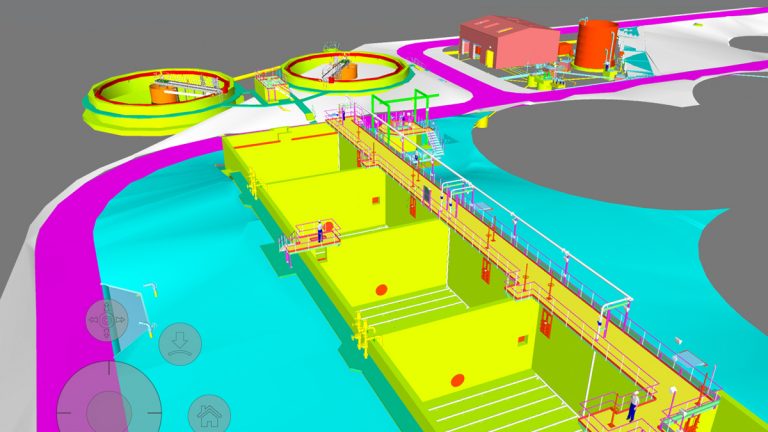

The new ASP at Bakewell STW – Courtesy of MWH Treatment

Engineering a solution through collaborative thinking

The original project drivers for Bakewell STW spanned different AMP periods and had different outcomes identified. These were:

- AMP5 Capital Maintenance Outcome: Comprising asset renewal and refurbishment.

- AMP6 Quality Outcome: Chemical dosing and tertiary solids removal to meet the new P consents being imposed.

3D image of site – Courtesy of MWH Treatment

The outcomes of both the schemes were reviewed and challenged by the team consisting of MWH Treatment and Severn Trent Water. The challenge would allow for further capital efficiencies to be delivered with all the previous outstanding risks mitigated, whilst also delivering a better TOTEX solution. The revised outcome was a single solution of a crude ASP with final settlement tanks and sludge handling facility.

Other benefits identified were:

- A reduction in the time of on-site construction from 30 months to 12 months through collaborative planning and utilising BIM.

- Ability to reduce operational risk and provide robustness for a transient population.

- Ability to reduce health and safety risk during construction.

- Benefit of reduced health and safety risk with the construction of a new works and up-to date assets.

- Reduced interface working and taking existing assets out of service for prolonged periods.

Challenges

The project team instigated the involvement of the construction team and supply chain being involved very early in the outline design stage. This allowed for early identification of key challenges, most of which were eliminated with effective use of 3D design and 4D scheduling, sharing of this information with relevant stakeholders and acting upon the early information provided. Some of the key challenges included:

- Restricted site access by way of a Grade 2 listed bridge limited to 40 tons.

- Private access road with restricted access covenant and Grade 2 listed gate posts.

- Small site with insufficient area for storage and site parking.

- High levels of groundwater.

- Peak Park location.

The ASP treats wastewater from a population of 10,000 – Courtesy MWH Treatment

All the early involvement gave the team the opportunity to plan well in advance and gave the team confidence in the security of the construction programme, knowing the site delivery team had intimate knowledge of the works well before construction commenced. The early involvement of the supply chain enabled the better integration of the new assets that deliver seamless interfacing. The key challenges could be managed, and construction methods and sequences were agreed by all parties well in advance of commencement on site.

Innovation

The solution was successfully engineered by teams of people ‘placing themselves in the end users shoes’ to form a collaborative approach to delivering the project. The result is a fully integrated set of assets that are delivering exceptional water quality whilst providing industry leading approach to asset management.

The project is due to be finished ahead of schedule – Courtesy of MWH Treatment

Some of the innovation identified can be detailed as:

- Lighting/instrument cable tray integrated into the access steelwork.

- ASP Access – modular design, quicker installation time with reduced work at height, integrated design with off-site manufacture and negating the requirement for temporary access.

- Sludge building layout: no trailing, low level trip hazards and no MCC trench. Effective use of space and cable duct routes.

- FST Walls were constructed using a new shutter system. This enabled a good finish, worked well, quicker and cheaper.

- All valve skids manufactured off site. Reduce manual handling/lifting with an integrated unit.

- Poly dosing area: use of GRP floor in entire area, no low level trip hazards.

- FST Launders constructed from GRP enabled a quicker installation and reduced/simplified wall construction.

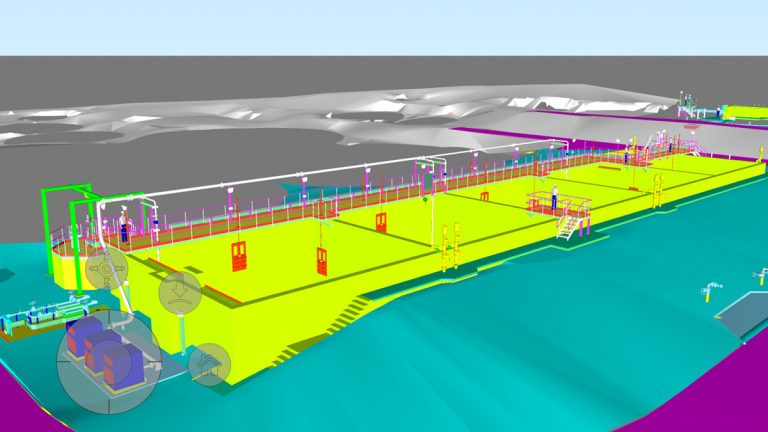

3D image of site – Courtesy of MWH Treatment

Lasting legacy for the community

The solution has replaced life expired assets that had various health and safety issues and also struggled to meet the varying flow and loads imposed through the transient population of the tourist town of Bakewell.

The new works is future-proofed and resilient, which will more than meet the demands of the ever changing population for years to come, as well as utilising cutting-edge technology to meet tighter consents imposed by the Environment Agency.

The new consents will ensure a better environment for the local communities that benefit from cleaner rivers where native habitats thrive, attracting more wildlife and also improving the water quality of these rivers and the surrounding catchments.