Carlisle WwTW (2022)

Carlisle STW: Showing the inlet works (bottom) with storm management area (left) and tertiary treatment are (top right) - Courtesy of J Murphy & Sons

Carlisle WwTW lies within United Utilities’ north Cumbria region. The site is located to the north-west of Carlisle’s city centre, on the banks of the River Eden, and serves the city of Carlisle. The treatment works receives domestic sewage, trade flows, and tankered imports, providing primary and secondary treatment prior to discharge to the River Eden. It is predicted that Carlisle will have a domestic population of 108,475 and a tourist population of 4,285 by the year 2035; these figures have been used as the design horizon in the basis of design for the proposed new works at Carlisle WwTW.

Background

Indigenous sludge from Carlisle and imported sludge from surrounding works are treated at the site where the process employed is liming prior to disposal to agriculture. The consented FTFT (flow to full treatment) is 104,976 m3/d (1,215 l/s) and flows in excess of this figure are discharged through storm tanks to the River Eden. Incoming domestic and trade flows from the catchment are received in a deep underground channel. Imported industrial flows and septage are discharged by tankers in the inlet.

Storm management & tertiary treatment area – Courtesy of J Murphy & Sons

Two duty/assist Archimedes screw pumps lift incoming flows and tankered imports to an elevated inlet works comprising three 6mm 2D inlet screens and two detritors. Site drainage is re-turned to the inlet upstream of the FtW (flow to works) screw pumps via gravity. Flows in excess of the capacity of the first stage pumps(2,141 l/s or 184,982 m3/d) are screened down to 6mm by a storm screen located in the CSO chamber. Screened stormwater overflows and discharges to the River Eden, while screenings captured are passed forward to the works. Screened flows up to FtFT are lifted to an elevated PST channel via two duty/assist FtFT screw pumps where flows are then biologically treated in primary and secondary stages.

Project objective

The works are needed to deliver the Environment Agency (EA) Water Industry National Environmental Programme (WINEP) outputs for a shellfish water quality driver and designed based on a 2035 design horizon. WINEP represents a set of actions that the Environment Agency have requested all 20 water companies operating in England, to complete between 2020 and 2025, in order to contribute towards meeting their environmental obligations.

The latest WINEP dataset was issued to United Utilities in March 2020, but specifically for Carlisle this means the works must achieve the following:

- Limiting the number of spills of stormwater to 10 per year or provide an equivalent form of treatment in the form of validated dose UV treatment for settled stormwater.

- Provision of event duration monitoring on all overflows to storm storage and stormwater treatment facilities.

Additional requirements of the project scope, not directly linked with the WINEP programme, are as follows:

- An increase in the screening capacity for stormwater.

- Increase standby capacity at the inlet works to bolster resilience and secure compliance in passing forward permitted flows.

- Additional treatment of the secondary treated sewage (final) effluent.

The inlet works

Increases in predicted storm flows to Carlisle WwTW require significant re-arrangement of the inlet works to accommodate the additional screening capacity. Built within propped cantilever cofferdam at an approximate depth of 4m, a new FRC CSO will increase the capacity of the current inlet CSO. As an addition to the current CSO, a new pipeline consisting of a gravity drain PCC solution at a depth of approximately 5m will be installed within a propped cantilever sheet piled temporary works solution and will create a new overflow outlet to the new storm management area.

Inlet works – Courtesy of J Murphy & Sons

Adjacent to the CSO pipeline a new screw FRC housing unit was installed with a propped cantilever sheet pile design; bridging existing cables supplying current operational plant. This was installed to an approximate depth of 4m with the challenges of a high-water table requiring dewatering works.

Further operational capacity is to be increased with two more FRC bypass channels, one including a new screening process. These channels are to be constructed to accommodate an additional 6mm screen, again equal in capacity to the existing screens in that group along with a new manually screened emergency bypass, all while the works continues to operate.

Challenges have continued as works to construct and install a third flow to works screw pump, equal in capacity to the existing screw pumps constructed in the 1970s, that connects into the incoming flows, which pass beneath a culvert that currently carries storm flows over the screw pump inlets.

Stormwater management

The stormwater management area consisted of a 3500m3 FRC stormwater detention tank, constructed on PCC driven piles, with a GRP pipeline returning to inlet. Feeding this is a large pumping station consisting of a secant pilled FRC structure, at a depth 17.5m using CFA method for piling. Piling works required 64 (No.) 1180mm diameter piles and 18 (No.) 660mm diameter piles. Rebar ranged in diameter from 32mm to 50mm. A FRC ring beam was formed at a depth of 3m, with reinforcement ranging from 12mm to 40mm and approximately 230m3 of concrete.

Stormwater management area – Courtesy of J Murphy & Sons

Carlisle WwTW Shellfish Waters Project: Supply chain (September 2022) – key participants

- Client: United Utilities

- Principal contractor & designer: Advance-plus JV (MWH Treatment, J Murphy & Sons, Stantec UK)

- Pumping station design: COWI UK Ltd

- Pysical scale model: Hydrotec Ltd

- Temporary works design: Murphy Applied Engineering

- Temporary works: Groundforce

- Piling: Murphy Ground Engineering

- Formwork: RMD Kwikform

- Cabling: Eric Wright Water

- Precast concrete: FLI Precast Solutions

- Over pumping/temporary works: Vanderkamp UK

- Above-ground pipework: Fluid Sealing & Engineering

- Structural & access steelwork: Alpha Plus Ltd

- Structural & access steelwork: Eden Fabrications

- Concrete storage tank: Bio-Dynamics

- Glass-linded steel tank: Goodwin Tanks Ltd

- Tertiary treatment plant: Eliquo Hydrok Ltd

- Screw pumps: Spaans Babcock Ltd

- CSO screens: Huber Technology

- 6mm inlet screen: Longwood Engineering

- Detritors: Jacopa Ltd

- Screenings handling: M and N Electrical and Mechanical Services

- FE & storm UV plant: Xylem Water Solutions

- GRP Pipe: Amiblu Norway AS

- Ductile iron pipework: Electrosteel Castings (UK) Ltd

- Penstocks: Glenfield Invicta

- Penstocks: Ham Baker

- Valves: Industrial Valves Ltd

- Pumps: Xylem Water Solutions

- GRP kiosks: Morgan Marine

- MCCs: Blackburn Starling Ltd

- Software: Tata Consultancy Services

- Generators: DT Gen

- Transformers: Smith Brothers Contracting

- Scaffold/temporary access: Paton Bros Scaffolding

- Lifting Equipment: T Allen Engineering Services

Tertiary treatment area

The tertiary treatment area consists of a PCC driven pilled FRC slab, with a new storm UV and FE channel, precast off site and fed from a pumping station via above-ground pipework. Construction included 56 (No.) 600mm diameter secant CFA piles at a depth of 14m with circular FRC ring beam installed on top.

In addition to the tertiary treatment area a 550m3 capacity glass-lined steel tank was constructed using the fixed-panel jacked system method.

Tertiary pumping station – Courtesy of J Murphy & Sons

Material changes

GRP pipe from Amiblu Norway AS was selected as the preferred option for pipework. GRP pipes are lighter than ductile iron, steel, concrete and most non-reinforced plastic pipes; making transportation less expensive. Additionally, pipes sized 1600mm-600mm in diameter can be nested within each other, reducing the cost of transportation and less expensive installation equipment can be used.

Pipes can be installed at 6m lengths and easily lifted via excavator, increasing productivity and reducing the need for more complex lifting on site. GRP pipes can also be cut on-site to suitable lengths.

Delivery savings due to weight alone are in the region of 20t of carbon. Lifting and handing on site result in additional savings.

Nested GRP pipework – Courtesy of J Murphy & Sons

Advances in site BIM delivery

The project delivery team are ensuring quality control and delivery assurance through the application of BIM 360 Glue and Field, ensuring digital delivery is at its heart and resetting the behaviours, processes, and methodologies to make it a success.

mView+ is also being utilised as the digital induction gateway to site. This is a fully interactive and immersive digital overview of the project in its entirety and is the first project on the United Utilities framework that is adopting this innovation site induction solution designed to change the way site hazards, phases of works, logistics plans and environmental and safety risks are communicated to those being inducted to site.

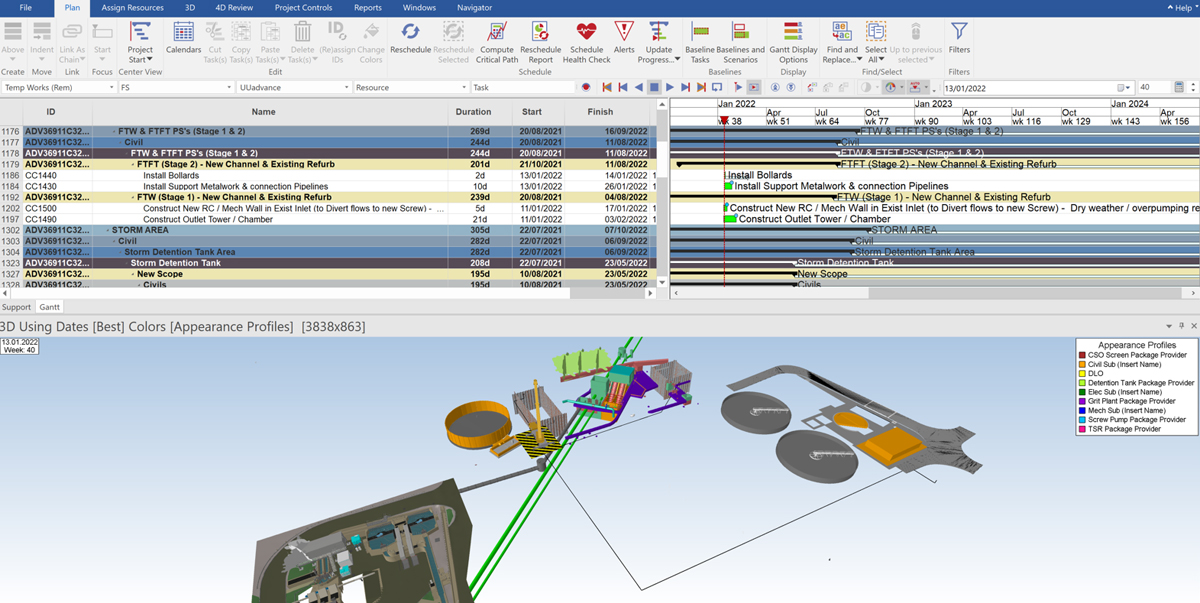

Synchro Pro (4D construction scheduling software) and Digital Rehearsals are being adopted to accurately timeline the construction process; turning the 3D model and programme into a fully integrated visualisation build sequence. By modelling the temporary works and high-risk activities, and rehearsing in readiness for breaking ground, the team are successfully driving a collaborative environment through engaging the client, supply chain, operations and site team, in developing and agreeing build sequences. This is promoting commitment and ownership of the programme at every stage, allowing the team to protect the delivery dates and provide delivery intensity.

Tertiary treatment area – Courtesy of J Murphy & Sons

Progress

At the time of writing (September 2022) the main civils work on the stormwater management and tertiary treatment areas are complete, with the focus now being pipework connections and the mechanical and electrical installation. Work continues with the sub-contractors to deliver the M&E install, to provide tested flows through the tertiary treatment plant to meet the requirements of the regulation date in late October.

Synchro Pro 4D construction scheduling software - Courtesy of J Murphy & Sons