Dean Clough Lower Impounding Reservoir (2022)

Installation of the twin pipe siphon system at Dean Clough Reservoir - Courtesy of Costain

Dean Clough Lower Impounding Reservoir (IR) is a Category A, earth-fill embankment reservoir, located approximately 6km north-east of Blackburn in Lancashire. It is currently used to provide storage for public water supply. It was formed by the construction of an earth embankment across the Dean Brook river and is the lower reservoir in a cascade of two dams, with Dean Clough Upper Reservoir immediately upstream. The dam is approximately 350m long, is straight in alignment and has a maximum height of approximately 20.3m. The top water level (TWL) is recorded as 163.62m AOD. The embankment has a clay core which extends into the foundation over the central section of the dam through the original stream channel.

Current facilities and reason for work

There are two existing draw-off pipes located approximately halfway up the right hand abutment. A 15-inch supply main (draw-off) passes under the spillway channel, however there is a branch off the main, just downstream of the downstream control, which feeds into the spillway channel. A 12-inch siphon scour system runs parallel to the draw-off main and runs into the spillway channel.

The maintenance work was required as part of United Utilities ongoing programme of improvements and to ultimately provide ability to efficiently lower the TWL by 5m to satisfy the Guide to Drawdown Capacity for Reservoir Safety and Emergency Planning.

Early contractor involvement

Initial outline design work had been undertaken by United Utilities, however due to a tight project programme, a collaborative and agile delivery approach was required and an early contractor involvement phase was employed to progress the design. A project delivery team was formalised in early August 2020 comprising of United Utilities, Costain and delivery subcontractor Eric Wright Water. A target date of summer 2021 had been set to complete the work.

Whilst relatively small in scale the technical, logistical and programme challenges were evident from the outset and required an agile delivery approach with the goal of ensuring the most efficient delivery programme whilst ensuring a high quality, efficient solution was delivered providing both the operational and safety benefits generated via the project but also the best value for United Utilities’ customers.

The agile delivery structure adopted combined the expertise of the group at the earliest opportunity; utilising both United Utilities and Costain engineering teams to develop the solution definition, coupled with the early engagement of the construction subcontractor Eric Wright Water; again combining the expertise across the team to generate early determination of methodology and opportunities.

During this early phase, a full assessment of the site was jointly developed and the scope options were reviewed weekly using an innovative 3D model, which informed the design proposals. This process was undertaken over the first eight weeks which allowed for any changes to be incorporated easily and any project risks identified and allocated appropriately and fairly.

The early engagement activity facilitated the identification of advanced procurement opportunities such as that of the long-lead 700mm PE pipework and reservoir specification valves, which among others were procured early to provide programme benefit and risk mitigation.

At the time of full contract award in early December 2020, approximately 80% of the design was complete, the PE pipework had been procured and vested off site to be brought in as required. During this time United Utilities drew the level of the reservoir down by 2m to enable work to proceed without the need for a cofferdam to be used to undertake the work, in turn reducing costs.

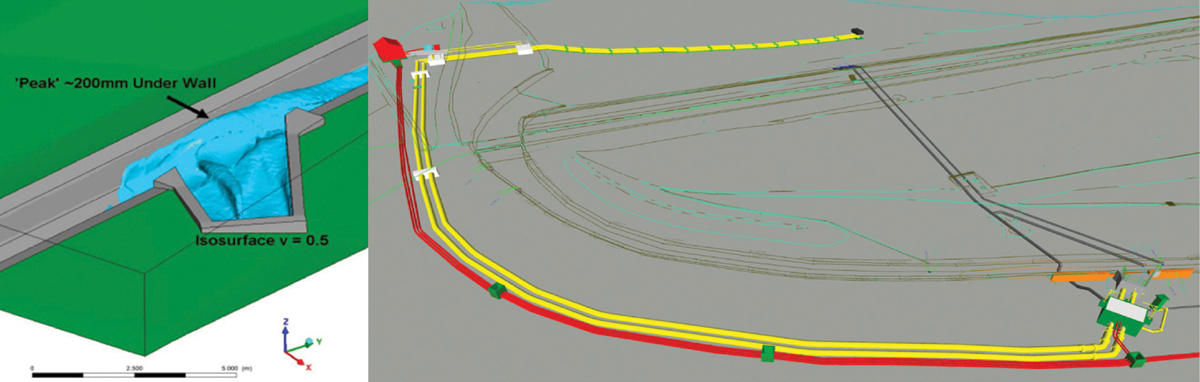

(left) CFD model showing discharge and (right) 3D model showing the whole scheme – Courtesy of Costain

Using a CFD modelling to identify out of channel flows

As part of the design, the new siphon would discharge into the existing spillway and potentially overtop due to the rate of discharge onto the dam mitre. An early decision was made to use computational fluid dynamics (CFD) modelling to prove the design with this information showing that no additional protection was required to the dam mitre when the new drawdown system was in operation.

Dean Clough Lower Impounding Reservoir: Supply chain – key participants

- Client & outline design: United Utilities

- Project delivery & lead design: Costain

- M&E design & delivery subcontractor: Eric Wright Water

- Diving operations: Red 7 Inshore Diving

The construction process

The site mobilised early in 2021 and despite significant bad weather the work commenced as planned. However, due to an early design change requirement to permanently reduce the reservoir top water level by an additional 800mm as part of the project scope, further input was required to be incorporated into the design, whilst maintaining the original programme. This lowering of the drawdown pipe significantly increased the depth of temporary works required to install the land side of the pipework.

(left) Existing discharge facilities and (right) existing overflow facilities – Courtesy of Costain

A flood contingency plan was agreed so that in the event of the reservoir filling due to a local storm event, the integrity of the dam could be maintained and any overtopping of the spillway could be directed as originally intended. This was reviewed weekly by the site and United Utilities reservoir team to accommodate any changes in either the weather or site operations.

The construction works involved:

- Breaking into the existing spillway and building the new discharge culvert in line with the model tying into the existing stone lined spillway.

- The construction of a stone clad and tiled building, built to comply with planning requirements.

- A diving team installed the in-water pipework to the suction table at 9m below TWL.

Delivering benefits

The design solution, agile approach and collaboration led to a number of benefits including:

- Early collaborative engagement reduced the programme significantly, saving around three months off the original programme.

- Appointing delivery subcontractors early ensured all parties were fully bought into the solution and had a direct input into how the project was designed and required to be constructed .

- United Utilities were able to deliver the project in accordance with their regulatory commitment.

- The effective management of change whilst maintaining the target programme schedule was a testament to the collaboration of the team.

- By understanding the requirements early and working closely with the sub-contractors on site, the solution provided the desired outcome, whilst removing/reducing risk during construction.

Efficiency through the design phase, utilising the combined expertise of the team generated solution efficiencies to the value of over £400,000 (20% of scheme value) providing best value to the United Utilities’ customers. This included examples such as pipework rationalisation, diving works methodology improvements and reduction in temporary works requirements through detailed consideration in the hydraulic design.

(left) Temporary works for the pipeline and (right) Dean Clough diving operations – Courtesy of Costain

Conclusion

The team were able to achieve great success across the delivery of the project. The strategic aims and ambition of the agile delivery approach were achieved in full and allowed the project to meet its regulatory commitments, providing a solution which was brought into service ‘first-time’ and snag free.

The success of the Dean Clough project team is not measured in scale of the project but in successfully coming together and buying into the delivery strategy with a clear aim from the outset and collectively implementing the required behaviours throughout the delivery of the project. The project was able to achieve its operational safety benefits and regulatory commitments whilst driving real efficiency in the solution.