Deephams STW – Biomethane Project (2023)

Deephams STW Biomethane Project pre-treatment package (siloxane and H2S removal filters) - Courtesy of SGN Commercial Ltd

Deephams Sewage Treatment Works (STW) is located in Edmonton, North London. In November 2018, Thames Water Utilities Limited (TWUL) issued take-over to the AECOM, Murphy, and Kier (AMK) joint venture for the replacement of the entire sewage treatment stream. The project increased the treatment capacity to 989,000 population equivalent and met the new final effluent flow to full treatment capacity of 5,750 l/s and the discharge consent quality concentration of 10/5/1/1mg/l (solids/BOD/NH3-N/P). As described in the UK Water Projects 2018 article Deephams STW – A630 Major Project, the project utilised integrated fixed film activated sludge (IFAS) media in the temporary and permanent phases of the works to increase the biological mass in the aerobic phase of the activated sludge process.

Biogas yield

Since the commissioning of the new sewage stream, TWUL operational excellence has resulted in the yield of biogas exceeding the best estimates of its generation from the anaerobic digestion plant. The unintended consequence being that both the CHP and boiler demands are met but regular flaring of excess gas occurs. To avoid these environmental emissions, the biomethane project at Deephams STW was born.

During 2020, TWUL created a design, build, maintenance and operation framework agreement for the provision of biomethane plants and in March 2021 a contract was awarded to SGN Commercial Services Limited for the project at Deephams STW. The plant is designed for a maximum 1,150Nm3/hr flowrate of biogas, with a maximum biomethane injection rate to the Cadent medium pressure grid of 825Sm3/hr after enrichment with the addition of propane.

Deephams STW Biomethane Plant flow diagram

Engineering technical solution development

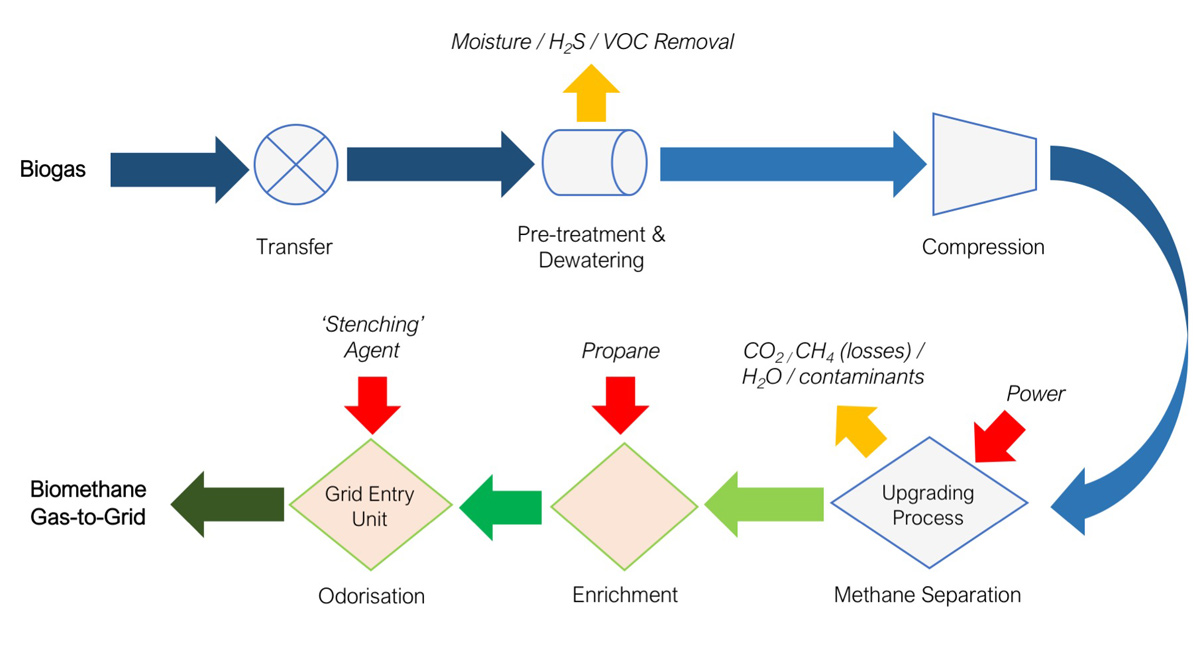

The biomethane plant gas-to-grid treatment stream comprise the following stages:

- Biogas transferred from the anaerobic digestion plant.

- Pre-treatment and dewatering.

- Compression and methane separation.

- Enrichment, gas quality monitoring, odorisation, and injection into the grid.

The design concept was to allow flexibility for the biogas to be diverted to either the biomethane plant or to the retained CHP capacity. Thereby, permitting biogas to feed the biomethane plant during normal operational periods but to be diverted to the CHP during high electricity demand periods from the STW plus fulfil any obligations to export electricity off-site to the electricity grid during high consumer demand periods.

Membrane unit – Courtesy of SGN Commercial Ltd

Biogas transferred from the anaerobic digestion plant: Upstream of the gas holder, a connection was provided to supply the biomethane plant. The biogas header operates at between 5–25mbar.

Biogas is saturated with water vapour, and its composition is 50-60% methane (CH4), 40-50% carbon dioxide (CO2), and small amounts of hydrogen sulphide (H2S), siloxanes, nitrogen (N2), Oxygen (O2), and other trace components such as volatile organic compounds (VOCs).

Compression and methane separation: The pre-treated biogas is then analysed and if it is within specification transferred to the compression stage (two 600Nm3/hr compressors capable of 50% turndown ratio) which creates a driving force for membrane separation of the CO2 and CH4.

The compressed biogas is further cleaned to reduce oil, water and any remaining contaminants to negligible levels to protect the membrane system’s operation and performance.

Highly selective Evonik Sepuran membranes supplied by DMT Environmental Technology are used to permeate the CO2 from CH4. The polymer of which the membrane is formed allows the larger CH4 molecule to be retained within the gas stream whilst the membrane polymer which is subjected to heat and pressure allows the smaller CO2 molecule to permeate through its structure and separate from the CH4. The CO2 passes through a vent and is then discharged to atmosphere.

Compressor room – Courtesy of SGN Commercial Ltd

Enrichment, gas quality monitoring, odorisation, and injection into the grid: The resultant biomethane gas (retained methane) is checked for compliance with the Gas Safety Management Regulations (GSMR); once satisfactory, it is conveyed to the grid-entry-unit for final conditioning. The biomethane has a lower calorific value, approximately 5%, than the indigenous network natural gas so requires enrichment with propane (a heavier hydrocarbon with a higher calorific value). Following the addition of propane, the gas passes through the Honeywell UK limited gas-to-grid entry unit where it is tested. If it is of acceptable quality for onward conveyance into the Cadent gas network, it is metered and undergoes its final conditioning phase with the addition of a sulphur compound or ‘stenching’ agent to introduce the distinctive ‘natural gas’ odour.

In the event of there being a problem in the Cadent gas network there is a remote operated valve (owned by Cadent) that can shut off the supply of biomethane gas from Deephams STW.

If at any phase of the process stream ‘gas’ is out of standard or specification the biomethane gas is rejected by the grid-entry-unit. These rejected gases are then either diverted to the waste gas burner (WGB) or returned to the biogas storage.

Deephams Biomethane Project: Supply chain – key participants

- Biomethane plant design/delivery: SGN Commercial Services

- DSEAR EPD: SLR Consulting

- Civil/electrical engineering: Bridges Limited

- Pipelines: South East Eco Utilities Limited

- Biogas upgrading plant: DMT Environmental Technology

- Gas-to-grid entry unit: Honeywell UK Limited

- Siloxane & H2S removal filters: CPL Activated Carbons

- Propane tanks: Flogas Britain Ltd

Honeywell UK Limited grid entry unit – courtesy of SGN Commercial Ltd

Non-engineering technical challenges

As with most projects, the complexity of its implementation was not solely restricted to the engineering solution.

Multiple other challenges were confronted and delivered, including:

- Third party agreements.

- Permitted development rights.

- Waste operation environmental permit.

- Application of Thames Water standards and gas industry standards.

- Renewable energy grants.

- Future opportunity.

Third party agreements: Engagement with Cadent was a key delivery component to ensure timely compliance with their guidelines; a pre-requisite for the biomethane to be injected into the national gas transmission grid. The first key component being to obtain a Grid Connection Agreement which permitted the physical connection to the medium pressure main; the second being granted the Network Entry Agreement which required the installation of Cadent approved plant to demonstrate the provision of ‘in-specification biomethane’ being ready for injection into the grid. This was achieved by utilising the Honeywell UK limited gas-to-grid entry unit; a tried-and-tested solution that Cadent had previously approved.

(left) Cadent-owned remote operated valve and (right) the electrical HV room – Courtesy of SGN Commercial Ltd

Permitted development rights: A key driver in achieving timely commissioning of the biomethane plant was for the project to be implemented under TWUL’s permitted development rights as a statutory sewerage undertaker. TWUL requested of London Borough of Enfield (LBE) an EIA Screening Opinion under Regulation 6 of the Town and Country Planning (Environmental Impact Assessment) Regulations 2017 for the proposed biomethane plant to agree that an EIA was not required (as if full EIA is required, permitted development rights are removed). LBE agreed and issued an EIA Screening Opinion confirming that full EIA was not required. TWUL hence notified LBE that the scheme would be implemented under their permitted development rights as Statutory Sewerage Undertaker. Subsequently, LBE agreed that the development constituted Permitted Development under Part 13 B (f) of the regulations, as none of the exclusions to development permitted under Part 13, Class B applied.

Waste operation environmental permit: The waste operation environmental permit for the CHP plant was varied to include an ‘R3: recycling/reclamation of organic substances (which are not used as solvents)’ activity for upgrading the biogas to biomethane, in a biomethane plant, for injection into the national gas transmission grid. In essence, the change had the effect of extending the CHP’s green permit boundary line. As a result of biogas being converted to biomethane, compliance with the requirements of the end-of-waste quality protocol for biomethane was a prerequisite. It defined the point at which the biogas (which is termed as a waste) ceases to be waste; and the by-product biomethane can be used as a product without the requirement for waste management controls as the point-of-injection into the Cadent gas network.

Propane tanks – Courtesy of SGN Commercial Ltd

Application of TWUL asset standards and gas industry standards: As the design developed, it was necessary to agree the order of precedence of TWUL corporate asset standards and gas industry standards. It was concluded that the conditioning plant up-front of the biomethane plant is typical of the gas conditioning plant for CHP unit, hence, TWUL adopted corporate asset standards to that area. Once the biogas meets the 15bar high pressure forwarding gas compressors (the ‘compression’ phase described above), then international and gas industry (IGEM) standards were adopted.

Renewable energy grants: It was identified that the project qualified for the Renewable Heat Incentive (RHI) accreditation scheme. A 20-year long-term financial support programme for renewable heat that closed on 31 March 2022. Notwithstanding the benefit of the project contributing towards TWUL goal of net zero carbon emissions in 2030, the financial benefits of meeting the RHI timeline were a driver. If the deadline was not met, it was planned on selling the biomethane into the Road Transport Fuel Obligation (RTFO) scheme. A non-guaranteed revenue stream dictated by market forces of supply and demand for the biomethane commodity. Following the closure of the RHI, TWUL is currently seeking an amendment to the Green Gas Support Scheme (GGSS) to allow retro-fits. This would support biomethane gas-to-grid projects like the Deephams STW project being built at other TWUL sites.

Future opportunity: To further enhance the benefit of such biomethane plants; investigations are on-going into the practicality of adding a carbon dioxide capture plant into the process. A key driver for its implementation will be whether validation is granted that the carbon dioxide is of food industry quality; plus assessing whether the technology currently available is commercially viable.

Deephams STW Biomethane Plant – Courtesy of SGN Commercial Ltd

Conclusion

The Deephams STW biomethane plant gas-to-grid solution is helping Thames Water Utilities Limited achieve its goal of net zero carbon emissions across all operations by 2030. Within the first year of operation, it has produced an average of 550m3/hr of biomethane being injected into the gas grid with 97% availability. This is enough gas derived from the biomethane plant to heat 4,250 homes in the London Borough of Enfield.

The potential for roll out of similar projects across TWUL’s estate is large; estimates indicate that there are twenty-four potential STW sites that could install biomethane plants to generate enough gas to heat over 50,000 homes. The Deephams STW biomethane plant project remains a suitable engineering example where technology provides a viable opportunity to produce renewable energy whilst helping to reduce carbon emissions.