Dynamic Demand Project (2018)

United Utilities (UU) provides water and sewage services to around seven million people in the north-west of England. As energy is one of UU’s biggest costs the mantra is to use less, generate more and use the company’s assets in a smarter way. It was ‘getting smarter’ that led to pioneering Dynamic Demand. A few years on and United Utilities are well on the way to building a virtual power station. Dynamic Demand is a patented technology supplied by Open Energi which was installed, integrated and commissioned by a project team consisting of Open Energi, Bilfinger Industrial Automation Services and Internal United Utilities resources.

Background

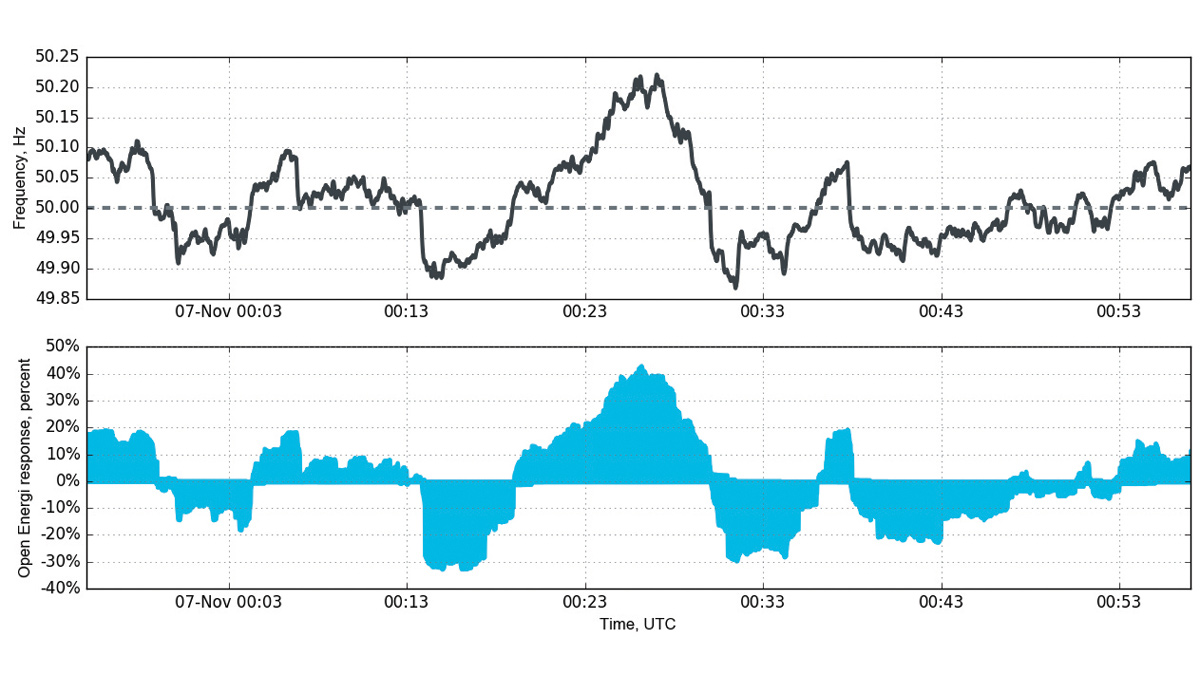

The National Grid has a requirement to maintain the frequency of the electricity system at 50Hz ± 0.5Hz by balancing electricity supply and demand in real time. Customers (or the ‘demand side’) can help to achieve this. Due to changes underway in the energy sector, National Grid is incentivising customers to vary their power demand in line with fluctuations detected in the systems frequency. National Grid pays users who can manage consumption in line with their requirements.

Open Energi’s Dynamic Demand technology provides a frontline service known as Dynamic Firm Frequency Response to help National Grid balance electricity supply and demand in real time 24/7/365.

United Utilities was the first to apply this technology within a regulated industry whose operations directly have an impact on the environment and public health. A challenge was set to identify assets that this technology could be applied to that met the following:

- The criteria for Dynamic Firm Frequency Response set by National Grid.

- There will be no impact to United Utilities customers.

- It will not cause United Utilities to exceed strict regulatory consents set by the Environment Agency (EA) or the Drinking Water Inspectorate (DWI).

- Provide a return on investment (ROI) within 5 years.

The Dynamic Firm Frequency Response service requirements set by National Grid are:

- Equipment must begin to make a change in power within 2 seconds.

- Equipment must have reached the maximum change in power within 10 seconds.

- The load must be able to maintain the changed state for a total of 30 minutes.

In 2014 United Utilities partnered with Open Energi, an award winning demand side response aggregator to take a further look at using this technology. Sites were identified that would lend themselves to this process and a trial began.

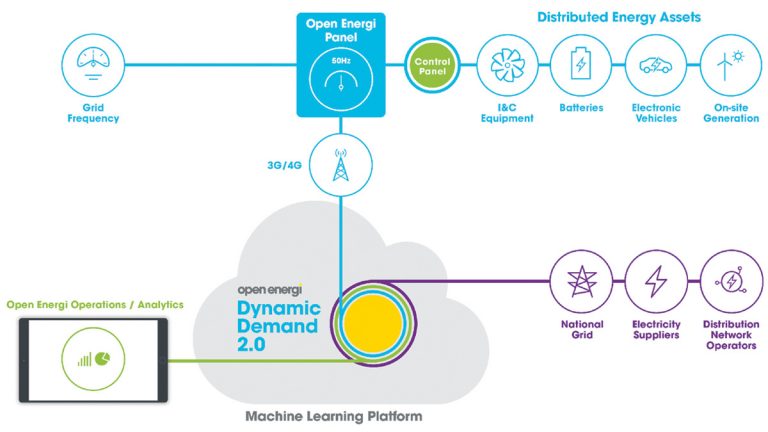

Dynamic Demand solution architecture – Courtesy of Open Energi

The initial trial

The trial focused on three locations, Hoghton Water Pumping Station, Bolton WwTW and Birkenhead WwTW. The plant equipment chosen had to be of sufficient power, meet suitable start up and running response times and provide good availability to switch. The preferred options pointed towards aeration systems which tend to run continuously and allow great flexibility to either increase consumption (high response) or decrease consumption (low response) without detrimentally effecting the process.

Phase 1 & Phase 2 feasibility studies

In the study phase it was important to include operations and maintenance staff in the consultation period. This helped them develop a greater understanding and appreciation of the system and what it was capable of. After a review of the study findings a number of sites were selected and in spring 2014 Phase one of the Dynamic Demand Project began.

Main feasibility study criteria:

- Liaise with Operational teams to establish any current site issues or concerns.

- Review existing control philosophy.

- Check the equipment is compatible.

- Assess any current process, mechanical or electrical issues.

- Confirm that process compliance will not be compromised.

- Establish the available KW load.

- Survey related process instrumentation.

Activated sludge process (ASP)

An ASP plant is fundamental in helping reduce ammonia in the wastewater treatment process. Returned activated sludge combined with oxygen biologically reduces the ammonia content in the secondary treatment process causing the ammonia to be nitrified to nitrates. United Utilities historically have adopted three main activated sludge processes namely fine bubble diffused air (FBDA), surface aeration and the Orbal system.

Rochdale WwTW FBDA plant – Courtesy of United Utilities

Design and definition

Installing Dynamic Demand requires an interface with the PLC control system. The surface aeration ASP plant typically consists of a number of lanes fitted with motor driven surface mounted aerators controlled by a PLC utilising the installed analytical instruments to ensure compliance. These aerators are used to alter the oxygen content in the wastewater. Dynamic Demand operates within the standard control philosophy of the process and switches the aerators on or off depending on the frequency of the National Grid.

Engaging with design and build Partner Bilfinger, a Functional Design Specification (FDS) was produced. This was reviewed and a subsequently a HAZOP meeting followed to discuss any process and safety concerns. Issues identified from the HAZOP were addressed before the project progressed to the implementation phase. Software modifications were then completed and a full Factory Acceptance Test carried out. This gave the opportunity to evaluate the changes using simulation software. This forms part of the United Utilities Technical Assurance Process.

Control system overview

The feasibility study allowed UU to determine what could be switched under Dynamic Demand control. Close liaison with operations and maintenance staff allowed for a full understanding of the requirements for their site. When designing the control software, consideration was given to the electrical loading on the main incomer ACB as the loading increases considerably when starting multiple motors within a 10 second time window. This increased loading was factored into the design to ensure the main ACB was not overloaded. Consideration was also given to over pressurisation of air lines. On some wastewater sites ammonia measurement is used as a control setpoint rather than dissolved oxygen as this can provide greater availability for Dynamic Demand. An enable/disable function on the local aeration HMI and SCADA is also provided to allow the operational staff to disable Dynamic Demand in the event of a TRIAD.

Operating constraints

- Dynamic Demand can be user enabled/disabled.

- The dissolved oxygen or ammonia values are monitored.

- The maximum time the aeration motors can be switched.

- The minimum run time before another switch can take place.

- A maximum number of switches in a rolling hour.

- Heartbeat monitoring between the two systems.

- Interlocks to provide plant safety and protection.

- Operational entry conditions

- The analytical monitoring instrumentation is healthy.

- Dynamic Demand has been enabled.

- The monitored dissolved oxygen/ammonia levels are within the set limits to allow a switch.

- The pre-set timers are in a state to allow another switch.

- The Modbus watchdog link is healthy.

- The PLC indicates the loads viable for switching are available and controllable.

Rochdale WwTW FBDA blowers – Courtesy of Open Energi

Implementation: example site

A single Open Energi control panel was installed in the ASP MCC room by Bilfinger Industrial Automation Services. This panel was connected to a metering panel via an Ethernet link. Using CT’s (current transformers) Open Energi was able to monitor the incoming three phase load. The individual motor loads are also monitored. The supply frequency is monitored locally so it is able to respond intuitively and rapidly to any fluctuations.

The existing aeration PLC was connected using Modbus to provide an interface between the PLC and the Open Energi panel. Power data is transmitted off site via a GSM link to Open Energi’s main operations centre.

As part of the design, the HMI and SCADA were modified to add a Dynamic Demand mimic screen, set point page and a small number of local on-site alarms. On completion of all hardware installation the next phase was for the modified software to be downloaded into the ASP PLC. At this point Bilfinger’s in-house system integrator attended site along with Open Energi’s Solution Architect.

Commissioning

The commissioning process followed a pre-determined set of tests in line with the United Utilities Technical Assurance Process. It was important to prove the system functioned as designed. The test procedure typically included:

- Proving of data transfer between the PLC and Open Energi’s panel.

- Testing of all relevant interlocks, inhibit and enable signals.

- Operation of the HMI and SCADA mimic and set point pages functionality.

- All Dynamic Demand alarms generated.

- High and low live switching and load testing.

Bolton WwTW activated sludge plant – Courtesy of United Utilities

Handover

After successful completion of all testing, Dynamic Demand was handed over to Operations staff who formally agreed to operate it. Training was given and a period of time was then established to further prove Dynamic Demand in action. Switching was evaluated by Open Energi and performance figures were reported back to United Utilities. Final handover followed once all parties agreed that the system was functional, reliable and switching as required with no impact to the process. At this stage UU had final sign off bringing the project to successful completion.

Benefits

Numerous benefits can be seen as shown in the list below:

- Helps National Grid balance electricity supply and demand in real time.

- Energy neutral (overall energy consumption remains unchanged).

- Not overly complex to install.

- Earns revenue for being available to switch.

- Paid for availability all year round.

- No adverse impact on business process, compliance or performance.

- Every MW of Dynamic Demand is a MW National Grid does not have to procure from a fossil fuelled power station, reducing UK CO2 emissions by an estimated 2,276 tCO2 per year.

Widnes WwTW Orbals plant – Courtesy of United Utilities

Conclusion

United Utilities has shown this technology to be highly successful in the water industry and for this project was officially honoured with ‘highly commended’ at the IET Innovation Awards 2016. To date, Dynamic Demand has been installed on 13 United Utilities’ sites becoming part of the day to day operation, with no detrimental effects on the treatment/pumping process. The system is monitored by Open Energi and has shown its potential by generating revenue for the business, in turn helping to offset rising energy costs.

UU’s aim is to provide access to 50MW of various Demand Side Response solutions for National Grid by 2020; enough to displace a peaking power station. The implementation of the Dynamic Demand service clearly demonstrates that the water industry has the potential to build a sustainable future UK energy market.