Technocover Ltd

High Security Enclosures for Water Assets (2020)

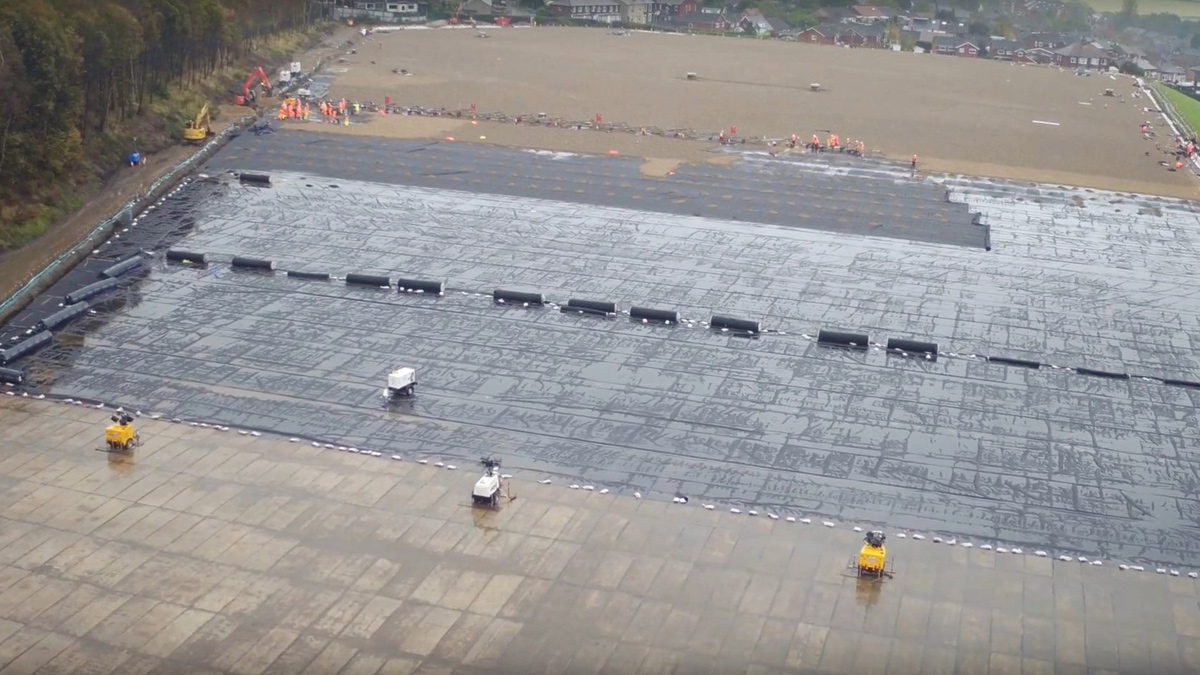

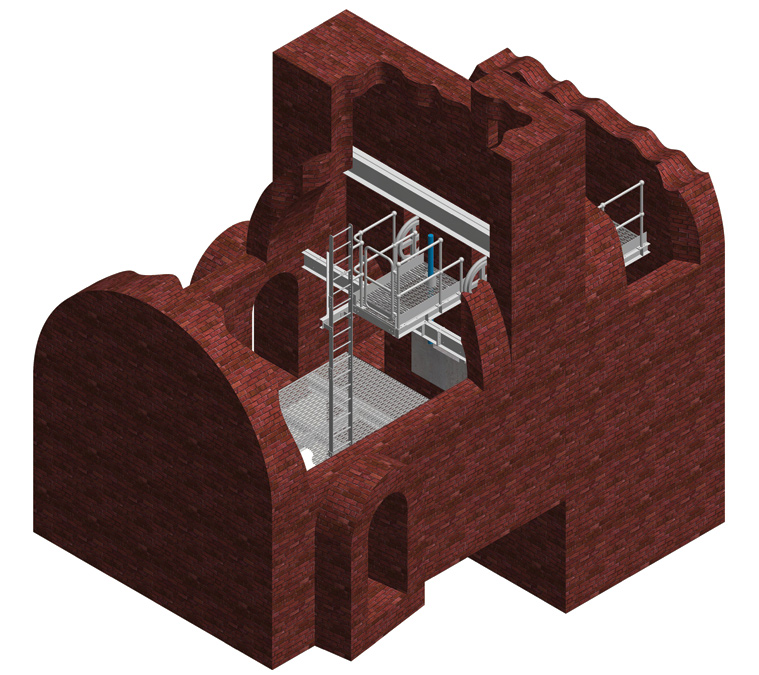

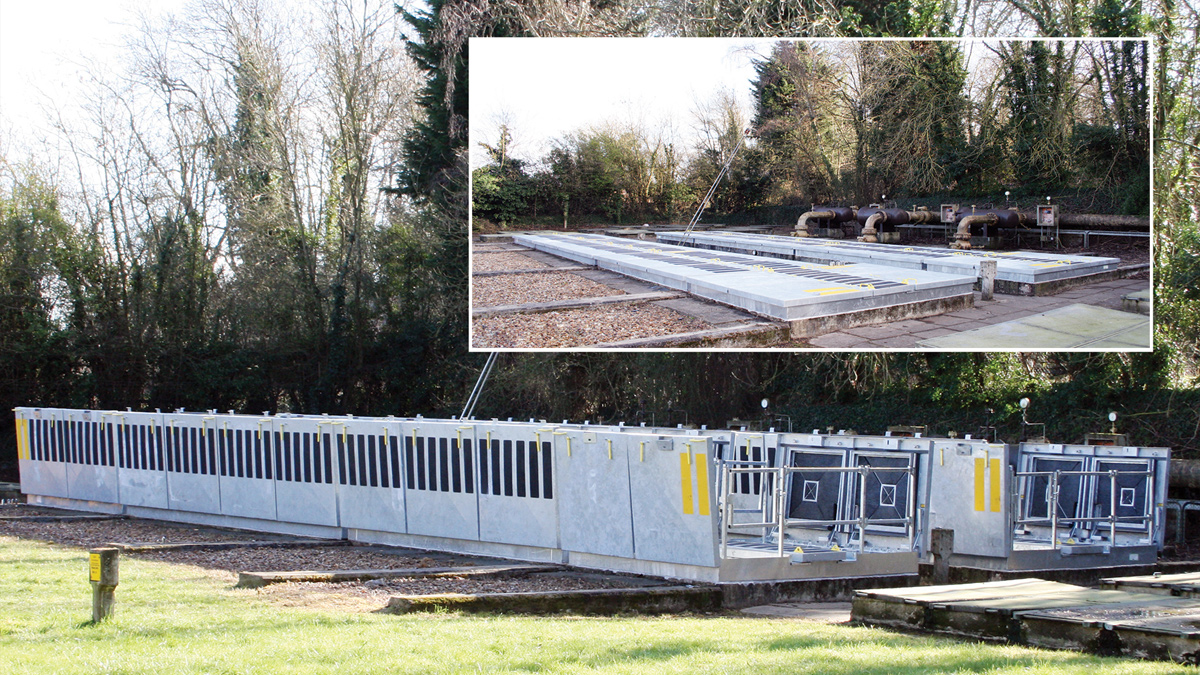

(left) High security, modular cage installed at impounding reservoir using a floating pontoon and (right) UltraSecure enclosures can be integrated within large and complex cover systems to provide protection and flexible access to newly constructed underground facilities, all within LPCB certification

The security of the UK water network is integral to investment plans and operational management for water companies in the face of an ever-growing hierarchy of threats. These risks range from trespass, vandalism, malicious damage and opportunistic theft, to organised crime, infiltration and sabotage by activists, and terrorist attack invariably intent on causing major disruption and harm to life. Any breach of a restricted area or critical process will have an impact on site operations, incurring time and cost of incident management, of equipment repair or replacement, and from service interruption. More catastrophic still, there may be ramifications for regional if not national water supply and public health.

Other emerging threats have highlighted the critical role of water supply resilience. Weather extremes and flooding caused by climate change pose the risk of network disruption and costly remediation, as well as unplanned maintenance due to the premature ageing or failure of infrastructure. Most recently we have seen that the response during a pandemic like COVID-19 relies on a secure water supply to maintain life-saving medical services and a population in lockdown.

In combatting these omnipresent threats, water companies continue to review and enhance the physical security of the water network alongside technology for surveillance, personnel ID and access control.

A mesh UltraSecure enclosure, measuring 3.3m x 7m on plan, being installed in two halves to harden asset protection at a pumping station site

As the UK water industry reaches an advanced level of maturity in physical protection, the high security enclosure has seen significant demand and diversification through AMP6. This is set to continue in AMP7 as manufacturers like Technocover push the boundaries in the design and versatility of modular buildings, kiosks and cabinets meeting the rigorous performance standard of LCPB security certification.

Working in close partnership with water companies and contractors, Technocover has designed, built and installed a diverse range of secure, steel enclosures with certified, measurable levels of protection for many applications – from boreholes, pumping stations and reservoirs, to treatment processes, power generators and switchgear, and the storage of hazardous chemicals and materials.

Technocover organised special transport and lifting plant for the delivery and installation of several pre-assembled enclosures measuring 6m long by 5.46m wide by 3m high to reduce site time

The core function of these enclosures is to protect the asset against forced entry by hostile actors, giving time for first responders to arrive. However, the design and planning of these critical pieces of engineering can also address other important project considerations in maximising whole life benefits and saving cost for the client.

For example, the mode of assembly should minimise, if not eliminate down-time, and overcome access and space constraints on site. Equipment design should provide scope to add functionality and contingencies to enhance operational safety and efficiency, while allowing for system extension or reconfiguration according to future needs. And, in line with TOTEX (total expenditure) accounting, the engineering should provide long-term, predictable performance and minimum maintenance in delivering best value over the product lifecycle.

In meeting these complex criteria, each enclosure is different. However, based on many years’ experience of solving challenges large and small, from urban to remote highland sites, Technocover has evolved three main approaches to the secure housing of water assets, suitable for refurbishment or new build.

Off-site assembly, delivery and installation of an LPCB SR3 enclosure

Solution 1: Wrap-arounds – installing a new enclosure around an existing asset

Long-established sites, especially those in urban areas, often have limited space for construction activities, and access to refurbish an existing asset can be very challenging. In this scenario, offsite assembly is playing a grow role in the upgrading of security enclosures to existing assets.

With a need for speed of completion and minimum disruption to water processes and service continuity, Technocover has devised the ‘drop-on’ security enclosure – a factory assembled unit which is shipped to site, often as one piece, and simply lifted over the existing enclosure and asset, to create a new, upgraded protective skin.

Drawing on Technocover’s full technical services in surveying, design, manufacture, logistics and installation, these solutions:

- Simplify assembly and eliminate the need to reinstall plant and fittings, reducing site time and minimising, if not avoiding, asset downtime.

- Are precision designed and fabricated to fit snugly around the existing structure with minimum encroachment on floorspace and aligning with vents, doors and apertures in the existing enclosure.

- Enable the unit to be distance lifted according to the capacity and reach of the permitted vehicle hoist or crane and its working location, whether on a public road or within the site.

Drop-on UltraSecure kiosk provides upgraded protection around existing GRP enclosure at water booster station

The photo above shows a ‘drop-on’ type UltraSecure kiosk being installed around an existing GRP enclosure at a water booster station site. The new kiosk features LPCB approved accessories including protective mountings for the security light, alarm and telemetry sensors. Guided by a detailed site survey and CAD design, it incorporates slightly wider doors with shallow thresholds to permit the inner GRP doors to open and close, as well as vents aligning with the existing unit. To prepare for the upgrade, Technocover extended the concrete base to allow bolting of the new unit.

The same ‘drop-on’ principle can be applied to the new generation of performance tested, heavy duty modular mesh systems. In addition to permitting natural ventilation of the asset, the see-through mesh allows instant visual inspection. This benefits site security and productivity by reducing the need for personnel to enter the enclosure involving the repetition of access protocols.

Technocover’s deep expertise in resolving the parameters of design, lifting logistics and LPCB criteria ensures that the most complex of assemblies are achieved right first time to minimise downtime.

Drop-on UltraSecure modular buildings can save several days of site time, allowing the existing brick structure and fittings to be retained and processes to remain live while hardening the asset to an enhanced standard.

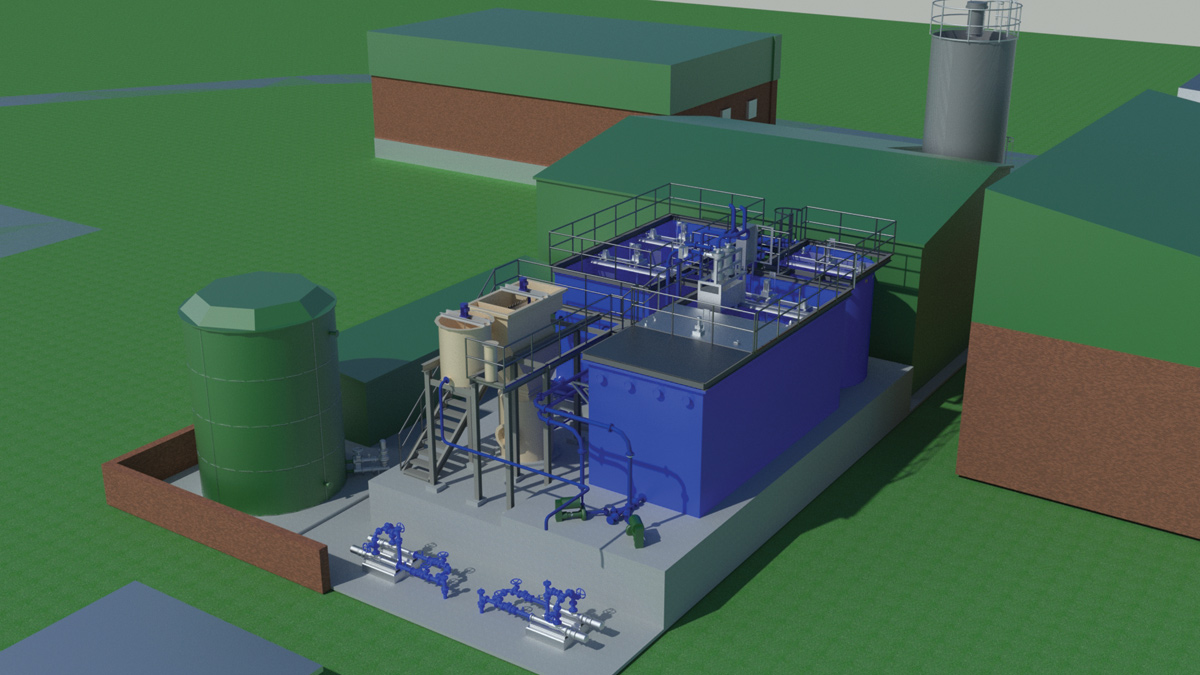

Solution 2: Secure enclosures for new build

With the opportunity to design from the ground up, the new build project offers the greatest scope to maximise the lifecycle benefits and return on investment from a secure enclosure. Through early involvement and close collaboration with the client and project team, designs can address and benefit many more aspects of the construction programme and life-time operations than is often anticipated.

Working together, all parties can consider the product at each stage of its life cycle, ensuring that the design responds to logistical, construction, health and safety, and operational needs, right through to its ease of dismantling at end-of-life. This enables potential problems to be designed out and features to be designed in that facilitate installation, site productivity and low maintenance, with a focus on time and cost savings and preserving service continuity.

Measuring 8.7m long by 5.3m wide by 3m high, this UltraSecure modular building was 3D modelled and precision manufactured to fit snugly around existing infrastructure with minimal extension of footprint

Depending on site logistics and co-running construction, kiosks can be planned and delivered as pre-built units with the option of pre-fitting with M&E services, for rapid connection to mains electricity. Alternatively, they can be supplied in ‘flat pack’ where crane lifting of a pre-assembled unit is undesirable and working space is less constrained.

Systems can be adapted to specific operational needs from a range of accessories and module options. These include single or double doors (with or without vision panels), venting louvres, roof escape hatches, and internal lining (timber or recycled plastic). This is supported by compatible LPCB approved padlocks and locking/user ID systems, entry and exit hardware, and full integration with site alarms and the latest access control management.

With the potential for creating significant buildings with large footprints, internal space can be compartmentalised to create separate control rooms, storage, welfare areas in addition to the main process or plant zone.

Enclosures can be supplied fully fitted with M&E services, tool racking, hygienic wall finishes and restroom facilities, to create ready-to-use accommodation that is security tested

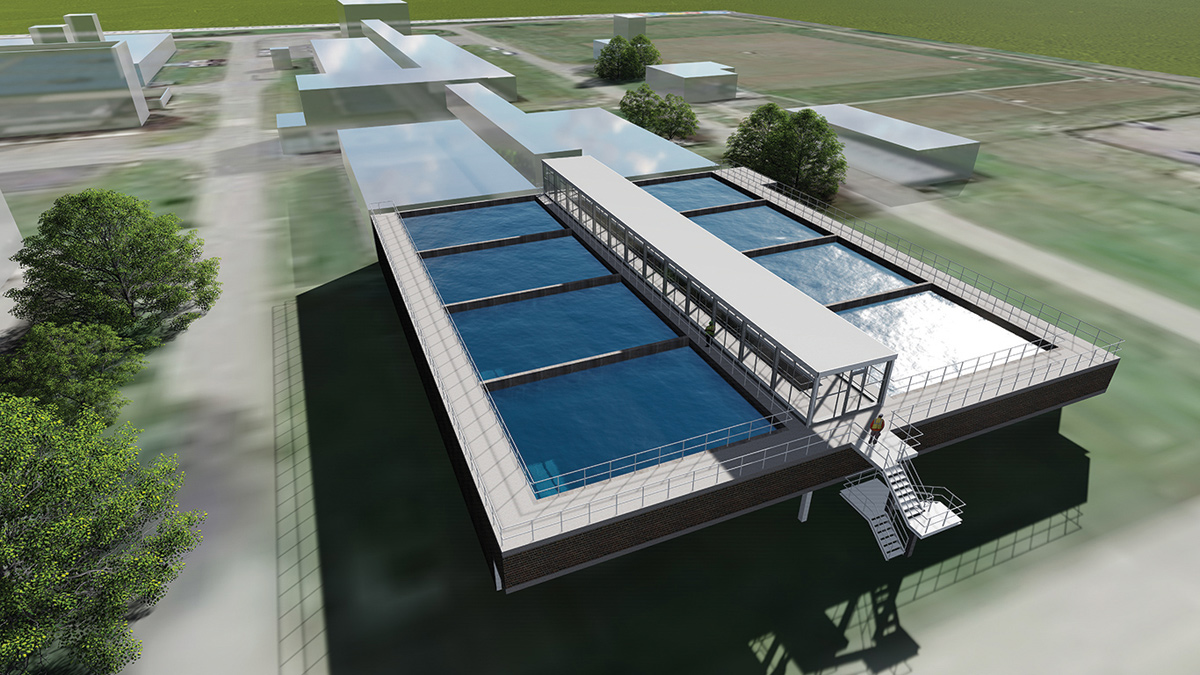

UltraSecure modules offer a sophisticated range of contingencies within the scope of their LPCB approval, including turned-out frames, special anchoring systems and support beam assemblies. These features allow them to be installed against concrete upstands and walls, or as part of a larger, integrated security assembly such as a multiple leaf access system over underground water treatment processes or UV equipment.

The tailoring of roof systems can add significant value to operational efficiency and ease of maintenance. Substantial pipe sections and large components are far easier through removable sections of roof which offer much larger apertures and manoeuvrability than available LPCB door systems.

A modular building, measuring 11000mm long by 8.6m wide by 3.15m high, designed with a roof assembly that can be removed in sections or completely for flexible plant access. Inset photo shows roof support beams and fall protection grids positioned below the roof access hatches

Precision manufactured by Technocover, the photo above shows a very large UltraSecure kiosk, measuring 11,000mm long by 8600mm wide by 3150mm high, with a roof assembly designed for multiple options for access to plant below, including complete roof removal. Note the proliferation of lifting eyes on roof panels and the series of upstand escape hatches, which are also assist safe assembly and dismantling. The inset photo shows the roof support beams and fall protection grids positioned below the roof access hatches.

The row of escape hatches are covered with a black, non-slip finish for the safety of personnel using them, while the roof structure is also domed to shed water.

The larger of these two special mesh enclosures has an irregular footprint and roof system to fit securely to an existing wall structure (see roof detail in righthand image)

Solution 3: Secure enclosures with unusual configurations

Sometimes, enhanced in situ security is required for ancillary plant, generators, cylinder or material storage located within recesses and close to walls. These can be resolved with tailored mesh assemblies, with or without roof sections, drawing on Technocover’s expertise and product capability to stay within the scope of LPCB certification.

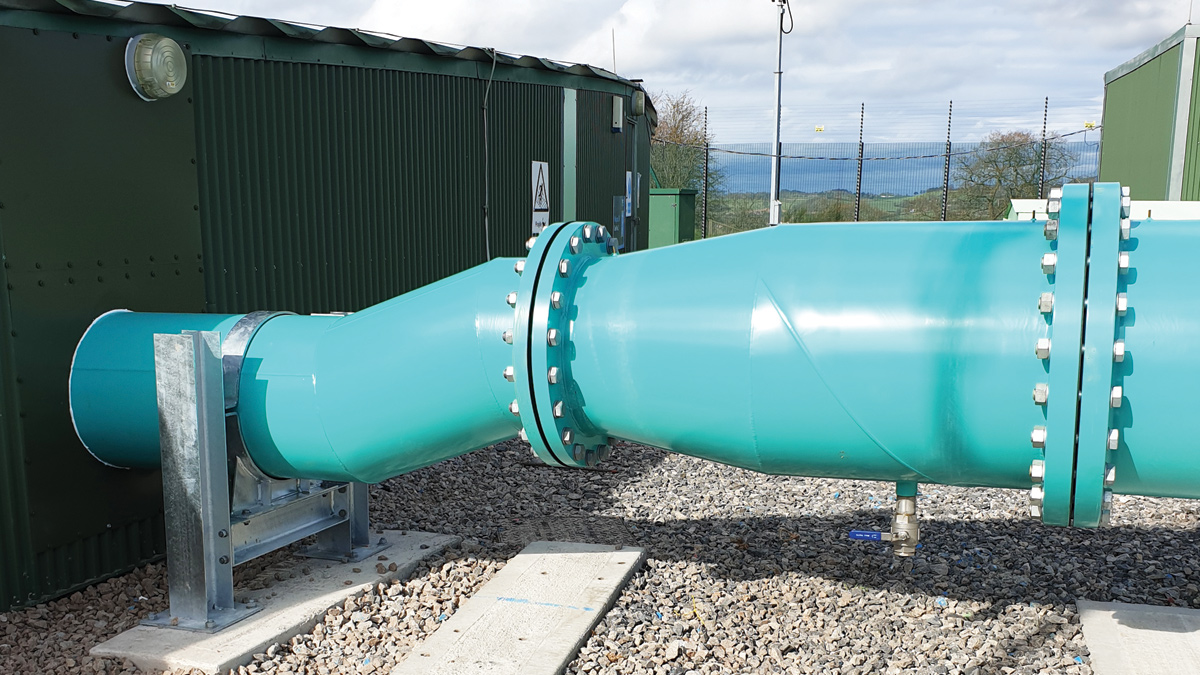

The example above shows a pair of special mesh enclosures to enhance the protection of a main discharge water pipe. The larger unit has an irregular footprint and roof system to fit securely to an existing wall structure. Similarly, solid enclosures provide scope for unusual shapes to fit site conditions, for example, to around kerbs, concrete plinths, retaining walls, and other structures (see examples below).

(left) UltraSecure kiosk, 3.8m x 3m on plan, with an angled side to leave clearance for the opening/closing of a nearby access cover, while fitting snugly between concrete wall elements, and (right) specially shaped kiosk with protective bumper strip to suit kerb location.

Whatever the size or complexity of enclosure, system integrity and longevity are assured by a high quality specification of structural steel and post-galvanised protection. This provides a demonstrable life expectancy of at least 20 years to minimise maintenance interventions, underpinning long service and cost certainty during the product life cycle.