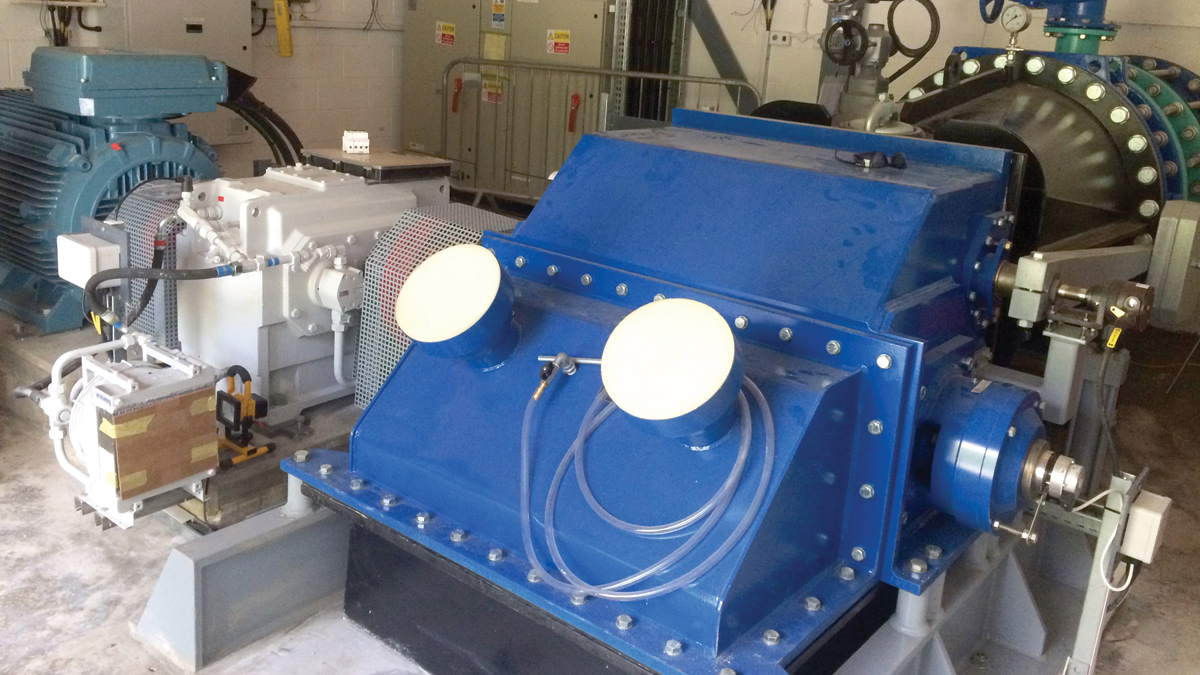

Howden Mini Hydro Electric Project (2017)

Ossberger Turbine installed May 2017 - Courtesy of MWH Treatment

Howden Reservoir is the first of three reservoirs owned by Severn Trent Water in the Upper Derwent Valley. The reservoir is bounded at its southern end by Howden Dam which impounds the River Derwent and overflows to Derwent Reservoir which in turn overflows to Ladybower Reservoir. Work commenced on the dam’s construction on 16 July 1901 and was completed in July 1912. The works involved constructing a temporary village at Birchinlee (or ‘Tin Town’) for the workers, a temporary railway line from the main line at Bamford and a link aqueduct to Derwent Dam. The dam is of solid masonry construction, is 36m tall and 330m long. A catchment area of some 21km2 drains into the reservoir which holds 8,600 million litres of water. The Upper Derwent Valley is a very popular tourist attraction for walkers, runners, cyclists and birdwatchers. It has two visitors’ centres, Fairholmes at Ladybower and Hatherdene at Derwent.

Harnessing the power of water

There are two existing pipes which run from Howden Dam to Bamford WTW. These were installed c1910 to convey water direct from Howden Reservoir to Bamford WTW, bypassing Derwent Reservoir. These have long been abandoned and it was realised that they could be used to feed a new turbine to generate renewable electricity.

MWH Treatment conducted extensive surveys on both pipes to establish if the scheme was feasible and these were found to be in very good condition. Working in conjunction with Severn Trent Water, MWH Treatment designed and constructed a mini hydroelectric scheme to harness the available energy from the 28m head difference between Howden and Derwent Reservoirs.

As part of their energy efficiency commitment, Severn Trent Water has a target of generating by 2020 renewable energy equivalent to 50% of their own consumption, and this project contributes to this target.

The cross-flow turbine, installed by MWH Treatment and manufactured by Ossberger in Germany, is rated at 300Kw and will generate 1,45GWh per annum of electricity, resulting an annual carbon saving of 760 tonnes of carbon dioxide. The electricity produced will be exported to the national electricity distribution network.

Howden Reservoir – Courtesy of MWH Treatment

Innovation

The idyllic location next to Howden Dam required careful consideration of the materials and appearance of the new turbine house. The use of locally sourced larch cladding has provided benefits in cost, carbon reduction and benefited the local community economics. There are a number of key benefits:

- Sustainability: Larch is a locally grown sustainable product sourced as part of holistic forestry management.

- Carbon: Hundreds of miles of road transport were saved reducing the overall embedded carbon footprint of the project.

- Community: The timber was processed in the local regional economy.

To blend the turbine house into the surroundings, a choice of using natural wooden cladding was made in agreement with the local planning authorities.

Typically, larch cladding is sourced from either Scotland, or Siberia which inevitably entails significant transport cost and associated carbon impact. At Howden however, the team worked with Severn Trent Water’s local site supervisor to arrange for the trees off their own estate to be used. Suitable trees were felled and transported to a nearby mill to be sawn and treated, thereby reducing cost, saving carbon and producing a quality product.

Wildlife considerations

Prior to construction, the banks of the reservoir were a popular breeding ground for sandpipers and little ringed plovers. To avoid disturbing their nests and general well-being during construction, MWH Treatment laid out black geotextile membrane to dissuade the birds from nesting in the working areas. These nesting birds have been restored as part of the landscaping. MWH Treatment worked very closely with the Forestry Commission and other agencies during the design and construction phases of this project.

Turbine house under construction – Courtesy of MWH Treatment

Community

The construction site was located a mile up a track alongside Derwent Reservoir. The track is part of a circular walking/cycling route around Howden and Derwent reservoirs and is very popular with the public. MWH Treatment undertook some extra measures on this site to mitigate the impact on both the local visitors and the wider community:

- Yellow safety fencing: The site was close to a steep slope and the use of yellow Heras fencing rather than the standard dull grey fencing made it easier for the cyclists to distinguish it, especially in the low light in winter and close to and under tree cover.

- Accompanied deliveries: With a mile of single track stone road to the site, the safety of pedestrians and cyclists was a key concern. To minimise and control the interface with transport every delivery was collected and accompanied in both directions. This ensured that the risk to the public was minimised.

- The site cabin area was fenced in close boarded timber: This helped reduce the visual impact of work. The cabins themselves included the use of an Eco-cabin which was totally solar powered.

Turbine house – Courtesy of Severn Trent Green Power

Summary

The Howden Mini Hydroelectric Project is an excellent example where Severn Trent Water and MWH Treatment have worked together, utilising their expertise to harness a small scale local renewable energy opportunity.

The scheme has been designed and delivered taking all stakeholder requirements into account. The completed asset will provide many years of renewable power to the grid and contributes towards Severn Trent Water’s renewable energy target.

All installation work was completed in May 2017 and commissioning work will be completed in August 2017. The turbine will be generating power to the grid from September 2017.