LED UV Water Treatment (2020)

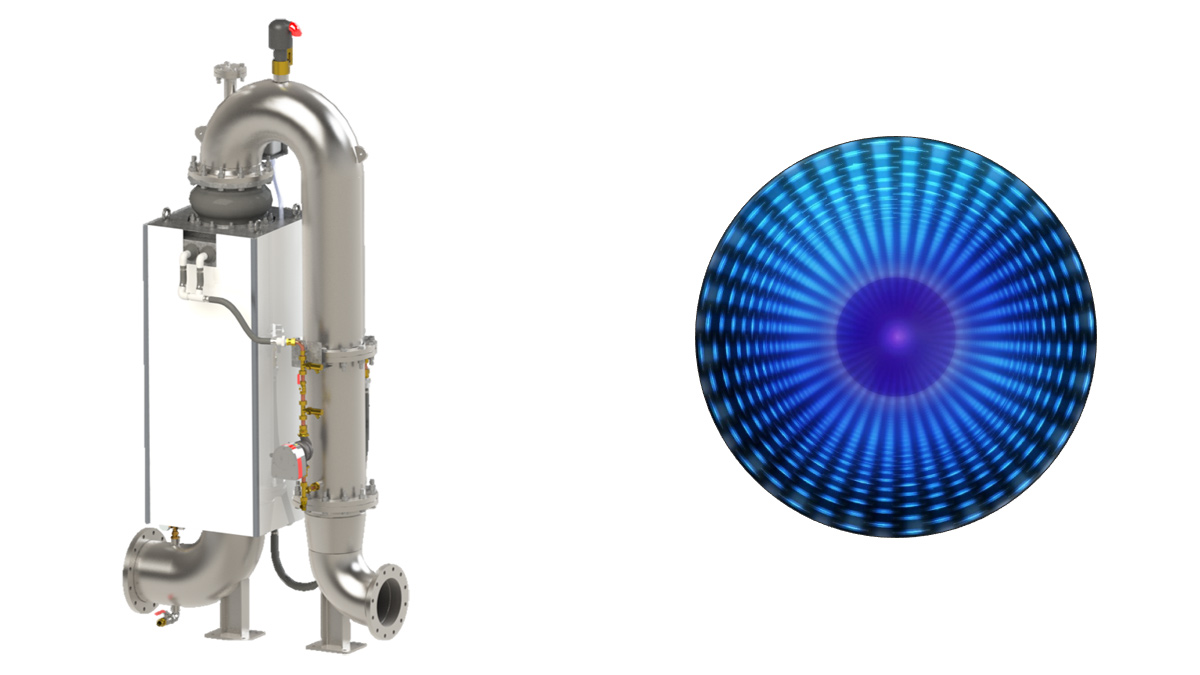

(left) The BIO-310 UV LED reactor, the world's first validated UV LED system validated to the USEPA UVDGM protocol in July 2018, and (right) a view inside the reactor showing the integrated array of 1,000 UVC LEDs - Courtesy of Typhon

United Utilities’ (UU) vision is to be a leading north west service provider, and one of the best UK water and wastewater companies. It is a challenging vision, but one United Utilities are capable of achieving by focusing on three objectives to deliver the best service to customers, at the lowest sustainable cost and in a responsible manner. To achieve this UU will need to operate under the following key core values: customer focus, integrity and innovation. In today’s fast paced world, all companies have to constantly innovate as what we do today must be better tomorrow. In February 2018 United Utilities developed the water sector’s first Innovation Lab Programme that provides successful applicants with the opportunity to test their solutions in a live environment, while gaining access to and building relationships with senior UU executives, with the potential to lead to longer-term commercial partnerships.

Selecting innovations

UU set out a challenge against five priority areas where United Utilities wanted to be better at what United Utilities do. These included:

- Connected water and customer.

- Proactive customer actions.

- Predictive asset maintenance.

- Safe and healthy worker.

- The catch all ‘future of water’.

Artificial intelligence leakage detection system, another approach United Utilities is using to reduce leaks and save water – Courtesy of United Utilities

Advertising to 1,500 suppliers, the aim was to reach out to people working in other sectors and countries. United Utilities received 80 applications, 55 of which were from new organisations United Utilities have never worked with. The list was narrowed down to 22, with the companies being invited to pitch their ideas. Seven successful finalists, named Innovation Lab Partners who impressed us with their pitches, were then selected to join United Utilities in the Warrington headquarters’ Innovation Centre.

Out of the seven to join the lab, five had never worked in the UK water industry before, with the companies coming from France, Portugal, Canada, Australia, India and two from the UK. Within 10 weeks, United Utilities delivered six field trials and engaged with over 100 customers. The successful ideas have led to supply agreements and further development in the new technologies.

Examples of new technologies to emerge from the Innovation Labs include using drones for safer working, and pioneering the use of artificial intelligence (AI) to track down leaks.

The drones have potential to save many valuable man hours in carrying out what was once a labour intensive exercise, but could now be a one man job with the drone system automatically producing a report within hours of it completing its flight path. This idea originated from a challenge set around health and safety, and as a result United Utilities have reduced the risk of their personnel working in a potentially dangerous environment.

The AI leakage detection system has been incorporated within UU’s Integrated Network system, and is able to accurately detect leaks by 86%.

Drones being used to carry out survey work, eliminating the need for confined space entry and reducing the health and safety risk – Courtesy of United Utilities

LEDs for UV water treatment

One of the most exciting new technologies emanating from the Innovation Lab is the use of LEDs for UV water treatment. Since 2015 United Utilities has been working with Typhon Treatment Systems on a game-changing innovation for water and wastewater treatment, and in the last year have seen the technology develop from lab scale to a commercial product. Typhon have developed a UV LED water treatment reactor that is specifically designed for high flow rate, 24/7 operation applications as would be required by water utilities.

The big advantages of UV LED technology compared with traditional UV systems is that it significantly reduces the power and chemical consumption, it provides an environmentally friendly, mercury free solution, and offers a system that has the potential to increase asset capacity with each new generation of UV LEDs.

UV disinfection has been a mainstay in water and wastewater treatment processes for over 20 years, used to protect potable water from dangerous microscopic organisms such as cryptosporidium and, when combined with a suitable oxidant in an advanced oxidation process, for removing hazardous chemical pollutants such as pesticides or pharmaceuticals.

Activated carbon is used for issues that can lead to taste and odour problems in water treatment. While both technologies are reliable and scalable, they are difficult to control and can be extremely costly for customers as they have high energy demand and high carbon emissions.

Trials

United Utilities first met Typhon Treatment Systems at a UU event to help small and medium-sized enterprises access the water sector and business support through Innovate UK and others. At that time they had researched and developed a breakthrough UV LED process that had the potential for a number of savings, efficiencies and benefits for UU’s water and wastewater treatment processes.

Typhon were then successful in UU’s first Innovation Lab programme and United Utilities started working with Typhon to accelerate the development of the technology by providing access to a test facility on a live operational site and supplying equipment and services to allow the field testing to be carried out in the most efficient manner possible. The aim of the trial was to prove whether energy-efficient LED bulbs can be used for UV treatment on a commercial scale and outperform traditional solutions.

Typhon UV LED reactors in manufacture in their Penrith factory – Courtesy of Typhon

The work with Typhon has enabled them to take a theory and apply it across two trials over a 12 month period – significantly faster than traditional water sector technology development.

The trials proved the ability of the UV LED system as part of an advanced oxidation process to remove taste and odour compounds as an alternative to conventional treatment processes. The trials also led to Typhon carrying out USEPA UVDGM validation testing of the UV LED System.

Technology benefits

- More than 50% whole life cost savings and up to 90% energy saving.

- Precision control and automation.

- Sustainable and resilient solution.

- Reduced operator intervention.

- Increased process reliability and safety.

- No direct contact with the flow of water and ultimately eliminates the risk of a glass break and mercury contamination scenario.

- Low headloss solution.

Project benefits

- Early stage end user involvement with product development.

- Significant reduction in time to move from concept to proven product (10-week Innovation Lab compared to months or even years for Typhon to do it alone).

- Opens the door for further validation testing in a UK testing facility.

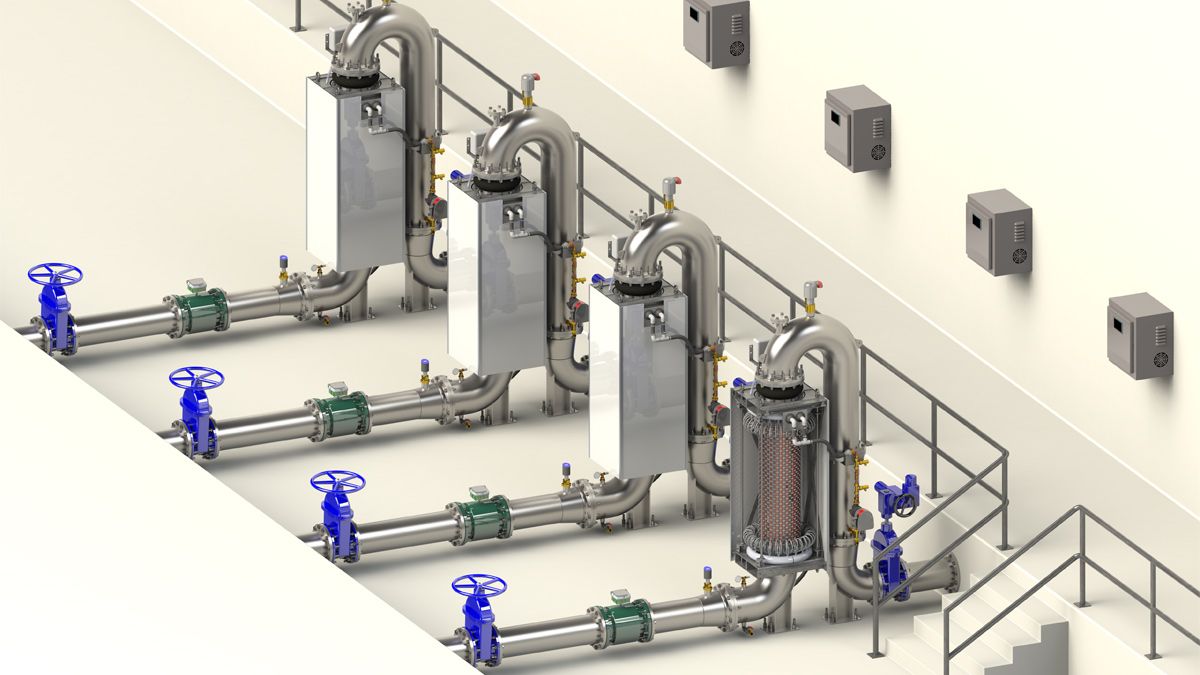

A 3D visualisation of Typhon’s UV LED installed on the outlets of the rapid gravity filters at Cumwhinton WTW – Courtesy of Typhon

The Typhon system is designed to enable better control and automation of the treatment process, reducing operator intervention and increasing process reliability. Working together, United Utilities and Typhon accelerated the technological development of UV LED systems for municipal scale applications and delivered the world’s first Validated UV LED System. United Utilities really believe in this technology and collaboration between UU and Typhon has helped prove the technology works for the benefit of the global water industry.

Cumwhinton WTW

To demonstrate commitment to this innovative solution, United Utilities are implementing the technology at Cumwhinton Water Treatment Works as part of a larger programme of work that is installing deployable UV systems on seven water treatment works. Six of the sites are progressing with traditional UV equipment, however, Cumwhinton WTW was selected to use Typhon’s new UV LED as the solution. Cumwhinton WTW has six first stage rapid gravity filters (RGFs), and the UV LED units are being installed on the individual outlets of the RGF cells.

Currently each unit can provide 3 log cryptosporidium inactivation at 6.0 Ml/d per unit with a UV transmittance (UVT) of 94.6% or greater. The treatment works has an output flow of 28 Ml/d making it an ideal fit with the validated range of the Typhon reactor.

Cumwhinton WTW filter gallery outlets, where the UV LED units are going to be installed – Courtesy of United Utilities

The programme of work was awarded in April 2019 to Mott MacDonald Bentley (MMB), one of United Utilities’ joint venture construction delivery partners. MMB have progressed with the detailed design of the system in conjunction with Typhon, including hydraulics, mechanical, electrical and ICA aspects to integrate within the existing WTW process.

Cumwhinton WTW site was due to be completed in 2020 but the impact of the Covid-19 pandemic has stalled progress somewhat and current projections estimate completion of commissioning by late 2021. In the next edition of UK Water Projects, United Utilities hope to unveil the world’s first commercial scale UV LED treatment installation and showcase the benefits of this system.