Mosswood & Lumley WTWs (2022)

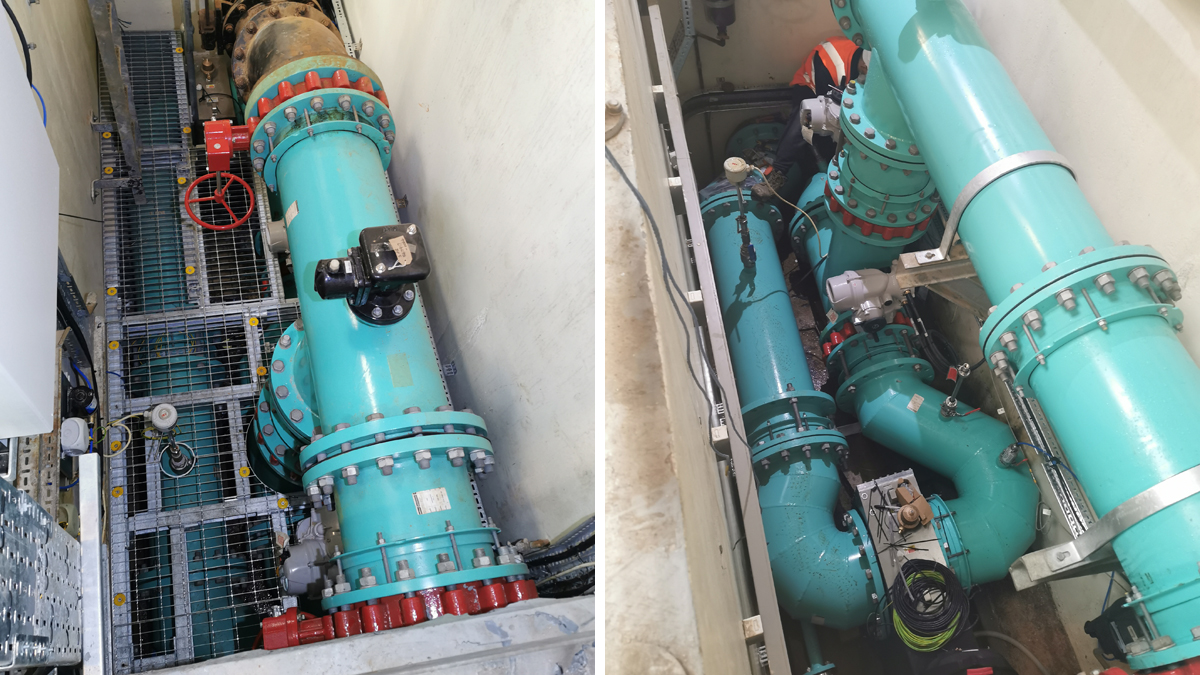

(left) In Mosswood’s smallest dry wells, GMS flooring was installed by FSE to provide safe access and (right) Successful pipework and reactor installation at Mosswood by Fluid Sealing & Engineering (FSE) - Courtesy of MMB

Northumbrian Water Group (NWG) have recently upgraded their clean water treatment processes at Mosswood and Lumley Water Treatment Works (WTWs). This was to increase quality and resilience of customers’ water supplies by adding ultraviolet (UV) irradiation as an extra barrier of protection. The main innovation of these projects was that they provided a vastly more robust treatment process without the need for any major civils upgrade. Mott MacDonald Bentley (MMB) modified pipework in the dry well of each of the 18 rapid gravity filters (RGFs) across the two sites, installing a UV reactor on the outlet of each filter. The UV reactors, supplied by Evoqua Water Technologies, were installed complete with individual control panels and sample monitoring boards.

Background

In 2017, prior to compact UV reactors being available for water treatment, MMB was initially awarded a contract to investigate and propose solutions to improve the treatment performance of Lumley WTW. From a process perspective, the preferred solution was for new granular activated carbon (GAC) adsorption cells. However, this option was adjudged to significantly increase maintenance and power requirements as well as the significant CAPEX investment.

MMB undertook a period of optioneering and identified that to guarantee compliance, additional treatment by UV irradiation was the most suitable solution, by offering 4-log removal (99.99%) of cryptosporidium and total coliforms. However, at the time UV technology within water treatment was in its infancy, and as such would have still required a large investment in infrastructure, such as a new offline building and an interstage pumping station to lift full works flow. This caused the project to be shelved following realisation that the cost would outstretch NWG’s budget for these works.

UV technology & pipework modifications

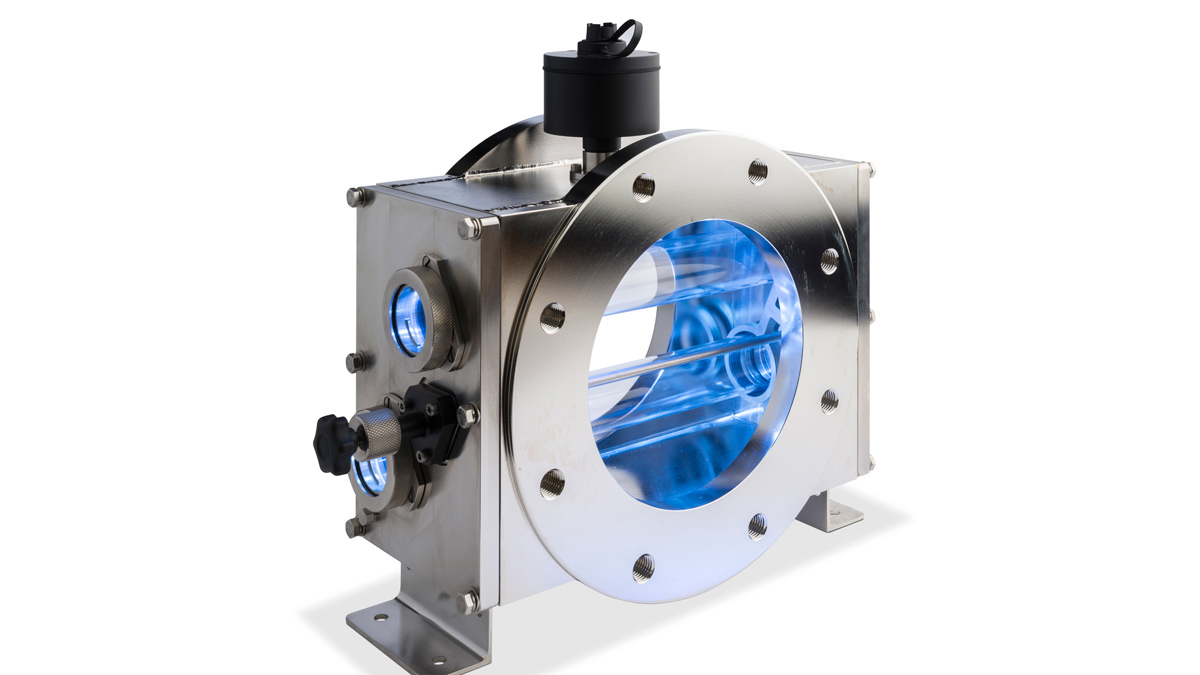

By 2020, NWG had embraced the rapidly developing UV technology by trialling the use of the new compact Wafer units at Mosswood WTW, supplied by Evoqua Water Technologies. The results of the trial showed that these UV reactors exceeded expectations for its treatment capability at WTWs. As such, NWG procured 17 more units – one for each RGF at Mosswood and Lumley.

Wafer® UV generator – Courtesy of Evoqua Water Technologies

At this stage, NWG approached MMB again, this time to carry out and manage the installation and commissioning of Evoqua Water Technologies’ Wafer UV reactors, including associated control panels and sampling boards. The design challenges presented to MMB were relating to access for installation, operation, and maintenance. Connecting onto the outlet of each filter by extending the DN400 pipework, meant the existing 1400mm wide dry wells provided a limited footprint for pipework modifications.

Whilst the trial proved that the UV reactors can be serviced, with lamps removed and replaced, from within the filter outlet dry wells, MMB’s design team ensured tapping points for monitoring and sampling were relocated from their position in the trial pipework to more accessible positions. The team agreed that this reduced the risk of operations or maintenance staff stepping on or over large diameter pipework as far as reasonably practicable. NWG agreed that the residual access risk for irregularly maintained assets such as actuators would be managed using temporary works such as scaffolding when required.

The Wafer UV reactors came with PN16 flange holes to allow easy installation and retrofitting to existing pipework. Evoqua Water Technologies confirmed suitability of the non-standard pipework design by preparing and running a computational fluid dynamics (CFD) model for each site. This enabled Evoqua to calculate the efficiency of their reactors in close proximity to bends and tapers, giving NWG further confidence in the new UV technology.

(left) Wafer UV reactor and (right) FSE commencing pipework installation at Mosswood – Courtesy of MMB

The project had several significant health and safety benefits when compared to original proposed solutions which stretch throughout the whole life cycle of the project, from construction and commissioning to maintenance and ultimately removal of the assets. The low-impact UV reactors installed on each filter individually removed the need for a larger collective treatment stage and pumping and is therefore comparatively low-maintenance.

MMB worked closely with the pipework subcontractor, Fluid Sealing & Engineering (FSE), during the detailed design phase to influence their proposed pipework. Challenging client specifications and a previously accepted design, MMB eliminated the need for a partial works shutdown at Lumley for each filter to relocate an actuated valve. The project achieved the same quality of output with significantly less coordination and disruption to NWG’s operation of Lumley WTW, contributing to the significant programme saving.

Temporary works

Throughout the design, decisions were made which improved the health and safety during construction, the most notable of which was regarding temporary works. At Lumley, the methodology which MMB inherited at the start of the design and construction (D&C) phase specified an access track be constructed up a grass bank at the end of the block of filters. On top of the proposed access track, MMB were due to install a crane pad to facilitate a blind lift of the reactors, control panels and pipework through a skylight above the filter gallery.

During an early site visit, the design and operations team discovered an opportunity to utilise a route for installed and removed equipment through the main building. The filter gallery was accessed by a number of steps, for which MMB had a temporary lifting frame constructed to enable safe transportation of equipment. As well as the safer construction methodology, this had significant commercial benefit for the project, saving time and costs associated with access track and crane pad construction.

Successful pipework and reactor installation at Lumley by FSE – Courtesy of MMB

Lumley & Mosswood WTWs UV Retrofit – Supply chain – key participants

- Main contractor: MMB

- UV solution design & supply: Evoqua Water Technologies

- Pipework installation: Fluid Sealing & Engineering (FSE)

- Electrical installation: Intelect (UK) Ltd

- PLC panel manufacturer: CEMA

- Systems integration: Peak Technology Solutions Ltd

Construction phase and collaboration

With the D&C contract being awarded during the COVID-19 pandemic, MMB had to strive to find an efficient method of project delivery which involved working remotely where possible. At the busiest period on the project, there were five subcontractors who each depended on each other’s success to complete their tasks on programme. MMB utilised Miro, an online collaborative whiteboard, to host remote planning sessions which formed the agenda at weekly subcontractor progress, planning and coordination meetings. This enabled the construction phase of the project to run smoothly, whilst efficient working within each filter dry well minimised periods of reduced WTW output, thereby minimising periods of additional strain on the potable supply network.

This project had a compliance date, set by the DWI, of March 2022 (Lumley) and December 2022 (Mosswood), which was initially seen as a challenging deadline to achieve. However, through strong collaboration between all invested parties, both projects were completed months ahead of their respective regulatory deadlines. The construction phase at both sites commenced in January 2021.

The client was initially nervous about working on strategic assets and as such was reserved about the project’s ability to complete an installation and allow a filter to be returned to service in an acceptable timeframe. Through collaborating with NWG project and operations teams, the initial project programme was therefore based on each UV reactor being installed, commissioned, and returned to service on each filter in sequence, with a proving period between the release of further assets.

PLC, control panel and monitoring backboards at Lumley – Courtesy of MMB

However, following the successful completion of the first UV reactor installation, in a shorter time than anticipated, NWG Operations gained confidence in the project team’s ability to deliver quality outcomes on their strategic assets. Further to this increased client confidence and the team’s utilisation of Miro, MMB were able to demonstrate to NWG the potential programme benefits of releasing two filters at the same time. This approach saw the programme streamlined by months and the financial position of the project improve. This also benefitted FSE as they were able to work efficiently between two filter dry wells, increasing productivity by utilising the natural down time in their individual installations.

The construction team, comprised of MMB staff and subcontractors, continually strived to learn from the previous installation to streamline the process for the next filter. Tweaks to methodology and sequencing meant the filter downtime reduced from three weeks for the first filter, to just five days in the final few filters. This was particularly beneficial during the hot weather this summer (2022) when many regions of the country had droughts declared.

A sustainable development

Following the initial design brief in 2017, Northumbrian Water went through several rounds of scope refinement which culminated in a leap of faith being taken in an emerging technology.

UV reactors being retrofitted to the outlets of existing RGFs is a low-carbon solution to a complex problem. MMB were investigating the alternatives to this solution in 2018 which included constructing a new bank of RGFs from reinforced concrete or a purpose-built structure to house older UV technology.

Both alternatives would have resulted in significant quantities of carbon being released into the atmosphere during construction and both would have necessitated an interstage pumping station to lift full works flow. This would have resulted in a large continuous additional power requirement and released the embodied carbon associated with power generation at source.

The UV installation has been viewed as a resounding success from both water treatment and construction perspectives. Northumbrian Water have publicised its use to utility media outlets and plan to expand the UV programme across its other major WTW sites. Knowledge and learning points have also been shared across regions within MMB to promote the use of the low-carbon installation to this common problem elsewhere in the country.

Individual UV control panel and monitoring board per filter. A view up Mosswood’s filter gallery – Courtesy of MMB

Social value

The process upgrades at two of Northumbrian Water’s major WTWs has increased the quality of water in customers’ taps. Through collaborative project management, this was achieved without any disruption to supply. The quality of raw water, whether from river or reservoir, naturally varies and can be influenced by factors such as weather conditions. Adding UV irradiation to the permanent treatment process safeguards the quality of drinking water supply by deactivating harmful pathogens that may be present.

The method of installing UV onto the outlet pipework of each filter also adds resilience to the increased quality of supply. A traditional UV installation in its own building would be a single point of failure and therefore during maintenance, would have required a full shutdown of the UV reactor. Installing a reactor per filter means during maintenance or asset failure, capacity may reduce but quality is never compromised.

The Lumley and Mosswood WTW upgrades were completed in October 2021 and August 2022 respectively at a combined cost of approximately £5.8m.