ReGenerator Technologies (2016)

Figure 1: SHARON® demonstration plant at Wards Island WwTP in Manhattan, New York Courtesy of M2T Technologies

The concept of sewage treatment plants as ‘energy factories’ originated in the Netherlands in the early 2000s. The Dutch water boards came together with the express aim of treating wastewater with a significantly reduced energy consumption and to increase energy production, such that their sites could be seen as true ‘energy factories’. The energy factory concept has since grown in popularity worldwide thanks to its ability to transform a waste treatment process into a means of generating energy and, now, to recover other bio-resources. Wastewater sludge is no longer seen as a problem, but as a fuel. In the UK the concept is a widespread ambition; e.g. United Utilities stated at the beginning of AMP6 that it had an objective to achieve energy neutrality across its wastewater treatment estate by 2020.

The ReGenerator® Concept

Sweco, a founder member of the Dutch-led energy factory projects, has not stood still since the creation of energy factories and has expanded the potential benefits, so much so that it decided in 2012 to re-brand the approach to The ReGenerator® Concept (RgC). With this innovative methodology, Sweco supports clients operating in a TOTEX environment, seeking lower whole life costs that benefit the end user and their consumers.

The RgC methodology sees Sweco sourcing new pan-European sustainable technologies that can increase biogas production for energy generation, reduce energy consumption, increase water recovery, recover nutrients, re-use surplus waste heat, and in the future recover other bio-resources. RgC focuses on maximising these potential OPEX revenue streams which can then be used to derive an optimised TOTEX solution.

Across a water utilities’ wastewater treatment estate, the ReGenerator® Concept has been shown to have the potential to halve energy consumption, double energy generation, reduce sludge disposal volume by 25% and provide useful excess heat for reuse; a true energy factory solution.

SHARON® and DEMON® liquor treatment technologies

SHARON® and DEMON® liquor treatment technologies play an important part in the ReGenerator® Concept approach. Treating liquors prior to returning the flows to the mainstream unlocks capacity in the secondary treatment stage and provides an improved effluent quality.

These benefits have given designers and end users new options when increasing capacity or quality at wastewater treatment works.

SHARON® (Stable and High Activity Ammonia Removal Over Nitrite) is a robust, cost-effective system used for the treatment of high strength ammonia liquors such as sludge dewatering liquors and the liquid fraction of pig manure. Unlike conventional nitrification/denitrification systems, nitrite, and not nitrate, is the intermediate product of the SHARON® system, resulting in significant energy savings compared to conventional treatment processes.

Figure 2: The DEMON® installation at Amersfoort, NL has been operational since 2012 – Courtesy of Sweco

SHARON® installations can be found throughout the world including New York (5,500kg/d), Geneva (1,500kg/d), Whitlingham (Anglian Water, 1,600kg/d) and Shell Green (United Utilities, 1,600kg/d).

The DEMON® (DE-amMONification) process followed SHARON® and further optimised OPEX costs, primarily via reduced chemical consumption. The DEMON® process is a nitrification/deammonification process in which ammonia and nitrite are simultaneously converted to nitrogen gas, without the need for organic carbon.

The advantages of the DEMON® system over other liquor treatment systems are manifold. Unlike older systems, DEMON® is a process that can typically achieve an ammonia removal efficiency of at least 85% without any pH correction or carbon dosing (usually achieved with an external source of carbon such as methanol). The innovative technology also uses 60% less energy than conventional processes.

DEMON® is controlled by changes in pH measurements. Aeration causes a decrease in pH whilst the influent feed causes an increase. Aeration is stopped when sufficient nitrite has been produced for the deammonification process, and restarted when sufficient alkaline feed has been introduced to increase the pH level. The system will react automatically to all variations in load – or even an interruption/shut down – without the need for operator intervention.

DEMON® is applicable for different types of liquors containing a wide range of ammonia concentrations. Weak liquors from 600mg/l, as well as centrate following advanced thermal hydrolysis digestion containing in excess of 2,000mg/l of ammonia nitrogen, can be effectively treated. Dilution with thickening liquors is sometimes required for the higher concentrations to ensure a stable process.

The first DEMON® system was implemented in Strass WwTW, Austria, which made an important contribution towards the site becoming an energy self-sufficient wastewater plant. To date, DEMON® technology has been successfully implemented at over 60 wastewater treatment plants around the world. Since 2009, Sweco has completed the design of 15 DEMON® installations in Europe (including Poole STW for Wessex Water) and a further five are under construction or at design stage.

Figure 3: WwTP Nieuwegein DEMON®, NL has been operational since 2011 (450 kgNH4-N/day, 4.9 l/s) – Courtesy of Sweco

DEMON® at Poole STW

DEMON® can be based on a standard sequencing batch reactor (SBR) configuration. As such, conventional SBR liquor treatment plant (LTP) sites can be upgraded to a DEMON®, offering OPEX savings and reduced chemical usage.

A recent example of this is at Poole STW in Dorset, where the upgrade to DEMON® helped the plant to overcome its high operational costs primarily due to caustic dosing. The installation of DEMON® at Poole STW resulted in an OPEX reduction from £0.91/kg-ammonia treated to just £0.10/kg-ammonia treated and up to 93% ammonia removal efficiency (without caustic dosing), up from the original SBR system efficiency of 85%. After the first year of operation payback was demonstrated to be 3.5 years, an improvement on the original forecast of 4 years.

Since Poole, several other UK existing LTP installations have been assessed (including the conversion of existing SHARON® installations to DEMON®), allowing water companies to further reduce their OPEX costs.

Addressing the UK need for liquor treatment plants

The need for systems such as DEMON® is increasing, particularly for UK wastewater treatment plants. The increased use of thermal hydrolysis processes (THP) in sludge treatment generates increased ammonia loads in the centrate but also introduces a certain level of inhibition, which was thought to limit the effectiveness of many LTP processes.

A pilot scheme conducted at the Blue Plains WwTP in Washington DC confirmed that DEMON® is effective when used as a side stream treatment for liquors generated by a CAMBI-advanced digestion plant utilising thermal hydrolysis. The pilot showed that the treatment of 100% CAMBI side stream liquors is achievable by reducing the ammonia loading per unit volume on the DEMON®system.

In parallel with the increasing use of THP is the increased acceptance of high-rate ammonia removal LTPs, such as DEMON®, due to the gains in lower OPEX costs compared to earlier technologies. For these reasons, many UK utilities companies are considering DEMON® installations, including Thames Water, Wessex Water, DCWW, Severn Trent Water, Anglian Water and United Utilities.

A recent trend in the UK is the adoption of twin DEMON® reactor designs. Each reactor provides 50% of the treatment design capacity. This approach provides additional security following any unexpected events and also allows critical plant such as instrumentation to be replaced, repaired or recalibrated with no interruption to treatment. For commissioning, only 50% of the seed sludge is required, and in the unlikely event of a reactor losing its deammonifying bacteria (DABs), the second reactor should be available as a source thereby saving on potential down time. Twin reactor designs enables Sweco to offer a design which has 100% treatment availability for a small increase in CAPEX cost.

Looking to the future with Mainstream DEMON® and inDENSE®

‘Cold Anammox’ processes in activated sludge plants (ASPs) are now becoming a reality using ‘Mainstream DEMON® (formerly EssDe®). This technology uses the surplus ammonia oxidising bacteria (AOBs) and deammonifying bacteria (DABs) of the DEMON® process as a seed sludge for the mainstream ASP. This, combined with changes to the aeration control philosophy, allows the DEMON® process to operate at the lower temperatures of the ASP, and aeration energy savings of 25-30% to be realised in addition to improved Total N effluent quality standards.

To date, Mainstream DEMON® has been installed at sites in Glarnerland (Switzerland) and Strass (Austria). In both cases, the plants have experienced ASP energy savings of 25-30% and increased nitrogen removal capacity. Several studies in the UK have also been undertaken and show that multiple wastewater sites could benefit from the lower OPEX costs and short payback periods. One such water utility company is now moving to a Mainstream DEMON® demonstration.

The installation of DEMON® LTPs affords the option of installing Mainstream DEMON® at a later date, creating the potential for further significant energy savings and effluent quality improvements. A DEMON® installation should therefore be viewed as a significant step towards establishing a wastewater treatment plant as a true ‘energy factory’.

A further spin off from DEMON® is the use of the patented hydrocylcone to promote the retention of the more dense, floc forming sludge, in the site SAS sludge (inDENSE®). The cyclone passes the denser floc back into the ASP and sends the majority of the less dense sludge (with a higher filamentous content) onto the SAS storage tanks.

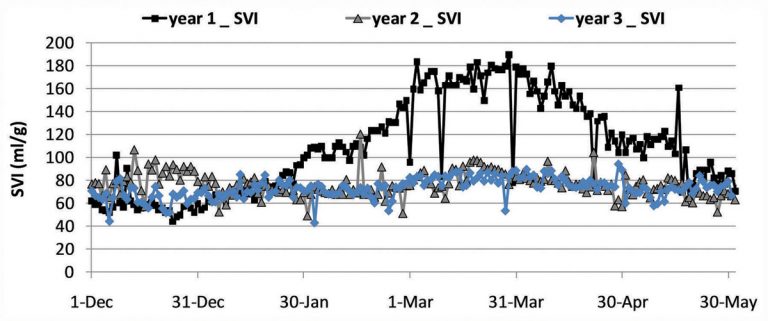

The initial installations of inDENSE® at Strass WwTW (Austria), Glarnerland WwTW (Switzerland) and Kapala (Sweden) have shown SVI reductions in the final settlement tanks of between 80ml/g and 100ml/g. inDENSE® is most effective where a site has an SVI of >150ml/g, such as caused by seasonal variations.

Figure 4 (below) shows the impact of seasonal load variations on SVI and how inDENSE® improves the SVI over time.

Figure 4: SVI results before and after installing inDENSE® at Strass WwTW, Austria – Courtesy of Sweco

The cyclones are installed in a carousel format at the end of each ASP lane (Figure 5), and can be scaled up or down to suit all sizes of installations. UK water utilities are showing interest in the technology as a means to resolve sites close to breaching consent due to a lack of final settlement tank capacity. As phosphate accumulating organisms are known to be good floc formers with a relatively high density, this has also created further interest from UK companies into the benefits of this technology at enhanced bio-P sites.

Figure 5: Typical inDENSE® carousel – Courtesy of Sweco

Summary

SHARON®, DEMON®, Mainstream DEMON® and inDENSE® are examples of technologies that minimise OPEX costs and are an integral part of the ReGenerator® Concept Sweco adopts for wastewater treatment schemes.

Editor’s Note

A follow up paper detailing the use of ReGenerator Technologies at Knostrop STW and Basingstoke STW was documented in UK Water Projects 2017.