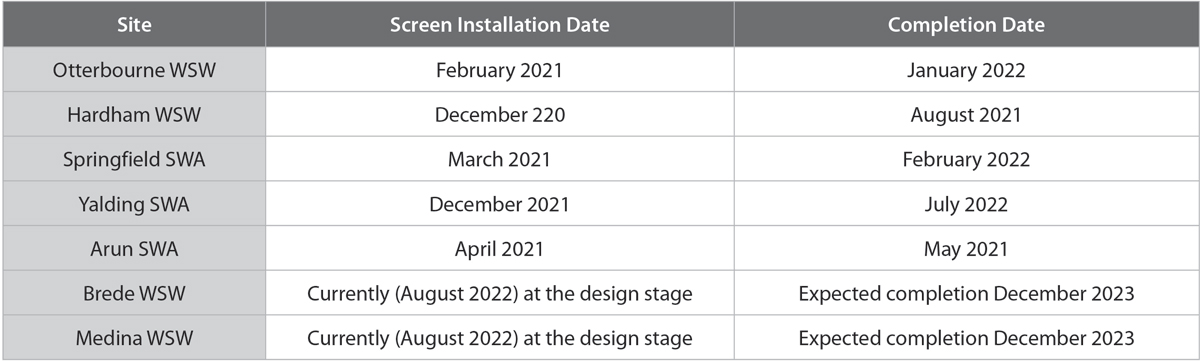

Southern Water Eel Screens Programme – Construction (2022)

Hydrolox eel screen installation at Hardham WSW - Courtesy of Trant Engineering

The Eels (England and Wales) Regulations 2009 requires an eel screen to be installed within a diversion structure capable of allowing at least 20m3 of abstraction in a 24-hour period. The focus of this programme is to protect a threatened species of fish, brook lamprey (Lampetra planeri). This eel-like ancient fish is rare in the UK and ranges from 10-15cm in length; its primary habitat is in rivers, streams and canals and generally feeds close to the river or canal bed. Under an existing framework, Trant Engineering Ltd was appointed to deliver a programme of eel screen installations for Southern Water across the south of England. Under contract, these had to be delivered within a reduced time-frame for design and construction.

Programme

In total, seven abstraction sites within the Southern Water region are included as part of this programme of works; all of which must meet stringent regulatory dates. At the time of writing (August 2022) five have been completed, and two are at the outline design stage. The table below shows key dates for each project:

Details of the existing intakes

The existing intakes and the seven site are as follows:

- Otterbourne Water Supply Works: Coarse bar screen (in front of intake) and a common intake chamber, band screens with chambers, common outlet chamber and pumping station wet well.

- Hardham Water Supply Works: Coarse bar screen (in front of intake) and a common intake chamber, band screens with chambers, common outlet chamber and pumping station wet well.

- Springfield Surface Water Abstraction: Coarse bar screen (in front of intake) and a common intake chamber, band screens with chambers, common outlet pipework to suction side of the three main delivery pumps.

- Yalding Surface Water Abstraction: Man-made intake channel and intake, coarse bar screens (low level and high level), band screens with chambers, and common outlet pipework to the suction side of the five main delivery pumps.

- Arun Surface Water Abstraction: Passive screen with common outlet pipework to the intake chamber with an automated air compressor system to blow off debris build up to self-clean the passive screen.

- Brede Water Supply Works: Coarse bar screen (in front of intake) and a common intake chamber that houses two raw water booster pumps and outlet pipework to Powdermill Reservoir.

- Medina Water Supply Works: An intake chamber, drum screens and common outlet pipework to the suction side of pumping station.

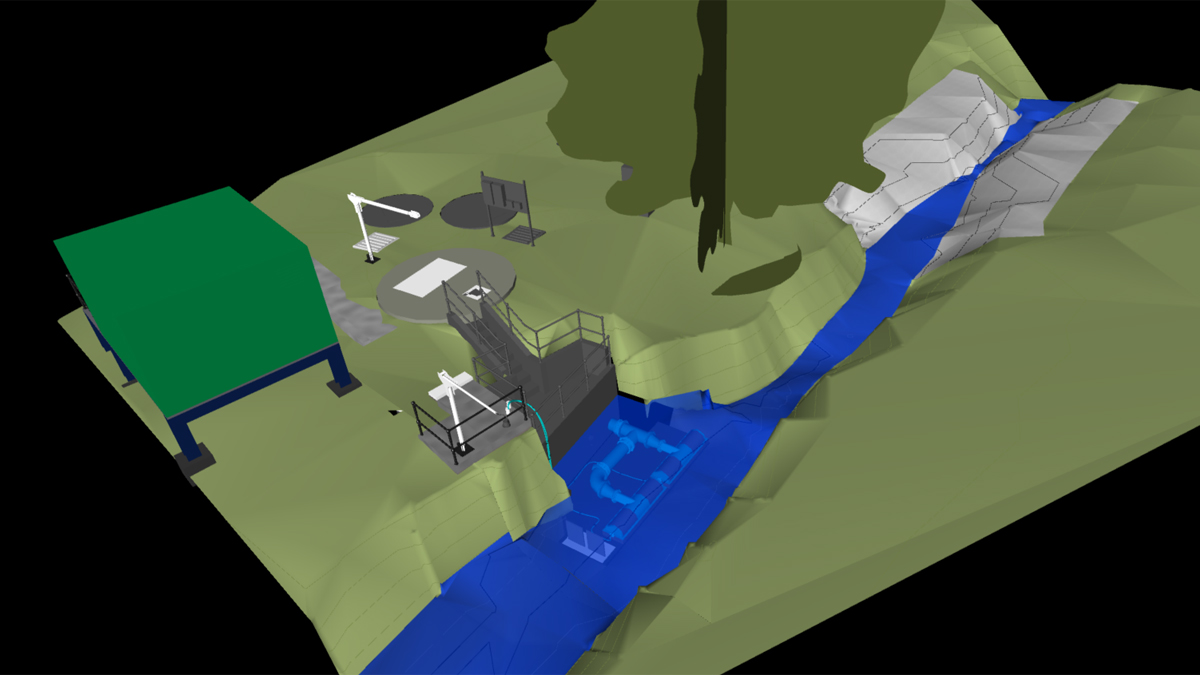

Brede outline design 3D model – Courtesy of Trant Engineering

Designs and key partners

For the seven projects, a concept design was completed by Southern Water. These designs were then fully developed by Atkins into an outline design and detailed design, followed by a build and commissioning package.

A 3D model was generated for all schemes and has been used for the construction phase of the project to resolve any design issues. The models have provided certainty of avoidance of any cross-discipline clashes, provided our site management team(s) a useful tool for constructability and aided the development of the project programmes.

Trant Engineering appointed specialist subcontractors to install the eel screens, silt curtains and electro-fishing to support its regulatory licencing.

The Otterbourne and Hardham Water Supply Works have deployed Hydrolox screens which are installed within a cassette type frame meaning that there are no fixing requirements when these were installed. This reduced the intrusive river works as these simply slotted into place due to their complementary design with secondary steelwork.

The Springfield and Yalding Surface Water Abstraction sites utilise GoFlo screens which are installed on a pivoting frame that is anchored to the riverbed. To ensure the screens are secured in place, they are lowered into a slot either end of the pivoting frame.

Intrusive river works were required at Springfield (due to the site remaining operational) and required a specialist dive team to install the base plates, pivoting frames and screens. Yalding, on the other hand, had a reduction in intrusive works as the site was not operational and a cofferdam was installed. This enabled the construction works and installation of the base plates, pivoting frames and screens to be completed in the dry, without the necessity to utilise a dive team.

The Arun Surface Water Abstraction site has had an Aqseptence Group passive screen installed, which is secured onto the bed of the river and connected to the suction pipework into a chamber where the raw water pumps pull the water through the system.

Hydrolox screen installation at Otterbourne – Courtesy of Trant Engineering

Southern Water Eel Screen Programme Supply chain – key participants

- Client: Southern Water

- Programme delivery: Trant Engineering Ltd

- Detailed design: Atkins Global

- Mechanical & secondary steelwork: Global Energy Group

- Mechanical & secondary steelwork: Woodhams Group

- Electrical: Linton Electrical

- Electrical: Amber Integrated Controls & Automation

- Electrical: FW Marsh (Electrical & Mechanical) Ltd

- Electrical: GA Electrical Services

- Mechanical installation: Terraflow

- Eel screens: Hydrolox

- Eel screens: GoFlo

- Eel screens: Aqseptence Group

- Washwater pumps: Xylem Water Solutions UK

- MCCs & System Integration: Saftronics

- MCCs & System Integration: MCS Control Systems Ltd

- MCCs & System Integration: Max Wright Ltd

- Fish recovery: APEM

- Dive works: Red7

- Dive works: Commercial Specialised Diving (CSD)

- River booms: Bolina Ltd

Security of supply

During the construction phase of all projects, no disruption to the existing abstraction process occurred. This ensured security of supply and wholesome water was delivered to Southern Water’s customers at all times. Trant Engineering ensured there was close engagement with key stakeholders such as the Environment Agency, Natural England, planning authorities, the local community, residents living on the River Medway, and Southern Water’s environmental/ecological team.

Compliance with the regulations around the environment and ecology are paramount in delivering sustainable and environmentally friendly construction projects.

GoFlo eel screen installation at Yalding SWA – Courtesy of Trant Engineering

Scope of works, installation & commissioning overview

Details of the work undertaken at each of the sites are as follows:

- Otterbourne Water Supply Works: The installation of two new Hydrolox S1800 vertical self-cleaning travelling belt screens, a washwater system, a platform around the screens for access and maintenance, a new MCC to control the eel screen system, and monitoring via Southern Water’s telemetry system.

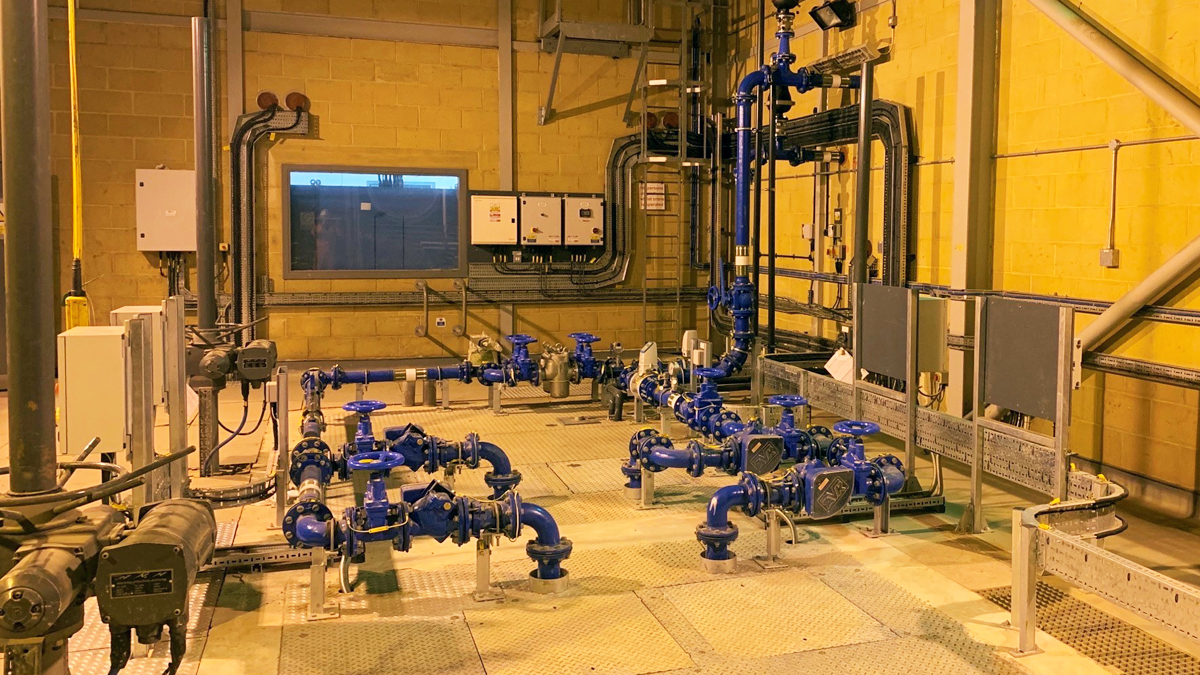

- Hardham Water Supply Works: The installation of two new Hydrolox S1800 vertical self-cleaning travelling belt screens, a washwater system, a platform around screens for access and maintenance, a new MCC to control the eel screen system, a power distribution panel to supply the eel screen and existing MCC, and monitoring via Southern Water’s telemetry system.

- Springfield Surface Water Abstraction: The installation of two new 6.1m GoFlo travelling belt screens, a washwater and launder trough system including a break tank, a platform around screens for access and maintenance, a new MCC to control the eel screen system, and monitoring via Southern Water’s telemetry system.

- Yalding Surface Water Abstraction: The installation of five new 8.25m GoFlo travelling belt screens, a washwater and launder trough system utilising the existing chambers, a platform around screens for access and maintenance, a new MCC to control the eel screen system, a power distribution panel to supply the eel screen and existing MCC, and monitoring via Southern Water’s telemetry system and integration into the existing site controls.

- Arun Surface Water Abstraction: The replacement of the existing half intake screens with fully compliant 2mm mesh passive half intake screens from Aqseptence Group.

- Brede Water Supply Works: Installation of two new passive half intake screens, a hydroburst air backwash cleaning system, a platform/access stairway for maintenance, a control panel for the screen system, monitoring via Southern Water’s telemetry system and integration into the existing site controls.

- Medina Water Supply Works: Installation of five new vertical passive screens, potable water supply to the new break tank (to provide jet washing facility for the screens), a platform for maintenance, new porta davits (to provide lifting facilities to remove the screens for jet washing), inlet penstock actuator and washout penstock actuator.

Yalding eel screen installation – Courtesy of Trant Engineering

Yalding SWA

The Yalding SWA site is the largest in the Eel Screen Programme having the biggest intake and man-made channel (away from the River Medway) within Southern Water’s region. Trant Engineering built the man-made channel in the 1990s when Yalding was originally constructed. The screens that have been installed are the longest eel screens GoFlo have fabricated to date each measuring 8.25m. These new eel screens have replaced the existing coarse bar and band screens and have been housed around new bespoke steelwork, including four access walkways/platforms:

- The washwater system platform enables access to the five washwater system valving configurations.

- The eel screen walkway gives access to the local control panels which control the screens locally.

- An upper walkway allows access to the screens when pivoted forwards for maintenance of the motors and spray bars, house key instrumentation for the control system.

- A lower walkway enables access to the coarse bar screen for clearance of any build up of debris.

A cofferdam was formed approximately halfway down the man-made channel to enable dry construction and installation works. All disciplines benefitted from this, and a well-managed collaborative programme facilitated a safe, controlled and decisive installation.

Yalding cofferdam – Courtesy of Trant Engineering

During the commissioning phase of the project, Trant Engineering had to collaboratively work with Southern Water as the requirement for Yalding SWA was requested to be put into service. For a period of two weeks, Trant and Southern Water operated the new eel screen system with the abstraction pumps to provide the resilience and supply of water to Bewl Reservoir. This has provided Southern Water with the additional water for the peak period of demand within the summer period of 2022.

Asset integration is a key part of commissioning which ensures a successful handover of these projects to Southern Water. This process allows Trant Engineering and Southern Water’s asset integration team to build a portfolio of standard operational and maintenance documents including project specific detailed drawings, commissioning evidence, operational processes, manufacturers literature, new asset information and maintenance regimes. On completion of a four-part process, the project is handed over after Part C with the principal contractor then under a twelve-month reliability defects period.

Trant Engineering is managing Yalding’s intake which will include monitoring and clearing the debris accumulation, communicating with Southern Water’s key operational staff when the site is operational and maintain the eel screen system. On completion of this, a report will be compiled detailing the successful maintenance of the eel screens. This will provide a straightforward handover of the maintenance requirements.

Kev Fausset, Southern Water Senior Project Manager, commented:

“… an outstanding performance by Trant Engineering Ltd to deliver these projects within such tight timescales and in an innovative way”.

Yalding washwater system – Courtesy of Trant Engineering

Moving forward

With the successful completion of five out of the seven eel screen projects, lessons learnt have been captured and incorporated into the remaining two schemes. This will allow for these to be delivered in a more efficient and innovative way, providing programme savings and opportunities to innovate.