Tamar Lakes ‘Q’ Scheme (2017)

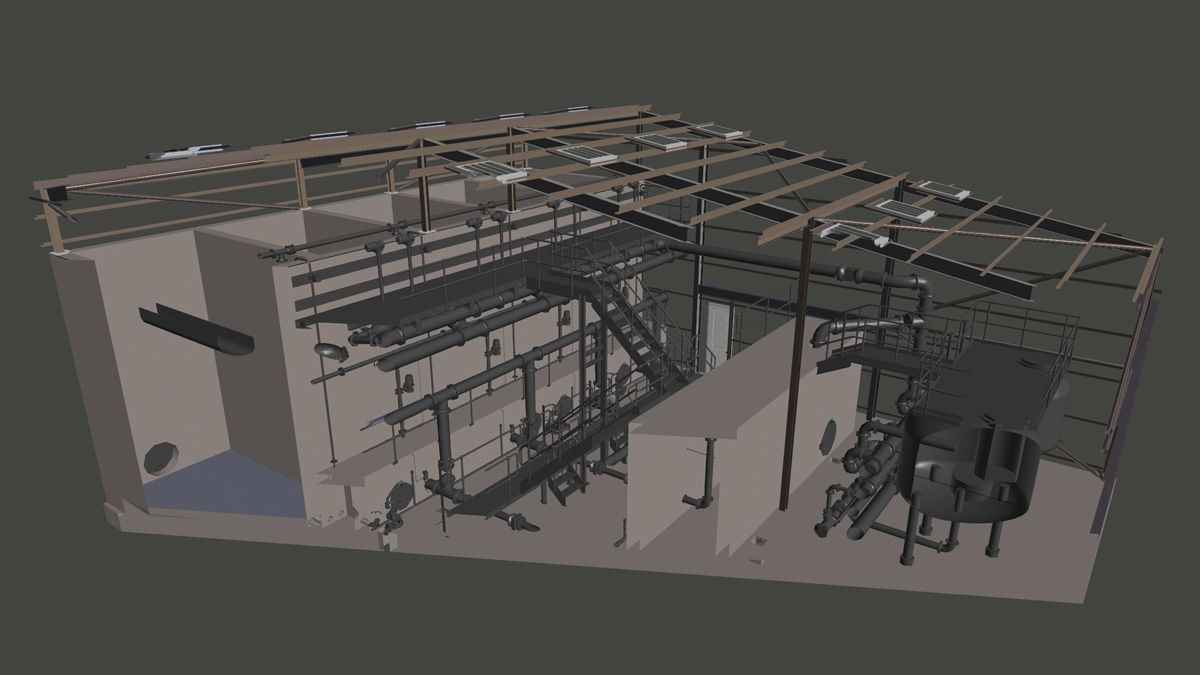

Extract from the integrated model - Courtesy of South West Water Delivery Alliance H5O

Tamar WTW was constructed in the mid 1970s and is located on the Cornwall/Devon border near Bude/Kilkhampton. Raw water is transferred to site by gravity pipework from Upper Tamer Lakes Reservoir. The works has a maximum output of 9.0 Ml/d and treated water is pumped by 2 (No.) sets of on-site high lift pumps to Welcombe and Hersham Service Reservoirs (SR). Tamar WTW is a critical asset serving 9,420 properties with a connected population of 21,666, of which approximately 10,000 have no alternative supply route. Hersham SR (9.35Ml capacity) can be supplied from Tamar and Northcombe WTW, but Welcombe SR (4Ml capacity) is supplied solely from Tamar WTW. Key customers supplied only by Tamar WTW include Park Resorts Ltd at Bideford Bay. The project evolved to cater for improvements to overall water quality, improvements to the manganese removal process, improvements to the existing rapid gravity filters (RGF) and essential capital maintenance items.

Scope

The scope of works was defined by the client in an output statement. This gave the required parameters for the team to work to. Prerequisites for the scheme included a new gravity granular activated carbon (GAC) plant, new secondary pressure filters (SPF), new UV primary disinfection reactors, a new sludge holding tank, refurbishment of old sludge holding area, new interstage pumping (for the SPFs), a new treated water high lift pumping station (HLPS) and existing rapid gravity filter (RGF) refurbishment.

An important part of the scope was the need to maintain supplies to the locale from the WTW during the construction, commissioning and handover of the works.

Timeline

In July 2015 Interserve Construction Limited (ICL) and Arcadis Consulting were selected as the Tier 1 design and construct partners within the H5O capital project delivery alliance for South West Water. (H5O refers to the five partners in the alliance, ICL, Arcadis, Balfour Beatty, Pell Frischmann and SWW to develop the design and cost for the project).

On the 1 March 2016 ICL received a contract award from South West Water to the value of £4.9m for the construction of the works, and mobilised to site in April 2016. The Completion date for the project was set for the 11 July 2017 with a forecast operational use date of 28 March 2017. Completion was targeted at 26 June 2017 following the submission of all completed documentation.

Contactor access manways – Courtesy of South West Water Delivery Alliance H5O

Project complexities & interface with existing works

Like many water and wastewater plants built in the 1960s and 70s the Tamar Lakes site had developed over the intervening years. In total the existing assets encompassed 75% of the overall site area including a recently installed bank of photovoltaic cells. This made for a very congested site in which the construction team had a significant amount of work to undertake.

The initial period of design development included a ‘root and branch’ review of the proposal received from the scoping team. This process revealed opportunities to provide the output requirements using different configurations of equipment. In addition, programme savings were identified by sequencing the works in such a way as to minimise the number of WTW shut downs required. This also de-risked the programme as shut down periods could not be relied upon. Finally, construction methods were integrated in conjunction with design methods to simplify the build.

The first example of the re-configuration of equipment and build sequence came with the first elements of the project to be constructed, namely the new transformer base and the new HLPS. This included the valve and tee feed arrangement from the existing treated water tank and discharge connections to the existing final water rising mains which feed the Welcombe and Hersham Service Reservoirs. Also, new feeder sections of the MCC, pump variable speed drives and a back feed to the existing works to maintain the existing process.

Moving the existing high lift pumping station outside the building had multiple benefits. It allowed the modification and reuse of the old HLPS as the new interstage pump station and enabled the existing contact tank, clean backwash tank and existing high lift sump to be connected and utilised as a common interstage pump feed sump. The cost of all of the pumps in the new dry well was less than the price of one of the new multistage pumps originally proposed.

(left) Range of cast-in pipe examples (cast into PC panels) and (right) dosing kiosk and flushing point arrangements – Courtesy of South West Water Delivery Alliance H5O

Investigation into the site power supply found that the agreed site power limit was 260kW, and that in the previous 12 months the average consumption had been close to this figure. To facilitate the additional load of approximately 100kW a new site transformer was required. To mitigate risks to the plant (power failure, or problems during installation) the location was changed and the new power supply brought on line in tandem with the existing.

One of the principle drivers for the scheme was the reduction of disinfection by-products generated by the use of chlorine in conjunction with organic material in the water. To combat this, a new UV plant was selected to replace the integral filtered water channel and contact tank built underneath the works building. The existing clean backwash tank was retained and combined with a section of the contact tank and filtered water channel to increase capacity. This was necessary to meet the backwash demands of the new SPFs and GAC plant. New larger pumps were also installed.

The serpentine arrangement of these channels made the conversion relatively straightforward with minimal shut downs and no impact to the water supply from the works.

Evolution of design and implementation of lessons learned from previous work

This was the fourth GAC project that had been undertaken by H5O. All had been designed by Arcadis and constructed by ICL in conjunction with various Tier 2 suppliers from the alliance.

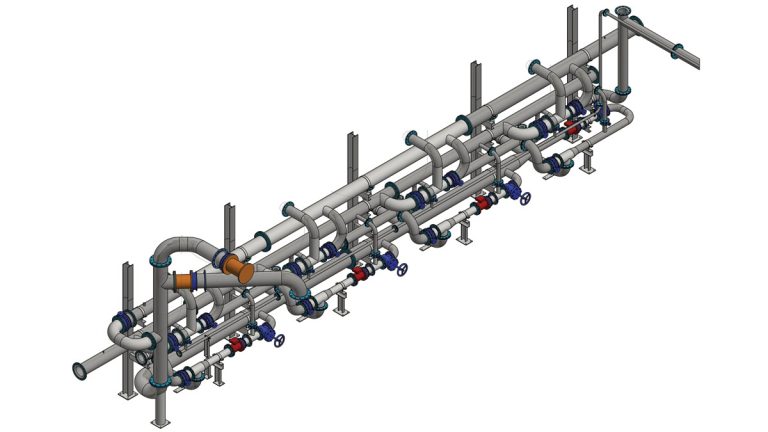

During the design and construction of these projects the benefits of precast concrete construction and off-site manufacturing and modularisation had been successfully implemented. This included the construction of large pipework assemblies and cabling runs as well as the large concrete contactors for housing the carbon filters. The latter technology proved successful in terms of programme with little impact on coordination.

The benefits of 3D design using BIM software (Revit, Plant, Civil 3D) had become apparent on previous work. Use as a visualisation tool was the principle advantage. This allowed early engagement with the client operations team and agreement on design details. In turn this permitted improved coordination with the supply chain to develop a complete design and operation scenario well in advance of the work starting on site and contracts being let.

Further gains were made in the mechanical, electrical, and civil coordination and inevitably helped H5O minimise queries at takeover and completion.

During the other projects the teams had demonstrated the benefit of precast concrete construction and the potential cost and time savings that this gave at site during the construction. They had also explored the integration of mechanical GAC gallery pipework into the steel access steelwork, and even modularisation of this, which again decreased the time and complexity of installation at site, and reduced H&S risk in undertaking working at height.

Example of SPF pipework from supply chain – Courtesy of South West Water Delivery Alliance H5O

At the Restormel project it was noted that to install the GAC filter underdrain and media, and access the GAC contactor cells during regeneration, access was required into the 6m deep cells.

The lesson learned to mitigate the deep tank access risk was to provide access manways at ground level. These were boxed out within the PCC GAC contactor wall units, such that access to each of the cells could be gained from ground level during the construction of the project. These manways also facilitated access for cleaning during operation completely taking away the need for hoists and man access from the top. This is described below in more detail.

Initially pipes were boxed out or sleeved in the PCC factory, or cored as required at site. Due to the commonality of the GAC designs, it became evident to the teams that epoxy coated wall couplings/pipes could be manufactured early in the programme, and then shipped to the precast factory in Ireland and cast in to the wall units before they were delivered to site.

In the construction of the Drift and Restormel projects a walkway was required across the top of the GAC contactor cells for two reasons:

- To act as a structural prop at the mid-point of the largest spanning GAC wall to reduce stresses within the reinforced concrete design. This was cast after the erection of the main PCC wall units and tied in/cast in to the top of the all units.

- To enable washing down during the media removal process.

However, after discussions between SWW operations and the specialist sub-contractor for the media replacement process, it was established that by providing wash-down hose reels, these walkways are not required for the maintenance and operation of the works. By removing these, the overall height of the GAC building has been reduced, saving a significant amount of working at height (required to cast and tie in these walkways), which has been offset by a slight increase in PCC wall unit thickness from 300mm to 400mm.

Example of the integrated design of pipework, walkways, stairs, structural frame and cabling in the GAC building – Courtesy of South West Water Delivery Alliance H5O

Gas and fume cabinet

The existing chlorine gas room could not be re-located and needed to be retained to supply the disinfection dose to the treated water and pre-manganese removal at the IPS. Vacuum dosing lines were adopted in lieu of the old motive water system. Extensive rerouting through the lobby of the existing treatment building was necessary. The nature of the existing building including large steel doors meant that it was difficult to create a gas safe room with full extraction at the point of application (POA) for the IPS.

During the detailed design and in liaison with specialist framework suppliers a gas safe dosing cabinet and localised extraction system was developed with the supply chain.

Re-cycling of instrument wastewater

In the previous projects, instrument wastewater was discharged to the drainage within the GAC gallery and wasted. Due to the Tamar Lakes Scheme introducing over 25 (No.) water quality instruments for the manganese removal, GAC and UV processes, the volume of water loss was 300l/hr.

During the detailed design stage of the project the team was able to engineer a solution that prevented this water from being wasted. At these stages of the process this water has already encountered significant treatment, and therefore cost.

It was decided that if the instrument waste flows and fast-loops were piped to a small collection tank, then submersible pumps with integrated float switches with nominal electrical consumption could pump these flows into the GAC dirty washwater/rinse system and be recovered by return through the supernatant system during normal operation.

Examples of wastewater recovery – Courtesy of South West Water Delivery Alliance H5O

Third party liaison and off-site influences

Though the Tamar Lakes site is in a largely rural area, there are a number of neighbours who needed to be considered during the design process. The two bungalows adjacent to the site boundary fence had previously been SWW owned operator houses but more recently became privately owned.

When the planning application for the project was submitted in March 2016, one of the neighbours that had recently purchased one of the bungalows objected to the planning, citing the location and proximity of the GAC structure as their concerns.

During the liaison and mitigation process the GAC building was rotated through 180° such that a lower elevation of the building faced the neighbours, as the levels of the building could not be altered due to hydraulic factors.

The planning office from Cornwall County Council also stipulated the requirement for a planted bund to be constructed along the boundary of the site, to aid in screening the building from the neighbours and noise attenuation.