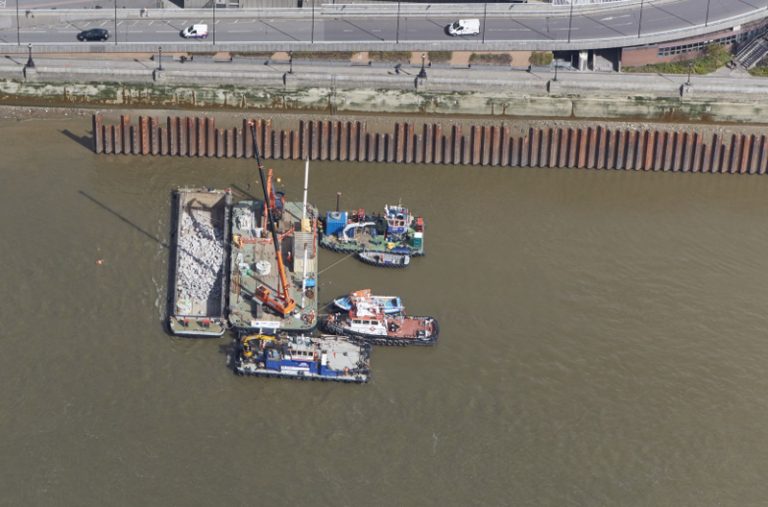

Tideway Central – Vessel Relocation (2017)

(left) Blackfriars Pier and (right) tubular piling for Blackfriars Pier - Courtesy of Tideway

London’s sewerage system was designed by Sir Joseph Bazalgette in the 1850s, for a population of four million people. Whilst the Victorian sewers are still in excellent working condition, they are struggling to cope with the demands of the city’s growth. Every year, tens of millions of tonnes of raw sewage pour into the River Thames from combined sewage overflow (CSO) discharge points all along the river. In 2014, 62 million tonnes of untreated sewage entered the river from Chiswick in the west through to Greenwich in the east. The solution to this unacceptable, unsustainable situation is a tripartite one. Thames Water has already delivered the first two components of the overall London Tideway Improvement Programmes; the Lee Tunnel, tackling the single largest overflow point near the Olympic Stadium in Stratford and the expansion of the five sewage treatment works on the tidal River Thames. The final piece of the puzzle is the Thames Tideway Tunnel.

Thames Tideway Tunnel

The Thames Tideway Tunnel is a planned 25km long 7.2m diameter interception, storage and transfer tunnel running across London. The tunnel will intercept and collect sewerage from thirty four of the most polluting CSO discharge points along the River Thames.

VolkerStevin was appointed by Tideway to carry out enabling works in advance of construction of the tunnel.

The project has been split geographically into three main construction contracts, which correspond to the anticipated tunnelling conditions in the central, east and west of the capital. Each section of the tunnel will be under construction at the same time to ensure that the Thames Tideway Tunnel can be completed effectively. This paper looks at the technical challenges of the enabling works for the Blackfriars and Victoria sites in the Central section.

Sheet piling for Blackfriars Pier – Courtesy of Tideway

Tideway Central scope for enabling works

VolkerStevin commenced work on the early contractor involvement (ECI) phase in December 2014, followed by the start of construction in November 2015 and is due for completion in June 2017. The scheme was required to allow access for the main tunnelling works for the creation of the new ‘super sewer’ beneath the river.

Working methodology

The construction works comprised:

- Construction of the new floating Blackfriars Millennium Pier for the Thames Clippers fast ferries.

- A new lift and staircase and associated landscaping to serve the new pier.

- Decommissioning of the existing Blackfriars Millennium Pier pontoon and access brow.

- A new slipway for an outdoor activity centre in Shadwell.

- The relocation of the PS Tattershall Castle, a floating pub and restaurant, to newly constructed berthing facilities.

- Removal of the old moorings for the Tattershall Castle and HMS President.

This was the first project undertaken by Tideway and tested the consenting processes established, including the four‐way legal agreement between Tideway and the river regulators which includes; the Environment Agency (EA), Marine Management Organisation (MMO) and the Port of London Authority (PLA).

Installation of scour protection for Blackfriars Pier – Courtesy of Tideway

The contract consisted of two phases.

- Phase one was an extended ECI phase to assist with the finalisation of the design and development of methodology.

- Phase two was an NEC ECC Option C construction contract.

Phase one was awarded in December 2014 and undertaken to procure long lead items, to commence preparing for and obtaining consents for the works, and to finalise design and construction methodologies for the works.

Tideway’s approach was that early integration of the delivery contractor within the team would provide significant benefit to the scheme. Having been awarded the contract in the summer of 2015, VolkerStevin co‐located a team of ten personnel to work with Tideway and their designer Arup, to develop work methods and commence preparation of over 170 consent applications.

The Blackfriars Pier pontoon en route from Holland – Courtesy of Tideway

Blackfriars Pier

Construction on the new pier commenced with a 92m long row of sheet piles, to stabilise the toe of the river wall to enable a berthing pocket to be dredged for the pier and clipper ferries it serves. The piles were cut off at bed level by a team of divers. The bed was also protected with a layer of geotextile and rock armour scour protection.

The new pier was constructed by Ravestein in Holland, along with the associated walkways and bankseat. The 84 metre long pontoon was transported across the North Sea on a submersible jack up barge and floated off once it reached the relatively calm waters of the Thames.

Once towed up the Thames, the pontoon was moored against two piles, each 1500mm in diameter, 32m long and weighing 46 tonnes. Four similar tubular piles were driven to support a bankseat structure along with two smaller hospital piles to hang the 60 metre long and 140 tonne canting brow from. The piles were driven with a vibratory hammer, followed by a 60 tonne impact hammer and noise shroud.

Towing the new Blackfriars Pier up the Thames – Courtesy of Tideway

Andy Alder, Tideway delivery manager, said:

“The opening of the new pier on schedule is a testament to the dedication and hard work of the team, and the many stakeholders we have worked with.”

Due to the less accessible location of the new pier versus the old, a new staircase and lift were installed from Blackfriars Bridge down to the towpath. Once the existing stairs and landscaping were demolished, the poor ground conditions dictated that 51 (No.) 225mm diameter concrete piles had to be driven to support the concrete slab foundations for the new stairs and lift plant room.

Due to the challenging access constraints, all plant and materials were delivered via river and removed using a jack up barge (JUB) and telescopic crane. Access between the JUB and river was via a bespoke set of steps and canting brow, as well as a spudleg linkflote barge.

Eagle eyed members of the public will notice that the lighting for the landscaping stairs and copper nickel clad lift is syncronised with the ebb and flow of the tide.

Lifting one of the new Tattershall brows into position – Courtesy of Tideway

Tattershall Castle

Relocating the Tattershall Castle involved the following operations:

- A sheet piled wall and dredging, similar to that carried out for the pier.

- Dredging to form a berthing pocket, in which an unexploded ordnance (UXO) was discovered.

- Two pairs of mooring dolphins and associated tubular piles along with grouted collars with bolted connections to guide beams for the vessel to float up and down on.

- A secondary mooring arrangement comprising of chains anchored to two additional tubular piles and screw anchors.

- 15 tonnes of additional ballasting in the engine room to off-set the additional weight from the new heavier brows.

- New utility connections.

- Removal and disposal of the old brows and access steps along with the supply and installation of news ones.

- Removal of the old mooring dolphins.

VolkerStevin worked closely with Tideway to keep the local authorities, business owners, residents, pedestrians and road users informed about the works, listen to views and feedback and help minimise disruption to the community.

Dredging the berthing pocket for the Tattershall Castle – Courtesy of Tideway

The ECI phase allowed VolkerStevin to establish a good working relationship with all stakeholders, including organisations impacted due to their vicinity to the works. Potential issues arising from noise pollution were mitigated through adapted working hours to suit performances at the Globe Theatre and avoid exams at the prestigious City of London Boys School.

Bespoke noise shrouds were installed around piling hammers and around the piles beneath the water level to reduce the impact on fish. VolkerStevin provided input regarding design change impacts to the construction methodology, cost and programme. This gave Tideway better clarity regarding the implications of forthcoming changes prior to entering into a contract.