Ufton Nervet WTW (2023)

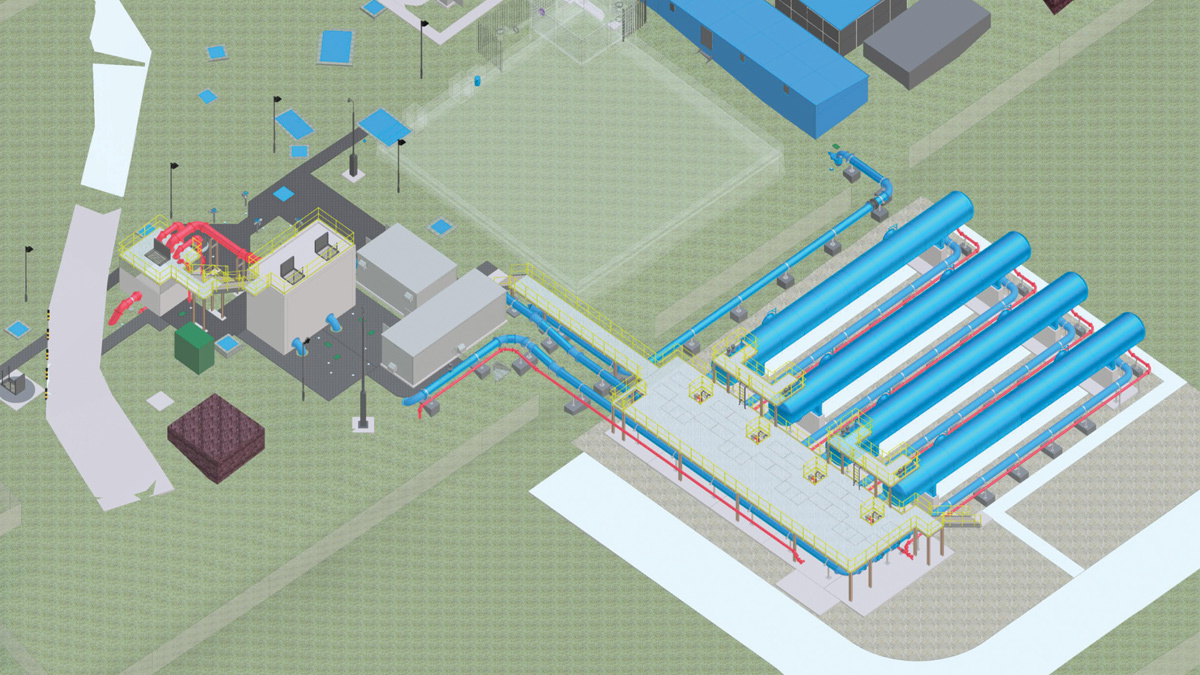

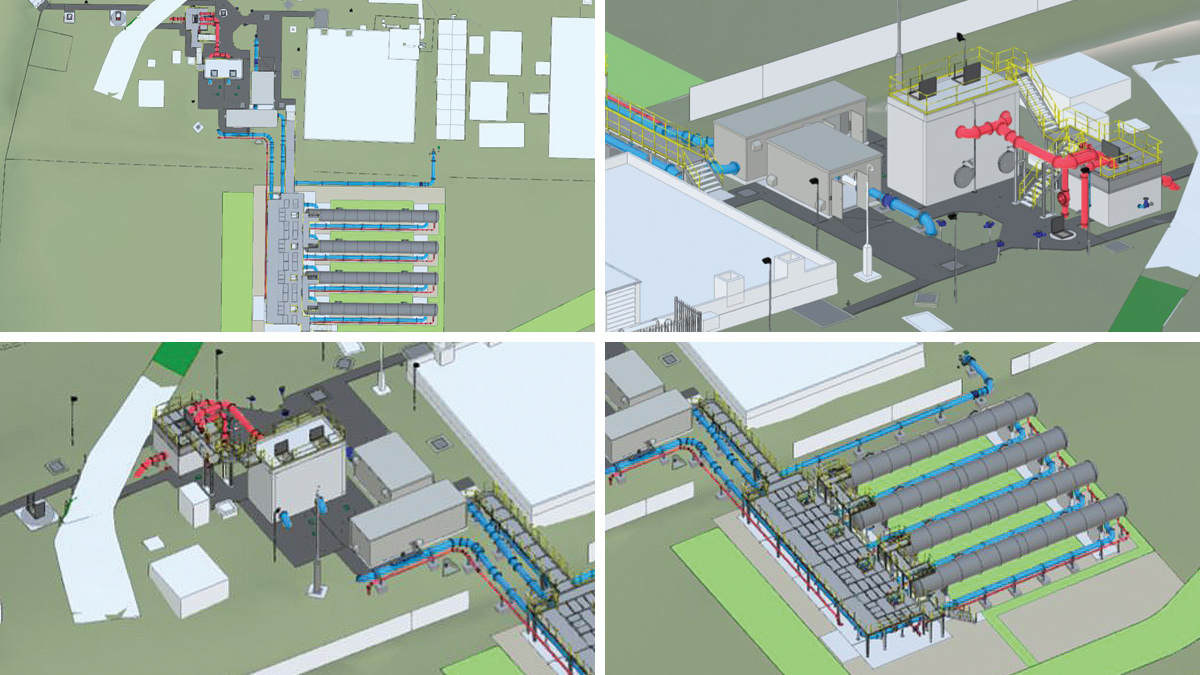

3D model showing the proposed works at Ufton Nervet WTW - Courtesy of MMB

Ufton Nervet WTW is a groundwater treatment site located in the Kennet Valley Water Resource Zone, to the south of Reading and supplies an ‘island zone’ of approximately 12,000 properties. Groundwater is pumped through pressure filters for iron removal after which chlorine is dosed before flows enter the contact tank, which is a single cell semi-buried tank of concrete construction where the water comes into contact with chlorine to achieve disinfection. SO2 de-chlorination occurs before high-lift booster pumps pump the water into the water supply network. Thames Water contracted MMB to design and build the proposed run-to-waste (RTW) and contact tank (CT) as part of the AMP7 Capital Delivery Alliance Lot 1- Water non-infra Thames Valley framework.

The problem

The existing contact tank asset has been raised on the drinking water safety plan as a resilience issue since it is not possible to take it out of service for a periodic planned maintenance inspection. This should occur so risks to water quality and long-term structural integrity can be managed, without shutting down water production to maintain customer supplies.

Since the existing contact tank is semi-buried, in the event of high turbidity, there is no permanent automated means to run-to-waste pre or post-contact tank. The only option available is a manual invention and over-pumping into an adjacent ditch. The project has to overcome the following constraints:

- The WTW feeds an ‘island zone’ network, meaning if the site becomes inoperable the customer potable network loses water and pressure in less than eight hours because there is no means to re-zone the network to feed it from another site.

- Ufton Nervet WTW is a small site with limited space which is surrounded by a watercourse ditch in poor condition. Areas of the site which do not contain existing assets have low to moderate categorised trees, or modified grassland in poor condition.

- The site is surrounded by agricultural land which is a floodplain so any new assets would need to be kept to a minimum to avoid having an impact on the floodplain storage, but still meet the planned operational and maintenance requirements expected of any asset.

- The site has restricted access via a single lane road meaning delivery of larger items would be challenging, but the contact tanks need to be large enough such that if one is taken out of service those remaining provide enough contact time between chlorine and water.

All these constraints mean any spare space is at a premium and careful planning is needed to phase the work to keep outages and overall programme as short as possible.

Existing contact tank – Courtesy of MMB

Solution

It is proposed to tie-in to the existing contact tank feed with DN500 pipework and isolation valves on each side of a new tee piece, which will enable the works to continue running whilst the new contact tanks are built offline, before the existing 200m3 tank is decommissioned and demolished at the end of the project.

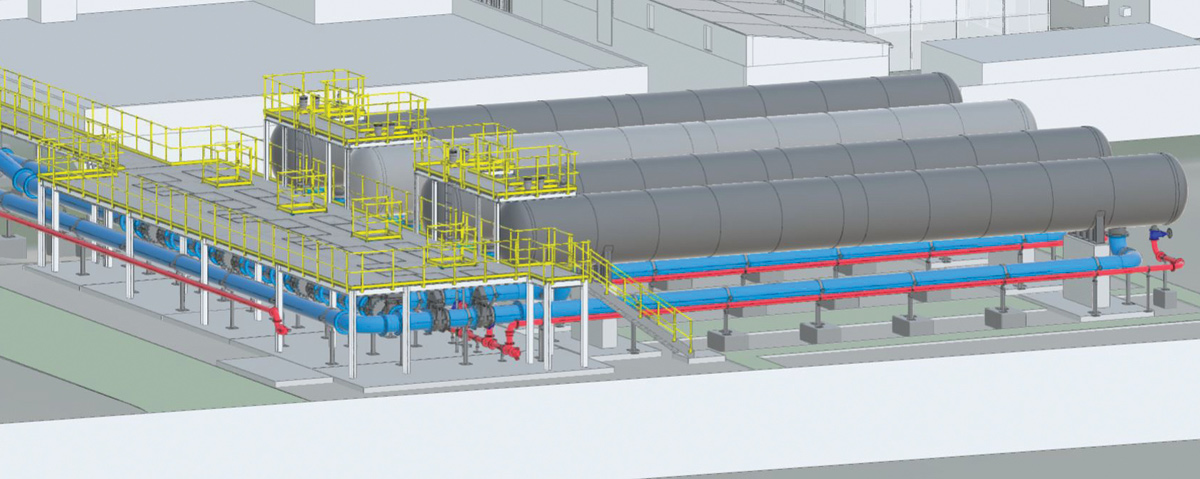

Four pressurised contact tank vessels will be installed in the field adjacent to the site. These are elevated out of the floodplain with an access gantry provided to allow operational staff to cross from the existing site to operate the tank isolation and maintain air valves. The contact tanks will be 21m long and 2.1m in diameter to meet the 15 mega litre/day (MLD) throughput and client asset standard contact time, even with one contact tank taken out of service for inspection to enable the site to remain operational.

Chlorine will be dosed via a new point of application (POA) static mixer and an aeration gas dosing system will be housed in kiosks with associated sample pumps, which will replace the current cascade aerator on the existing contact tank.

A balance tank will provide the hydraulic break between the pressurised contact tanks and existing high lift booster pumps, with an internal dividing wall to allow either cell to be taken offline.

Two pairs of actuated valves and turbidity instruments will allow for a manually initiated automated system pre and post the contact tanks to be de-chlorinated before running to waste. The RTW system will comprise a dichlorination chamber, flow meter chamber, sample chamber, and headwall all sized for a maximum discharge rate of 120 l/s.

A new site road will provide vehicle access to the contact tanks and a perimeter security fence installed around the extended site boundary.

3D model showing the four pressurised contact tank vessels – Courtesy of MMB

Ufton Nervet WTW Contact Tank: Supply chain – key participants

Because the project scope is complex and requires specialist input and early supplier engagement the following multi-disciplinary teams were involved in delivering the project.

- Client: Thames Water

- Principal contractor & designer: MMB

- Specialist design (planning, CFD, ecology): Mott MacDonald

- Civils/groundworks: Hercules Site Services Ltd

- Topo/GRP/Point Cloud: 40Seven Ltd

- Ground investigations: Dunelm Geotechnical & Environmental

- Contact tanks: Vessco Engineering Ltd

- Mechanical installation (pipework): JB Fabrications

- Mechanical installation (metalwork): FabTek Ltd

- Electrical installation: IMAC Ltd

- MCCs/systems integration/ICA: BGEN Ltd

- Kiosks & security covers: Morgan Marine Ltd

- Static mixers/aeration system: Statiflo International Ltd

- Valves: AVK UK Ltd

- Precast concrete: FLI Precast Solutions

- Legato® interlocking blocks: Elite Precast

- Instruments: ABB Ltd

- Instruments: IFM Electronic

- Instruments: Siemens

- Sample pumps: Grundfos Ltd

- Security systems: Reliance Ltd

- Security fencing: Allen Fencing Ltd

- Flood protection measures (borehole pump buildings): Flood Control International

Overcoming the constraints

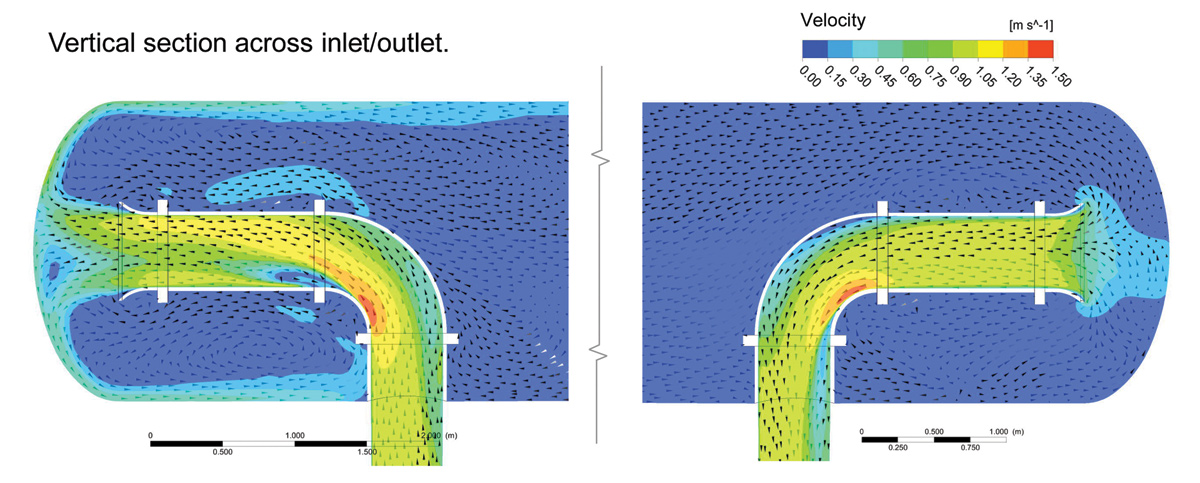

Computational Fluid Dynamics (CFD): CFD modelling of the proposed contact tanks at Ufton Nervet WTW was undertaken to prove the performance of the proposed design. The performance of the contact tanks is measured in terms of the standard retention time t5 (the time taken for 5% from the point of the chlorine addition to measurement at sample point No. 4 after the contact tanks).

CFD modelling – Courtesy of MMD CFD Team (Spain)

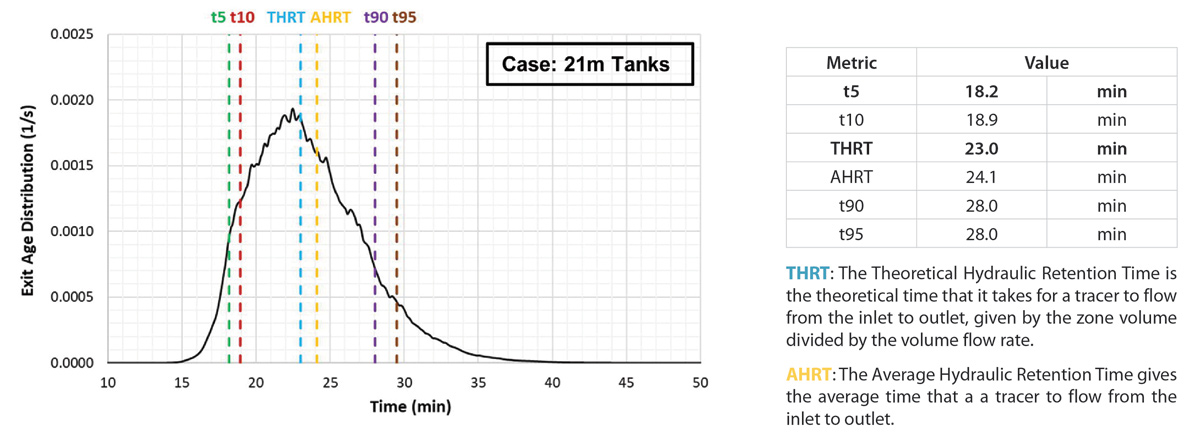

The purpose of the model was to provide evidence that the water has a minimum t5 retention time of 20 minutes to comply with the standard if the raw groundwater is considered unstable, or 15 minutes if considered stable. A non-reactive tracer was added to the model at the primary dosing point and measured at the outlet through time to obtain its exit age distribution. The model was run as a worst-case scenario with one of the furthest of the four tanks taken out of service; meaning only three were modelled including interconnecting pipework. The model was also based on a 15 MLD design horizon which is conservative as it is 1.5 MLD beyond the abstraction limit and capability of the existing borehole pumps.

It was agreed with the client that the groundwater was considered stable such that a 15-minute t5 was the target figure, and the model showed an 18.2-minute t5 with 21m long contact tanks. This offered a saving of approximately £230k by having shorter tanks because the CFD modelling showed that 25m long tanks would have been required for a 20-minute t5. This would have made delivery of the tanks down Ufton Lane even more challenging. Even so, Autotrack analysis was completed to confirm in theory there was a route to the site, which was viable for delivery of the 21m tanks, which the tank suppliers’ delivery management company confirmed was possible during a pre-delivery survey. This was considered to be the right balance of resilience and affordability because it is unlikely the unstable groundwater events would occur at peak design horizon demand whilst one of the contact tanks is out of service.

Exit age distribution of tracer measured at the outlet – Courtesy of MMD CFD Team (Spain)

Use of SYNCRO to hold a digital construction rehearsal to de-risk programme: A P6 programme has been produced which lists numerous construction activities and outages limited to eight hours due to the island zone constraint, and a 3D model has been produced to illustrate the physical space each asset needs when installed. As part of MMB’s Digital Delivery Plan SYNCRO (one of the digital tools utilised by MMB) was used to hold a construction rehearsal which led to the following benefits; a better understanding of the space constraints, engaged client stakeholders for programme buy-in, improved safety and a de-risked programme.

By combining the P6 programme with the 3D model and reviewing it via SYNCHRO software allowed a better understanding of the concurrent activities and the ability to spot where there could have been potential space constraints. The digital rehearsal revealed that the design was proposing to install precast pipe support plinths and the access metalwork at the same time as the contact tanks were being installed, so SYNCHRO was used to update the P6 programme live to re-sequence the work.

This rehearsal simulated the contract lift of the contact tanks and illustrated just how much space was needed to have a safe working area to complete a lift of a 21m long 10t tank on a 20m radius. This again led to a change in the construction sequence of the mechanical installation of pipework and access metalwork.

Focusing on safety and being prepared to challenge programme where there looked to be too much concurrent working, should ensure a right first-time approach before committing to starting on site, reducing the risk to quality or safety and having to abortively re-plan works, which may end up increasing costs.

MMB SYNCHRO digital rehearsal – Courtesy of MMB

The digital rehearsal review coincided with a change in a key construction assurance client team member, so the above process sought their buy-in and confidence in the construction programme and occurred at a significate project milestone (contractual solution review) where the client can make a go/no-go decision on whether the project goes ahead into detailed design and construction. The review received positive feedback from the client that the session proved to be a valuable and more engaging way to bring them up to speed with the scheme and the construction programme.

The project will revisit SYNCHO to plan in more detail at other key milestones like works outages, or whilst on site as a more visual way of completing 5-week-look-ahead planning sessions. MMB has a Digital Delivery Network which is a community of people who can support projects with tools like SYNCHRO and others which can be found on the MMB Digital Delivery Hub.

The benefits of this digital rehearsal were more cost/risk mitigation rather than direct cost reduction on a project. The estimated consequence of not having realised the space constraints and programme concurrent working is 10-weeks lost time meaning £148k cost increase ‘saved’ (avoided). It is difficult to estimate the cost saved/benefit of having a happy engaged client stakeholder like a construction assurance engineer. This is assumed as saving/mitigated a potential two-week delay resulting in a approximately £30k saving.

Providing maintainable assets vs keeping flood plain impact negligible: The existing site not only feeds an ‘island zone’ network; it also becomes an island during flood events and is surrounded by drainage ditches.

Relocating the entire site would be uneconomical and too intrusive so expanding the treatment works into the adjacent field is the best whole life cost solution even if that field is a flood plain. This meant any new assets needed to have as small a footprint as possible to ensure it had negligible impact on the flood plain, and yet still needed to be assessable for the planned maintenance and main driver for the scheme; to be able to take one contact tank out of service for quality and structural inspections.

Flood plain location of contact tanks – Courtesy of MMB

The solution is to install the steel contact tanks on slim 2m tall concrete plinths, with the inlet/outlet stainless steel pipework supported off steel pipe supports founded on Legato blocks or strip foundations. Precast units were selected where practical and economical to speed up the install to reduce the risk of needing to poor concrete into a floodplain as part of the 10-month long construction programme.

The outlet pipework was looped back to join the inlet pipework such that all the isolation and air valves can be operated from the same common access platform, which is 21m long by 6m wide and stands 2.8m above ground level, which saved approximately £400k in metalwork and civil plinths The platform then bridges over the ditch between the treatment works and adjacent field to provide operational access.

To ensure all the new assets didn’t have a negative impact on the floodplain a flood model and flood risk assessment was completed based on the volume of new assets to be installed in the field, which showed negligible impact to the flood plain.

The contact tanks can be accessed at ground level outside of flood events via a new Grasscrete access road, which removed the need for road drainage which saved £37k. Foundations would have the existing underlying alluvium layer of soft organic clay replaced to target the medium dense gravels layer with stone to allow for better drainage during periods of rainfall and reduce the risk of settlement.

The alternative to the elevated assets would have been to bund the entire area which would have had significant cost, carbon and floodplain offset impact which was calculated using the Mott MacDonald Moata Carbon Portal.

Ufton Nervet WTW 3D models – Courtesy of MMB

Biodiversity net gain (BNG): Approximately 2m of the existing ditch will be disturbed to install the new headwall, so another section approximately 10m long will be enhanced from poor to moderate condition equating in a 13.3% BNG in river units. The 0.1ha of agricultural grassland will be enhanced from poor to moderate condition to achieve a net gain of 10% to account for that lost from installing the new assets.

Approximately 88 urban trees are proposed to be planted and maintained to moderate condition along the 180m boundary fence line to achieve a net gain of approximately 40%. To achieve a net gain of 10% would mean only 22 small trees needing to be planted, but this would of only provided a visual screening along 25% of the fence line. Therefore a hedgerow will also be planted along approximately 125m of the inside of the fence line to provide further visual screening and offer at least a 27% net gain in BNG hedgerow units.

Conclusion

The project started in January 2022 so has been delivered through the COVID pandemic with a team remote-working via MS Teams but making use of Mott MacDonald’s practice network has enabled colleagues from across the UK, Spain, and India to work together for the first time.

The project is anticipated to start on site in April 2023 and to be completed by January 2024.