Evergreen Water Solutions

Volute Sludge Dewatering (2022)

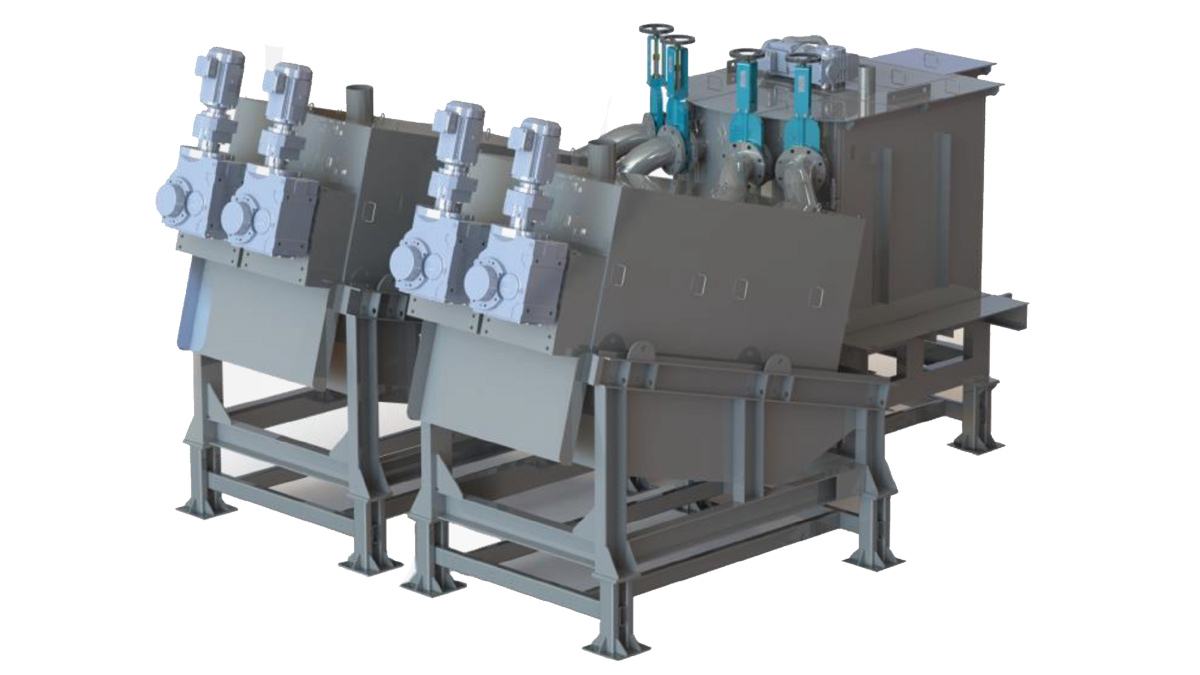

Single Screw FS Model – The volute FS model is fitted with a single V-screw in the central shaft - Courtesy of Evergreen Water Solutions

Water utilities face challenges dewatering clean water sludges as they possess different key properties when compared to wastewater sludges. Clean water sludges exhibit lower fiber and organic content, thus lowering its compressibility. The challenge to dewater clean water sludges is common to all dewatering technologies; to achieve adequate separation of water from dry solids with low energy and polymer consumption. However, one benefit of dewatering clean water sludges is that pathogenic regulations are not applicable as compared to wastewater sludges. Therefore, the processed dry cake can be used directly by local farmers, ensuring zero waste and ultimately helping the water utilities move towards their net zero carbon pledge.

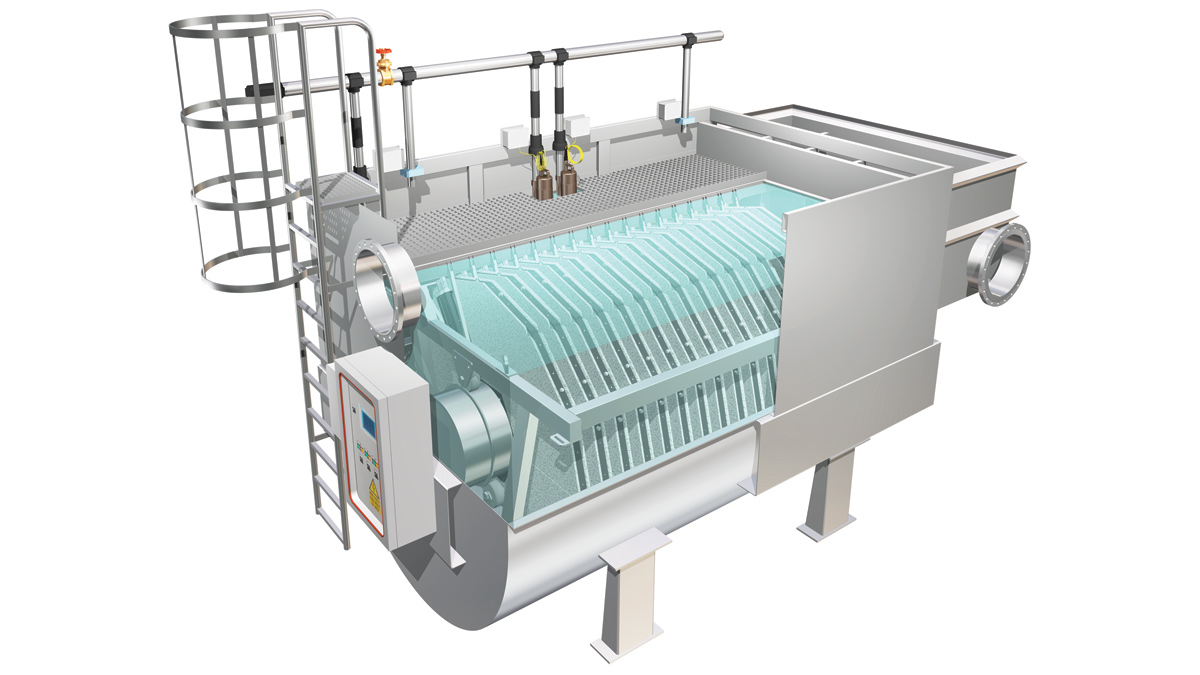

Volute Dewatering System

Evergreen Water Solutions Ltd have implemented the innovative technology of the Volute to ensure the water industry can face the challenges of the future. These challenges include:

- Reducing the lifetime energy consumption of dewatering equipment towards the Net Zero carbon pledge.

- Reducing consumption of polymers.

- Reducing operating and maintenance costs.

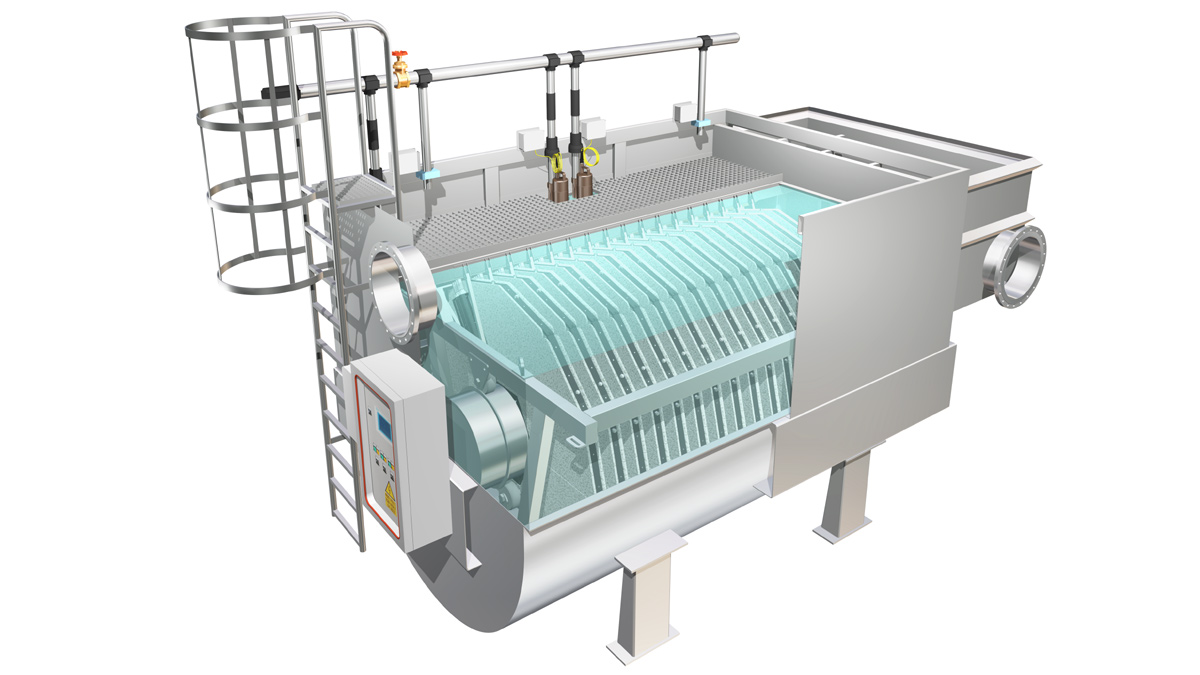

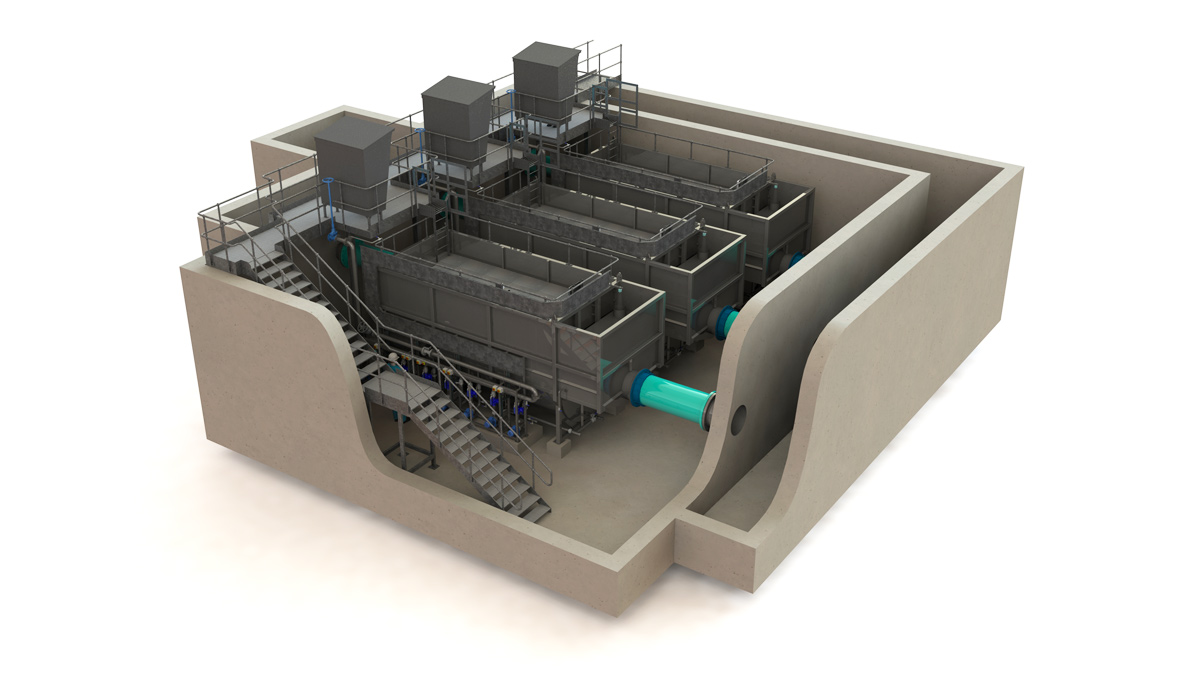

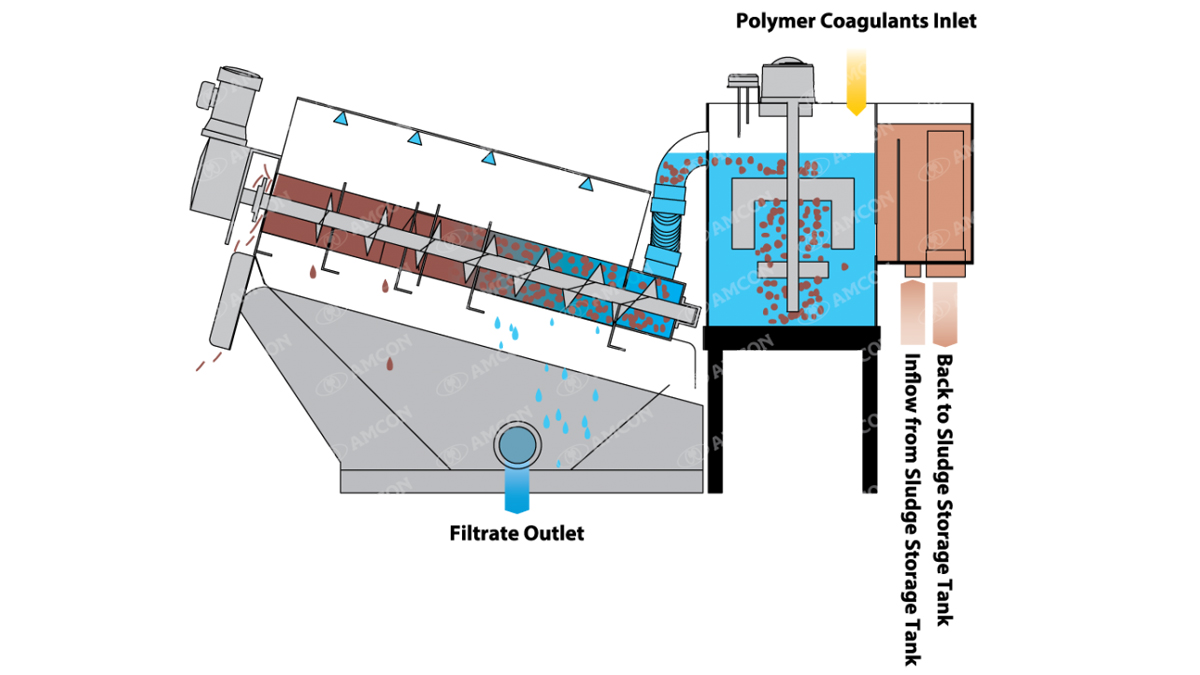

During Volute operation, pre-dosed polymer mixed sludge is pumped into the flocculation tank. Within the flocculation tank, an agitator assists in the floc formation and polymer mixing.

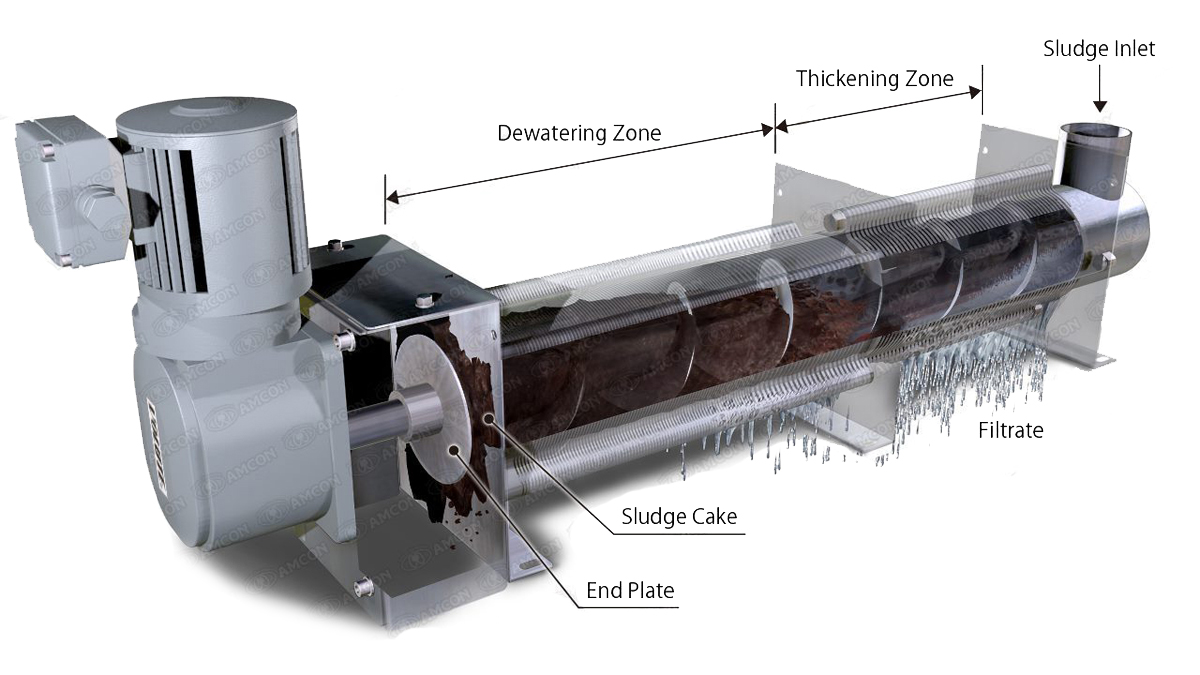

The flocs weir over into the Volute’s dewatering screw chamber where they are pushed along the central shaft by a V-screw encased by a series of fixed and moving rings. As the sludge moves up the central shaft, the distance between the rings decreases, further increasing the pressure along the screw which causes the sludge to be further compressed.

The sludge is thickened and dewatered due to this increasing compression along the screw, causing more and more carrier water to be removed as filtrate. With the filtrate water removed from the feed, a dry cake is produced at the end of the Volute screw chamber as a result of this process.

Sectional view of the Volute Dewatering Press – Courtesy of Evergreen Water Solutions

Process benefits of Volute technology

- Dry sludge cake: up to 35% dry solids.

- > 84% energy reduction compared to typical centrifuge technologies.

- High filtrate quality: < 50mg/l suspended solids.

- Low polymer consumption: < 4kg/tonne of dry solids (TDS).

- High total solids capture: up to 99.9%.

- Dewaters a wide range of sludges.

- Integrated flocculation tank with upstream static mixer.

- Auto-self cleaning shaft which significantly reduces maintenance, water consumption and odour.

- Low operational maintenance & downtime.

- Screw service interval < 30,000 hours.

- Ring service interval < 10,000 hours.

- Capable of 24 hour unsupervised, automatic operation.

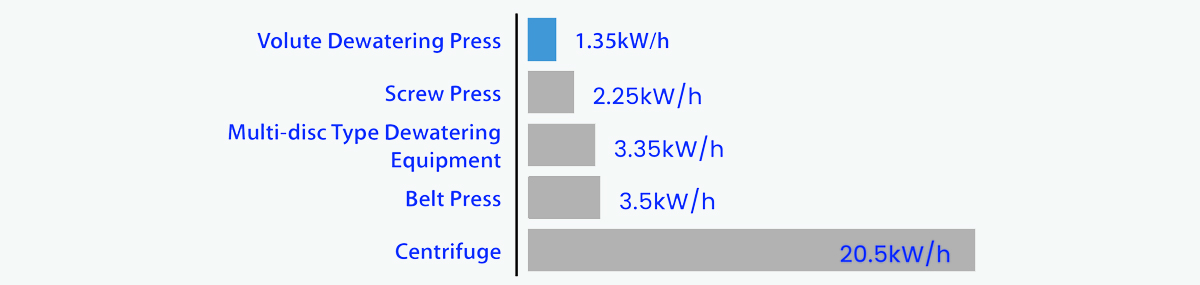

Low power usage (<4kW per/TDS for municipal sludge)

Energy consumption (kW/hr of usage) for the Volute is extremely low when compared to all other dewatering systems, which is a fundamental driver in process selection. This puts the Volute technology at the forefront when considering equipment to move toward the net zero carbon pledge across the industry as a whole. The figure below highlights the comparative energy values for a Volute against other dewatering technologies. It clearly demonstrates a significant reduction in power consumption. With energy prices sharply rising, the long-term power consumption is a key consideration when analysing the Volute’s whole life cost.

Comparison of power consumption among sludge dewatering equipment (throughput 45 kg-DS/h) – Figures based on research by AMCON

Quiet operation

Another key design feature of the Volute Dewatering Press in comparison to other dewatering technologies is its low noise and vibration. The Volute operates at 63 decibels and is therefore under the permissible levels requiring ear protection.

The motor speed of the Volute typically runs at a speed of 2-6 RPM. This significantly helps to mitigate against harmful decibel levels and noise pollution to both operators and the local environmental community. This quiet operation also reduces the need for additional sound deadening.

Case study: Williamsgate Water Treatment Works

Williamsgate Water Treatment Works (WTW) is a newly built drinking water facility designed to meet the growing demand for water consumption in the north-west of England. The site is designed to process untreated water from a regional reservoir, utilising a combination of modern process selection and dewatering technology to efficiently dewater sludge.

Incoming untreated water from the reservoir leaves Williamsgate WTW as either treated clean water, or as dewatered sludge cake.

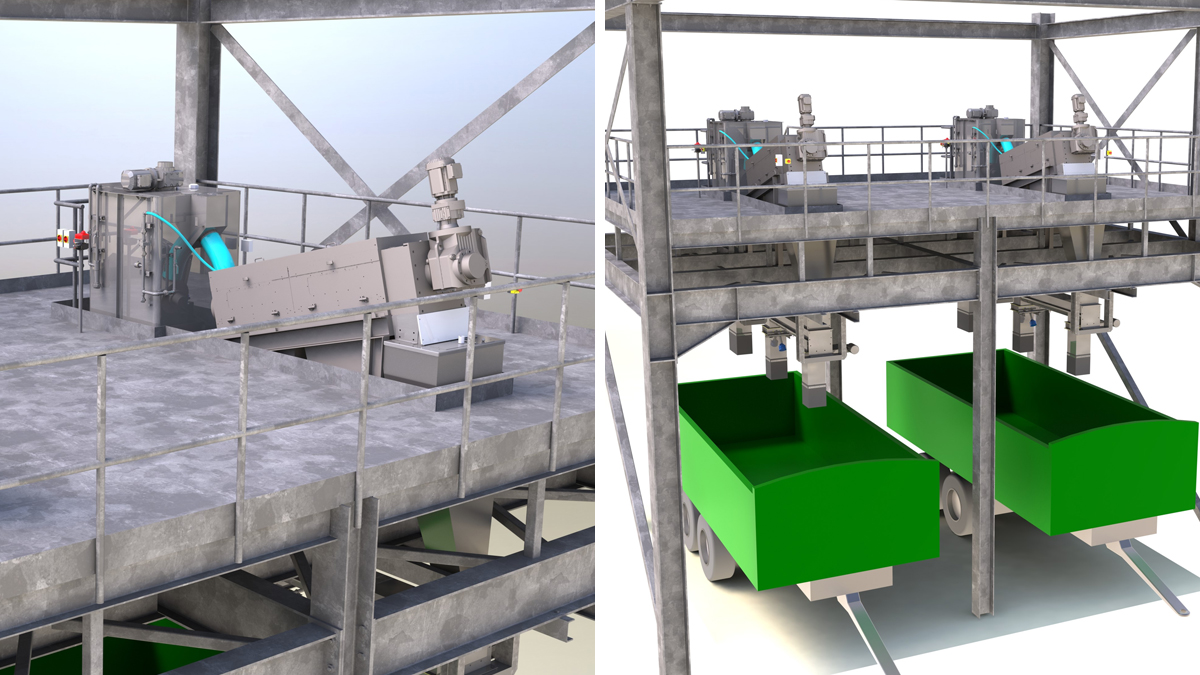

The processed cake can then be deposited directly into trailers for re-use. This avoids conventional process methods, which further increase flows to the wastewater network and may risk exceeding flow discharge permits of local sewage works.

Williamsgate WTW is the home of the UK’s first permanent Volute dewatering installation on a clean water site. Evergreen Water Solutions Ltd was employed by Advance JV on behalf of United Utilities to provide an innovative sludge dewatering and cake conveyor system based on the following performance criteria:

- Polymer consumption: < 6kg/TDS

- Filtrate: < 500mg/l

- Dry cake solids: >18%DS.

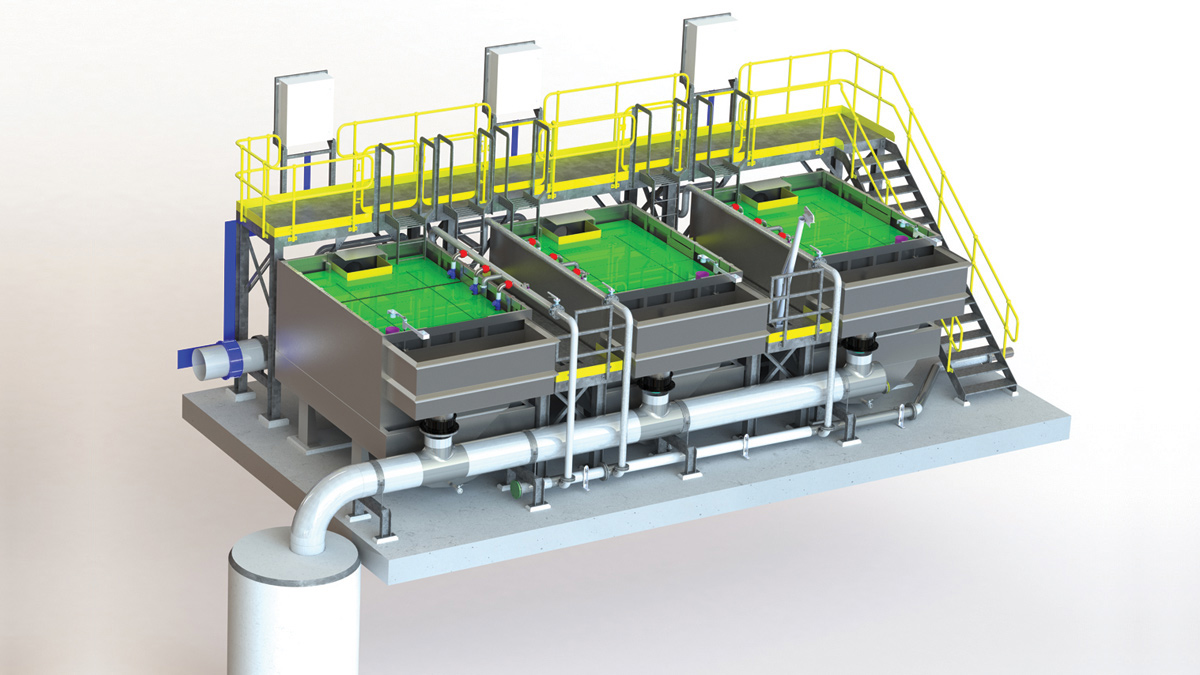

The dewatering plant consists of two Volute FS351 systems installed in a parallel configuration, which are paired to operate in a duty/assist arrangement. The Volute dewatering plant at Williamsgate WTW has been selected and sized to process clean water sludge as a result of incoming site flows of up to 80 mega litres per day (MLD).

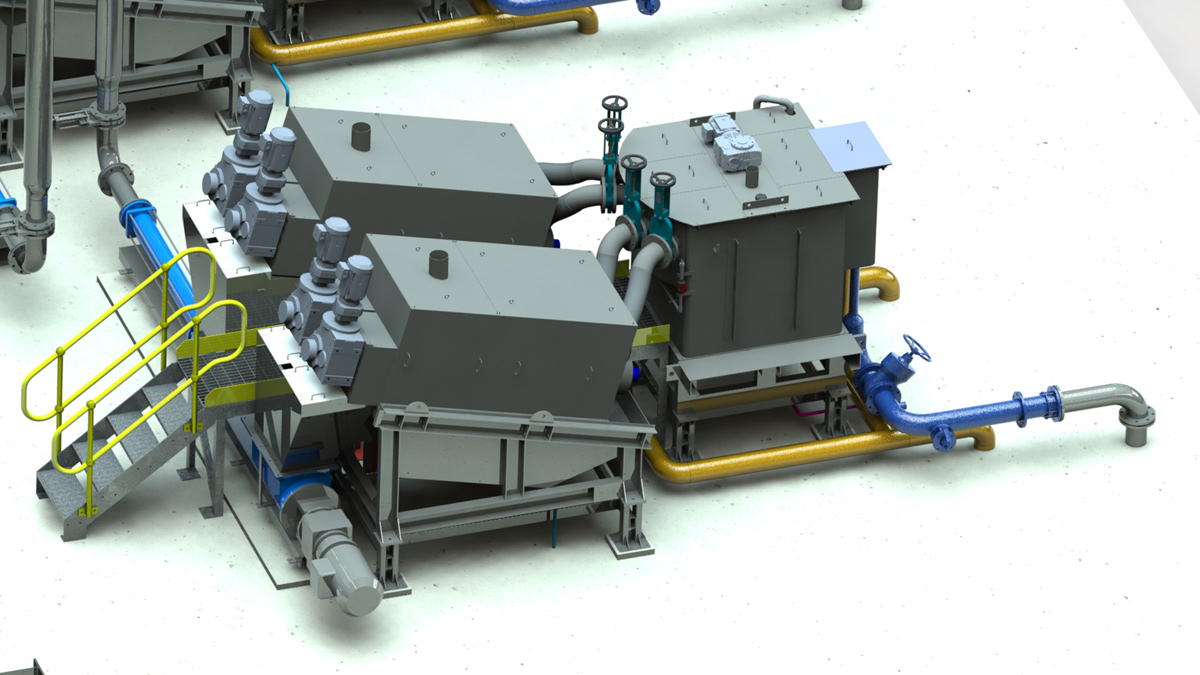

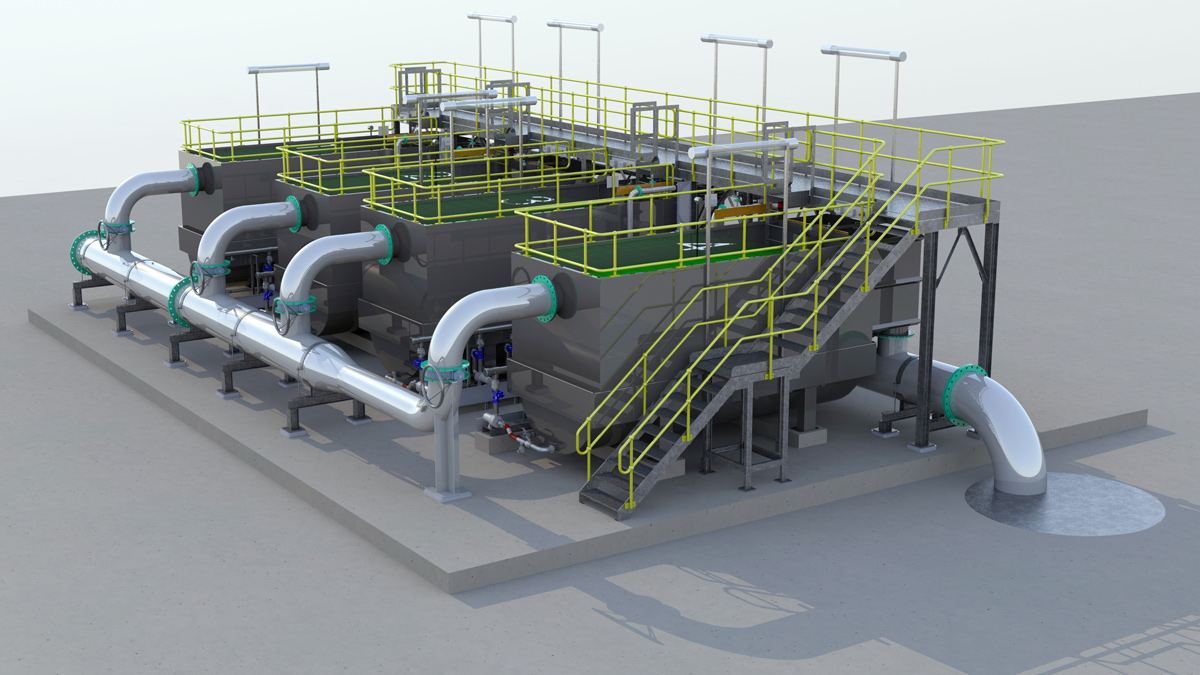

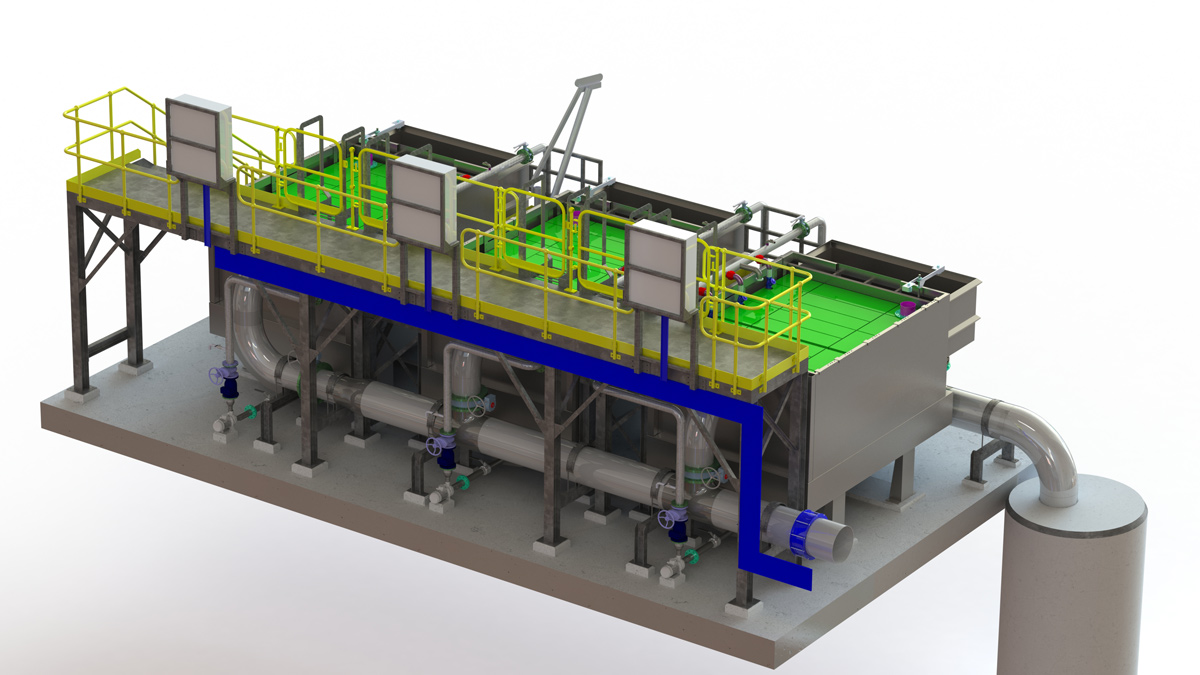

(left) 3D model of installed Volutes and (right) 3D render of Volute and cake trailer design – Courtesy of Evergreen Water Solutions

The sludge fed to the Volutes arrives from upstream lamella clarifier tanks where the solids are accumulated and pumped periodically into two 60m3 sludge holding tanks.

The Volutes are capable of dewatering a wide range of sludge thicknesses. At a recent pilot trial, Evergreen Water Solutions Ltd proved the Volute’s capability by successfully dewatering a 0.1-3% DS sludge into a dry cake of > 18% DS.

The Volute’s ability to adapt to a wide and varying range of incoming sludge properties is due to its integrated software. The control philosophy of the Volute dewatering system at Williamsgate WTW allows the Volute to automatically adapt to varying throughput characteristics whilst achieving a consistent %DS dry cake production. The system’s automatic control is sufficiently sensitive that operational parameters are adjusted accurately, and with a minimal requirement for operator intervention or supervision.

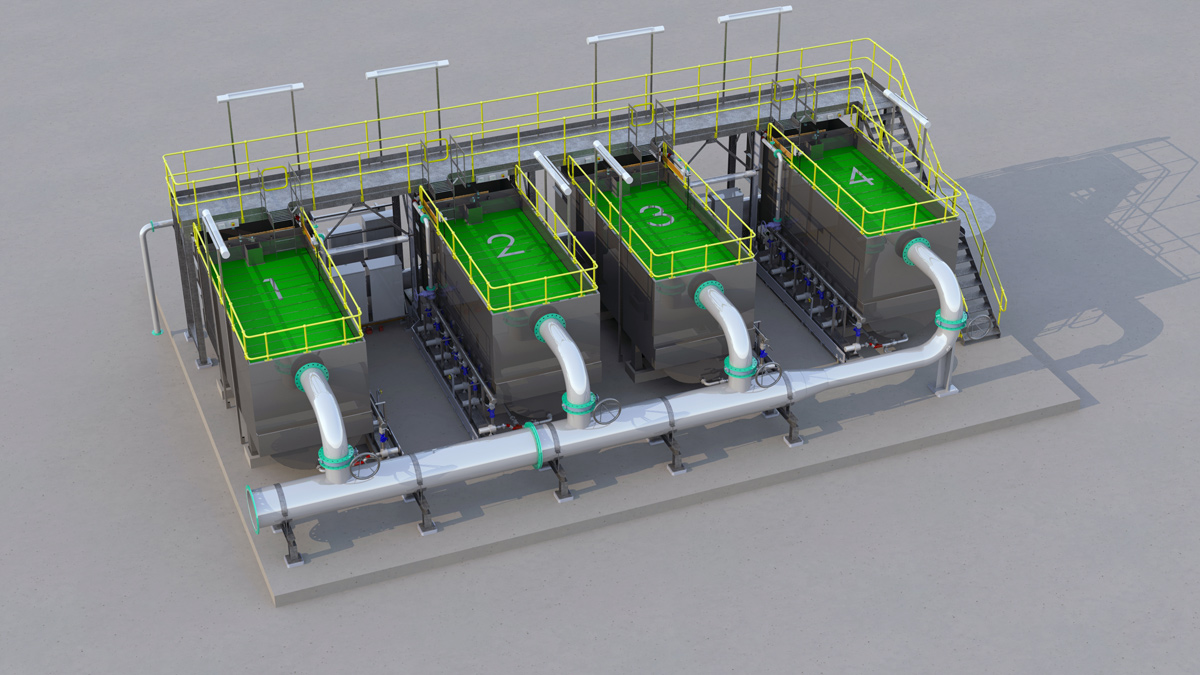

The two Volutes at Williamsgate WTW, direct their cake filtrate into lamella clarifiers. This ensures protection from a high concentration of suspended solids being returned to the head of the process.

The filtrate performance of the two Volutes support this process intent by outputting an average filtrate suspended solids concentration of 25 mg/l. This in-turn allows the lamella clarifiers to achieve a further reduction, resulting in a supernatant output suspended solids concentration of <5mg/l.

To improve filtrate quality, the Volute’s split filtrate pan design allows the filtrate to be separated into two sections; the ‘Thickening’ and ‘Dewatering’ zones. The Volute filtrate highest in volume and lowest in suspended solids concentration is collected below the Thickening Zone; this is the Volute filtrate directed to the lamella clarifiers.

Conversely, the Volute’s filtrate collected below the Dewatering Zone is lower in volume and elevated in suspended solids concentration relative to the Thickening Zone. This filtrate is returned to the sludge holding tanks for the Volutes to reprocess, thus screening the filtrate quality to the lamella clarifiers.

The Volutes’ filtrate divergence ensures a high quality filtrate output with a high total dry solids capture. The Volutes at Williamsgate WTW have achieved an overall total dry solids capture of 99.9%.

Volute operation – Courtesy of Evergreen Water Solutions

Williamsgate current data and process overview

- Processed cake at an average of 19% dry solids.

- Filtrate at < 50mg/l suspended solids concentration.

- Average sludge flow rate of 5m3/hr per Volute.

- Polymer consumption of 5.5kg/TDS.

- Each Volute screw motor is running at just 1kW during operation.

- Solenis LT22S was the selected polymer, based on jar tests and site trials.

- Feed sludge is in a range of 0.5-0.8 % DS.

At the time of writing (September 2022) the commissioning process is ongoing with performance testing and handover due to take place by the end of 2022. Volute Dewatering Presses are sold under license in the UK and Ireland by Evergreen Water Solutions Ltd.

For more information: Evergreen Water Solutions Ltd: +44 (0)1455 639760 | www.evergreenengineering.co.uk