Westnewton WwTW (2021)

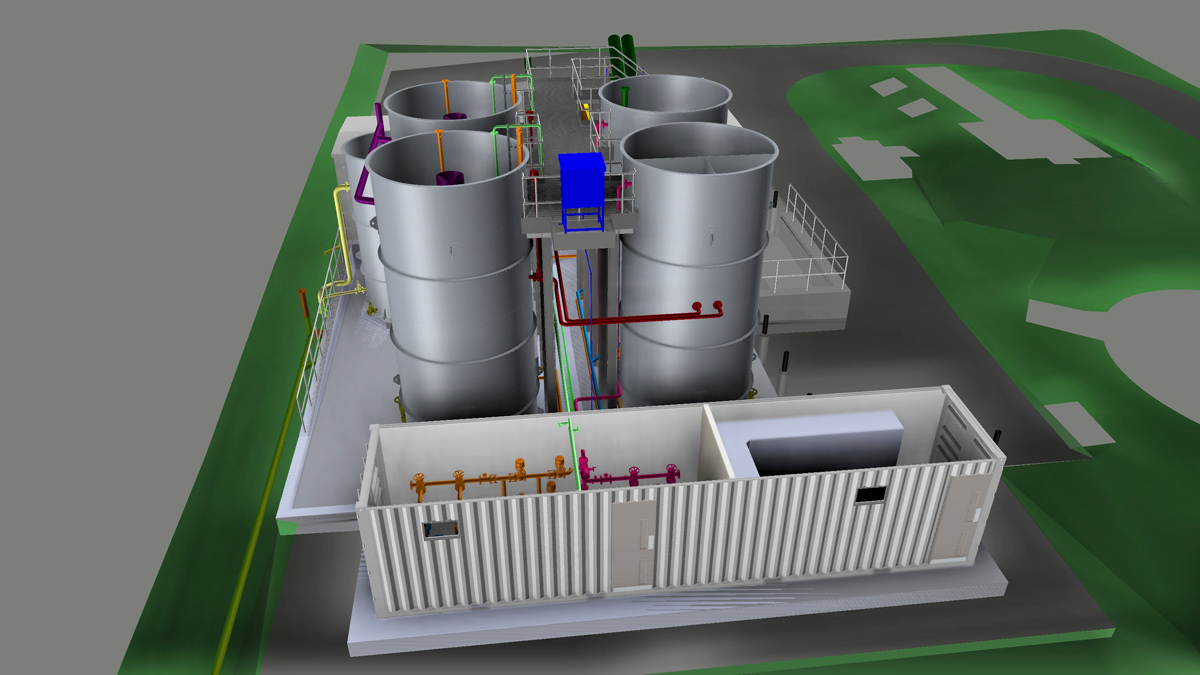

The Westnewton package Nereda plant - Courtesy of Royal HaskoningDHV

Westnewton is a small rural village situated in Allerdale, Cumbria, three and a half miles from the Solway coast at Allonby and eight miles west of the market town of Wigton in the North West of England. The wastewater treatment works (WwTWs) serves a population equivalent (PE) of less than 300. The catchment was previously served by a traditional trickling filter works, that was no longer able to cope with new stringent water quality drivers applied in AMP6. The sewage network feeds into a terminal pumping station on the main road just below the WwTWs and is then pumped up to the works for treatment. The final effluent flows via the works outfall into Westnewton Beck, which runs to the north of the site.

Project drivers

Westnewton WwTW has been named in the Environment Agency’s (EA) National Environment Programme (NEP) Phase 5, with a Water Framework Directive (WFD). The aim of this project is to improve the quality of the receiving watercourse (Westnewton Beck) to ‘good’ from its current status of ‘moderate’, thereby contributing 7.48km to the Rivers Improved Performance commitment.

Traditional solutions for phosphorus removal at WwTWs usually require chemical dosing and often alkalinity replacement. At United Utilities, 34 new phosphorus permits were introduced in AMP6 and there are another 51 new permits in AMP7. Many of these permits are coming into force at small works where dosing can be difficult (due to access, aged assets, intermittent flows, low flows, poor mixing and the need for a potable water supply for chemical safety showers), therefore the company needed to find more effective solutions for these types of sites to become less chemically dependent.

Google map showing Westnewton village and the location of the wastewater treatment works – Courtesy of United Utilities

Benefits of the small scale Nereda® solutions

- Lower whole life cost (not proven on Westnewton due to significant design costs, project overrun and temporary works required to support the first design and installation, however due to collaborative working between parties this will be significantly reduced going forward).

- Reduced company chemical use and tanker movements due to the move to biological phosphorus removal.

- Smaller footprint compared to conventional solutions.

- Reduced reliance on ageing assets for phosphorus removal when adding chemical dosing to existing works.

- Circular economy (as it opens the door for recovery of products such as phosphorus and biopolymers).

- Alignment with United Utilities’ systems thinking strategy.

The solution

The new build project features the first Nereda package plant, an innovation that sees Nereda technology deployed to serve a smaller population. Instead of using chemicals for phosphorus removal, Nereda technology has the benefit of utilising enhanced biological phosphorus removal (EBPR). The Nereda package plant is a ‘plug and play’ process, whereby the tanks and container have been prefabricated and factory tested before being transported to site where they are simply lifted onto a pre-constructed civil slab and assembled. The process contains a buffer tank which holds a larger volume than required for buffering alone, to allow increased hydrolysis, and the control includes simpler more reliable instrumentation, all ideal for small rural sites.

Extract from 3D model showing control building (with roof removed) and Nereda® reactors – Courtesy of United Utilities

Nereda technology

United Utilities has a long history of trialling and implementing Nereda technology starting in 2013, which led to the company awarding four contracts for Nereda solutions at population equivalent (PE) values ranging from 23,000 to 400,000. The latest and largest of the four contracts at Blackburn is currently in the process optimisation and commissioning phase and when complete will be the largest new build Nereda installation in Europe.

Previously, Nereda technology supplier (Royal HaskoningDHV) had focussed on the design of large scale Nereda solutions. In contrast to the large plants mentioned above, during the work on the Nereda trials at United Utilities, the opportunity to develop a package solution for small works was identified. Royal HaskoningDHV has since developed small (Package) and medium scale (Mini) solutions for 200-2,000 PE and 2,000-10,000 PE respectively, with support from United Utilities and C2V+ (the construction design partner for both the Morecambe WwTW Nereda plant and the first ever Nereda package plant at Westnewton WwTW).

Package and mini concept

Nereda package plants have evolved from experience along with new and ongoing challenges in the water industry, and the plant at Westnewton is a global first at a small works. The Nereda Package and Mini concepts are a ‘design one, build many’ approach and United Utilities alongside C2V+ has been working with Royal HaskoningDHV to agree the standard layout designs. The solutions feature the Nereda controller used at larger installations, but control is based on simpler instruments including dissolved oxygen, pH and redox in contrast to the complex instrumentation required at larger installations.

Westnewton WwTW

United Utilities was looking to improve the final effluent from Westnewton WwTWs to achieve a permit of 0.85mg/l total phosphorus (TP) annual average (measured by spot samples). C2V+ was awarded the contract to deliver the solution. In conjunction with United Utilities, C2V+ worked closely with RHDHV and Suprafilt, the experienced MEICA suppliers, to develop the technology as a package solution.

Nereda package plants are a smaller version of large-scale Nereda plant and the installation at Westnewton WwTW is a global first. The solution includes a reduced range of instrumentation compared to large-scale plants, which still allow the operators to closely monitor the underlying biological performance of the plant whilst removing the more complex instruments that can be difficult to maintain at small, unmanned sites.

Westnewton WwTW: Supply chain – key participants

- Main construction contractor: C2V+

- Nereda process design and consultancy: Royal HaskoningDHV

- Internals & general MEICA installation: Suprafilt

- General MEICA installation: Austin Lenika

- Inlet screens: Huber Technology

- Washwater booster system: Grundfos

- Systems integration: Tata Consultancy Services

- MCCs: Lloyd Morris Electrical Ltd

Westnewton WwTW is located in a rural landscape – Courtesy of United Utilities

Now the Nereda package plant concept has been developed for Westnewton WwTW, similar plants can now be tailored for other small PE WwTWs. The Nereda package solution is a ‘design one, build many’ modular approach and all parties collaborated to demonstrate the concept and agree standard reusable layout designs.

Nereda package plants provide a repeatable factory-built, competitive, sustainable, low whole life cost solution, which is designed as a DfMA solution. Nereda package plants have been designed in three sizes to meet the requirements of wastewater treatment plants using either two or three reactors, depending on the required treatment capacity. The system installed at Westnewton WwTW is a Package 100 (comprising 2 (No.) 50m3 reactors), to serve approximately 300PE.

Buffer tank – hydrolysis/pre-fermentation stage

RHDHV has included a buffer tank within its solution to balance flows and loads to the Nereda reactors, but to also act an hydrolysis or pre-fermentation stage. The purpose of the pre-fermentation operation in the influent buffer is to biologically convert COD from the influent into volatile fatty acids (VFAs) to support the biological phosphorus removal. The influent buffer is operated with a waiting phase to allow settleable biodegradable solids to accumulate and hydrolyse to soluble COD. These can then ferment to VFAs in the buffer or during the Nereda feed phase. Periodic solids removal through feeding Nereda without a waiting phase can be applied to minimise growth of methane forming bacteria and subsequent loss of VFAs. The mixing and recirculation phases are applied to encourage contact between influent and biomass in the buffer.

The requirements for operation are presence of settleable biodegradable solids, anaerobic conditions, sufficiently high pH (>5) and alkalinity, and an appropriate solids retention time for the temperature (typically around 2-6 days).

This approach is currently only applied to the Nereda Package and Mini range, mainly due to ‘economy of scale’, meaning that the influent buffer can easily accommodate the increased volume required for hydrolysis, with negligible cost increase. This is an opportunity which United Utilities is exploring for large scale Nereda plants to remove or minimise chemical dosing at future installations. The Nereda package plant is targeting low total phosphorus drivers in small communities, where conventional chemical dosing isn’t a sustainable option. In order to realise this consistently, the promotion of VFAs is key to the biology for phosphorus reduction.

Intensive sampling and monitoring was undertaken prior to commencing the completion tests, and measurements show that the concentration of VFAs have increased from the crude sewage in the influent buffer tank on average by approximately 30-50%. This has obviously been aided by recent warm weather conditions, so further analysis will continue in the colder months to understand and track the benefit the buffer tank operation provides.

Hydrolysis tank/pre-fermentation tank, Nereda reactors and sludge buffer tank – Courtesy of United Utilities

Nereda reactors

The 2 (No.) 50m3 Nereda reactors provide biological wastewater treatment in a cyclic batch process. Each cycle compromises of the following operations:

- Fill/discharge

- Crude sewage is pumped from the buffer tank into one of the Nereda reactors, displacing treated water at the top of the tank.

- Aeration

- The water level is reduced to prevent fine solids discharging from the reactor.

- Sludge decant.

- Pre-nitrification.

- Aeration.

- Settle

- Contents of the reactor allowed to settle.

Each reactor contains an aeration grid, centrally located bellmouth for discharge, sludge decant nozzle, redox, DO, ph and level instrumentation.

Redox control

Traditionally Nereda batches are treated based on aeration time dependant on flow or to achieve an ammonia or phosphorus set point. Westnewton Nereda Package Plant removes the requirement for expensive, high maintenance, ammonia and phosphorus instruments and focuses on redox control as there is no ammonia permit on this site, meaning low cost, reliable redox instruments can be utilised. Aeration requirements are focused on biological phosphorus uptake and by limiting the amount of air entering the system by controlling at a pre-set redox level, the amount of aeration is reduced. This prevents nitrification initiation, which in turn reduces power use, giving OPEX benefits, and the optimum conditions for biological phosphorus uptake can be maintained. The redox set point in the summer months has been targeted at a lower setpoint than needed for colder, winter months as temperatures drop, more aeration will be required to achieve the same performance.

Westnewton WwTW: pre AMP6 traditional treatment assets shown to the left, typical of many small rural WwTWs, replaced with the new Nereda Package Plant and ancillary preliminary treatment stages (screening and degritting) to the right. Access road and village in the background – Courtesy of United Utilities

Sludge removal and storage

The ‘after feed’ sludge selection or wasting method has been chosen and coincides with the water level correction (lowering the water level) prior to aeration. This method relies on the upflow velocity during feeding which lifts the slowly settling solids towards the top of the tank before a valve opens and a volume of sludge is discharged from the tank, controlled either on time or level.

The waste sludge removed from each batch is stored in a dedicated (per Nereda stream) sludge buffer tank. Here the sludge is allowed the settle. Supernatant is returned to the Nereda feed buffer tank and thickened sludge transferred to the holding tank, which serves both sludge buffer tanks, prior to being tankered from site to the receiving works. Consideration was given to aerating this volume, however due to the low volume, circa 1m3/day and the fact that no mechanical thickening was being carried out on site (with the potential to release phosphorus from the sludge) it was decided that the cost outweighed any benefit of aeration, unlike the large scale Nereda sites which all have aerated sludge tanks as standard.

Performance to date

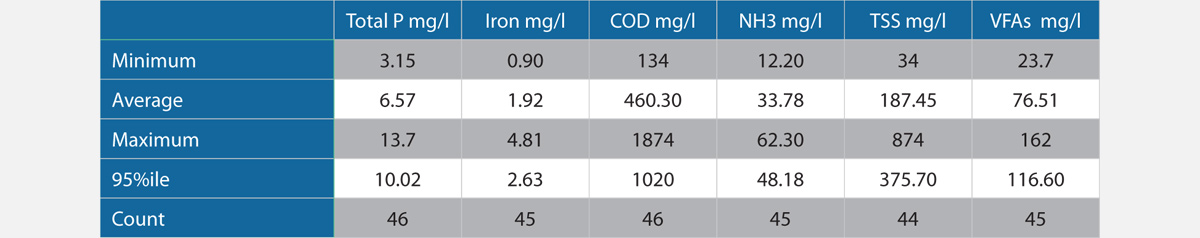

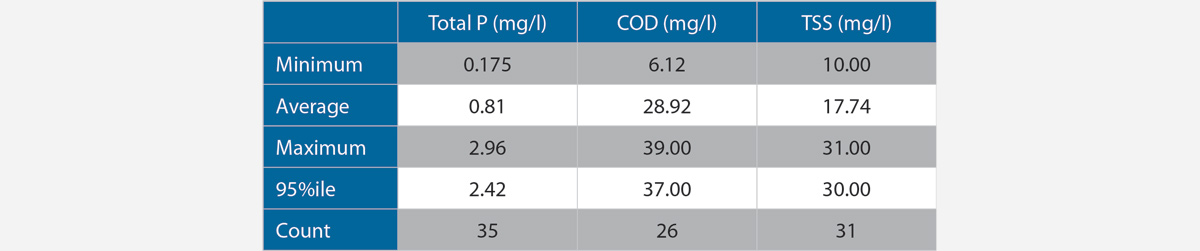

Westnewton sewage is from a purely domestic catchment. The following outlines the typical constituents sampled over the period March-July 2021:

Table 1

Sludge granules were transported from United Utilities’ Morecambe WwTW Nereda installation. The granules had been dormant for a number of weeks (stored offline in unaerated storage containers) and combined with transportation had begun to release phosphorus. Once aerated for a couple of days the levels of orthophosphate quickly reduced from 17.5mg/l to 2.5mg/l, showing the granules are resilient and able to respond to changes in their environment.

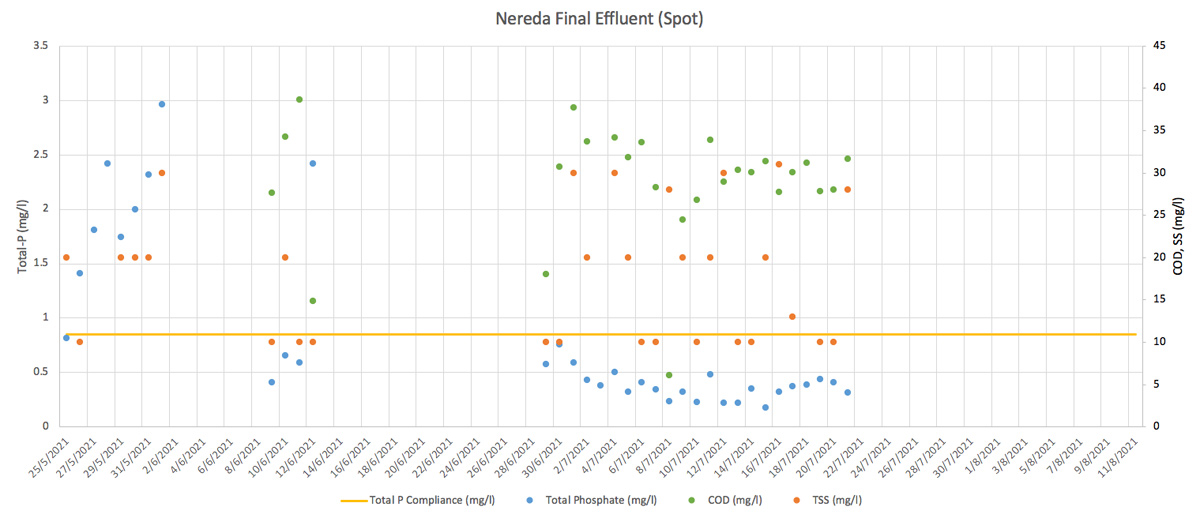

The Nereda Package Plant began to perform well and was achieving permit concentrations consistently within a few days. However, a rain weather event highlighted the requirement for a recipe change, as the orthophosphate levels spiked under first flush conditions, and following this intervention the low phosphorus levels were re-established. Reactor 2 began to show some signs of poor aeration visually via the surface water aeration pattern which needed intervention from Suprafilt who identified a small number of faulty diffusers. The decision was made to replace all diffusers in both reactors in the second week of July.

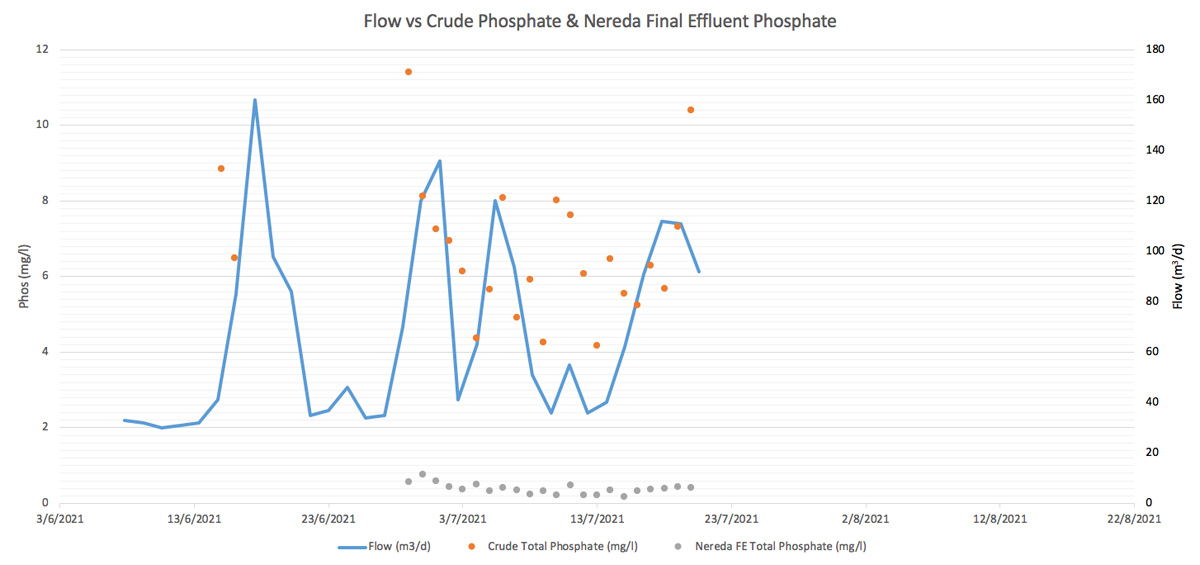

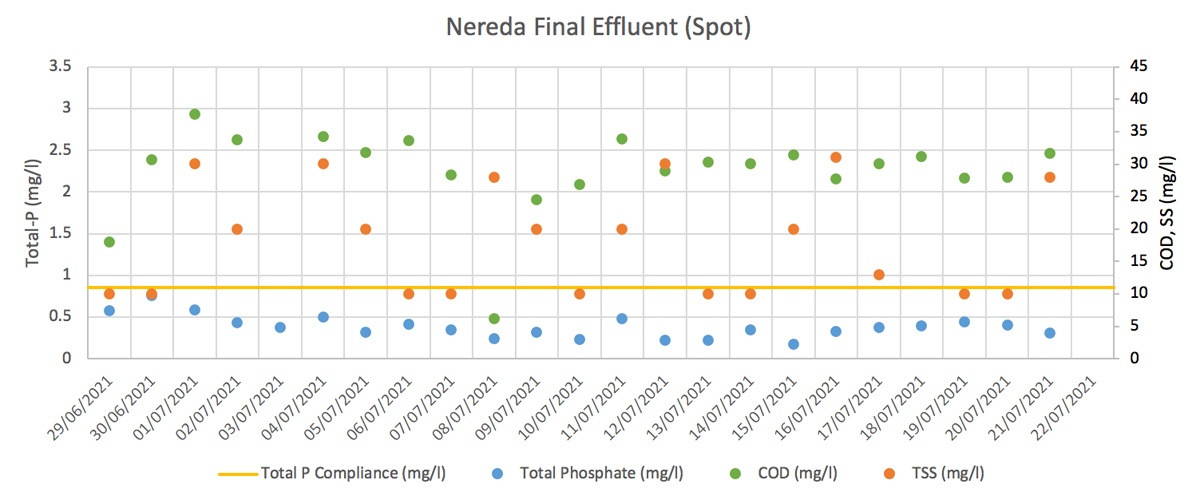

Recent results are promising as shown in the following graphs.

Graph 1: Influent vs final effluent phosphate results

Graph 2: Final effluent performance

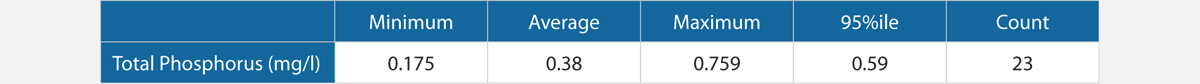

The table below outlines final effluent performance from the Nereda Package Plant to date. Clearly since the diffusers were replaced, performance has improved, however weather conditions have been favourable and the process will be tested over the course of the next few months as extended completion Tests (CTs) continue.

Table 2

If performance was based only on the data since the diffusers have been changed, the results would have been significantly better than presented in the above table.

Table 3

Graph 3: Zoomed in period from Graph 2 to highlight performance since diffusers replaced

However as the technology is in early days of optimisation and has yet to be tested with various rates of change, both flow and load, low temperatures etc, these results should be read with caution.

Conclusion

At the time of writing (July 2021) commissioning and optimisation is ongoing. Completion tests (CTs) are due to commence mid-August. Completion is due mid-October 2021, dependant on the CT results. United Utilities has extensive lessons learnt from this project which will assist with streamlining innovative technologies going forward and feedback results to optimise Nereda design and control for existing and potential solutions in AMP7 and AMP8. The solution at Westnewton is a global first, proving the success of the long-established relationship between the three parties. As a first adopter of this technology, United Utilities continues to demonstrate its reputation as one of the leading innovators in the UK water industry.