Sewaco Ltd

Sewaco Ltd specializes in design, manufacture, supply and construction of purpose built plant and equipment for use in water supply systems and treatment of municipal sewage and industrial waste water.

Our range of products includes:

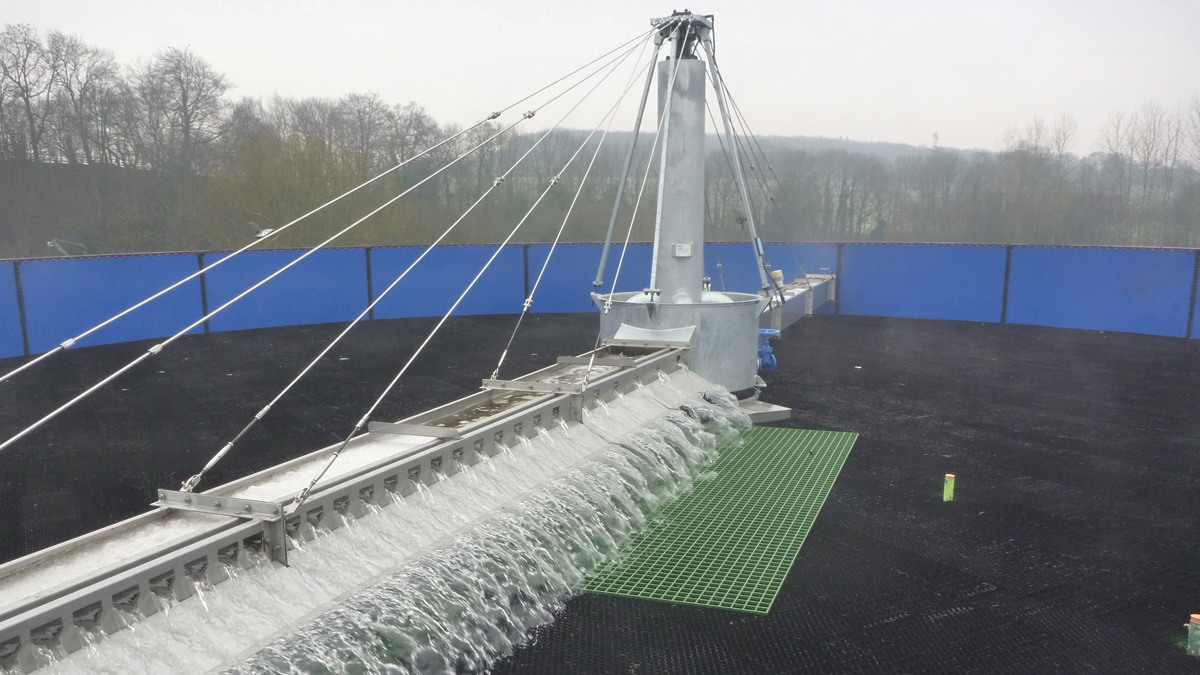

- HYCOVER Static & Rotary distributor systems (from 5 l/s up to 980 l/s flow range) with optional auto cleanse and electro pneumatic belt drive mechanism, respectively.

- HYRATE Polytower biofilter systems using modular plastic media for:

- High Rate (BOD/COD reduction), upstream of existing treatment plant.

- Secondary ( BOD removal only or combined BOD removal/Nitrification).

- Tertiary Nitrification applications, downstream of existing secondary treatment processes.

- HYRATE Polytowers can easily incorporate natural ventilation or air extraction systems for odour control purposes, as required.

- Factory built timber support matrix for secondary modular plastic media support.

- Modular media installation and re-packing undertaken by our experienced site team.