Waterworks Bridge Reconstruction (2019)

Elevation of Sewer 5 showing first sewer removed - Courtesy of SMB JV

Waterworks Bridge is an oblique three-span structure of approximately 30m length crossing the Waterworks River in Stratford, East London and forms a key part of the Greenway footpath and cycleway providing access to/from the Queen Elizabeth Olympic Park from the south-east. Most significantly, Waterworks Bride houses a section of the Northern Outfall Sewer (NOS). Built by Joseph Bazalgette in the 1860s in response to the ‘Great Stink’, the 5-barrel sewer continues to serve 4 million people and is capable of removing enough sewage to fill an Olympic sized swimming pool from North London every minute. As such, Waterworks Bridge is a critical piece of infrastructure in the context of maintaining the successful operation of London’s Sewer network.

Introduction

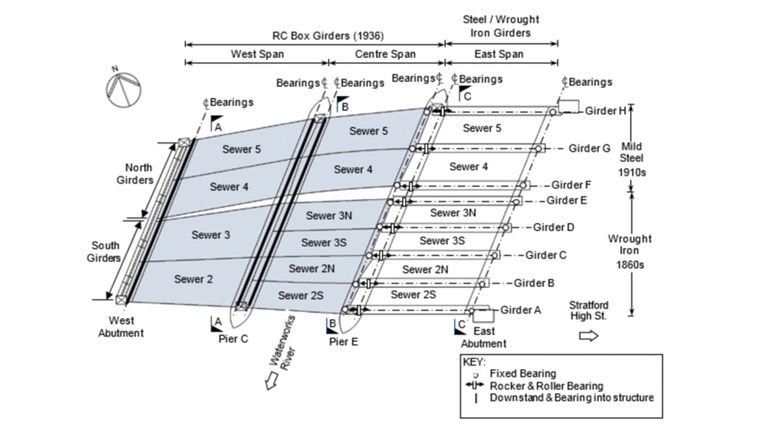

The bridge comprised of two spans of reinforced concrete box girder construction dating from 1936 as well as one span of wrought iron box girders (circa 1860) and mild steel plate girders construction (circa 1910). It carries 4 (No.) NOS sewer barrels over the western span, two of which (Sewers 2 and 3) then diverge over the central span to leave 6 (No.) sewer barrels over the eastern span.

The wrought iron and mild steel span demonstrated major signs of failure and thus urgent action was required to either repair or replace. Without intervention, the future collapse of the bridge would lead to a major pollution event and impacting services both upstream and downstream of the structure.

Design

The design process commenced with a thorough investigation into the current condition of the bridge to fully understand the structure. An assessment had indicated the need for eventual repair or replacement of the wrought iron structure (Sewers 2 and 3) with precautionary interim measures being put into place restricting all vehicular and pedestrian traffic from using the bridge. In part due to the original design of the structure, this section was considered to be beyond economic repair.

The condition of the mild steel structure (Sewers 4 & 5) was assessed as fair to poor and could potentially have been repaired to extend the service life by 15 years without further intervention. However, due to the design of the bridge, the proposal to repair had a large number of health and safety issues and as such the cost difference between repairing and replacement was outweighed by the increased risk in terms of health and safety and programme risk. Consequently, the decision was taken to replace this section as well to produce an entirely new east span. This decision was further justified by experience within the team of replacing a similar nearby structure in AMP5.

The concrete spans were generally fair to good and no immediate risk to the structure was apparent. Nevertheless, the roof slabs were assessed as inadequate to take the bridges 7.5 tonne loading and as such required strengthening.

Figure 1: Plan view of Waterworks Bridge

Having identified the strategic imperative to replace the structure, the team applied Highways England’s design standards throughout the project. The key challenge was to maintain flow within the NOS during the reconstruction in order to retain serviceability to Thames Water customers – this entailed closing only a single sewer at a time.

An existing internal girder supported two adjacent sewers, adding additional complexity as an entire sewer and its supporting girders could not be demolished simultaneously or serviceability would be lost. The design intention was to reuse the substructure in order to reduce the cost and carbon footprint of the project. This was only feasible if the overall structural weight did not increase, providing a challenge; concrete was the preferred construction material as opposed to steel. It was selected despite the increased weight to match existing aesthetics, reduce maintenance requirements and increase lifespan. The structural envelope was redesigned so that the level of fill over the structure was reduced resulting in no net increase in structural weight and geometrically optimised to avoid existing girders. As such, the construction strategy for the works centred around the following stages:

Stage 1

- Removal of the fill to lighten the bridge structure to maintain its integrity prior to the works below taking place.

Stage 2

- Strengthening the slab over the concrete spans to enable it to take the required 7.5 tonne highway loading.

- Replacing the mild steel span.

- Replacing the wrought iron span.

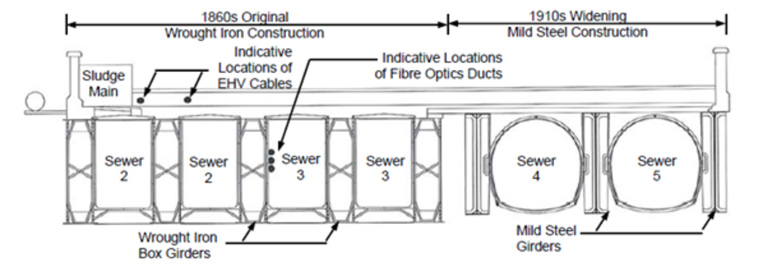

Figure 2: Cross-section of Waterworks Bridge

Procurement

This project was procured under the eight2O Alliance AMP6 framework, and involved Thames Water, Atkins, Balfour Beatty, Skanska, MWH Treatment and partners. Having the client embedded within the organisation allowed the designer, contractor and client to work collaboratively and engage relevant expertise to efficiently achieve the project goals.

Close engagement with Thames Water operations facilitated safe and timely closures of respective sewers and provided valuable knowledge of the network and maintenance requirements including associated operational issues alerting the team to the potential for significant silt build up within the sewer of up to 1.6m. De-silting was included in the initial costing, avoiding an unexpected cost and construction delay. A cost and quality benchmark was established to allow the project to receive alliance gateway approval.

Construction

The site itself, in Stratford, East London, is heavily constrained further complicating the implementation. The team proposed that access from the A118 and Cycle Superhighway 2 would be avoided, to eliminate the interaction between construction vehicles and the public. Instead primary site access was limited to 26 tonne vehicles via Bridgewater Road Bridge. These access restrictions were mitigated through thorough and efficient planning and scheduling of the works.

Both design and construction were undertaken with a systematic and highly considered approach, sequencing activities to complete the works safely and to schedule whilst maintaining flow through the sewer. This sequencing was verified using a 4D model demonstrating phasing of the works.

The steel span was to be replaced first due to the brittle nature of the cast iron barrels. This could have resulted in deformation not being observed prior to any structural failure, making structural monitoring for adequacy more challenging. As such, the second phase of construction began with the removal and replacement of Barrel 5 and continued across the structure to finish with the replacement of Barrel 2S.

Waterworks Bridge – Courtesy of SMB JV

The team designed a bolted moveable platform, with contractor and consultant input, to be slung under the existing sewer from large span girders.

The platform maintained the existing load paths through the structure, avoiding expensive temporary strengthening works. A single sewer was closed and the surrounding structure carefully demolished piecemeal. The platform also doubled as temporary formwork for casting the new reinforced concrete sewer barrel base. Webs were then cast, so that the sewer became self-supporting at this point and could receive the top slab. This reduced the temporary platform size, again reducing cost, embedded carbon and disruption.

A collaborative site office was established for eight2O staff and subcontractors, allowing close working between different parties across different levels. The communication and collaboration this fostered allowed issues to be resolved quickly and efficiently. For instance, at a regular lessons learnt meeting, the steel fixers informed that the commonly adopted standard steel reinforcement lap lengths were challenging to install around top flange permanent formwork. The team responded, designing certain areas with bespoke shorter steel lap lengths, offering significant time savings in the subsequent construction.

Completion of Waterworks Bridge road surface – Courtesy of SMB JV

The construction team actively sought to reduce the amount of embedded carbon in the project, with 55% of carbon emission-heavy ordinary Portland cement replaced with waste granulated ground blast furnace slag (GGBS), resulting in lower heat of hydration during concrete curing. This reduced early thermal cracking stresses and, consequently, less reinforcement was required.

The concrete barrels were also designed with a waterproof spray applied liner and crack widths that were self-annealing to eliminate water leakage and minimise future maintenance.

The site team had the opportunity to go above and beyond in engaging with the local community and inviting pupils from the local Carpenters Road School to decorate ‘Doodle Bugs’ that had been created from plywood. These neatly painted bugs were affixed to site hoarding. These efforts, and others, resulted in the scheme being recognised as beyond compliant by the Considerate Contractors Scheme.

Conclusion

The scheme has successfully achieved its outcome of increasing the remaining lifespan of the sewer bridge and respecting the aesthetics of the existing structure. A low maintenance, robust structure has been provided, the new structure has been constructed on time and within budget using a light touch approach. Innovations such as solar powered site lights, hybrid battery generators and noise monitoring has meant the 1000 nearby residents experienced negligible disturbance.

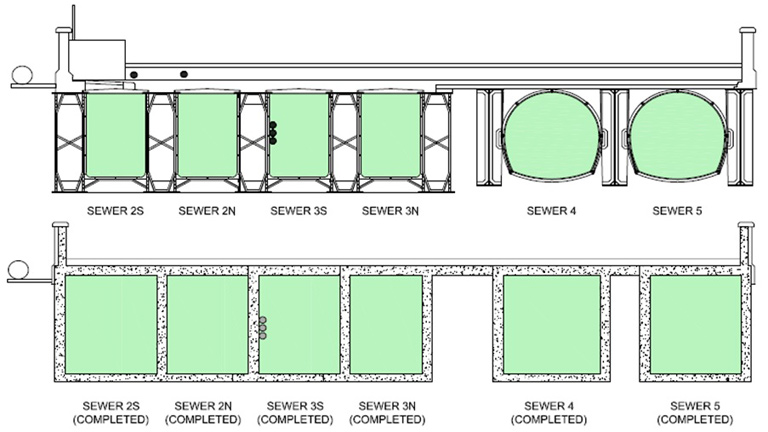

Figure 3: Comparison of original and final cross-section

The upgraded structure will soon become part of TfL’s Quietway Cycle network. Furthermore, the enabling works for this structure necessitated a temporary increase in structural load rating on the adjacent spans. It was identified that these works could be made permanent for a negligible cost, consequently increasing the overall structural load rating above the project scope requirement without additional cost. The project has finished on time, below budget and is RIDDOR free. A significant achievement on an £18m project with numerous constraints that has gone above and beyond the project brief wherever it can.