Belaugh & Waveney Raw Water Intakes (2021)

View of the River Bure at Belaugh from the intake - Courtesy of Essex & Suffolk Water

Eel populations have seen a sharp decline since the 1980s and whilst the exact reasons are unknown, legislation in the form of the ‘Eels (England and Wales) Regulations 2009’ was brought in to provide eels with extra protections. Within the regulations there is a requirement to prevent eels becoming trapped within raw water abstraction systems. Exclusion screening (2mm mesh, maximum approach velocity 0.25m/s) was required at the Belaugh and Waveney Intakes at the riverbanks to prevent such entrapment. Both sites had primary screening at the river, comprised of coarse bar screens with (approximately) 22mm spacing and additional finer screening (6mm) nearer the pumping stations provided by two cup screens. Neither of these screening types conformed to the requirements of the Eels Regulations and the cup screens were at the end of their serviceable lives so were due for replacement.

The sites

Both the Belaugh and Waveney sites are owned and operated by Essex & Suffolk Water (ESW), part of the Northumbrian Water Group (NWG).

The Belaugh Raw Water Intake is located on the River Bure to the north-west of the village of Belaugh near Wroxham in the Norfolk Broads National Park. Belaugh abstracts up to 27.2 Ml/d which is transferred approximately 18km eastwards for treatment at the Ormesby Water Treatment Works, which supplies approximately 52,000 properties in Norfolk and Suffolk. Belaugh predominantly runs at night when pumping costs are lower and the raw water is transferred to the Ormesby Broad where it is stored before being abstracted into the treatment works.

The River Waveney Raw Water Intake is in Shipmeadow to the west of Beccles, Suffolk, also in the Norfolk Broads National Park. Waveney abstracts up to 28 Ml/d which is transferred approximately 2.5km eastwards for treatment at the Barsham WTW, which supplies approximately 43,000 properties in Norfolk and Suffolk. The Waveney Intake is run continuously to supply Barsham 24/7 as the raw water abstracted at this site goes directly to the WTW rather than storage.

Young eels – Courtesy of Ros Wright, Environment Agency

Feasibility investigations

Integrated Water Services (IWS) were engaged to investigate options for eel-friendly screening at the two sites. There were a number of challenges with the locations, being on narrow, low flowing rivers with very little depth restricted the number of options available as the preferred rotating band screen solution (already installed for regulatory compliance at other ESW sites) was not feasible due to the lack of water availability for screen washing.

The screening type chosen instead for Belaugh and Waveney was 2mm passive wedge wire cylinders (PWWC) with an airburst cleaning system. The narrow mesh size is essential for keeping out the smallest life-stage of eel (glass eels and elvers) that could be present at these locations.

Design and construction

ESW appointed Tilbury Douglas Construction Ltd (formerly known as Interserve Construction Ltd) to undertake the design and construction phase of the project, working with Wood Group PLC as principal designers.

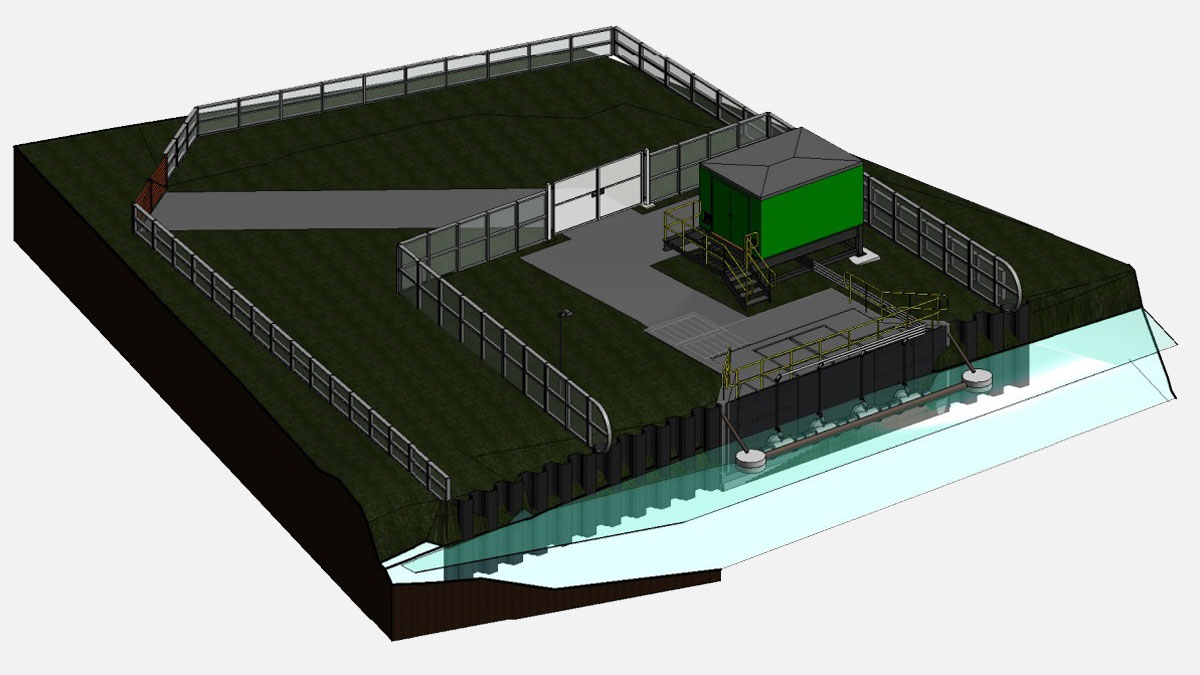

The 3-D model shown below is for the Waveney intake, both sites were very similar in the overall design with site-specific parameters affecting the placement of the kiosk and the number of screens. A fence was added to the final design along the river edge joining up to the new handrail to improve safety and site security.

Waveney intake viewed from the River, 3-D model from early design phase – Courtesy of Essex & Suffolk Water

Belaugh & Waveney Eel Screens: Supply chain – key participants

- Principal contractor: Tilbury Douglas

- Principal designer: Wood PLC

- Feasibility: Integrated Water Services

- Eel screens: Andritz

- Hydroburst skid: Quantum Engineering Developments Ltd

- MCC: CEMA

- Kiosks: Quinshield

- Dive team: Durrant Diving

- Steel frames, air pipework, chamber covers: Waveneys

- Steel frame for Belaugh kiosk: AJ Hodgson

- Electrical installation: Loxton Installations Ltd

- Ducting: T4 Intelligent Infrastructure

- Debris boom: Bolina Ltd

- Spider crane: GGR Group/Speedy Hire

- Piling: GeMech

Screens

Tilbury Douglas selected Andritz Group to supply the screening systems, utilising their Euroslot SAS solution. The drum-shaped screens sit submerged in the river on the front of the existing concrete structures supported on a new galvanised mild steel (GMS) framework.

There is no rotation or wash water system for this type of screen, so cleaning is achieved by a compressed air purge that provides a backwash. This Hydroburst air burst system was skid-mounted and housed along with the MCC in a kiosk on the bankside behind the screens. Level monitoring upstream and downstream of the screens provided differential data to trigger a clean at a specified limit. Cleaning was also set on a timer so if the differential trigger level was not reached the cleaning action would occur at a maximum interval of 12 hours.

One screen unit being prepared for installation at Waveney – Courtesy of Essex & Suffolk Water

Each screen was in a T-arrangement with a half-screen each side of a central pipe. They were fabricated from a copper-nickel alloy (CuNi9010) which deters mussel attachment and other organic growth.

At Belaugh there were three screens with an overall diameter of 505mm and a T-width of 1,755mm with each half-screen 580mm wide. River depth ranges (relative to chamber invert) 1.204m to 2.59m, for a maximum flow rate 315 l/s (27.2Ml/d).

Waveney needed four screens to achieve the appropriate approach velocity due to the minimum depth being lower than Belaugh. The screens had an overall diameter of 464mm and a T-width of 1,655mm with each half-screen 530mm wide for a maximum flow rate of 324 l/s (28Ml/d). River depth ranges relative to chamber invert 1.12m to 3.00m.

GMS frameworks were constructed to support the screens off the front of the intake structure. Both sites had existing concrete aprons in the rivers which were utilised to set the frameworks on. The aprons were cleaned of silt then the frameworks were installed by divers. The frames were lined with neoprene at the points where the metal met the existing concrete apron and intake wall to ensure there were no gaps where eels could pass through.

Screen framework during installation at Belaugh – Courtesy of Essex & Suffolk Water

Kiosk, skid and control system

The Hydroburst skid and controls were installed in green GRP kiosks on the riverbank behind the screens, raised on GMS frameworks set at the ‘1 in 100 year’ flood risk level plus an allowance for climate change of about 20%. The River Waveney suffered heavy flooding shortly after installation in December 2020 and the water reached close to the top of the support frame so for future learning an even greater flood allowance would be recommended.

The kiosks were fabricated with an integral floor. They were lifted into position on the support frames first then the skids were installed later by removing the kiosk roofs.

The MCC was supplied by ESW’s framework supplier CEMA; the Hydroburst controls were housed within a Form 4a Type 2 multi compartment control panel, mounted on the skid in the Quantum Engineering Developments Ltd’s factory. The skid was manufactured with an off-site build approach allowing for factory acceptance testing and pre-commissioning prior to delivery to site and this controlled approach had particular benefits during Covid-19, by reducing the numbers of people on site, as well as reaping the cost and health and safety benefits of reduced site activity.

At Waveney, the airburst cleaning sequence is subject to tidal fluctuations affecting the flow direction so a method to determine the direction of flow was needed to ensure that the screens washed in the correct sequence (upstream to downstream). A bespoke instrument was considered but an alternative method was found utilising the existing level monitor with a mathematical algorithm within the PLC.

Waveney kiosk on its raised steel frame – Courtesy of Essex & Suffolk Water

The direction of flow was calculated by assessing whether the river level rises or falls over a user-defined time period (currently 15 minutes). If the level is stable and the wash is due, it will wash in the nominally upstream to downstream direction (west to east). This simple solution proved to be not only cost-effective but reliable.

Debris boom

Both rivers are used by small craft (for canoeing, rowing etc.) so the intakes needed to be separated from river users for their safety and the protection of the screens. Floating booms were chosen that would provide this protection as well as shielding the installations from river debris such as reeds, leaves and the occasional tree.

The booms supplied by Bolina were model PDB600 but with two floats per metre rather than one, to provide a larger mass for stability and to absorb more of the energy of the wave produced by each air burst (giving greater protection to passing river craft and reducing the risk of bank erosion). The floats were fitted only to the back face of the curtain so the side facing the river was smooth allowing debris to pass more easily.

Belaugh floating debris boom – Courtesy of Essex & Suffolk Water

The booms were attached to model SP3 floats at each end which were connected to the intake structure via standoff tubes to maintain the correct distance from the screens. The standoff tubes were secured with chains fixed to wall plates that were attached to the intake walls, the chains also served to prevent unauthorised access around the back of the boom. This arrangement allowed each boom to rise and fall over the whole range of river levels providing continuous protection even during high floods.

A highly visible yellow PVC-coated stainless steel arrestor wire was fixed approximately 300mm above the top of the boom (supported by short masts fitted to the floats) to prevent small craft from attempting to push their way over the front of the boom into the screening zone.

Installation – Diving

The concrete aprons in front of the intakes had built-up silt deposits so they were cleaned using a combination of a 360-digger scraping the bulk from the surface and divers jetting the remainder. A silt curtain was deployed to contain the material in a controlled area to protect the intakes from ingress and protect the rivers from clouding up.

At Belaugh abstraction was halted during the day to avoid drawing any material towards the intake but Waveney had to be maintained in service throughout, so an over-pumping system was devised taking river water from an area outside of the silt curtain and pumping into a chamber behind the intake structure. The chamber was isolated from the river using an existing penstock.

As divers were used for the silt removal and the installation of the supporting steel frameworks and the screens, the use of expensive cofferdams was avoided. Both sites would have required over-pumping for long periods to maintain the essential abstractions so with the divers able to work predominantly without any intake isolations was of significant benefit both financially and operationally.

Divers in action – Courtesy of Essex & Suffolk Water

Installation – Kiosk support piling

A ground investigation was carried out to confirm the bearing strata. Bottom-driven piling rigs were used which had several benefits, a smaller machine allowed easier access across the difficult boggy ground without requiring expensive long-term hire of track matting.

The bottom-driven approach also produced less noise and therefore had less of an impact on local residents (the nearest properties being about 250m from the works). The piles were terminated with a precast cap at ground level and the legs of the steel frames for the kiosks were aligned on top.

(left) Small piling rig at Belaugh and (right) Waveney kiosk lifted into place on the support framework – Courtesy of Essex & Suffolk Water

Installation – Lifting

A spider crane was used to lift the kiosks into place, the team were really impressed with the manoeuvrability and the small size made it ideal for getting to these hard to reach sites.

Conclusions

During commissioning, some optimisation was carried out to reduce the number of washes per day and therefore keep any disturbances to a minimum. The screens are set on a timed wash every 12 hours at 09:00 and 21:00. The noise from the air burst is not significant and is very short but it was preferred to avoid quiet times as much as possible.

These ‘maintenance’ washes have proved effective so far as there have been very few occasions when the screens have been called to wash for blockages (on a detected differential). Coming into summer there’s a greater chance of river debris so the effectiveness of the air bursts will be monitored by the operational teams over the next few months.

Belaugh installation completed – Courtesy of Essex & Suffolk Water

Plenty of wildlife was spotted during the works including marsh harriers, kingfishers and otters and it’s hoped the new intake screens will make a positive contribution towards improvement of these habitats.

The project team were well supported by engaged and enthusiastic local operations teams, which combined with a strong collaborative approach with the principal contractor resulted in great products delivered before the EA deadlines and on budget. Excellent outcomes from an enjoyable and positive project experience.