BIM4Water (2017)

BIM4Water

BIM seems to be a term that has a marmite effect on people; they love it or hate it. Often the perception that is held of BIM is whether it is interpreted as ‘Building Information Modelling’ or ‘Better Information Management’. The BIM4Water Owner Operators Group definitely see BIM as driving ‘Better Information Management’. In some organizations BIM is being recognized as an enabler that fits into the wider development of a digital business capitalizing on the technology of the fourth Industrial Revolution.

PAS 1192:2 and PAS 1192:3

The BIM approach set out in PAS 1192:2 (Capital Projects/Construction Phase) and PAS 1192:3 (Operations Phase) is part of rethinking how we deliver to customers, the people paying the bills and receiving the services. The titles of PAS 1192:2 and 3 start with ‘Specification for information management…’ and this should be where the water industry starts and be the primary focus with the objective of enabling improvement in the service to customers.

There is now a growing set of tools which are being used in the delivery of construction and operations. This maturing Information Technology (IT) servicing design and construction; Engineering Technology (ET); and operations; Operations Technology (OT) is starting to converge. The benefits of the convergence of IT/OT/ET helps to resolve an issue that the water industry has wrestled with for many years, integrating design and construction with operations, maintenance and repair.

Engineering technology & operations technology

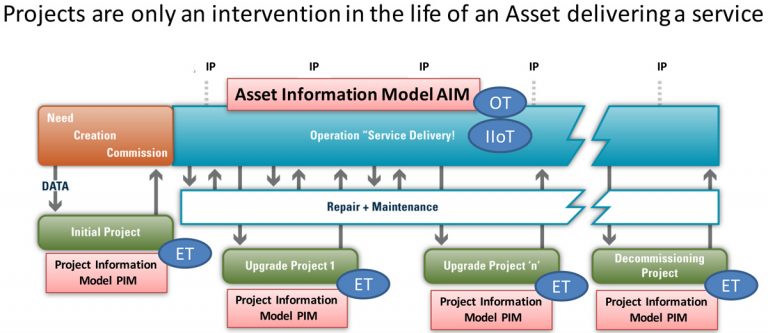

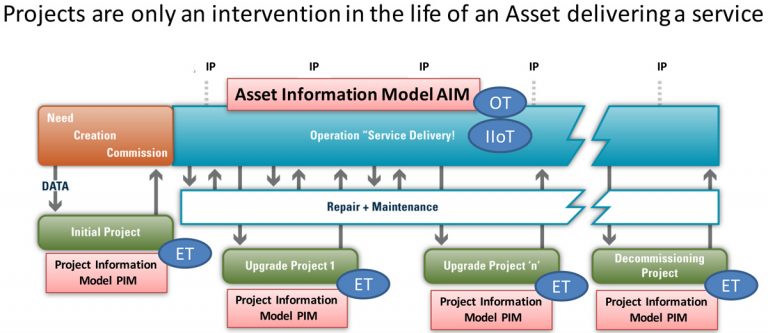

Assets are created through projects to deliver a service to the customer. The creation of the asset starts with the development of the scheme using ET to build up a Project Information Model (PIM). A project is only an intervention in the life of an asset, as shown in Figure 1.

Figure 1 – Courtesy of MWH Treatment and BIM4Water

The value in the ET models is often lost and not transferred into the OT environment where it builds up the Asset Information Model (AIM). This means that when repair and maintenance is carried out information is not always available in the AIM and updates to the asset data in the AIM as a result of the repair and maintenance is not always recorded. When the next project comes along there are resurvey costs in building another PIM using ET. The convergence of ET and OT enables the asset data to be kept up to date so the physical asset and the digital asset are in sync, sometimes referred to as the digital twin.

Industrial internet of things

There is another technology that is also maturing which is the sensor industry to monitor assets in the operations phase. This is part of the development of intelligent assets as part of the Industrial Internet of Things (IIoT). Designing these sensors into the ET model and understanding how the data will be used as part of the OT model enables asset performance monitoring to a new level.

This can be further developed into asset performance modelling which enables predictive maintenance and proactive interventions. With predictive modelling, outages can be reduced; if an outage is unavoidable customers can be informed ahead of time if their service is going to be impacted.

Information management

The water industry is in the early stages of developing the IT, ET and OT tools. It is clunky in the way that data and information moves or is linked between the Project Information Model (PIM) and the Asset Information Model (AIM). Resolving these interoperability and work process issues will take time, energy and investment. Justifying this investment is difficult if just viewed in the asset and project context.

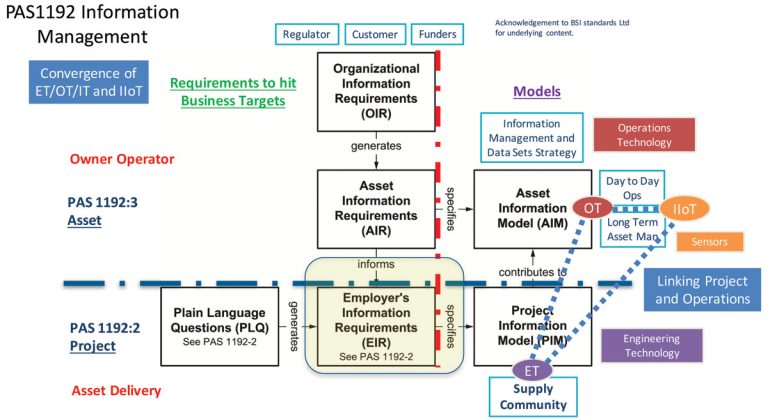

The real value of this effort is realized when placed in a business context as shown in Figure 2, an annotated extract from PAS 1192:3. ET and OT models need to support the overall business objectives in meeting the needs of various business stakeholders. Showing how OT and ET models can reduce risk, enhance resilience, increase shareholder value, satisfy regulatory requirements, increase customer engagement and provide investor and contractor confidence for large schemes (>£100m) should be some of the issues to be considered.

Figure 2: Information management (annotated extract from PAS1192:3) – Courtesy of MWH and BIM4Water

Taking risk and resilience as an example WaSCs have a number of potential high consequence low probability risks to manage. Which one will materialise? Eliminating the risks is likely to be too costly. However having good data and information will increase the resilience of the organisation to be able to respond to such events if one occurs. It has been said that in years to come the quality of the asset data held by an owner operator will appear on the balance sheet either as an enhancement or impairment.

Water industry competition

The introduction of water industry competition should be a driver to focus attention on asset data and performance. Understanding what the Organisational Information Requirements (OIR) are is the first step in being able to set up the appropriate OT systems with a supporting information management and data strategy. The OIR is the set of business information requirements needed to satisfy the stakeholders. Knowing the OIR the OT environment will then be able to request the appropriate information from the ET environment.

The ET which supports projects is only an intervention in the life of an asset which has OT systems supporting it through the whole operational life including repair and maintenance (see Figure 1).

Figure 1 – Courtesy of MWH and BIM4Water

![]() Benefits of BIM

Benefits of BIM

The real benefits of BIM will be realized when the ET and OT systems are seen to be delivering business value in the C-Suite of organisations. Converging IT/OT/ET and integrating live data from the IIoT is now delivering benefit in some organisations showing the opportunity ahead. Understanding the Organisational Information Requirements to set BIM into context will help in understanding where real value can be gained and what information systems and data are required. Developing this industry capability will take time. How many organisations have good information and data maps?

An additional driver for BIM is the growth in awareness of Cyber attacks which has created a renewed focus on knowing where data is held and how it is managed. PAS1192:5 is a ‘Specification for Security-Minded BIM…’ picking up the Critical National Infrastructure aspect.

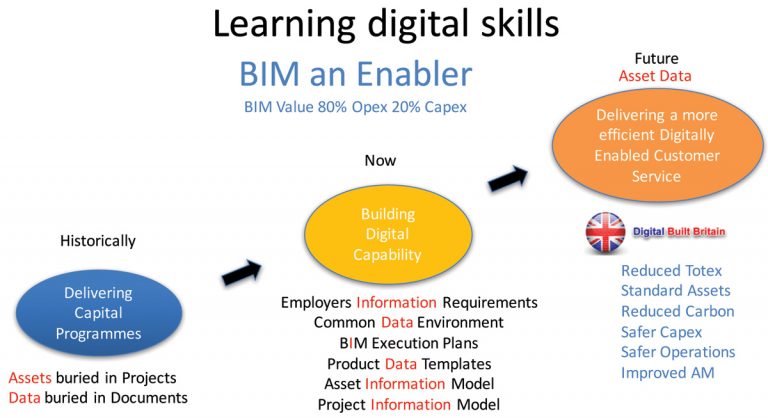

The implementation of BIM processes is a learning curve for the whole industry (see Figure 3 below). The industry is building digital capability within tools, processes, systems and the workforce. The culture change also requires a move from a projects and documents mentality to a data and assets focus. Assets are buried in projects and data is buried in documents. Information and data are the key and have value. An improved governance to ensure data is valued and is of the required quality will also assist in the skill development and culture change.

Figure 3: Learning digital capability – Courtesy of MWH and BIM4Water

![]() BIM4Water

BIM4Water

BIM4Water with British Water have been working with the twelve Water and Sewerage Companies (WaSC) in the UK to assist in developing a better understanding in the water sector of what BIM means and offers. A guide (1) has been published in response to industry stakeholder calls for a more consistent approach across the sector. There is a recognition that collaboration in some areas on standards could yield efficiency benefits for the sector as a whole. For example having an asset hierarchy and knowing what data is required assists in bringing together the ET and OT worlds.

Collaboration in these areas supports innovation and competition because there is confidence in the overall environment. In the industrial revolution rail standardised on a gauge and also set a UK time zone. That does not mean all rolling stock is the same or trains run to the same timetable. These standards provide the basic fundamentals within which competition then takes place with different rolling stock types and a variety of timetables.

Conclusion

If the water sector adopted a common asset hierarchy by for example contributing to Uniclass 2015 it would give a framework of asset classes within which to develop Product Data Templates (PDT). Rather than each WaSC, designer, supplier and contractor attempting to develop PDTs in isolation the pooled resources would reduce the overall effort required and give a common framework. It is encouraging that bodies such as BIM4Water, BuildOffSite Water Hub, WIMES, UKWIR and other bodies are now starting a dialogue on areas where it makes good sense to work together as an industry.

The development of standards and protocols will take time and there will be blind alleys but it is essential these are put in place as foundations if the long term potential of BIM is to be realisied. But don’t lose heart, there were many failures in the industrial revolution, and it has taken many years to move from Stephenson’s Rocket to an Airbus A380; but look at what we have now and the customer benefits.

In the meantime Better Information Management (BIM) is still a fundamental underpinning the realisation of an improved customer service. So let’s keep working at moving the industry forward step by step, learning new skills and keeping an eye on the vision of the digital future ahead.

The editor and publishers would like to thank Andrew Cowell, Chair of BIM4Water and Engineering Director with MWH Treatment, for providing the above article for publication.