Derg WTW (2023)

Aerial view during construction - Courtesy of DLG Water

NI Water’s Derg Water Treatment Works (WTW) is located in the north-west of Northern Ireland and produces on average 20 Ml/day, supplying water to approximately 10,000 homes to a wide area including Castlederg, Strabane, Omagh and their associated rural areas. In recent years there have been multiple exceedances of the pesticide, MCPA [(4-Chloro-2-methylphenoxy) acetic acid], from water supplied from Derg WTW. Furthermore, the level of trihalomethane (THM) precursors in the final water was rising and there had been numerous exceedances of the NI Water compliance standard. In response, a number of investigations were commissioned by NI Water to identify any performance issues at the works and to recommend options for implementation. The final solution to construct a new inlet, new clarifiers, powdered activated carbon (PAC) dosing and new sludge treatment commenced in April 2021 and the project successfully achieved beneficial use in March 2023 with expected handover due in October 2023.

Existing treatment process

Raw water for Derg WTW is supplied directly from both the Derg River and Strule River. The dominant land use of the Derg and Strule catchments is agriculture and forestry and as a result there have been herbicide and pesticide issues identified in the Drinking Water Safety Plans (DWSP) for both rivers.

The raw water is pumped to the inlet flash mixer chamber where it is sampled for colour, turbidity and pH and subsequently dosed with lime or sulphuric acid for pH correction and aluminium sulphate for coagulation. From the flash mixer water flows to four flocculators before passing through to four dissolved air floatation (DAF) cells.

pH adjusted clarified water then passes through five primary filters to remove any residual floc before moving on to six granular activated carbon (GAC) filters for taste and odour removal. From the GAC filters the water is dosed with lime and sodium hypochlorite before it enters four manganese filters. Final water is then dosed with orthophosphoric acid before it enters the clear water tank.

(left) Construction of new inlet, clarifier, interstage pumping station and sludge tanks and (right) new flocculator tanks – Courtesy of DLG Water

The need for investment

The number of exceedances of MCPA has increased in the final water from Derg WTW over recent years. The most effective means of MCPA removal is using activated carbon. A treatability report carried out stated that there was a significant range in percentage reduction within the existing GAC filters, suggesting that on occasions there could be issues with the performance of the filters.

When the GACs were originally designed to address any taste and odour issues, therefore, the size of the tanks and the type of carbon used were not optimal for herbicide removal. The type of carbon in the filters were changed to a carbon more effective at MCPA removal; this was a short-term measure only as it required a compromise on the taste and odour removal.

The investigations at the works also highlighted the elevated turbidity at the outlet of the existing DAF cells. This subsequently was putting pressure on the downstream assets and to ensure good quality water the throughput of Derg WTW was limited to below its maximum capacity. It was proposed that review and optimisation of the inlet chemistry would be undertaken to improve the performance of the DAF.

Optioneering

A suite of pilot studies was commissioned to assess potential solutions and to optimise the inlet chemistry, these included a DAF, sedimentation, PAC dosing, GAC filters and ion exchange technologies. The DAF, sedimentation clarifier and ion exchange plants were serviced with raw water and the GAC from the outlet of the primary filters.

The trials showed a significant improvement in final turbidities with a sedimentation clarification process over DAF process. It also confirmed that the coagulant already in use at Derg WTW was the most effective coagulant but refined the optimum dose. From an MCPA perspective both GAC and PAC were shown to be effective in treating MCPA to the required level; however, PAC dosing would require less space and was a less expensive option than large GAC filters and was selected as the preferred option. The PAC that proved to be the most effective was a new product, Purafloc, that had only received DWI approval at the beginning of the pilot trials. The trials showed the dose rate of Purafloc was less than other PACs while still effectively removing MCPA.

The addition of PAC into the process and the potential for increased organic removal would result in an increase of sludge produced at Derg. The sludge treatment at the works was already under strain; this necessitated additional sludge thickeners were included in the scope as well as improving the sludge press and sludge storage arrangements on site.

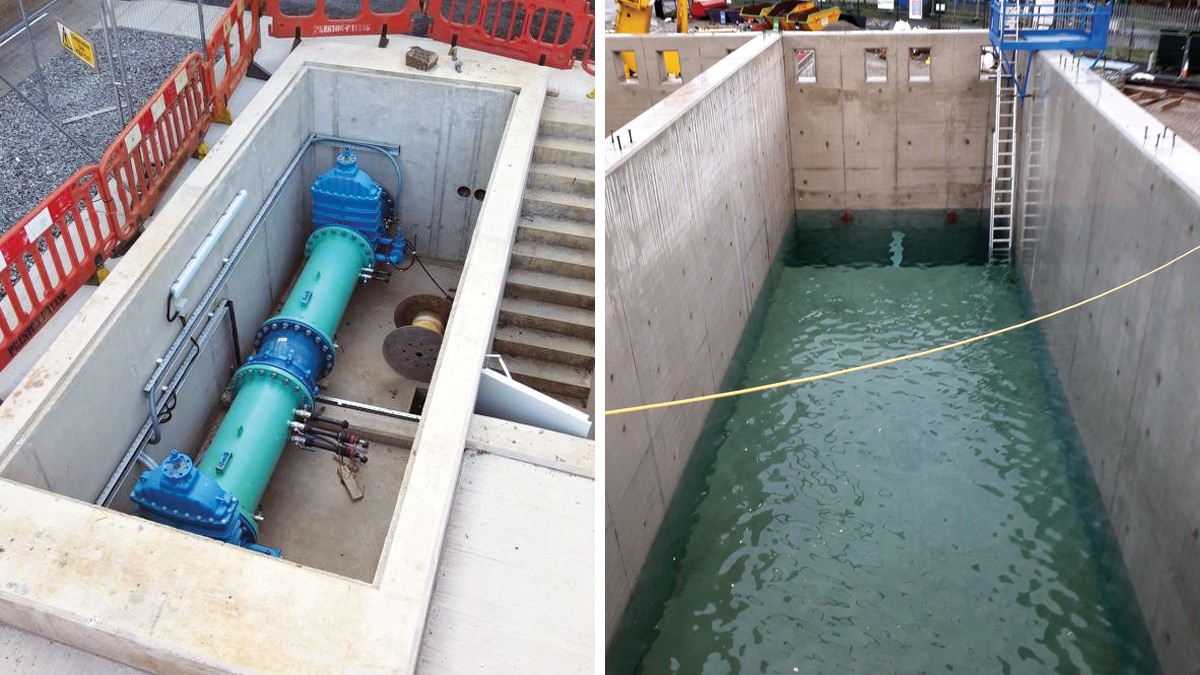

(left) Installation of static mixer and (right) water testing Clarifier 1 – Courtesy of DLG Water

Project delivery

Following successful approval of the Business Case, RPS was retained as Technical Advisor and NEC Project Manager for the delivery of the project.

DLG Water – a joint venture between Deane Public Works Ltd, Lowry Building & Civil Engineering Ltd and Glan Agua Ltd – were initially engaged under an Early Contractor Involvement (ECI) Contract to construct the pilot scheme and was kept on as main contractor for the full-scale construction project. Following design sign-off, an NEC ECC Option A Contract was awarded for the detailed design, construction, commissioning and testing of a new inlet works, clarifiers, sludge treatment and all associated works.

The scope of work required design and assessment from civil, mechanical, structural and process engineers. DLG Water appointed Murphy to oversee the process and MEICA design and McAdam as their civil/structural designers.

Derg WTW: Supply chain – key participants

- NEC project manager: RPS Consulting UK & Ireland

- Principal contractor & designer: DLG Water Ltd

- Civil/structural design & CFD modelling: McAdam

- MEICA, PLCs & SCADA: Murphy

- Temporary works piling: Ward Contracts

- Re-bar: Romtech

- Concrete: Multicrete Precast Concrete

- Concrete: Supermix

- Groundworks: LBCE

- Concrete & rebar placing: Raptic Ltd

- Precast manholes, covers & pipes: FP McCann Ltd

- Precast slabs: Ernecast Ltd

- Structural steel: PACC Engineering Ltd

- Cladding: Contract Services

- Blockwork: O’Connor Scaffolding

- Ground support & sheet piling: Trench Control

- Sheet piling: R Hopper

- Security doors: Fortress SEFA

- MCC & PLC panel: LMP Controls Ltd

- External pipe supply & valves: APP Fusion Group

- Lamella plates: Nordic Water (Jacopa)

- Zickert sludge scrapers: Nordic Water (Jacopa)

- Grit King® grit removal system: M and N Electrical and Mechanical Services Ltd (Hydro International)

- Grit classifier: SAVECO Environmental Ltd

- GRP tanks: Forbes Technologies

- PAC (Purafloc): Clinty Chemicals Ltd

- Stainless steel sludge tanks: Stortec Engineering Ltd

- Interstage pumps: Drilling & Pumping Supplies Ltd

- Thin sludge & supernatent pumps: Xylem Water Solutions

- Static mixers: Statiflo International Ltd

- Static mixers: TPS Filtration

- Chemical dosing: Grundfos Ltd

- Flow meters/instruments: Park Electrical Services Ltd

- Analytical instrumentation: s::can

- Access steelwork: Russell Metal Fabrication Ltd

- Access steelwork: SMP Fabrications Ltd

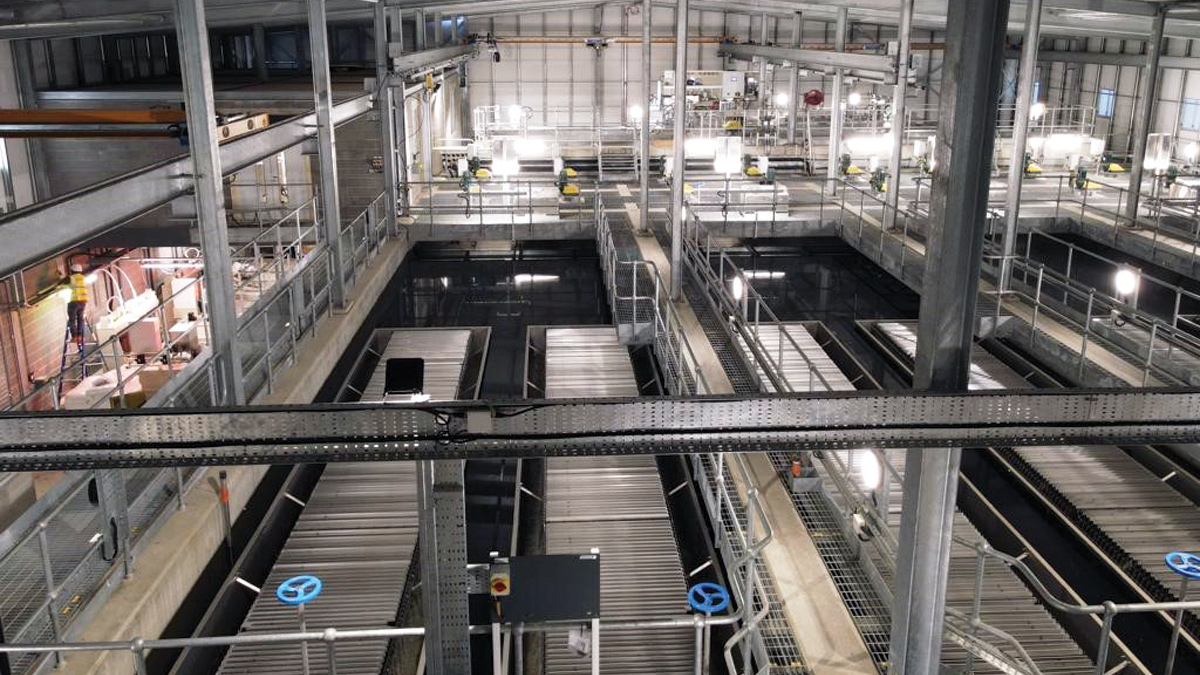

New clarifier lanes – Courtesy of DLG Water

Challenges

The contract was awarded in May 2021 and a challenging target date of March 2023 to achieve beneficial use was set. The project was immediately put under pressure when an unexpected buried electrical cable was uncovered traversing the site. The contractor then had to hand dig around the cable while waiting for NIE to attend site a redirect the cable. All in all, it added 6-weeks to the programme. Following the relocation of the cable the DLG Water pushed on with construction and were still on track to meet the March deadline.

Aside from the tight timescales of this project there were two other main challenges.

The first was the result of using a new product and not being familiar with the properties of the product. Following the pilot study it was decided that Purafloc would be used on two other NI Water WTWs that also had MCPA issues. These works were considerably smaller than Derg WTW and were used to refine the installation and operation of the larger plant at Derg.

Approximately 6-months after installation it was reported that there were issues keeping the PAC in suspension. Investigations were carried out and other means of mixing and circulating trialled before it was confirmed that internal vertical mixers in addition to the recirculating pump would be required. In order to mirror this at Derg WTW, roof panels had to be removed in order to lift out the new PAC tanks and send them to the manufacturer appropriate modifications. Furthermore, additional access platforms were required to access the motors for maintenance and a new hatch installed in the roof to allow for the removal of the mixers. A temporary dosing plant was installed to ensure the March 2023 deadline was met and the tanks were reinstalled in June 2023 and the mixers commissioned in August 2023.

The second challenge was not realised until the commissioning stage. The raw water records had shown 95%ile for true colour was 170 Hazen for true colour with a peak value of 210, the alum dose design was 300mg/l for that 95%ile colour. In the months of June and July this year the colour has been between 200 and 250 Hazen with a peak at 298 this has required a review of the coagulant and pH correction systems to ensure optimum treatment conditions.

New building alongside existing works – Courtesy of DLG Water

Successes

The new installation has been in operation since March 2023 and has delivered excellent results, proving itself in challenging conditions. Since the optimisation of the coagulant and pH correction there have been no MCPA or THM failures at Derg WTW.