Fixby WTW (2025)

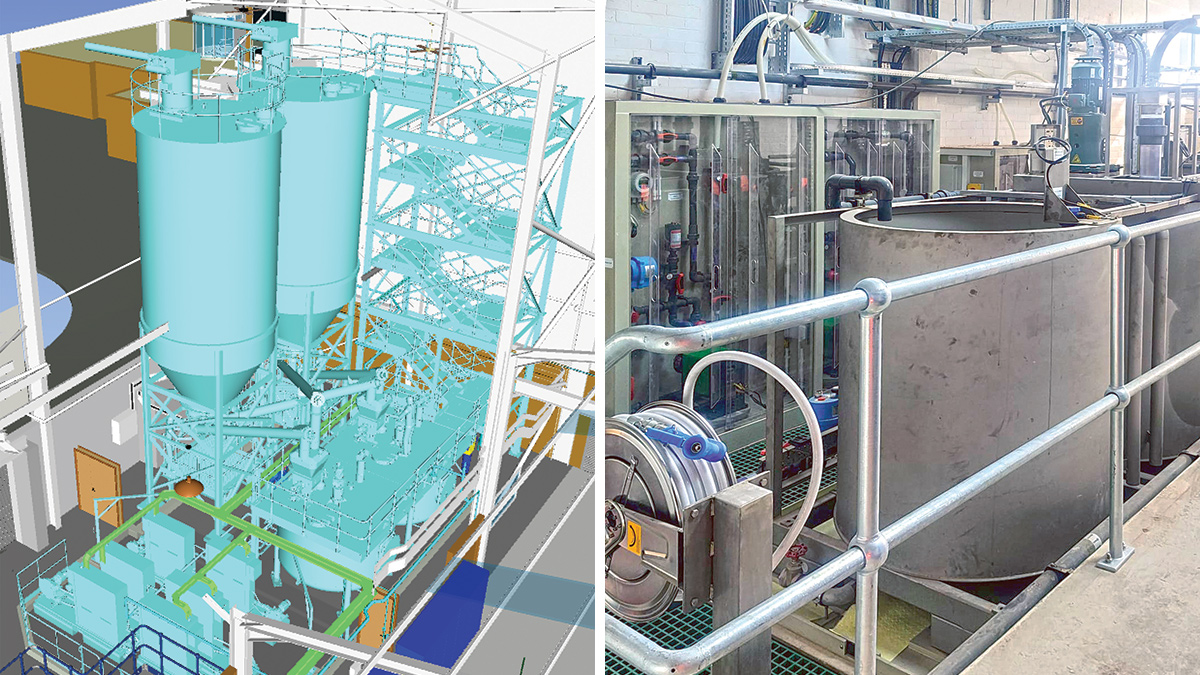

(left) Polyelectrolyte dry powder batching and (right) New inlet blend tank being installed onto a new steel support structure - Courtesy of Enpure

Fixby Water Treatment Works (WTW) supplies approximately 80,000 homes around the areas of Huddersfield, Kirklees, Wakefield and Calderdale. Water is sourced from two upland Pennine impounding reservoirs (Ringstone and Baitings), which is blended at the works inlet. High levels of colour and dissolved organic compounds in the raw water supplies feeding Fixby WTW coupled with ageing assets risks the formation of increased trihalomethanes (THMs) in the outlet supply. With a supply limit of 50 μg/l of THMs, this project served to optimise the treatment processes at Fixby WTW ensuring continued compliance with regulatory standards as well as increased plant throughput.

Existing works & project need

The 3-stage works comprises enhanced coagulation (via ferric sulphate and lime addition), dissolved air flotation (DAF) clarification, first-stage rapid gravity filters (RGFs), manganese contactors, followed by disinfection using chlorine within the clean water tanks (CWTs).

Prior to this project, Fixby WTW typically achieved a maximum throughput of circa 17 MLD (to mitigate the risk of THM non-compliance), but following the upgrade/refurbishment being undertaken by Barhale Enpure Ltd JV (BE JV), the site will be capable of supplying in excess of 30 MLD of wholesome and compliant water to the local network at flows.

Scope of works

To achieve the necessary improvements, the project’s objectives were to enhance the front-end blending and dosing of the two incoming raw water sources, improve dissolved air flotation performance, enhance rapid gravity filter treatment, install a replacement lime dosing system and a new polyelectrolyte dosing system for both RGFs and supernatant return.

Fixby WTW: Supply chain – key participants

- Client: Yorkshire Water

- Feasibility/outline design: Aqua Consultants | Stantec UK

- Main designer & contractor: BE JV

- Civils: Barhale

- Process & M&E: Enpure Ltd

- Mechanical installation: Staptina Engineering Services Ltd

- Electrical installation: Field Systems Designs Ltd (FSD)

- MCC/PLC & SCADA: Lintott Control Systems

- Polyelectrolyte & lime dosing: Chemdose Ltd

- Lime preparation: Spirotech Ltd

- RGF media replacement: Western Carbons Ltd

- Recycle pumps: KSB Pumps

- Flash & static mixers: NOV Process & Flow Technologies

- Valves: Cotswold Valves Ltd

- Eccentric plug valves: GA Valves Sales Ltd

- Service water pumps: Dutypoint Ltd

- Service water storage tank: Forbes Technologies Limited

- Trace heating & lagging: Jade Insulation

- Waste flow chamber & MCERTS: SIRIS Environmental

- Flow meters: ABB Ltd

- Turbidity monitors: Badger Meter Limited

- pH & temperature monitors: Endress+Hauser Group

- Pressure instruments: IFM Electronics

- Level transmitters: Siemens

- Hose reels: Arco Ltd

(left) Service water storage tank (right) service water pumps – Courtesy of Enpure

Raw water blending

At the works inlet, in order to provide a more stable incoming water quality, BE JV designed and installed a new 18.64m3 stainless steel inlet blend tank/overflow chamber positioned on a new support structure at high level above the two existing inlet pipes.

New pipework (two 600mm nominal bore [NB] inlets, one 600mm NB overflow and one 700mm NB outlet) in 304 stainless steel connects this new asset back into the existing works.

The outlet flow from this new tank passes through a new static mixer ensuring thorough blending of the two raw water sources prior to the addition of ferric dosing for coagulation and lime for pH correction.

This involved modification of the associated 600mm pipework feeding the site from Sowood Pumping Station and replacement of the existing pumps.

Dosing

The existing lime system, with the exception of the storage silo structures themselves, has been replaced in its entirety, with the plant changed over to temporary caustic dosing to facilitate the extensive upgrade of the lime system, undertaken by BEJV and Spirotech Ltd.

The silo hopper outlets have each been modified to convert then to accept two silo conveyors, each feeding one of two new lime mixing/batching tanks and have Spirotec’s Rotoflo anti-bridging technology fitted. A new access stairway was also provided to replace the ladder to the top of the silos where at the top new replacement filter units have been fitted to each silo.

Working with Chemdose Ltd, all the lime pumps and the associated dual contained dosing lines to the three dosing locations (inlet, pre-manganese filters and final pH adjustment) have been replaced using progressive cavity rotary lobe dosing pumps.

The MCC that serviced the existing lime, ferric and inlet control has been replaced with two new MCCs; one for lime and one for the ferric/inlet control. To fit in these new assets and maintain plant operation, a new steel mezzanine structure has been designed and constructed.

(left) 3D BIM model of the lime silos, batching and dosing systems and (right) polyelectrolyte batching and dosing system – Courtesy of Enpure

Polyelectrolyte system & environmental controls

The existing polyelectrolyte system has been replaced in its entirety including powder handling, batching and dosing pumps. Polyelectrolyte is used to aid coagulation of solids in the rapid gravity filters (RGF) inlet flow, at times of the year when the inlet water quality requires it and also to reduce the solids returned to the process from the DAF blanket sludge and RGF dirty backwash water. The polyelectrolyte system was installed into the redundant salt treatment building which was extensively refurbished to ensure a dry and clean environment.

To stabilise the atmospheric conditions in the polyelectrolyte room new temperature control and heating/cooling systems have been installed together with dry room segregation to protect the process against the harsh inclement weather that the site experiences.

DAF plant

The six DAF scrapers and sludge beach were replaced, and the saturated air system was upgraded to utilise Enpure’s patented dissolved air flotation headers and nozzle technology. The recycle pumps were also replaced and upgraded with larger pumps that provide greater quantities of air saturated water to improve the flotation process and increase plant throughput. The DAF plant MCC was replaced including all the new cabling to all the existing and new equipment/drives.

Refurbished DAF lanes – Courtesy of Enpure

Rapid gravity filter improvements

Working with Western Carbons, BEJV have removed and replaced all the 16/30 filer media and increased the depth by 200mm to provide additional filtration capacity.

The existing outlet flow control butterfly valves have been replaced with eccentric plug type, and the old orifice plate flow meters have been replaced with a reduced bore magnetic flow meter, which together, provide a more stable outlet flow control from each filter. Underbed pressure transmitters have also been provided to prevent over pressurisation of the existing filter floor as the new control system has been modified to optimise backwash flow rates, ensuring optimum bed expansion that is now temperature compensated. The complete control system/control desk was replaced for these first stage filters.

The existing service water booster set has been replaced with a transfer pump set that lifts service water to a new 13m3 insulated HDPE buffer/storage tank. From here, three new service water pumps (duty/assist/standby) feed all the existing and new service water requirements.

Control system upgrades

The project includes a significant upgrade to the ageing motor control centres (MCCs) and PLCs.

BEJV, working with Lintott Control Systems has supplied a new main LV switchboard, replacement DAF MCC, replacement ferric MCC, replacement lime MCC, replacement MCC at the remote Sowood Pumping Station (which pumps raw water to the Fixby WTW from the Ringstone Reservoir) plus a replacement RGF control system including modifications and integration with the remaining PLC’s and site assets.

All the new MCCs include Schneider Modicon M580 PLCs that replace the outdated PLCs. BEJV has also replaced the service water system for the whole site. All this has been completed whilst maintaining continual operation of the water treatment works.

New LV switchboard – Courtesy of Enpure

Other modifications

Other more minor modifications have been to provide that include a new MCERTS compliant flow measurement system and new control valves (and associated control system modifications) that serve to ensure that Yorkshire Water are compliant in terms of the daily and instantaneous peak flow of wastewater to the sewer network.

Also, BEJV undertook an extensive refurbishment of all the flat roofs and skylights on the site and upgraded ageing windows, doors (including security upgrades) as well as a refurbishment of the office areas to serve as our site establishment and meeting room during the project delivery without the need to provide mobile site welfare.

Both 2D and 3D design have been utilised for the regulatory compliance works with Barhale’s in house designer ESL undertaking structural and civils design for the site, not limited to:

- Process plant building fabrication upgrade together with façade replacement and building security improvements to SR4 rating (windows, doors and louvres).

- Fire protection improvements by using fire rated doors, lintels and partitions including the lime room’s 80m2 wall.

- Lime and ferric dosing equipment, delivery bunds, plinths, walkways and drainage.

- Routing of electrical and dosing line routes together with Points of Application.

- Washwater diversions and MCERTS flow monitoring utilising both flow meter and specialist tank monitoring equipment.

- Polymer dosing wet and dry rooms.

Status

The upgraded works successfully achieved the Drinking Water Inspectorate (DWI) compliance date having completed the process critical works improvements by 31 March 2025. The full project is due to complete at the end of 2025.

This scheme has successfully improved the ability to treat the poor quality of the incoming raw water whilst increasing throughput, adding substantial resilience to the local Yorkshire Water network and for the benefit of future generations.