Holderness Flood Alleviation Scheme (2024)

The completed East Hull Pumping Station - Courtesy of JBA-Bentley

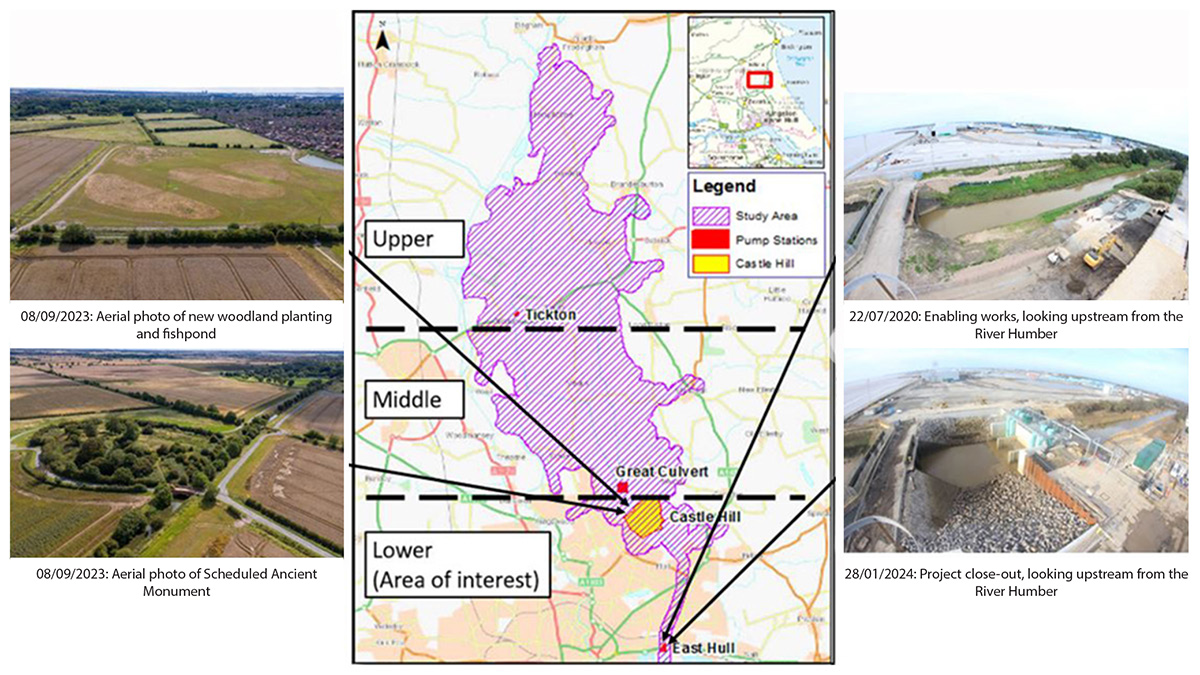

The Holderness FAS is a £28 million package of works delivered for The Environment Agency (EA), in the 6-year period from January 2018 (quotation and scoping) to March 2024 (project closeout). The scheme comprised of two working areas – a new 10m3/s online pumping station at East Hull, and a flood storage area ‘Aquagreen’ at Castlehill, along the route of the Holderness Drain ‘Main River’. Holderness Drain is the sole outfall for a 238km2 drainage catchment (see Figure 1 below) and backs ups twice daily when it becomes tide-locked by the Humber Estuary. During heavy rainfall events, this can have significant impact, as seen in 2007, where over 55,000 homes and 95 schools were flooded in Hull city centre. The requirements to reduce flood risk and Build Back Better were key project drivers.

Undertakings & funding

The works were undertaken by JBA-Bentley, a joint venture between designers, JBA Consulting, and principal contractor, JN Bentley. This was through the EA’s £2.5 billion Water and Environment Management (WEM) Framework – Asset Delivery. The project was delivered under an NEC 3 Engineering and Construction Contract (ECC) Option C Contract.

The project was funded by key partners including Hull City Council, East Riding of Yorkshire Council, Highways England, Humber Local Enterprise Partnership, Northern Powerhouse, and DEFRA.

Figure 1: Holderness Drain Catchment Area (238km2) and outfall location – Courtesy of JBA-Bentley

Design

Climate resilience and adaption was at the heart of the design as evidenced by a 20% overdrive capability built into the East Hull controls, temporarily increasing pumping outputs to 12m3/s, delaying the need for future pump upgrades.

At Castlehill, multiple social, environmental, and economic benefits have been realised, increasing flood storage within the catchment, delivering new woodland habitat, and integrating ‘access for all’ walking routes around the site. This solution reduced the peak pumping requirements at East Hull and created a valuable social space for the community in dry periods, improving biodiversity.

East Hull Pumping Station

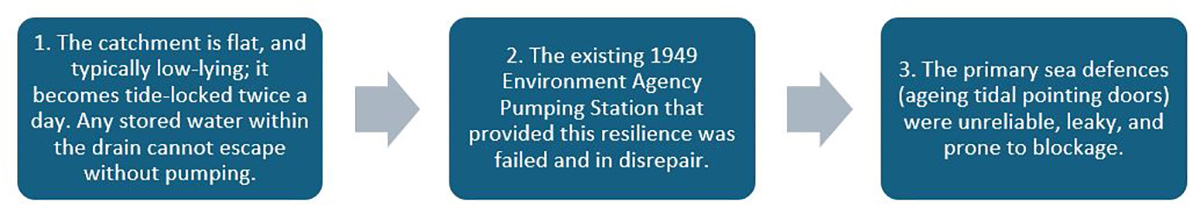

Existing flood resilience was impacted by 3 key factors:

Figure 2: Flood resilience factors

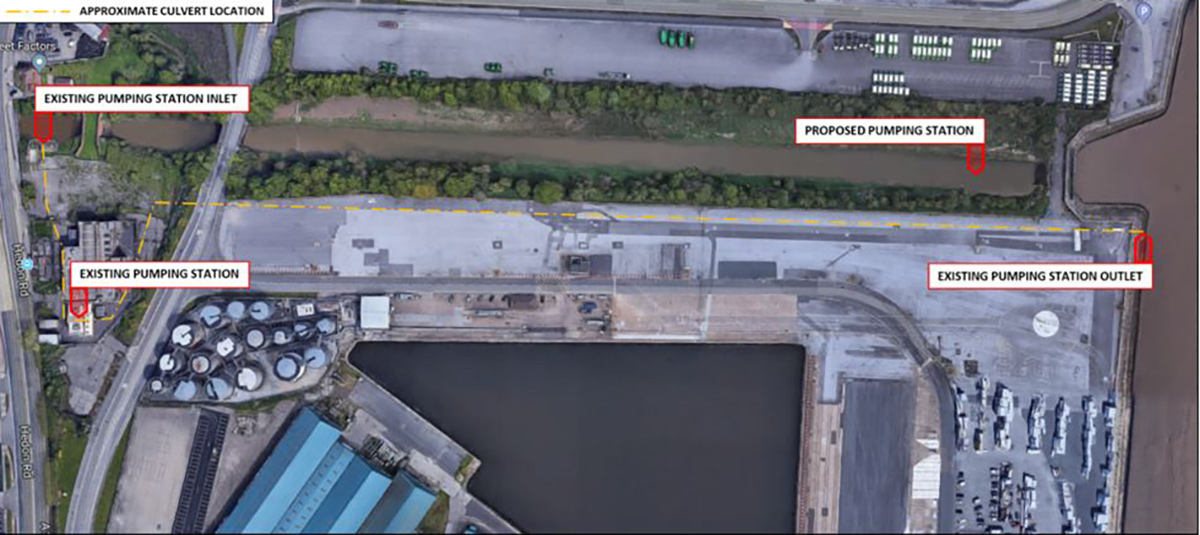

The project faced significant delivery challenges:

- Space was at a premium and securing land was considered prohibitively non-viable, so the pumping station was constructed ‘online’ within the drain’s footprint. This reduced land cost, and habitat displacement when compared to an offline build.

- The works in the river could not impinge on the essential gravity flow needed to keep water levels low in the catchment.

- The site borders the Humber Estuary, an environmentally protected SSSI, RAMSAR, SPA, SAC designated site.

- The site was protected from the sea by unreliable tidal defences and exposed to the full 7m tidal range.

- The site is constrained on the West by a culverted outfall to the Yorkshire Water pumping station which was backfilling the failed EA station and overpumping the Holderness Drain during extreme events see Figure 3 (below).

Figure 3: Site location – Courtesy of JBA-Bentley

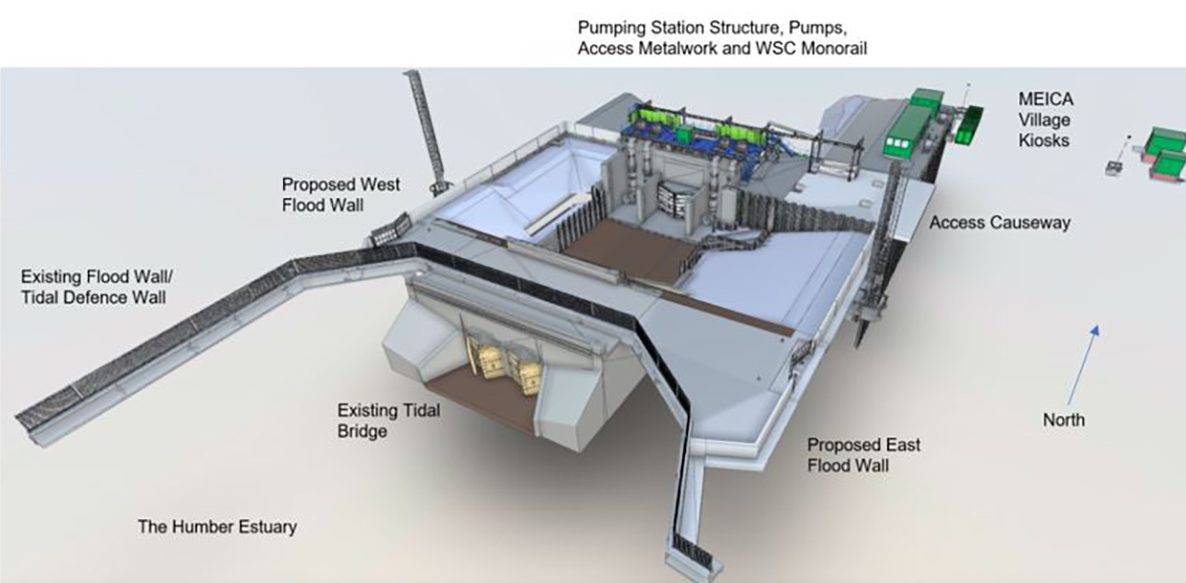

As such, JBA-Bentley were contracted to design, build and commission a replacement pumping station 50m North of the confluence of the Holderness Drain and the Humber Estuary (50-year life). This was a multi-disciplinary scheme, requiring civil, structural, MEICA, geotechnical and hydrological/hydraulics inputs. Completing this scheme as a joint-venture allowed an expedited programme through increased design-construction integration and buildability efficiencies.

The new pumping station consisted of four 2.5m3/s pumps (13T each) operating in a duty-assist-assist-assist configuration, two per wet well. A gravity channel was constructed for flows outside of tidal-locking scenarios, which can be isolated using new tidal pointing doors and a penstock sluice gate for secondary containment (see Figure 4 below). This improved reliability of the failing tidal defences in conjunction with new floodwalls.

(left) Figure 4: Tidal pointing door installed across gravity channel – Courtesy of Binnies UK, and (right) Figure 5: Canister pump installation using 250T crane positioned on the access causeway (21/06/2023) – Courtesy of JBA-Bentley

The pumps were controlled by a motor control centre (MCC) kiosk, which is part of the site’s MEICA Village: MCC; NPG substation, providing a DNO mains connection; an EA Switchgear room; and a 2000kVA step-down transformer.

Rock armour, gabions and reno mattresses were installed for scour protection in-channel and on the drain’s banks, preventing the pumping station’s foundations from being undermined. An access causeway was constructed for safe crane access, up to 250T (see Figure 5 above). The pumping station and access causeway were founded on steel H-piles and concrete CFA bearing piles to minimise settlement.

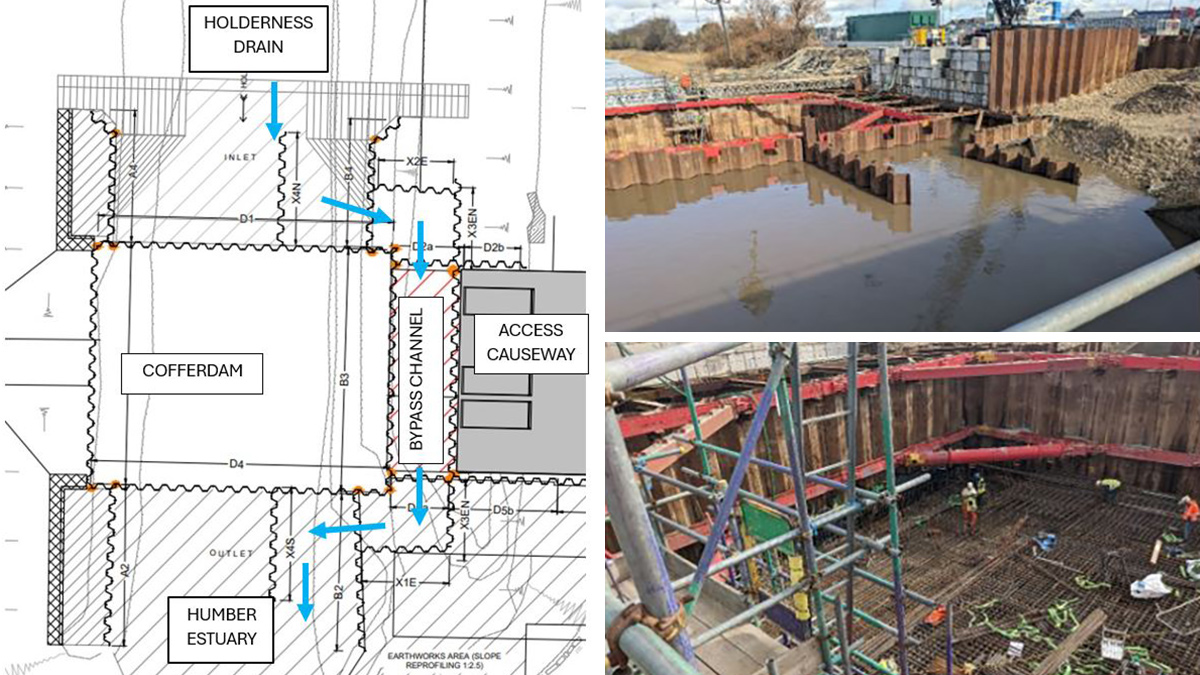

To deliver the works effectively and safety, a large central 30m x 25m cofferdam was formed and incorporated a bypass channel. The bypass was sized to convey all river flows up to 30-40m3/s seen in winter months. As seen in Figure 6 (below), these temporary works would eventually be integrated into the permanent works saving time, cost, and carbon.

Figure 6: (left) Cofferdam and bypass channel overview, (top right) the cofferdam and access causeway, and (bottom right) the pumping station main structure – Courtesy of JBA-Bentley

The complexity of the solution – particularly the phasing of the combined temporary and permanent works – led the team to deploy various digital delivery tools to aid the process. A 3D federated Revit model was created for the scheme that facilitated collaboration between JBA-Bentley and the many sub-contractor design packages and ensured effective clash detection was possible and that client and landowner input was communicated and captured.

Construction on East Hull Pumping Station started July 2020. During the works, the site and design team responded to many external challenges and worked closely with stakeholders to resolve them. For example, one of the existing tidal pointing doors sea defences protecting the drain from the Humber failed mid-works, requiring an emergency response to prevent an increase in flood risk.

This was not the most challenging issue faced. Nearing completion, a decommissioning process was required to remove parts of the cofferdam and return gravity flows to the new central gravity channel – closing off the bypass channel. Dry working options were preferred, but a new option emerged when JBA Bentley approached Yorkshire Water for use of their pluvial pumping station to redirect the Holderness Drain into the Humber directly (something they already did in emergencies). This option created a dry working area using temporary dams and stoplogs at the upstream listed Hedon Road bridge, allowing potential for 24/7 working to reduce the programme. This method was safer than alternatives like pontoon working in low neap tides, additionally preventing water stagnation and silt build-up from impacting the protected Humber. It was also less carbon-intensive than sheet piling across the whole drain, and allowed for more rapid demobilisation of temporary works if there was a storm event during the decommissioning.

24/7 working saved 3 months of planned programme time, reducing cost and carbon by 48%. However, it left the catchment completely controlled by pumping.

4D time and motion modelling (Synchro 4D) was used to garner stakeholder agreement for this. 4D modelling simulated a digital twin of the real life works, aiding virtual planning of the complex decommissioning phase. This significantly reduced construction risk by highlighting plant clashes and working room restrictions and became a critical stakeholder engagement tool.

Figure 7: East Hull Pumping Station 3D Revit model – Courtesy of JBA-Bentley

Holderness Flood Alleviation Scheme: Supply chain – key participants

- Client: Environment Agency

- Designer: JBA Consulting

- Principal contractor: JN Bentley

- Principal designer: Callsafe Services Ltd

- ECC project manager: Turner & Townsend

- ECC supervisor: Binnies UK

- Sheet piles (temporary & permanent): Sheet Piling (UK) Ltd

- Concrete bearing piles: Aarsleff Ground Engineering

- Shoring/temporary works: MGF Ltd

- Main structure, floodwalls & MEICA Village Foundation rebar: Express Reinforcements Ltd

- General civils: MBK Civils Ltd

- General steelwork Installation: APT Marine Engineering Ltd

- Access metalwork: Steelwork Engineering Services Ltd

- Structural steelwork & flooring: Fab-Tek Installations Ltd

- LV installation: Circle Control & Design Systems Ltd

- 11kV switchgear (HV electricals): Hornbill Engineering Ltd

- MCC software & control: Technical Control Systems Ltd

- NPG substation design & DNO connection: Northern PowerGrid

- Drainage: Keyline Civils Specialist Ltd

- Penstock & HPU: Oilgear UK

- Canister pumps: Bedford Pumps Ltd

- Castell mechanical interlocks: GA Valves Sales Ltd

- Penstock, tidal pointing doors, Weedscreen cleaner & stoplogs: Aquatic Control Engineering Ltd

- Weedscreen cleaner monorail: Landustrie Sneek BV

- East & west floodgates: 1st Defence Fabrications Ltd

- GRP MEICA Village kiosks: Kingsley Plastics Ltd

- Legato blocks: Elite Precast Concrete Ltd

- Granular materials: Ashcourt Group – Aggregates

- Concrete: Ashcourt Group – Concrete

- Rock armour & gabion stone: Breedon Group (Leyburn Quarry)

- Stone surface dressings: Marchington Stone Ltd

- Gabions & reno mattresses: Miers Construction Products

- Kiosk fire detection: Protec Fire & Security Group Ltd

- Security fencing: Burn Fencing Ltd

Video 1: An overview of the Holderness Flood Alleviation Scheme – Courtesy of JBA-Bentley

Castlehill Flood Storage Area

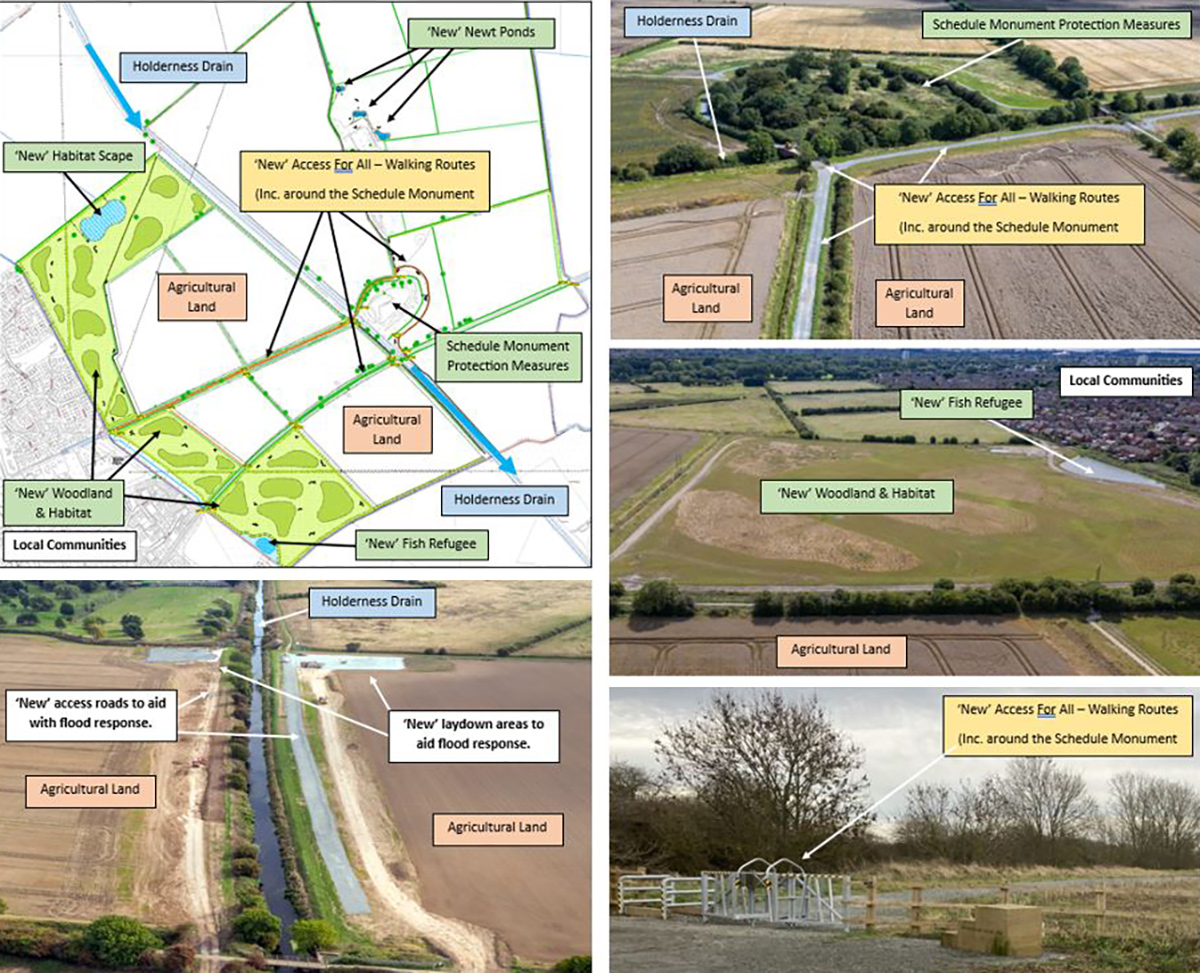

Initially Castlehill formed part of the existing Holderness Drain floodplain, forming a buffer between the drain and local communities. The area was predominately agricultural, and its topography left it wet and inaccessible throughout the year.

Castlehill now delivers a multi-functional site. The scheme’s primary purpose was to deliver a more climate resilient solution by delaying overspill into the floodplain and making use of untapped storage within the drain itself. Secondarily, through consultation, the scheme created new social spaces, ‘access for all’ walking routes and a link-up with the TransPennine Trail. The local community were key stakeholders in this scheme, helping to form requirements for these social areas and participating in tree planting initiatives.

Figure 8: Overview of Castlehill Flood Storage Area ‘Aquagreen’ and (right) Sutton Cross Drain and East Carr Drain sheet piling works – Courtesy of JBA-Bentley

New woodland planted could sequester more than 6000T of carbon and will offset the Castlehill construction emissions within 10 years. Some 15 years later, it will also have absorbed 50% of the East Hull capital carbon – this provided not only new habitats, but also a direct resilience benefit. The table below compares capital carbon emissions to woodland sequestration.

| Capital Carbon (materials, plant, and site works) | |

| East Hull: 5,450 tCO2e | Castlehill (planned design): 280 tCO2e |

| Total: 5,730 tCO2e | |

| Castlehill Proposed Woodland (150,000m2) | |

| Carbon sequestration after 15 years | 304 tCO2e (Castlehill capital carbon neutral) |

| Carbon sequestration after 25 years | 3,375 tCO2e (East Hull over 50% capital carbon neutral) |

| Carbon sequestration after 35 years | 5,019 tCO2e (East Hull over 85% capital carbon neutral) |

| Carbon sequestration after 55 years | 6,566 tCO2e (East Hull capital carbon neutral) |

The scheme worked directly to improve protection of neighbouring properties through re-alignment of Sutton Cross Drain further North-East (further into the floodplain), and through installation of over 140m of sheet piling along the length of Sutton Cross Drain and East Carr Drain. This also allowed for the space to create a joint wetland shelf/fish refuge in dry periods along the re-aligned drain’s route.

Overall, the scheme provides biodiversity net-gains for the following protected and priority species:

- Nesting birds (creation of scrub and woodland habitats and retention of arable farmland).

- Otters (improved water quality, fish stocks and resting areas).

- Badgers (new sett building opportunities in new woodland).

- Water voles (created marginal vegetation shelf on Sutton Cross Drain, which has previously held water voles).

- Great Crested Newts (3 new ponds created at north of site).

Another aim of Castlehill was to improve access to and understanding of the historic environment, due to the presence of a Scheduled Ancient Monument on the site. Information boards were installed, and inclusive K-gates and barriers were fitted to provide safe entry and prevent unauthorised site access e.g., by motorbikes etc. This will protect the historic site and preserve it for future generations.

Finally, and in keeping with the requirements for improved resilience, the project also incorporated new elevated gravel laydown areas to assist effective flood incident response, see Figure 9.

Figure 9: Castlehill multi-functional site – Courtesy of JBA-Bentley

To conclude, this multi-faceted design has made provisions for a new online pumping station at East Hull and has increased resilience and social-environmental value of the flood storage area at Castlehill, achieving significant improvements to the Standard Of Protection to properties along the course of the Holderness Drain. These works were technically complex, but thanks to the ‘One Team’ focus of the JBA-Bentley joint-venture, significant design and construction challenges were overcome using innovative temporary works and digital rehearsal/delivery strategies at every step.

The solution became operational in December 2023 and has already supported effective incident response and recovery by protecting properties during six recent and consecutive storm events (Elin, Fergus, Gerrit, Henk, Isha and Jocelyn). The flood alleviation works has delivered significant improvement to the Standard Of Protection afforded to around 1000 properties, increasing from approximately 20% AEP to 0.5% AEP from fluvial and tidal events, in-line with the Humber strategy.