Layer to Langford Pipeline (2023)

Layer to Langford route plan – Courtesy of Essex & Suffolk Water

Essex and Suffolk Water, part of Northumbrian Water Ltd, supplies drinking water to 794,000 properties. Maintaining a supply to those customers requires the distribution of up to 670 Ml/d of high-quality drinking water. In Essex, the two primary treatment works are Hanningfield WTW, a physio-chemical works near Chelmsford and Layer WTW, a biological works, near Colchester. These are supplied by raw water stored in two large reservoirs at Abberton and Hanningfield. In 2016, and more recently in 2022 low levels of rainfall and hot weather compromised the raw water quality in Abberton Reservoir which led to significant challenges to the biological process at Layer WTW. This meant unprecedented demand was placed upon the chemical works at Hanningfield WTW, which in turn drew down the water level in Hanningfield Reservoir to levels not seen since the summer of 1996.

The challenge

Whilst this low water level at Hanningfield Reservoir was observed, the level in Abberton was healthy due to the process constraints of the biological works at Layer. To mitigate the scenario of having two reservoirs, one relatively full, and another extremely low, occurring in the future, Northumbrian Water applied for enhancement funding in AMP7 to construct a 20km pipeline between Layer WTW and Langford WTW, also a physio-chemical works, where water from Abberton could be reliably treated.

This in turn would allow water from the River Chelmer and River Blackwater that would normally be treated at Langford, to augment the water level in Hanningfield Reservoir by utilising existing transfer pumping facilities between Langford and Hanningfield Reservoir. Providing this connectivity, albeit by substitution, will allow Northumbrian Water to balance the water levels in both Abberton Reservoir and Hanningfield Reservoir, and mitigate a potential scenario where no water is available to supply Hanningfield WTW.

The project

In 2019 Essex & Suffolk Water teams began to plan a pipeline route between Layer WTW and Langford WTW for a pipe that could support flow rates up to 50 Ml/d. This figure was determined as the optimum flow rate to allow balancing of the reservoirs to take place and ensure security of supply when faced with long term drought conditions.

The pipeline will take advantage of the capacity and capability of the existing pumping station at Abberton which can deliver up to 255 Ml/d to Layer WTW. The route would begin with a strategic connection into the existing raw water mains that deliver water from Abberton Reservoir into Layer WTW.

From this point a route was sought that would allow water to run under gravity conditions to Langford WTW where it would be discharged into two existing bankside storage reservoirs each with a capacity of 35 Ml.

The pipeline from Layer to Langford would operate as a gravity main, with the upstream head being set by the pressure in the rising main at the take-off point. With approximately 5 bar of available driving head, the flow out of the pipeline will be controlled by a downstream flow control valve. The pipe sizes have been selected to ensure a positive pressure is available throughout the pipeline and to provide sufficient differential pressure at the outlet at maximum flow.

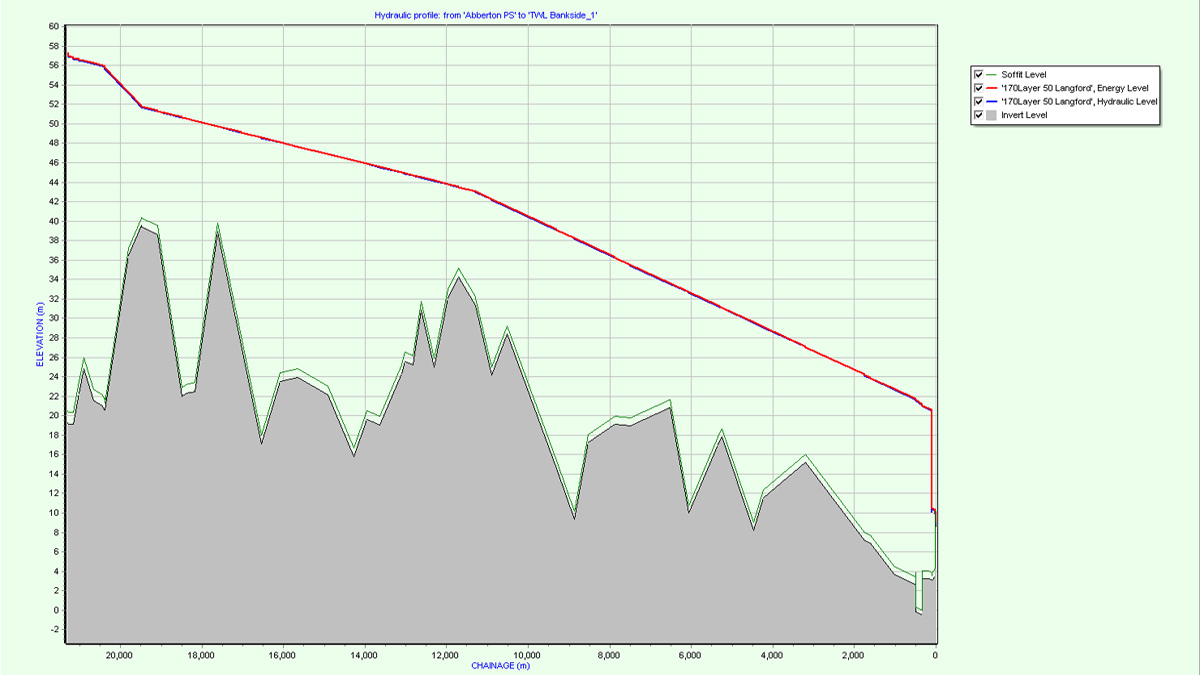

Hydraulic profile

The hydraulic profile shown below (pipeline pressure is shown in red) extends from Abberton Pumping Station to the outlet at Langford WTW. Chainages are measured back from the Langford outlet (at chainage 0m) and the start of the new pipeline construction is at approximately chainage 20,000m. Note the falling available head due to friction losses along the pipeline and its change in gradient at approximately chainage 12,000m. This change in gradient is due to a change in pipe size which is the result of the pipeline optimisation.

Hydraulic profile – Courtesy of Stantec UK

The direct connection from the pumped rising main to Layer introduced a number of hydraulic complexities. A key issue was the control of transient pressures, particularly associated with a sudden loss of output at Abberton Pumping Station. Existing surge vessels provide robust surge control, however, the addition of the 20km extension to Langford would require careful consideration.

The time to close the outlet valve at Langford, particularly following a sudden loss of pumping at Abberton, would need to be sufficiently long to avoid exacerbating transient pressures while a closing time too long would risk depressurising the pipeline and the risk of drawing air into the pipeline. The occurrence of transient air pockets at high points could create further transient pressures if encountered by the initial pressure waves.

While these challenges could be largely avoided by separating both pipelines entirely with a break tank, the tank would need to be sufficiently large and elevated to provide the same driving head. The design team are, instead, progressing an optimised solution to avoid these additional capital works through thorough detailed understanding of the problem, careful selection of the control valves and the implementation of a control system that remains simple yet capable of maintaining pressures within acceptable limits.

Ground investigations

To support the design of the pipeline Essex & Suffolk Water has now completed ground investigation work along the route to determine ground and groundwater conditions and help inform excavated material management decisions. The ground investigation work comprised:

- 63 dynamic sampler boreholes up to 6m in depth.

- 11 cable percussion boreholes up to 10m in depth.

- 27 soil resistivity tests.

- Post-installation groundwater monitoring at approximately 12 locations.

This work was completed by Essex & Suffolk Water’s framework partner Allied Exploration & Geotechnics (AEG) in October 2022 based on a specification written by Stantec UK. This ground investigation work will help Stantec to determine the appropriate pipeline material.

(left) Ground investigation work and (right) pipe installation – Courtesy of Essex & Suffolk Water

Pipe material selection

The use of steel, ductile iron (DI) and polyethylene (PE) were all considered. Due to aggressive ground conditions, appropriate corrosion protection would be needed for ferrous materials. PE would remove the corrosion risk but the large diameters needed and the associated pipe thickness would require careful control of welding during construction. At the time of writing (June 2023), final selection is ongoing but, following initial assessment of cost, constructability and maintenance issues, either an all DI pipeline or a mix of DI and PE are considered most favourable.

Project planning

The project is currently moving through the detailed design phase and one activity that has been conducted concurrently is the liaison with the council districts that the pipeline crosses, both Colchester City Council and Maldon District Council.

In the experience of Essex & Suffolk Water, large diameter cross country pipelines have typically required Environmental Impact Assessments to support the planning process. For this project, an alternative approach was taken where the team designed the pipeline and its construction methods, including associated compound areas, to have the least possible impact from a number of perspectives including ecology, visual impact and traffic and transport in advance of submitting our EIA Screening Request.

This design, including examples of how measures were introduced to provide a less impactful route than one that may have been presented prior to completing these mitigations, helped support the EIA Screening request. In response to that request both Councils viewed the screening request favourably and allowed the team to complete the work using permitted development rights recognising the efforts of Essex & Suffolk Water to plan and design the least impactful route possible.

Archaeology

Essex & Suffolk Water now plans to complete the archaeological work associated with the project over the summer period of 2023. Throughout the early phase of the project Essex & Suffolk Water has worked closely with AECOM to complete a desk based assessment and then develop a Written Scheme of Inspection.

This has now been approved by the council archaeologist and comprises 552 trenches measuring 2m x 30m across a 40m corridor along the 20km pipeline route. This work will be completed over a 16 week period, 8 weeks for the field work and a further 8 weeks for recording and report preparation. Due to the archaeological history in the area it is expected that some archaeological artefacts of interest will be uncovered. This may in turn necessitate further mitigation trenching along the route.

Layer to Langford Pipeline – Supply chain (as of June 2023)

- Principal designer: Stantec UK

- Ground investigation: Allied Exploration & Geotechnics

- Land owner engagement: Savills

- Technical input: Saint Gobain PAM UK

- Archaeology: AECOM

- Pipe installation: Northumbrian Water

- Pipe supplier: Electrosteel Castings (UK) Ltd

Schedule

The installation of the majority of the 20km pipeline will begin in February 2024 in order to complete the work in March 2025, allowing Essex & Suffolk Water’s in house team to complete the installation in one pipelaying season.

Work has already commenced on a number of minor road crossings to coincide with the work of other developers in the area and minimise impact on our customers. Work is also scheduled to commence on the directional drill crossing that will be required beneath two main rivers as part of the project, the River Blackwater and the Langford Cut in September 2023.