Lee Tunnel – Introduction (2011)

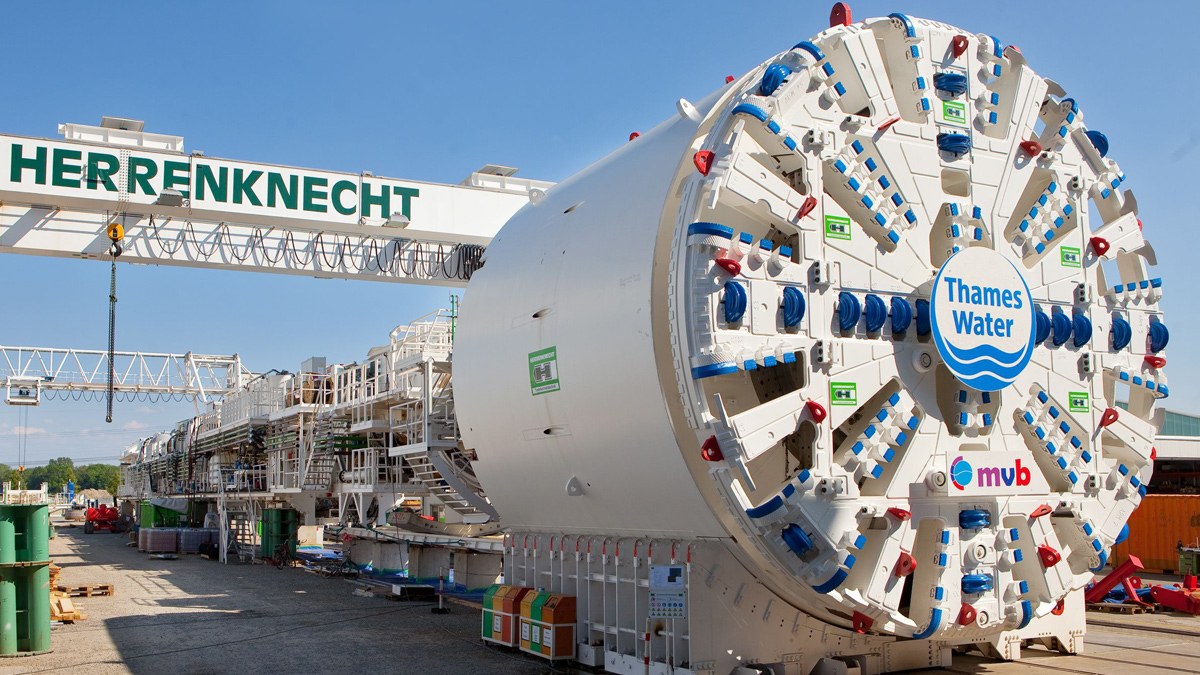

The Lee Tunnel mixshield slurry tunnel boring machine - Courtesy of Herrenknecht AG

For the last 150 years, London’s wastewater has been disposed of through an elaborate network of interceptor sewers built by Victorian engineer, Sir Joseph Bazelgette. This system was a single combined stormwater and sewer network, which incorporated over 50 (No.) Combined Sewer Overflows (CSOs) to the River Thames and the River Lee. These overflows were designed to operate only during occurrences of exceptionally heavy rainfall, but now significant discharges happen, on average, at least once a week, and can be triggered by as little as 2mm of rainfall. The discharges exceed the requirements of the Urban Wastewater Treatment Directive (UWWTD) as enacted in the Urban Wastewater Treatment Regulations 1994. To comply with the UWWTD, Thames Water have proposed a programme of work to upgrade London’s five principal sewage treatment works (at Mogden, Crossness, Beckton, Long Reach and Riverside), as well as undertaking two major tunneling projects, which will collect and transfer both foul sewage and storm water run-off to the upgraded and enhanced treatment works. This article details the first of the two Thames Tideway Tunnels, the £635m Lee Tunnel.

Concept

At the Abbey Mills Pumping Station in Stratford, east London, a single Combined Sewer Overflow is responsible for about 40% of all stormwater flows into the River Thames. The 6.9km long, 7.2m diameter Lee Tunnel will carry these stormwater flows from Abbey Mills to Beckton Sewage Treatment Works (STW), which is to be upgraded and expanded to ensure that the facility can handle these additional stormwater flows. The Lee Tunnel is the first project to get under way in Thames Water’s London Tideway Improvements scheme, which will return the River Thames to an acceptable state of cleanliness by 2020.

Aerial view of Abbey Mills site – Courtesy of Thames Water

The shafts

The project includes four permanent large diameter shafts, three sited at Beckton STW and the fourth at Abbey Mills. The shafts are sized and function as follows:

Beckton Overflow Shaft: 20m internal diameter and 74.5m to invert level.

The Beckton Overflow Shaft will serve as the TBM launch shaft. On completion of the project, the shaft will connect directly to a new outfall channel to the River Thames, which will be constructed as part of the project.

Beckton Connection Shaft: 25m internal diameter and 78.5m to final invert level.

The Beckton Connection Shaft is directly on the line of the main tunnel, and will transfer the tunnel sewage flows into a separate suction tunnel, passing from the Connection Shaft to the Pumping Station Shaft.

Beckton Pumping Station Shaft: 38m in internal diameter and 86.5m to invert level.

Centered 60m from the Connection Shaft, the Beckton Pumping Station Shaft will house up to 6 (No.) 3MW pumps, which will transfer the tunnel sewage flows for treatment at the Beckton STW. The Pumping Station Shaft will feature a full height dividing wall, so that it can operate fully on one side in the event that there is a flood or other emergency failure of the other side, serving both the needs of the Lee Tunnel prior to completion of the Thames Tunnel, and thereafter the whole of the Thames Tunnel network.

Abbey Mills Connection Shaft: 25m internal diameter and 68m deep.

During the construction phase, the Abbey Mills Connection Shaft will serve to receive the TBM of the main tunnel drive. When the project is complete, it will transfer sewage flows from two pumping stations (A and F) to the main tunnel by means of a series of cascade platforms.

Shafts under construction – Courtesy of Thames Water

Other components

The remaining major components of the Lee Tunnel project are:

- Beckton Outfall Channel – A new outfall channel will be constructed from the top of the Beckton Overflow Shaft to the River Thames, at a point well downstream of the intake of a recently commissioned desalination plant, also located at Beckton. This channel will enable the direct discharge of excess flows during exceptional storm events.

- Surface infrastructure at Beckton STW, including odour control plants, screen cleaning plant at the head of the Connection Shaft, ventilation plant at the head of the Pumping Station Shaft, and a new power supply complex.

- New surface culverts and sewerage flow connections at the Abbey Mills Pumping Station complex.

Contract

In January 2010, Thames Water awarded the main contract to design and construct the Lee Tunnel to the MVB joint venture. MVB is a consortium of three major engineering companies:

- Morgan Sindall plc (formerly Morgan Est plc).

- VINCI Construction Grands Projets SAS.

- Bachy Soletanche Limited.

MVB has in turn appointed three organisations to provide design services:

- Mott MacDonald: Shafts civil engineering (other than diaphragm walls), hydraulic engineering (other than main tunnel and Shaft F), and mechanical, electrical, instrumentation, controls (MEICA) engineering.

- Underground Professional Services: Tunnels and surface structures engineering.

- Bachy Soletanche Ltd: Shafts diaphragm walls engineering.

Additionally, Donaldson Associates Limited has been appointed as Category III design checker.

The Lee Tunnel contract has been let as a target cost, using the New Engineering Contract (NEC) 3rd Edition Option C with Activity Schedule. The employer is Thames Water and the project manager and supervisor is a CH2M HILL-led team. The Project Management Team’s (PMT’s) duties comprise administration, on behalf of Thames Water as employer, of contractual, technical and commercial aspects of the contract. All permanent works designs, as well as temporary works designs, which may impact the permanent works or are otherwise deemed significant, require the acceptance of the project manager.

Beckton STW – Courtesy of Thames Water

Design

Prior to contract award, Thames Water developed a reference design for the Lee Tunnel, in line with the concept described previously. The contract’s specification, part of the works information, describes performance requirements for which a detailed design is to be developed, based upon the reference design.

The main tunnel drive has a number of unique features and challenges in relation to tunnelling beneath London. It will be the deepest tunnel ever constructed beneath London, and will encounter a full face of flint laden chalk, under groundwater pressures at up to 8 bar.

Accordingly, the particular specification for tunnelling prescribes the permitted types of Tunnel Boring Machine (TBM) – Earth Pressure Balanced Machine (EPBM) or Slurry Pressure Balanced Machine (SPBM) – and detailed requirements for many items including excavation system and spoil treatment, ground settlement control, cutters and cutterhead interventions, grouting systems, and seals.

The specification for the design and supply of the precast concrete segmental tunnel linings is similarly very detailed in respect of the requirements for design, materials and testing, especially for the gaskets.

Tunnel lining

The main tunnel drive and all four shafts will be double lined throughout their full extent. The primary lining for the main tunnel will be 350mm thick fibre reinforced precast concrete segments installed as the TBM progresses. The secondary lining will be constructed of 300mm thick fibre reinforced in-situ concrete cast within travelling shutters. Double linings have been adopted to ensure water tightness, since this tunnel system is very deep and will experience high differential fluid pressures, both due to groundwater pressures when empty and when surcharged by the sewage fluid.

The primary walls of the shafts are being constructed of reinforced concrete diaphragm wall panels, with thicknesses of 1.2m, 1.5m or 1.8m depending on the diameter and depths of the shafts.

Aerial view of Beckton Pumping Station and Connection Shafts site – Courtesy of Thames Water

Construction at Beckton

In the first half of 2010, MVB was largely occupied with the setting up of its project specific design and construction procedures, and initiating the development of the reference design. It took possession of existing construction site offices at Beckton STW, and proceeded with site establishment. On 30 September, a groundbreaking ceremony took place at the Beckton Overflow Shaft site to mark the start of diaphragm wall construction.

While wall panels continued to be constructed for the Beckton Overflow Shaft, the other site was being prepared for diaphragm wall construction to start for the Pumping Shaft in January and for the Connection Shaft in February 2011. A further site at Beckton has been used to establish a concrete batching plant, which now supplies all concrete for the diaphragm walls.

Construction at Abbey Mills

The project’s other major construction site is centred on the Abbey Mills Connection Shaft. Enabling works here commenced early in 2011 with the diaphragm walls planned to start in August 2011. Works at Abbey Mills also involve constructing considerable changes and extensions to the existing surface culverts leading from Pumping Stations A and F, and enhancements in the vicinity of the existing outfall culvert.

Diaphragm wall excavation has proceeded by means of a soil grab through the re-excavated material and a ‘hydrofraise’ suction cutter for the underlying soils and chalk. The hydrofraise has two heavy duty wheels with cutters attached, which rotate to break out the ground. The arisings are being removed in bentonite slurry, which is pumped into the excavation. The wall panels are constructed in sequence with 7.2m wide primary panels formed from three passes of the hydrofraise concreted first, followed by a single pass secondary panel where the cutter removes part of the concrete from the sides of the adjoining primary panels to ensure waterproof joints.

The TBM was transported in sections from Germany in June/July 2011 – Courtesy of Thames Water

The tunnel boring machine

In April 2010 MVB let the design and construct contract for the supply of the Tunnel Boring Machine (TBM) to Herrenknecht AG, based in Germany. Named “Busy Lizzie”, the colossal machine measures 120m in length and at 8.88m in diameter is the width of 3 London buses. In June 2011, the machine was transported by barge in sections via Germany’s River Rhine to Rotterdam, before being shipped across the North Sea to Tilbury, on the Thames estuary in Essex, from where the sections were driven to Beckton STW in July.

The machine maintains the stability of the excavation face and removal of spoil using a slurry system, which is separated at a large slurry processing plant at the surface, before loading onto ships for transport to land reclamation further down the River Thames.

Current status

At the time of writing (July 2011) fabrication of the main tunnel’s primary lining segments is well underway at the Morgan Sindall Precast Concrete facility at Ridham, Isle of Grain, Kent. The major construction milestone in 2011 is completing the installation of the main tunnel TBM within the Overflow Shaft.

Tunnel excavation is planned to get underway very early in 2012, and completion to Abbey Mills due in the latter half of 2013. Thereafter the tunnel’s secondary lining construction will proceed, with all concrete being supplied from the site batching plant at Beckton. From early 2014 installation, testing and commissioning of all the MEICA equipment is programmed, leading to completion of the Lee Tunnel project in mid 2015.