Llyn y Fan Fach Reservoir (2024)

Llyn y Fan Fach Reservoir - Courtesy of Arup

Llyn y Fan Fach is a reservoir at the head of the Afon Sawdde, located within the Bannau Brycheiniog National Park. Constructed between 1914 and 1919 by conscientious objectors it raised the original lake by approximately 3m. The spillway for the reservoir is via a 6.1m ogee weir in the centre of the main dam. This discharges into a masonry and concrete stilling basin and spillway channel before flowing freely into the Afon Sawdde. The reservoir was previously used to supply water to a treatment works downstream but is now used to provide compensation flows to a fish farm that was created at the same location as the treatment works.

Inspection

Alongside routine maintenance, a Section 10 Inspection under the Reservoirs Act 1975 was undertaken on 15 October 2019. The inspection report stipulated the following Measures in the Interest of Safety (MITIOS):

- Arrest the structural cracking and eliminate leakage into the draw-off shaft. This will be in the form of a new structural liner to the valve shaft and sealing of the existing structure.

- The spillway apron and vehicle crossing will be reconstructed to safely convey the safety check flood.

The initial preferred option was discontinuance and returning the area back to its original state, however, the spillway structure was given a Grade II listed status in 2021 for special historical interest with its use of conscientious objectors for construction during WW1. Therefore, discontinuance was no longer a suitable solution and refurbishment was progressed through to design.

Spillway prior to works – Courtesy of Arup

Tower works design

To address the tower cracking and leakages several options were explored including concrete liners, conventional crack repairs, and partial rebuild of the tower. To assist with the design, an investigation was undertaken to determine the most likely driver of the cracking. This investigation reviewed the locations and history of the cracking and hypothesised that, due to thermal effects, a volumetric change of the dam walls that connect to the valve tower is inducing tension stresses in the shaft walls causing cracking exacerbated by environmental actions. An Finite Element model was developed to verify the tension stress areas that would be expected due to this action.

Owing to the size of the dam walls and the nature of the action it could not be effectively restrained, therefore the solution needed to accept these cracks as movement joints, prevent water ingress and protect the cracks from environmental actions that contribute to accelerated deterioration. The proposal consisted of the following three components:

- A glass reinforced plastic (GRP) liner that is flexible enough to accept the thermal strains of the existing dam wall elastically, whilst being strong enough to resist the hydrostatic loading from the reservoir. The GRP liner is also designed to withstand the environmental conditions within the tower as it is the primary means of preventing water ingress to the shaft. Arup worked closely with the supplier, iLine Technologies Ltd, to guide their design and verify it met the requirements.

- The existing cracking to be raked and filled with a flexible sealant. The sealant allows the cracks to continue to move. It is shrouded from UV radiation and temperature effects by a new façade to extend its working life.

- A new reinforced concrete wall on the upstream face of the tower to structurally replace the cracked valve tower wall. This wall is made of two leaves cantilevering from the dam walls with a movement joint down the middle. This structure will also insulate the cracks and their repairs from environmental effects as well as being the first line of water ingress defence with a waterbar around its perimeter and waterproofing admix.

(left) External lining construction – Courtesy of Arup, and (right) Installation of GRP lining from iLine Technologies Ltd – Courtesy of Morgan Sindall

Spillway works design

The proposal was to fully replace the lower spillway with a precast structure capable of passing the 1,000 year (design) and 10,000 year (safety) flood events for the Category B dam. The wall heights were designed to contain the flows including full USBR freeboard. In order to maintain cultural heritage of the existing spillway, the spillway was lined with stonework.

Llyn y Fan Fach Reservoir: Supply chain – key participants

- Main contractor/designer: Morgan Sindall Infrastructure

- Consultant designer: Arup

- Mechanical contractor: Whitland Engineering Ltd

- GRP liner: iLine Technologies Ltd

- Precast concrete: FLI Precast Solutions Ltd

- Formwork: Cordek Ltd (using Filcor 90)

- Shuttering support: PERI UK

- Concrete repair: Beton Bauen Ltd

- Underwater survey/repairs: Edwards Diving Services

- Over pumping: Pump Supplies

- Valves: Glenfield Invicta

Delivery

Constructing this scheme was going to be challenging due to the site constraints including remoteness, narrow access roads, SSSI areas, National Park status, listed structures, bridge weight limits and popularity of the location with members of the public. From the main site office to the working area there was a 240m altitude difference over the 2.4km access road.

Due to the site location, opportunities for off-site fabrications were maximised to minimise the challenge of getting fresh concrete to the working area. Due to the distance from the concrete batcher, narrow access roads and having to offload concrete for transportation to the dam, it would take nearly two hours to get concrete to the work-face.

A significant constraint was the low clearance and low capacity bridges on approach to the site. This restricted the size of plant that could be transported and in turn, the size of components that could be handled. Therefore a large number of precast concrete units were required to make up the spillway structure with a considered and minimised use of in situ stitches. Another example where this constraint influenced delivery was that the tower required GRP sections with a 2.7m internal diameter being transported over a 2.4m wide bridge. The rings were therefore formed in half sections and assembled in situ.

(left) Lined tower – Courtesy of HR Wallingford, and (right) Completed external lining – Courtesy of Morgan Sindall

The use of prefabricated products gave the additional advantage of reducing site risks from concrete washout, excess materials, reduced potential quality issues, minimised working at height and reduced amount of plant to be transported to the working area. This also helped to reduce the overall programme had conventional methods been used and had a positive effect on minimising the construction impact and carbon footprint on the project.

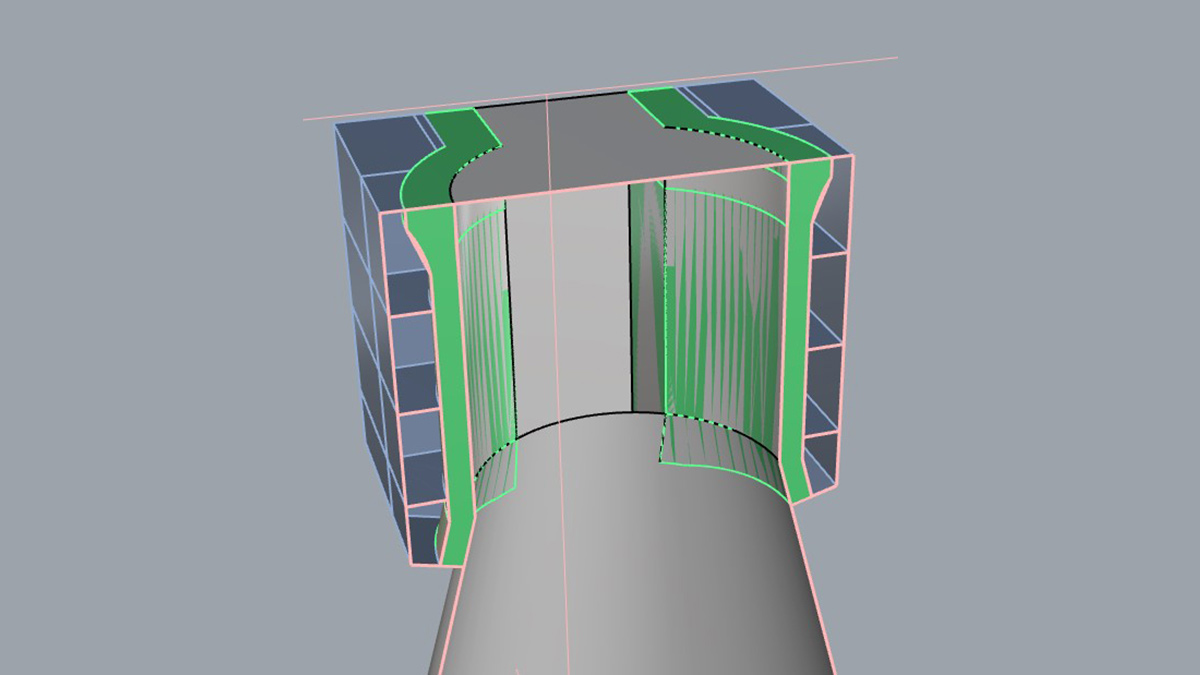

The site team utilised Filcor 90 expanded polystyrene shuttering from Cordek Ltd to make the external repairs to the drawdown tower and dam face. This innovative shuttering solution used the output from 3D surveys to fabricate the intricate curvature of the existing tower and corbel detail and then mold the shuttering off site, allowing delivery to site in manageable sections. Given the location of the dam, the at times poor weather conditions the site team faced, traditional timber shuttering would not have been able to form the shape of the tower.

3D external formwork – Courtesy of Morgan Sindall

Demolition and reconstruction of the spillway was the most critical aspect of the project due to the inherent risks on the dam structure from scouring if it were to spill during construction. Water levels in the reservoir were lowered to provide a minimum storage capacity for a 1 in 150 year storm event as was stipulated by the Welsh Water Dam Safety Team and QCE.

To ensure that water levels were managed in the reservoir throughout the scheme, a temporary storm pumping system was established using 12” electric pumps. The pumps were located on floating pontoons on the reservoir to keep them off the reservoir bed to avoid silt issues. Due to the criticality of the works, a Dam Safety Construction Management Plan was developed to control any increased risk to the safety of the dam during construction. Duty and standby pumps and generators were installed with auto changeover facility and telemetry systems that would automatically call out personnel in the event of an issue.

Under normal operating procedures, water from the reservoir was drawn off using a submerged siphon pipe which passed through the draw off tower, tunnel and down the mountain. The first valve on the siphon pipe located in the tower had to be replaced requiring our specialist diving contractor to install a temporary blanking plate within the reservoir to stop flows in the pipeline.

An additional temporary over pumping set up was installed to maintain the required flows down the mountain to supply the local fish farm. Isolating flows enabled the removal of the existing valve and replacement with two new units and pipes and subsequent re-commissioning of the siphon pipe. Remote operated vehicles were used to minimise manned diving and also to prove isolations before anyone entered the water. All diving works were closely managed with the site management and client representatives by operating under “gold command” which provides detailed planning and scrutiny of all activities to always ensure the safety of personnel.

A biodiversity enhancement scheme was undertaken to help improve the local environment and offset the impact of the works which saw the planting of over 200 new trees and the installation of a dipper box by the main watercourse.

Spillway construction and lining – Courtesy of Morgan Sindall

Summary

The scheme was completed in two phases from July 2022 until late December 2022 and from May 2023 to September 2023 and delivered successfully on time. Completion of the scheme has now provided Welsh Water with an asset that they can operate for many years to come and has enabled them to close off their statutory obligation under the Reservoirs Act 1975.

Throughout the scheme there were no reported accidents or injuries and a great safe working and positive intervention reporting culture was clear to see. “How Are We Doing?” feedback was obtained through the project from Welsh Water and received excellent comments. The scheme has also now been signed off as achieving Perfect Delivery by Welsh Water which is a testament to the hard work and professionalism shown throughout all stages of the project.