Ovingham Raw Water Pumping Station (2023)

(L) Vertical turbine pumps from Bedford Pumps Ltd and (R) formed suction intake fitted prior to lifting of the pump - Courtesy of MMB

Northumbrian Water’s Ovingham Raw Water Pumping Station (RWPS) is an abstraction station located on the north bank of the River Tyne in South Northumberland between the towns of Wylam and Ovingham. The station provides raw water from the River Tyne to Horsley Water Treatment Works (WTW) and the Great Southern Reservoir at Whittle Dene WTW. Treated water is then pumped to Birney Hill Reservoir and supplies the City of Newcastle upon Tyne and Tyneside with a population in excess of 800,000.

Background

There are two delivery mains to Horsley WTW (eastern and western mains), and the pumping station currently contains six pumps (four fixed speed Pleuger pumps and two pumps on variable speed drives). In the recent years these pumps have suffered multiple failures which puts at risk the supply of raw water to the WTW. A feasibility report completed in March 2016 stated that the root cause of historical mechanical failures of the existing pumps is a large volume of silt being carried over into the pump bays when the river is in flood. There are also operational and maintenance issues around the current high voltage inverters and drives.

Northumbrian Water Group (NWG) appointed Mott MacDonald Bentley (MMB) to investigate viable options for pump replacement in 2018 and the pump options returned by suppliers were for submersible pumps, submersible borehole pumps, axially split casing pumps, and vertical turbine pumps. MMB and NWG agreed that vertical turbine pumps (VTPs) were the most appropriate pump option for the site and the pumping station was designed to the following duty requirements:

- Deliver 110.7 MLD (1280 l/s) with a standby pump available.

- Deliver 154.7 MLD (1791 l/s) with all pumps running, including the standby pumps.

- Be capable of a minimum station flow of 40 MLD (462 l/s).

- Be capable of feeding Horsley and Whittle Dene simultaneously.

- Provide the full range of flows between these figures, whether the river is at LWL, HWL, or anywhere in between, and irrespective of whether delivering up the east main, the west main or both.

- Be most efficient at 106 MLD (1226 l/s).

Following a tender process Bedford Pumps Ltd were chosen to supply the new VTPs.

Ovingham RWPS – Courtesy of MMB

Scope of the works

- The replacement of two existing variable speed pumps with a duty of 384 l/s with two Bedford Pumps VTPs c/w 680kW IP 68 motors capable of pumping 452 l/s and minimum solids handling capacity of 25mm to improve the pumping and solids handling capability of the station.

- The installation of two floor-mounted high efficiency 3.3kV 680kW drives air cooled variable speed drives and a new PLC control system.

- Associated heating, ventilation and air conditioning (HVAC), steel support beams, platforms and electrical/instrumentation works.

Ovingham RWPS: Supply chain – key participants

- Client: Northumbrian Water

- Construction delivery partners: MMB

- Hydraulic modelling: Mott MacDonald

- Topographic surveys: Atlantic Geomatics

- Geotechnical & environment Investigation: Dunelm Geotechnical & Environmental Ltd

- Vertical turbine pumps: Bedford Pumps Ltd

- Electrical installation: Intelect (UK) Ltd

- Local control panels: Blackburn Starling Ltd

- Systems integration: IDEC Technical Services

- VSD design & installation: Quantum Controls

- VSD construction: Schneider Electric

- Metalwork: JHT Fabrications

- Kiosks: Morgan Marine

- Surge system integration: Quantum Engineering Developments Ltd

- HV Cabling: Integrated Utility Services

- Pump refurbishment: Fluid Sealing & Engineering Ltd

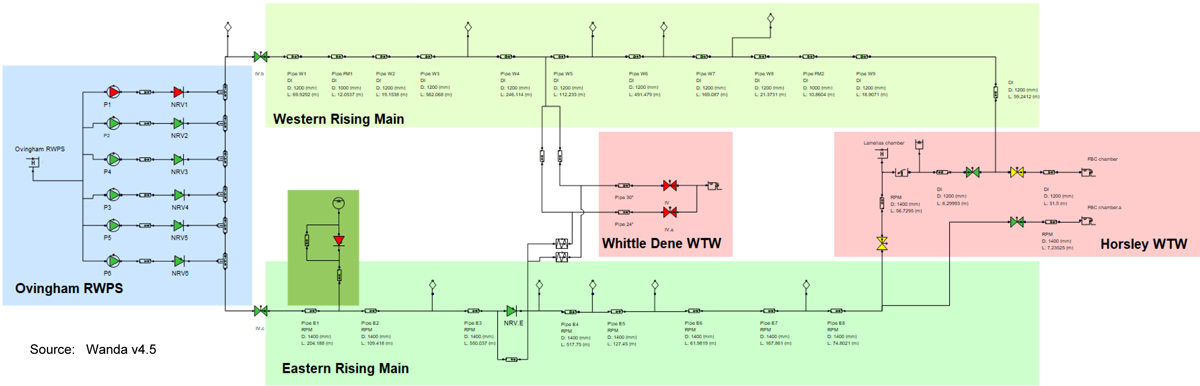

Hydraulic model schematic extract from Ovingham RWPS Refurbishment Technical Note – Courtesy of MMB

Detailed design and engineering challenges

Hydraulic analysis: A hydraulic model of the delivery mains (eastern and western mains) was built in Deltares WANDA v4.5 to calculate the steady state and transient pressures for a number of different operating scenarios. The maximum operation flows are 165 MLD (eastern main) and 180 MLD (western main). The subsequent technical note recommended the following:

- Ten existing air valves should be refurbished and four new air valves should be installed to the eastern and western main (completed).

- The 35.98m3 surge vessel on the eastern main should be replaced (future works).

- A surge vessel should be installed on the western main (completed).

- Fast acting double plate non-return valves should be installed on the pump outlet pipes (future works).

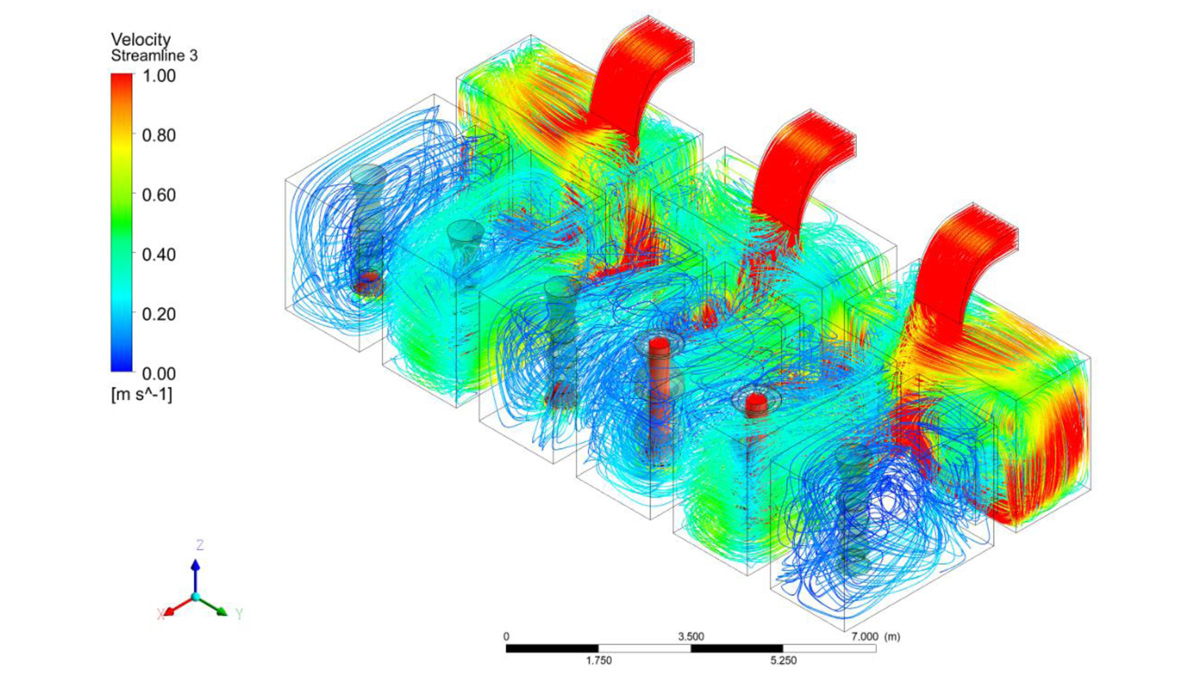

CFD modelling: Computational fluid dynamics (CFD) was carried out to assess the most suitable wet well location to install the VTPs to minimise potential adverse hydraulic effects that could be induced by the joint operation of the VTP and Pleuger pumps. The modelling report recommended that the VTPs should be installed in wet wells No. 3 and 4.

Extract from Ovingham RWPS CFD modelling report – Courtesy of MMB

Cooling water: The motors installed on the new pumps needed to be IP68 due to the high likelihood that the RWPS would flood up to roof level, therefore fan-cooled motors were not suitable. The motors were supplied with a helical design cooling water jacket which was extensively tested in the motor supplier’s works. A number of options were considered to provide cooling water to the VTPs:

- Automatic changeover duplex strainers using rising main pressure.

- Potable water closed loop or ‘once through’ systems.

- Duty/standby automatic flushing filters.

- Duty automatic flushing filter with static filter standby.

Due to the lack of spare low voltage capacity within the station and the lack of a nearby potable water supply Option 2 was ruled out. Option 3 was discounted due to lack of space but will probably be installed in the future when MMB complete the design of new eel screens at the site. Option 4 was discounted due to the amount of maintenance intervention.

Option 1 was therefore designed and installed with automatic switch over between baskets on high pressure drop to enable a basket to be cleaned while the pump is in service. A pressure reducing valve was required to reduce the pressure from 10 bar down to 5 bar and this fitting has experienced pressure drops due to leaf debris passing through the inlet screens and so the layout will be modified.

Electrical and instrumentation works: This element of the works included:

- Design, supply and installation of two off high efficiency, air cooled 3.3kV 680kW variable speed drives. This involved the de-commissioning and removal of the existing drives.

- Design and implementation of modifications to the existing 3.3kV Switchboard to allow the new VSDs to interface with the control circuit within the switchboard.

- Upgraded ventilation to the MV switch room to ensure the new VSDs operate at a suitable temperature.

- Bespoke local instrumentation/monitoring panels for the new pumps. Rather than adopt the standard panel offered by Bedford Pumps, bespoke panels were designed to integrate both the pump instrumentation and external instrumentation.

- A new PLC and remote I/O panel were installed to accommodate all of the new I/O associated with the systems being installed. Fibre optic cabling was employed to reduce long lengths of traditional cabling being installed.

- Systems Integration at site level and full SCADA integration at Horsley to provide the client with local and remote operation.

Vertical turbine pumps from Bedford Pumps – Courtesy of MMB

Heating ventilation air conditioning (HVAC): Heat gain within the building due to pumps, MCCs, screen motors etc. was modelled to ensure that during the summer the temperature within the building did not exceed 40° C when the external temperature was 30°C and during the winter the temperature within the building exceeded 5°C when the external air temperature was -5°C. Side wall mounted LPCB SR4 security rated aluminium louvres with a 30% free area were specified to the east and west of the building along with a 370W fan to extract warm air.

Noise assessment: A pre-works noise survey was carried out to give a base line. The subsequent report found that plant noise breaking out of the station was low and so recommended that the design target noise levels for the replacement plant should be to achieve the same output noise level. Achieving these noise levels would ensure the adjacent properties would not be detrimentally affected.

Construction

Site works commenced March 2021 and ran through until October 2022. The client insisted that as the pumping station was a key operational asset it must stay operational throughout the works and so a big challenge was to complete the works whilst providing critical raw water supplies up to Horsley WTW. The pumping station which is situated in a rural location in Northumberland brought its own logistical challenges. Site staff had to consider that any plant used for lifting operations could be demobilized and moved from site prior to a flood event at short notice.

Access to the pumps was via six large openings in the roof and covered by heavy concrete slabs. All lifts were done ‘blind’ and planned to precision to ensure everything ran smoothly with some complex lifts carried out.

An adjacent HV building supplied power to the pumping station and required the installation of new VSDs. An environmental survey confirmed the presence of bats and so site staff ensured a qualified ecologist was on hand to make sure the bats and their roosting spots were not disturbed. The works were monitored and carried out during selective working hours. Following the successful completion of the works the ecologist confirmed the bats had not been affected.

Ovingham RWPS east elevation – Courtesy of MMB

Customer

NWG are very keen on community projects and ‘leaving a legacy’. MMB carried out works to refurbish park benches at Wylam Village and to refurbish the sports pavilion at Ovingham as a thank you to the local community for any disruption during the works.

Looking ahead

MMB were asked to design and construct a new surge vessel for the western main. This work was completed in September 2022 alongside the VTP works. New travelling band screens compliant with The Eels (England and Wales) Regulations 2009 are also required and MMB are currently at the design stage with a view to starting on site May 2023. New non return valves (NRVs) and replacement of the eastern main surge vessel is also expected to start in 2023.