Parkmore Pumping Station & Trunk Main (2023)

(left) Isolation valves installed to the south-side of the bridge structure and (right) inside the new modular Parkmore Dungonnell Water Pumping Station - Courtesy of WSP

Northern Ireland Water’s Cushendall Water Pumping Station (WPS) is housed on the outer perimeter of Dundonnell Water Treatment Works (WTW) situated on the outskirts of Cargan village in the middle of County Antrim. The WPS solely supplies Parkmore Service Reservoir (SR) with potable drinking water, which in turn gravity feeds three other downstream SRs (Knockans, Mullarts and Knockenny), which provide for the surrounding Glen’s of Antrim district. Parkmore SR has a capacity of 1.3 ML suppling a population equivalent of approximately 2000 with an average day demand in peak week (ADPW) of 17.6 l/s.

The existing trunk main

The Cushendall Water Pumping Station to Parkmore Service Reservoir Trunk Main was constructed back in the 1970s using 6” PVC pipeline across bog land on mountainous terrain outside Cargan village. This has posed operational problems over the years when locating and repairing any leakages or bursts. Repair machinery has become stuck and unable to navigate the poor ground conditions raising access issues and Health & Safety concerns for staff and operatives attending repair works.

Some bursts in the off-road pipeline have caused expensive tankering operations to keep the ~2000 customers with a reliable supply of potable drinking water to the villages of Cushendall, Cushendun and Glenariff. In addition, the existing Cushendall WPS has been difficult to maintain due to the age of the surge vessel, panels and pumps.

Project scope

NI Water, as part of the IF105 Integrated Partnerships Framework, identified the need to relocate the Cushendall WPS and associated trunk main due to the ongoing operational problems and supply outages.

The new scheme included the following scope:

- A new modular, prefabricated, modular, plug and play water pumping station located in the verge close to a picnic area off the Glenravel Road, approximately 0.5km south of Cargan Village, Co. Antrim.

- Connection to the existing 18” trunk main in the same picnic area, and approximately 400m of new suction main to deliver water to the new pumping station.

- Approximately 2km of new 225mm HDPE rising main to deliver water to Parkmore SR installed in the carriageway for improved access.

- Alternative connections to live tanks at Parkmore SR (non-siphoning), including baffle curtain works and the addition of a 200mm bypass and meter.

- Civil and MEICA abandonment works of existing Cushendall WPS, and re-tapping the existing chlorine residual pump.

Dual lay pipework inside steel sleeves – Courtesy of WSP

Detailed design and engineering challenges

Following ECI works in October 2021 by the Farrans/Glanua Group Joint Venture under a NEC4 option ‘A’ contract, engineering designs were undertaken comprising of a range of elements including:

- Proposed trunk main route, longitudinal sections, and connection details.

- Scheme plans with details on bridge crossing and new water pumping station location.

- Reinforced concrete slab drainage and ducting detail for modular pumping station.

- Surge analysis report and proposals.

- Hydraulic assessment of the new trunk main with total head loss, average flow, and peak flow information.

From these reports it was concluded that surge could occur when the pump flow increased or decreased to suit changing water demands or uncontrolled sudden pump failure. From this the WPS was designed with a 500-litre bladder type surge vessel in accordance with the selected 38Kw pumps chosen for a 35 l/s and 7 bar charge arrangement. The rising main was designed with six air valves to aid high/low pressure spikes or transients during operation.

The hydraulic analysis of the new rising main from the picnic area to Parkmore SR, using the average day demand in peak week (ADPW) of 17.7l/s, calculated a total head loss average flow of 1.10m and peak flow 3.09m for the total 4.2km of the 225mm HPPE pipeline.

Construction

The construction contract was awarded under NEC4 Option ‘C’ Target Cost Contract to Farrans/Glanua Group JV. Construction began in December 2022 and took place over a 14-month period at a total cost of £1.3m. The scheme was situated in an Area of Outstanding Natural beauty, this brought its own unique constraints and limitations.

Due to ground conditions, opencut excavations was the method of installing the 2km of 225mm HPPE pipe under a DFI Roads approved lane closure using a rolling traffic light system operated and maintained by traffic management company, McVeigh Contracts Ltd.

(top left) traffic management barriers, (bottom left) notice of works and lane closure for pipeline installation and (right) pipeline track excavation – Courtesy of WSP

Bridge crossing

Following trail holes and liaison with DFI Roads at ECI stage, two sections of 180mm HPPE pipework were installed inside 250mm steel sleeves and C30 concrete and steel mats used for protection over the span of the 35m bridge structure.

A reduced road cover level of 700mm was agreed and approved with DFI Roads to ensure the structural integrity of the underside of the bridge remained unchanged.

Parkmore Service Reservoir works

In tandem with the construction of the pipeline, a specialised company Waterworx Ltd carried out the alteration works to the live Parkmore SR. Each cell was shut off and drained individually to aid the installation of the inlet pipework and repositioning/installation of the new baffle curtains.

All of the SR works were undertaking in close liaison with NI Water Operations who ensured stringent drain down and sampling timelines to ensure continuous water supply the local area.

(left) the existing baffle curtain and (right) new anti-siphon inlet pipework and baffle curtain at Parkmore Service Reservoir – Courtesy of WSP

Modular pumping station

The new modular ‘plug and play’ WPS included the following elements:

- Pumping system and associated ancillaries.

- Control panels.

- Telemetry.

- Surge suppression.

- Building services.

The kiosk and skid base of modular pumping station was supplied by Morgan Marine Ltd. The assembly of the mechanical and electrical items were completed at Profitec Solutions’ headquarters in Cookstown. Electrical switchgear was built into the kiosk to facilitate an external portable generator in the event of mains supply failure.

Following a factory acceptance test, the modular WPS was delivered to site in November 2022 and craned into position on top of the 450mm reinforced concrete base slab. For the inlet supply to the WPS an under-pressure Tee was installed onto a live existing 450mm cast iron trunk main, this allowed for seamless transfer to the new section of trunk main without any disruption to current trunk main supply in the district.

Parkmore Water Pumping Station & Trunk Main: Supply chain – key participants

- Delivery contractor: Farrans/Glanua Group JV

- Design/project management: WSP

- Civil Design: Jacobs Design

- Main Contractor (Civils): Farrans

- Main Contractor (M&E): Glanua Group

- Civil team: McCormick Contracts Ltd

- Electrical works: Profitec Solutions

- Traffic Management: McVeigh Contracts Ltd

- Kiosk for new WPS: Morgan Marine Ltd

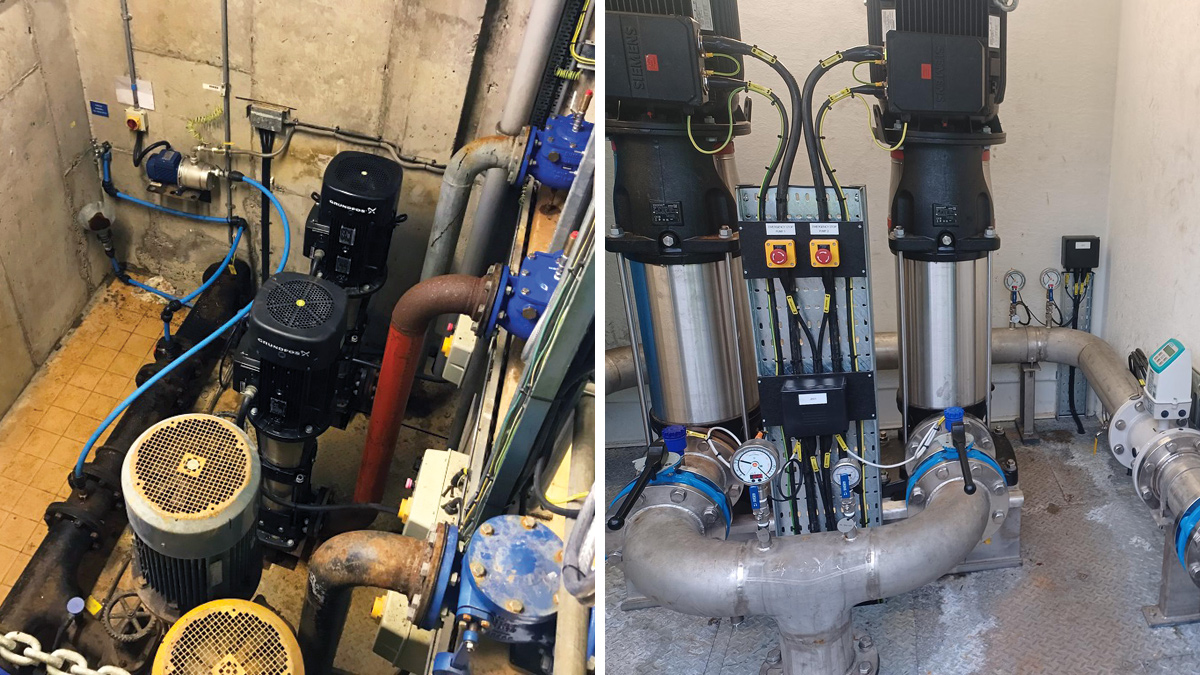

- Pumps: Grundfos

- Under-pressure tee connection: Waterworx Ltd

- Quarry products & reinstatement: Northstone Materials Ltd

- HDPE pipe: APP Fusion Group

- WPS automatic control (PLCs & HMI): Mitsubishi

Mechanical, electrical and instrumentation works

The Parkmore WPS consists of two Grundfos 38 KW CR125 booster pumps working on a duty/standby regime which can be controlled manually or automatically by way of variable speed drives. The duty/standby system is set to switch over after each pump stop its programmed cycle.

(left) The existing Cushendall WPS and (right) the new Grundfos pumps and inlet/outlet pipework – Courtesy of WSP

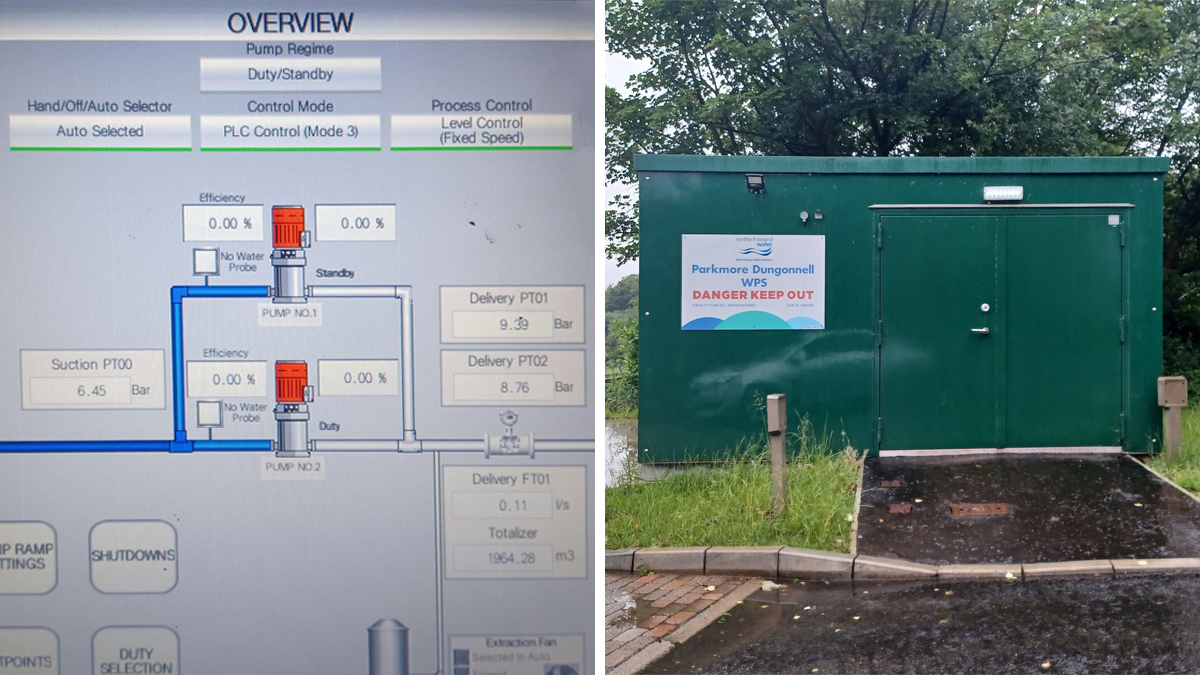

The two modes of control available are the primary, level-based control, and the secondary, pump fixed speed mode control. The chosen method by the client is the level-based method, remotely controlled on Telemweb with agreed low and high Parkmore Service Reservoir set-point levels (pumps on at 2.2m and off at 2.8m).

The WPS automatic control is achieved using a Mitsubishi iQ-R series Programmable Logic Controller (PLC) system attached to a 12” Mitsubishi GOT Human Machine Interface (HMI). The PLC communicates status/alarms/events and exchanges set-points between the PLC and the telemetry talus unit via Modbus RS232. Critical status, alarms and controls are hardwired to/from the telemetry talus unit.

The HMI provides information to the MCC for pumps 1&2 with the following list of options for NIW operatives to manually operate inside the WPS:

- Plant data.

- Plant mimics.

- System screen.

- Control system settings.

- I/O test pages.

- Trends and alarms.

(left) HMI screen and (right) Parkmore Dungonnell WPS – Courtesy of WSP

Project summary

Commissioning of the new pumping station began in early January 2023 and the existing pumps at Cushendall Pumping Station were turned off, allowing the 28 days commissioning period to begin. Following a successful testing period and training of NI Water Operatives, the new Parkmore Pumping Station is solely suppling the strategically important Parkmore Service Reservoir regularly during the day.

The redundant Cushendall WPS has been electrically isolated and associated pipework has been sealed and capped off. To date the new pumping station has supplied over 60,000m3 of clean drinking water to Parkmore SR and has proven to be a resilient and reliable trunk main asset to NI Water.