Roundhill & Lower Gornal STWs (2023)

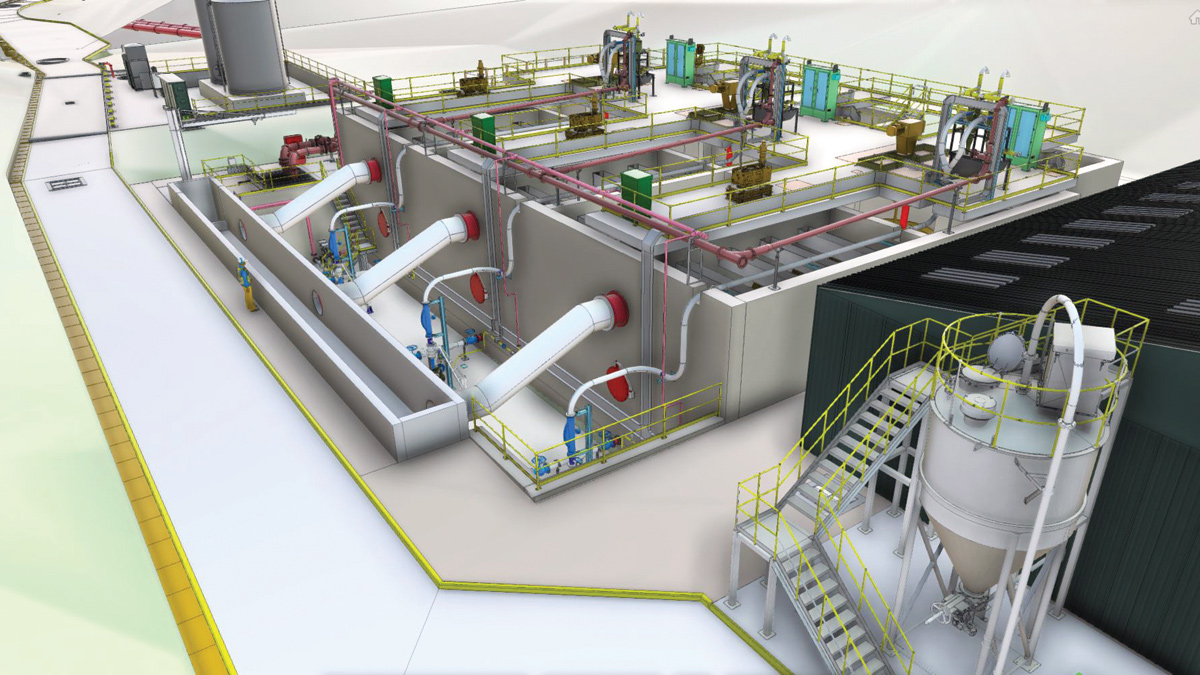

BIM image of Roundhill STW proposed TSR Area - Courtesy of Mott MacDonald Bentley, Veolia Water Technologies & EPS Water

Roundhill Sewage Treatment Works (STW) is a large wastewater treatment site in the Severn Trent region serving Stourbridge and the surrounding area. It treats a flow to full treatment (FFT) of 1781 l/s and a population equivalent (PE) of around 300,000. The works was extensively rebuilt around the year 2000, with the large rectangular biofilters and humus tanks replaced with five radial primary settlement tanks (PSTs), a 6-lane activated sludge plant (ASP) and, to date, seven radial final settlement tanks (FSTs). Lower Gornal STW is a medium sized wastewater treatment site located around 10km to the north of Roundhill and serving the Lower Gornal area of Dudley Borough. It treats a FFT of 253 l/s and a PE of around 35,000. The works has been steadily expanded over the past 50 years and today operates four radial PSTs, 19 radial biofilters and a combination of two radial and four Dortmund-type humus settlement tanks (HSTs).

Drivers & solutions

As part of the AMP7 programme of work, Severn Trent raised schemes at both sites with the aim of meeting reduced phosphorus and ammonia permits. Roundhill STW had tightening consents of 0.25mg/l (down from 1mg/l) for phosphorus and 4mg/l (down from 5mg/l) for ammonia, whilst Lower Gornal STW’s consents were tightening to 0.3mg/l phosphorus (from 2mg/l) and 1.5mg/l ammonia (from 10mg/l).

The proposed solution from Severn Trent’s outline design was to close the site at Lower Gornal and replace it with a terminal pumping station which would transfer all non-storm flows to Roundhill. Roundhill in turn would receive upgraded treatment equipment in the form of an additional ASP plant, new settlement tanks, a new tertiary solids removal (TSR) plant, and upgrades to the primary and secondary sludge thickening streams to manage the additional flows from Lower Gornal and another site proposed for closure at Kinver.

Background to the Mott MacDonald Bentley early contractor involvement

Mott MacDonald Bentley (MMB), along with other Severn Trent Tier 1 Contractors, had previously been asked to price the non-Infrastructure scheme at Roundhill STW (the closure of Lower Gornal and associated infrastructure project was to be treated differently by Severn Trent at the time) but an agreement on target cost was not met. Challenges with the variance to the original affordability targets set by Severn Trent were the principal issue and led to Severn Trent wishing to take a different approach to reduce costs associated with the works at both Roundhill and Lower Gornal.

Severn Trent invited a team of operational, design and commercial staff from MMB to complete an early contractor involvement (ECI) for the scheme with a view to improving on the unfavourable cost position to which the schemes were subject.

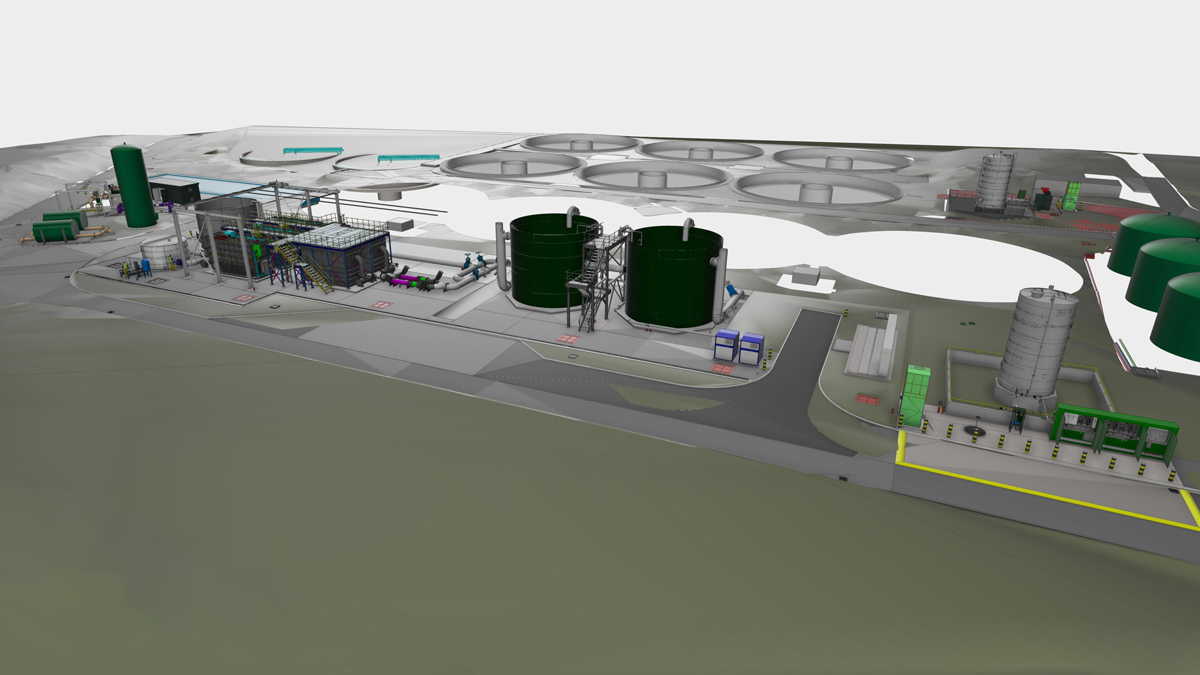

BIM image of Lower Gornal tertiary area – Courtesy of MMB, Colloide, FLI Water and Eliquo Hydrok

Execution of the ECI contract

To deliver the cost efficiencies that Severn Trent were looking for between the two schemes, MMB had to start at the beginning, looking at the individual drivers on each scheme to understand what had led to the decisions made in outline design and whether any of the assessments made could be reviewed.

It was identified that the key decision that led to a significant portion of the scope between the two schemes was the one to close the Lower Gornal works. Installation of a pipeline connecting the two sites, the terminal pumping station at Lower Gornal and a percentage of the upgrade works at Roundhill can all be directly attributed to this decision, and it felt like an obvious place to challenge the assumptions made.

After a collaborative challenge between MMB and Severn Trent, MMB were able to review scheme drivers with a view to what could be done to keep Lower Gornal open and avoid a costly and disruptive pipeline installation to Roundhill.

MMB had completed similar schemes to Lower Gornal (tightened phosphorus and ammonia on a biofilter works) in the past at Trescott STW and Little Aston STW so were able to quickly produce a proposal incorporating a new Moving Bed Biofilm Reactor (MBBR) and tertiary solids removal (TSR) to meet the tightened consents.

Further benefits in retaining the works at Lower Gornal could also now be realised in mitigating significant operational expenditure of running a new transfer pipeline and associated pumping equipment.

BIM image of Lower Gornal tertiary area – Courtesy of MMB, Colloide, FLI Water and Eliquo Hydrok

With the option of retaining Lower Gornal STW, the MMB team could focus on providing only what was necessary at Roundhill to meet the tightened permits there. With input from Process Engineering, MMB were able to challenge Severn Trent on the requirement for a second ASP.

It was felt that with only a marginal tightening of ammonia, the existing six-lane ASP system at Roundhill STW could be optimised to meet this requirement. It had also recently received a complete replacement of its blowers, allowing increased airflow to the lanes if required. When the flows from Lower Gornal were to be sent to Roundhill the threshold for requiring a second ASP was clearly met, but without it and an appropriate assessment of the risks presented, it was decided that a second ASP was not required to meet the new consent.

With the scope removal of the second ASP, also came removal of a second returned activated sludge (RAS) and surplus activated sludge (SAS) pumping station with associated pipework. Introduction of a second ASP to Roundhill was to lead to splitting the bank of eight (including one new from the AMP7 scheme) final settlement tanks into two, to service each ASP. The project saw a significant saving in scope not having to carry this out.

MMB were also able to challenge the outline design choice of TSR made in the ECI. For the scale of flows and loads involved, ballasted coagulation technologies are often favoured over more traditional cloth and sand media systems due to cost and scalability. Within the subset of ballasted coagulation, numerous technologies exist that differ principally in the type of ballast used.

The various ballasted coagulation technologies were assessed by MMB and Actiflo® from Veolia Water Technologies was found to be most efficient from a whole life cost perspective.

BIM image of Roundhill STW proposed TSR Area – Courtesy of Mott MacDonald Bentley, Veolia Water Technologies & EPS Water

Conclusion

The ECI completed has been considered very successful by all parties involved. With the removal of the requirement to transfer flows from Lower Gornal to Roundhill and the subsequent reduction in scope requirements for the scheme at Roundhill itself, Severn Trent saved more than £20m from the original cost build-up, bringing the delivery of the two schemes as close as possible to the original affordability target.

MMB and Severn Trent worked together collaboratively to deliver the ECI with the common goal of improving the scheme affordability in mind.

Current estimates of embodied carbon in the construction of Roundhill alone have halved because of the ECI activities undertaken. This is a significant achievement, and one that will be further assessed and reported on as the projects at Roundhill and Lower Gornal progress.

MMB have subsequently been awarded a contract for the detailed design and construction of the schemes at Lower Gornal and Roundhill. These commenced in 2022 and are due to be completed towards the end of 2024.