Saltcoats Rising Main (2024)

Installation of temporary bypass pipework - Courtesy of Paul Milligan & Caledonia Water Alliance

The Saltcoats Rising Main project involved upgrading just over a kilometre of existing pipe on the most burst-prone section of the rising main, which stretches between the towns of Saltcoats and Stevenston in North Ayrshire. The rising main was originally installed in 1992, and it runs approximately 3km from Saltcoats WwPS towards Stevenston WwTW. The existing main is a 700mm diameter ductile iron (DI) pipe, ranging from two to five metres in depth, conveying a flow of around 500 l/s.

Background

The driver for this fast-tracked project was that the main had burst on various occasions, with four bursts before Caledonia Water Alliance’s (CWA) involvement and a further burst during the design phase.

The failure on the pipe became evident along the invert, with noticeable ‘channelling’ discovered after taking cut-outs during the repair works. There is a bathing water nearby and bursts were causing the pumping station to spill and have a direct impact on the water, prompting Scottish Water to seek permanent solutions to improve the pressure main’s functionality instead of continually responding to leaks.

(left) Aerial view of the project and (right) rising main failure – Courtesy of Caledonia Water Alliance

Project scope

- Lining of the first 1km of existing 700mm diameter DI rising main from Saltcoats WwPS.

- Installation of cured in place pipe (CIPP) lining by hot curing.

- Installation of one air valve and one scour valve. The scour valve to be relocated off carriageway for future ease of access and maintenance.

- Excavation of five lining pits to enable lining in both directions.

- Two bypass installations to enable over pumping of all flows during lining works.

- Planned shutdown to install valve arrangement for bypass.

- Installation of approximately 1km in length of overland 700mm steel pipes.

Site investigation

Given the environmental impact of bursts to the nearby bathing waters, the project started moving quickly and CWA were engaged to review potential solutions. While reviewing the requirements for a potential offline replacement, it became apparent that this would take some time and require multiple third-party approvals before any work could take place.

It would also involve finding a suitable location for a new pipe, which would involve executing the works through an existing golf course and through the only access road in and out of a busy caravan park. To limit the impact of the works and reach the site quicker, Scottish Water agreed to use a trenchless solution and re-line the existing rising main. Scottish Water instructed Caledonia Water Alliance to focus on the first 1km of the main, as this would cover the section of previous bursts to date.

This would make the scope more achievable in lieu of the bathing season approaching, given the location of the remainder of the pipe.

Pipe delivery – Courtesy of Caledonia Water Alliance

Project summary

- Project name: Saltcoats Rising Main

- Project cost: £4m

- Start date – design: 1 November 2022

- Start date – construction: 31 March 2023

- Completion date: 27 October 2023

Planning

With the agreed solution of lining the pipe now in place, the focus turned to getting on site as quickly as possible. This meant fast-tracking numerous stages, such as ground investigation and detailed design, and instead progressing with a high-level detail of the proposal, with various assumptions in place. The main issue which arose was how to manage the flows.

Caledonia Water Alliance proposed different options to SEPA, ultimately suggesting that they could turn the pumps off and tanker/spill the flows while working on lining the pipe. This would have been the quickest solution but would involve the rising main being offline for several months, which SEPA, as a regulator, could not accept.

SEPA did however appreciate why Caledonia Water Alliance were asking the question. Caledonia Water Alliance had anticipated this being the case with the only other option to bypass the flows with an overland pipe while working on the existing main. However, this posed issues – mainly around laying 1km of 700mm diameter pipe over a golf course and how they could cross a busy road. Given the services within the road and the time constraints, Caledonia Water Alliance could not bury it, even partially.

Assembly of overhead pipe bridge – Courtesy of Caledonia Water Alliance

This led to the proposal of an up-and-over bridge crossing. Caledonia Water Alliance was initially reluctant, given the visual impact this would have but, realistically, had no other choice. In the end, this worked out well, through extensive communications with the local residents, businesses, and caravan park, all agreeing the work was necessary to rehabilitate the rising main. The next challenge was to get the 1km bypass installed and operational before the bathing season beginning on the 31 May 2023.

From receiving the project at the end of October 2022 and starting on site in March 2023, Caledonia Water Alliance was able to collaborate with Environmental Techniques Ltd to design a cured-in-place liner with pit locations; working alongside their specialist subcontractor Selwood, to develop the overland bypass pipe.

As above, Caledonia Water Alliance went to site with some assumptions of the rising main location and depth, so they knew there would be changes as the project developed on site.

Saltcoats Rising Main: Supply chain – key participants

- Project delivery: Caledonia Water Alliance

- Trenchless rehabilitation & liner design: Environmental Techniques Ltd

- Civils subcontractor: Jacks1 Civil Engineering

- Underpressure connections: Swan Pipelines

- Scaffolding: AHL Scaffolding

- Temporary works/shoring: Groundforce

- Water supply: Enviroclean

- Liner supply: Insituform

- Bypass pipework: Selwood

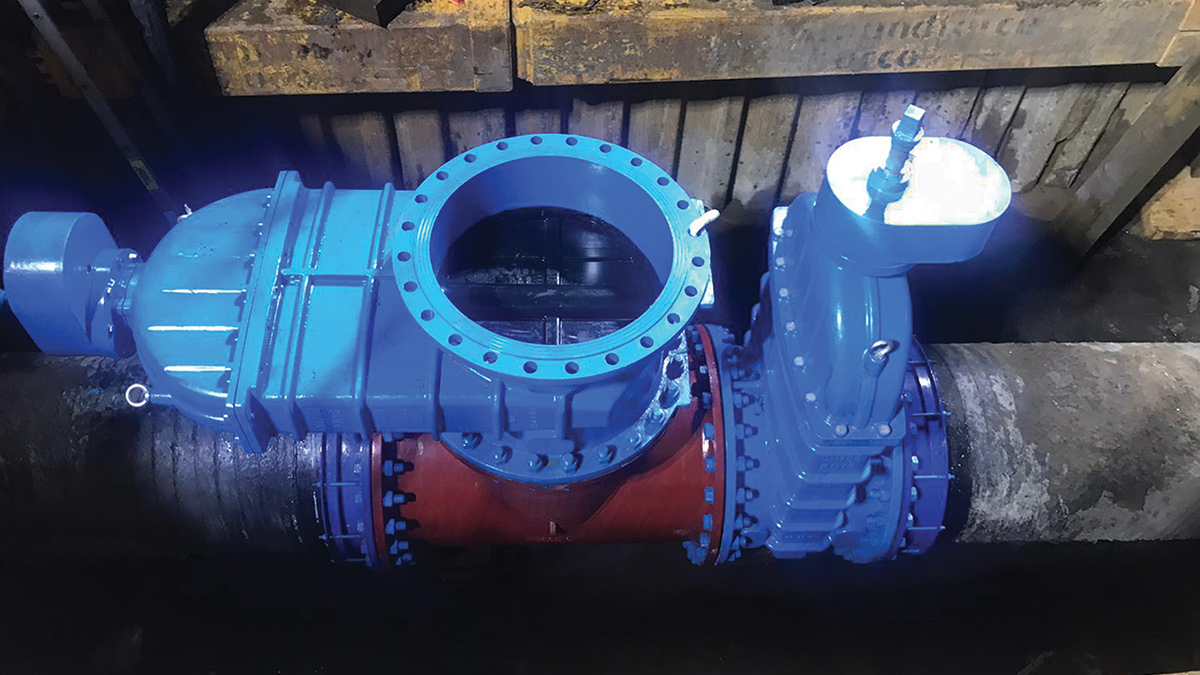

Bypass pit showing pipework cut out and a new ‘T’ piece and valve arrangement – Courtesy of Caledonia Water Alliance

Temporary bypass

The first part of the work, after establishing the site, was to install the temporary bypass. The bypass utilised a 700mm diameter flanged steel pipe, bolted together. This was strung out from a bypass pit adjacent to Saltcoats Pumping Station, approximately 1km downstream.

This required a tremendous effort to deliver a large quantity of pipework, drop it in place and bolt it together whilst working on both bypass pits at either end of the 1km section of pipe. The team completed the works on the bypass on time before the bathing season. With this now operational, CWA ensured the safety of the first 1km of the main from potential bursts.

Liner installation

The liner chosen was a cured-in-place pipe liner (CIPP) as this would provide the structural capacity of the host pipe. CIPP lining has been extensively used throughout the UK to repair failing sewer pipes, prevent infiltration and to add structural strength where required.

Designing CIPP liners for pressurised pipe systems presents unique challenges that differ significantly from their application in gravity-fed sewers. In pressurised systems, the liner must withstand not only external forces such as soil, groundwater, and traffic loads but also the continuous internal pressure exerted by the fluid within the pipe.

Additionally, the liner must also be able to withstand negative internal pressures, or vacuum conditions, which can cause the liner to experience inward forces, particularly near joints and bends. The design had to account for these vacuum scenarios to ensure that the liner remains stable and securely bonded to the host pipe, preserving the structural integrity of the pipe under varying pressure conditions.

Liner installation – Courtesy of Caledonia Water Alliance

The liner was designed with the operating and supplied test pressures of the existing rising main. The number of known bends, as well as the potential for more unknown bends, meant that the hot water curing was a more suitable process for this project as the liner would invert itself under the pressure of the curing water, navigating around the bends automatically.

A scaffold tower was installed at the installation pits to secure the end of the liner and to ensure enough vertical height to allow the water pressure to invert the liner through the length of pipe required. The hot cure process utilises a hot water boiler to raise the temperature of the curing water which begins the process of hardening the resin.

The liner provides a 60-year design life, similar to installing a new pipework, but with significantly less digging requirements and waste production.

Drone image showing the scaffold tower and the liner installation operation underway – Courtesy of Paul Milligan, Caledonia Water Alliance

No-dig technique

The decision to use trenchless relining methods was primarily driven by the need to minimise the number of excavations, significantly reducing disruption and environmental impact. In Saltcoats, this approach required only five lining pits and two bypass pits along the existing rising main, demonstrating the efficiency of trenchless technology compared to traditional dig-and-replace methods.

One of the key benefits of trenchless relining is the reduced need for extensive excavation, which minimises surface disruption to roads, traffic, and the surrounding environment. This is particularly in Saltcoats to minimise disruption to the local communities, golf course and caravan park. By using trenchless techniques, the project can be completed faster with less noise, dust, and inconvenience to residents and visitors to these areas.

For the bypass pits, existing pipe sections were cut out, and new T-piece and valve arrangements were installed. This allowed for the connection of temporary bypass pipes, enabling the flow to be managed through valve operation without interrupting service. The trenchless approach also reduces the risk of encountering unforeseen underground utilities, which can lead to costly delays and repairs.

Overall, trenchless relining offers a safer, more efficient, and less invasive solution for repairing and upgrading pipeline infrastructure.

Conclusion/update

The project was completed successfully on site and within the proposed programme, despite coming across some major obstacles on site. Once the lining was completed, it was inspected, tested, and finally put into commission by transferring the flows back into the newly rehabilitated main.

CCTV output pre and post lining – Courtesy of Caledonia Water Alliance

Following successful commissioning, the rising main was run for a period of 48 hours without any defects. After this time, Caledonia Water Alliance was able to start dismantling the bypass pipe, removing it from site and reinstating the area.

Undertaking the Saltcoats Rising Main Rehabilitation Project was a significant effort by all involved to first install and have the bypass pipe operational before the bathing season, and then to have the existing main rehabilitated and working within the timescales which Caledonia Water Alliance provided Scottish Water at the start of the works.

This was particularly impressive given the fast-track nature of the works and getting a large-scale project to site quickly. There is now a Phase 2 and 3 proposed for the remainder of the rising main to Stevenston WwTW to rehabilitate it over its entirety. These will be looked at over the next 2 to 3 years.

Overhead temporary bypass being dismantled - Courtesy of Caledonia Water Alliance