Sandown WSW: pH Correction (2025)

Sandown Water Supply Works located next to the River Eastern Yar - Courtesy of Trant Engineering

Southern Water’s Sandown Water Supply Works (WSW) supplies water to the Isle of Wight. The works treats water from the River Eastern Yar, a ‘flashy’ river with wide swings in turbidity and colour. The works treats river water by coagulation and flocculation, clarification, filtration, activated carbon adsorption and disinfection. The works provides a steady supply and allows the rate of extraction to be reduced in winter so groundwater levels can recover. Due to the nature of the river catchment area, during periods of heavy rainfall, the works has seen significantly lower-level pH in the raw water.

Background

Weather has a major impact on raw water quality. Typically, rainfall increases flow in the river and, with it, turbidity. Colour, an indicator of natural organic matter, reduces in wet weather and increases in drier spells. Climate change has increased the intensity of rainfall, and this reduces the pH of the river water, making control of coagulation, which depends on colour, turbidity and pH, more difficult.

Higher turbidity during storm conditions requires a higher coagulant dose, and this further depresses the pH. This issue has, on several occasions, resulted in a shut-down of the works which struggled to meet treated water quality goals. Southern Water notified the DWI of this process issue and were issued with an improvement notice which required a long-term solution to be implemented by 28 February 2025.

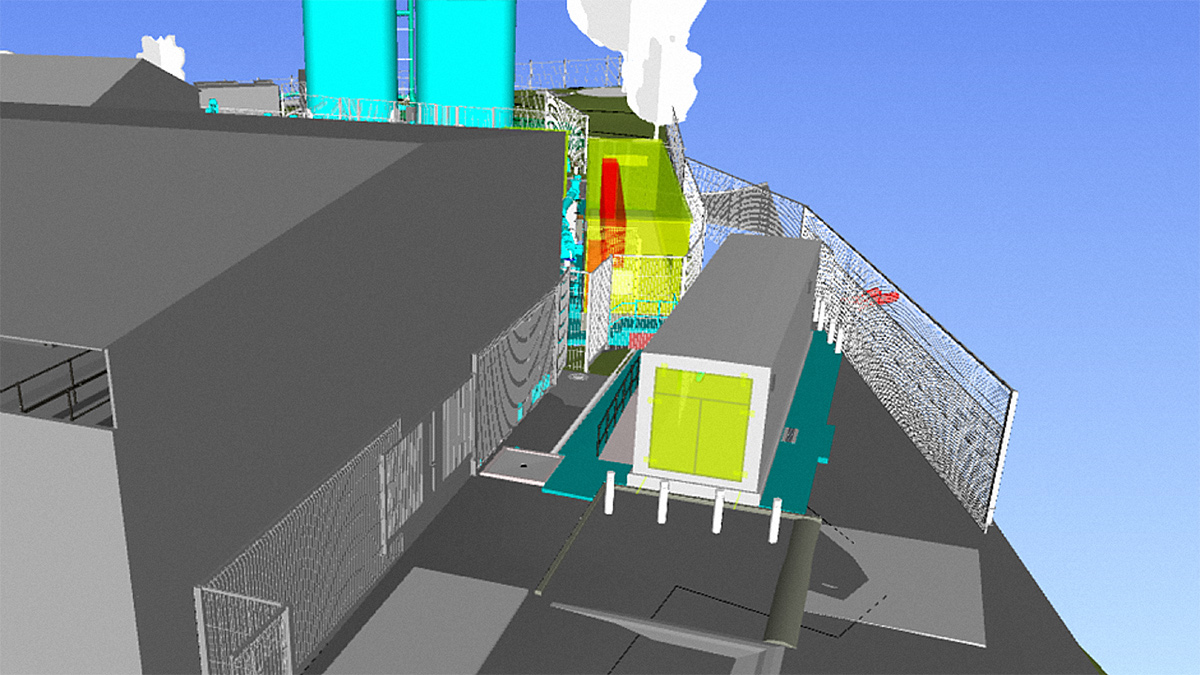

BIM image of the new dosing kiosk – Courtesy of Trant Engineering

Outline design

Southern Water engaged Trant Engineering to develop and implement a solution. Trant had a dedicated team at Sandown working on other schemes and had good working relationships with the Southern Water Project Team and Operations. This meant that they already had a good understanding of the problem and were able quickly to propose a solution consisting of chemical storage, pH control and a caustic soda dosing system together with all the associated piling, reinforced concrete plinths, paths, slabs and buried service ducts.

The proposed process solution treated chlorinated process water through dosing with sodium hydroxide within carrier water immediately prior to entering the contact tank. A measured dose is applied to the process, calculated by measuring pH and flow. The dose is then adjusted as required through a process feedback loop to maintain a required target pH set point.

Project scope

- Buried service duct installation.

- SFA piling works.

- Reinforced concrete plinths, paths and slabs.

- Gas service diversion.

- Diversion of incoming raw water mains.

- Chemical delivery area including delivery bund, interlocked delivery valving system, drainage works and chemical interceptor tank.

- Installation of safety shower.

- Installation of static mixer and chemical dosing point of application (POA) enclosure.

- Two bunded 5000L chemical storage tanks to store 28% concentration sodium hydroxide.

- Carrier water break tank.

- Carrier water hardness analyser and water softener system.

- Dosing pumps enclosure.

- Motive water pumps enclosure.

- pH Analyser Backboard.

- Process instrumentation, pressure sensors, level controllers and actuator valving.

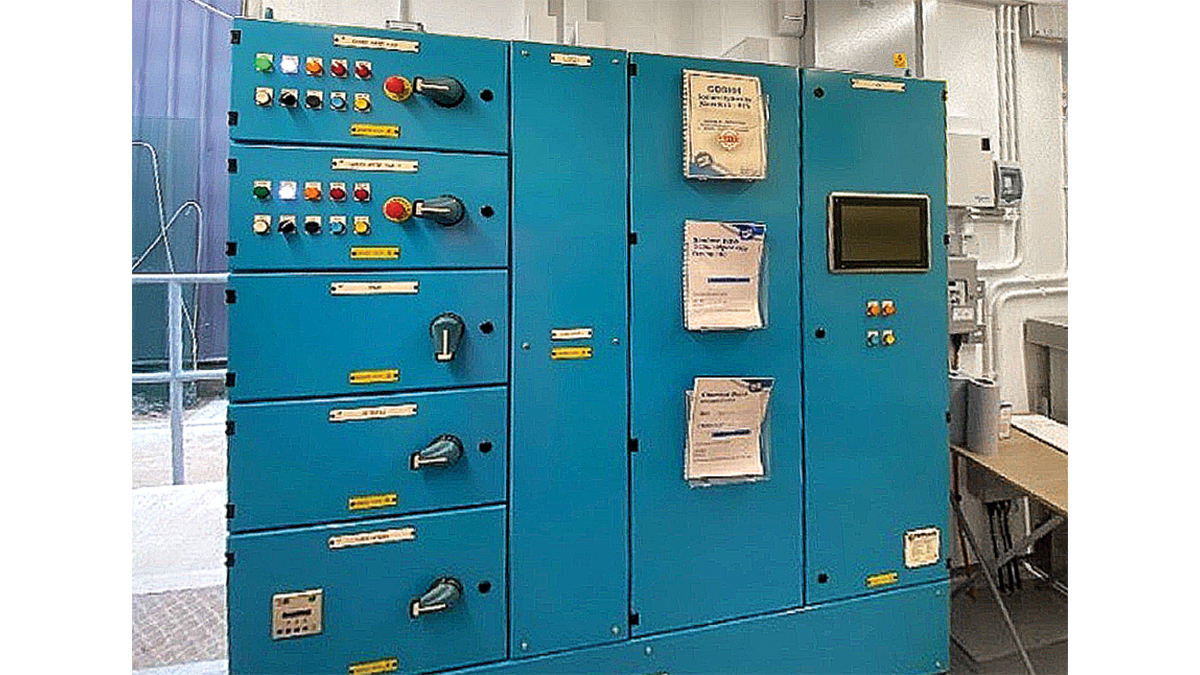

- Dosing control panel with HMI.

- System integration with existing site controls.

- New dosing kiosk.

Design & build

Because of space constraints, the incoming raw water mains had to be diverted. The dosing system required a pH analyser/controller mounted on a backboard with process instrumentation, pressure sensors, level controllers and automatic valves. Carrier water pumps and a water softener completed the dosing package with an adjacent dosing control panel with PLC and HMI.

Sandown WSW pH Correction: Supply chain – key participants

- Client: Southern Water

- Main contractor & civil works: Trant Engineering

- Civil design: AtkinsRéalis

- Piling works: Southern Piling

- Dosing system: Chemidose Limited

- Safety shower: Aqua Safety Showers International Ltd

- Control system, panels & systems integration: FW Marsh

- Static mixer: Statiflo International Ltd

- Kiosks: Morgan Marine Ltd

- Access fabrications: Toomers Ltd

Challenges

There were several key challenges. Highly limited space available for the equipment required, extensive buried services, and challenging project delivery timescales to meet the regulatory outputs. Working closely with Southern Water and the established delivery partners Atkins Realis, Chemidose and F W Marsh, Trant’s team was able to complete the necessary Design, HAZOP and ALM process early in 2024.

The design was prepared with programme constraints heavily in focus and incorporated an off-site ready built kiosk with integral floor. This enabled the full kiosk fitout to be undertaken in parallel with the civils work on site and resulted in significant programme improvement. The dosing system was fully FAT tested offsite at Chemidose’s premises.

Space was tight to fit the kiosk on site, and tight within the kiosk to fit the process equipment needed whilst maintaining good access. A collaborative design process and a great team enabled this to be achieved within the constraints. Challenges were encountered on the civils design including unmapped significant pipework and unfavourable geotechnical conditions in the only viable location for the kiosk. The team moved quickly to resolve solutions which required a piled foundation to address the ground conditions and avoid loading the unmapped pipework whilst diversion was resolved.

Local control panel with HMI – Courtesy of Trant Engineering

Installation & commissioning

The civil works and on-site preparatory M&E works were completed in parallel with the dosing kiosk fitout. This combined with the level of offsite fitout and testing substantially minimised the on-site installation period. The dosing kiosk was delivered to site as the civil works were completed, and a limited period of M&E works were required to connect into the existing site process.

The result

Within four weeks of the kiosk delivery, commissioning was able to commence. A successful commissioning period allowed project works to enter active service several weeks ahead of the DWI regulatory date for installation. The project achieved full formal handover well ahead of the DWI regulatory date for commissioning.

By close cooperation throughout the supply chain, commissioning was able to commence within four weeks of the kiosk delivery. Being familiar with the site, Trant’s Instrumentation, Control & Automation (ICA) team was able quickly to integrate the new controls, and the new works was in service and formally handed over several weeks ahead of the DWI regulatory date for installation.

The solution deployment has been successful in addressing the problem of low pH causing a need to shut down the works during periods of heavy rainfall and this success has been welcomed by all parties.