Vivian (Six Bells) Mine Water Treatment Scheme (2023)

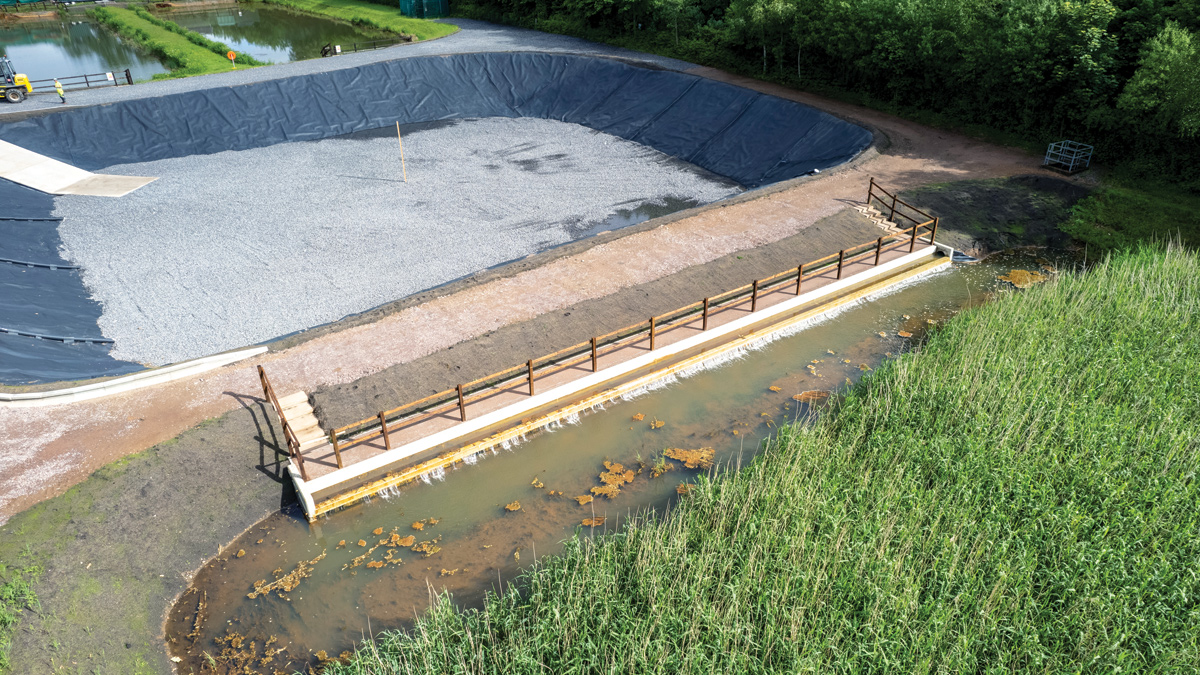

Cascade in use - Courtesy of JBA Bentley

A mine water treatment scheme was implemented at Vivian (Six Bells) by the Coal Authority as an environmental service under its national remediation programme in 2006. Vivian (Six Bells) is located in South Wales, approximately 20km north of Cardiff next to the village of Abertillery. A mine water discharge from the Vivian Shaft was discovered in 1998, causing a significant impact to the Ebbw Fach. The scheme, with a new abstraction borehole, was implemented to treat the mine water and decrease the impact on the Ebbw Fach. The scheme was initially built and commissioned in 2006 with two settlement lagoons, a reed bed and a sludge drying bed to treat the mine water passively. The additional features, which include a cascade and a hydrogen peroxide dosing plant, were built in 2012 to achieve sufficient oxygenation, effective iron removal and to abate the release of hydrogen sulphide (H2S) into the environment.

Existing works

Six Bells Mine Water Treatment Scheme (MWTS) is operated by Severn Trent Services on behalf of the Coal Authority. The existing works treats 60 l/s of mine water that is dosed with hydrogen peroxide solution, injected to provide oxidation of ferrous iron. This water is then transferred to two setting lagoons via a cascade structure.

There are two parallel lagoons and the combined discharge of these two lagoons is transferred to a reedbed, at the bottom of the site, before being discharged into a local river. Six Bells was flagged as an ‘amber’ MWTS in the Coal Authority’s Risk Register due to number of health and safety issues with the condition of cascade. Due to the limitations that the existing inlet and outlet structures put on treatment effectiveness, the site was chemically dosed to aid water treatment, with the chemical dosing facility in need of refurbishment in the coming years.

The objective of the project was to improve the efficiency of the treatment plant and Health & Safety standards. The Coal Authority employed JN Bentley as framework partner to design and build the refurbishment works.

How it works

- Water is pumped from the borehole.

- Air mixes with the mine water as it falls down the cascade steps, which causes the iron to oxidise and form particles.

- The water moves slowly through the lagoons. Large iron oxide particles fall out of solution and settle in the bottom of the lagoon.

- The water transfers to a reedbed which acts as an additional filtering layer.

- Periodically the iron sludge is removed from the lagoons and taken to the drying bed, to remove excess water so it is easier to store or move.

- Water is discharged into Ebbw Fach.

Sludge drying bed and reedbed – Courtesy of JBA Bentley

Objectives of the works

The scheme proposal was to improve the efficiency of the treatment plant and the Health & Safety standards, by ensuring the works have a suitable and sufficient design; by achieving an efficiency enhancement in the treatment process, the lagoons and reedbeds performance shall improve.

A new cascade structure will improve management of the flows as well as improve the operation and maintenance abilities of the operator. Enhancing the access and egress of the lagoons and reedbeds, the risk to operators’ Health & Safety were also set to be reduced.

The effluent discharge quality during the refurbishment works was to remain within the permitted discharge consent limits that are stipulated by Natural Resources Wales (NRW). With the treatment works operating more efficiently, the chemical usage was to be reduced by the relocation of the dosing points due to the modified lagoon inlet pipework. The proposed refurbishment works would improve both the operation and environmental impacts of the site, improve the treatment capability, and prevent mine water pollution.

The Coal Authority’s innovations team are researching new ways of reusing the ochre to minimise waste and cost. Possible uses found to date include ground remediation projects, within water treatment systems and as a pigment in paints

Permits, consents & licenses

To facilitate installation of works at Six Bells the following permits, consents, licenses and restrictions were applied for and approved by the respective consenting authority prior to commencement of the work.

- Consent to discharge: Working under the client’s existing consent to discharge permit.

- Blaenau Gwent County Council General Permitted Development.

De-sludging

Throughout the design and construction stage, the final operability of the scheme was continually reviewed, and standard construction details modified to suit. When in operation the lagoons need to be regularly de-sludged, which has historically been undertaken with extensive pumping and with considerable resource. This scheme’s levels were designed to facilitate a permanent gravity piped solution from the lagoons to a new sludge drying bed. This will both reduce operational costs and aid operation during the scheme’s life.

Reedbed inlet channel – Courtesy of JBA Bentley

Cascades

The cascade requires periodic maintenance to prevent the buildup of ochre on the steps. Therefore, the cascades were split into two sections with access steps in the middle to facilitate maintenance. The standard precast solution was modified to extend the width of the cascade. This posed several construction challenges due to the weight of units to be installed, which were exacerbated by the lifting restrictions from the site boundary constraints. Working collaboratively with the designers, construction team and Craven Concrete (the precast concrete supplier), the inlet and outlet units were divided into sections with a maximum weight of 4.5t, so each one could be lifted and installed with an excavator.

Six Bells Mine Water Treatment Scheme Refurbishment: Supply chain – key participants

- Client & principal designer: The Coal Authority

- Principal contractor: JN Bentley

- Detailed design of earthworks, cascades, lagoons, pipework, MEICA infrastructure and environmental ecologist support: JBA Consulting

- Precast concrete channels: Craven Concrete Ltd

- Concrete kerb – HGV & HB: Marshalls

- Geomembrane lining: Celtic Lining Ltd

- Pipework: Scott Parnell

- Sludge drying bed drainage: Keyline Civils Specialist

- Aluminium fixings: Celtic lining Ltd

- Fencing: Travis Perkins

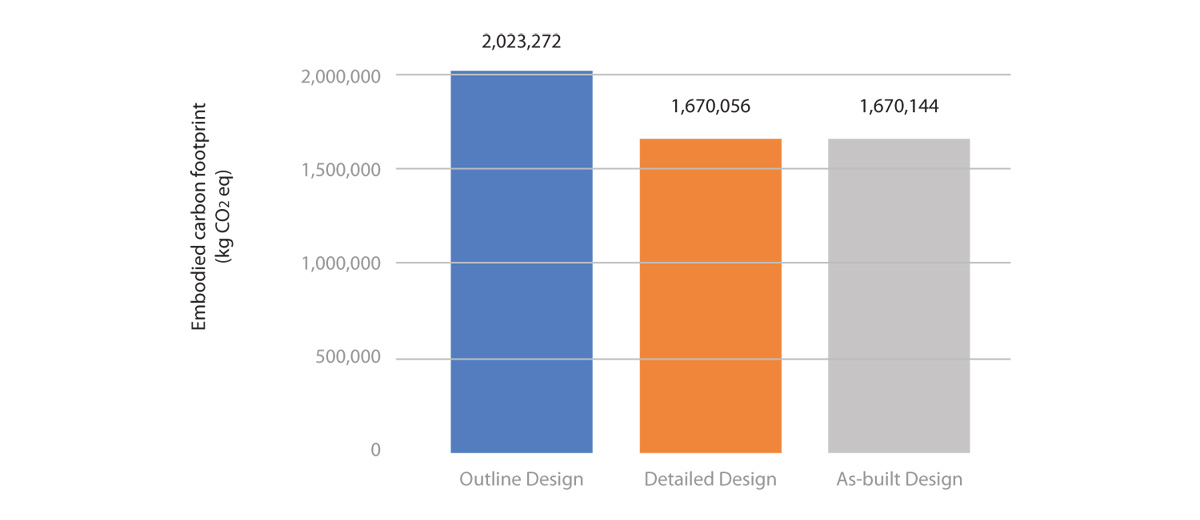

Carbon reduction

In line with JBA Bentley’s carbon reduction policy, carbon tracking was undertaken throughout the design and build process. By targeting a reduction in concrete and minor modifications to standard details a total saving of 22% reduction in capital carbon was achieved from the outline design stage. Several changes are highlighted below:

- Reduction in the levels of the cascade. This has allowed for the edge of the cascade to get closer to an existing path behind Lagoon 1 and therefore not requiring two separate smaller paths next to each other at different levels. Concrete was saved by reducing the weir length from 8m to 6m.

- Cascade dosing was removed from the scope.

- GRP steps.

- Concrete retaining wall, saved 63T of concrete, replaced with above ground blockwork.

- Removal of top launder channel drainage pipework and valves by client.

- Outlet pipework length reduced by client.

Total embodied carbon footprint comparison – Courtesy of JBA Bentley

Summary

The improvement works to the lagoon has enhanced the even flow distribution and eliminated the risk of short-circuiting of the flow. The entire available area of the lagoon can now be used for treatment. The additional treatment capabilities will likely reduce the chemical consumption for treatment works, saving money on hydrogen peroxide and increased maintenance costs.

The works undertaken to the sludge drying bay prevents the mine water leachate to ground and allow polluted water collection in the chamber for recirculation to the lagoons and treatment prior to discharge. The new cascade offers better operational and maintenance capabilities.

Finally, the works allow the Coal Authority and their operational contractors to maintain the scheme within the discharge consent limits. The biggest benefit to the community that the project has brought about is the scheme prevents untreated mine water entering groundwater resources.