Tiptree & Langham Pumping Station Refurbishments (2017)

Tiptree Pumping Station - Courtesy of NWG

Northumbrian Water Group (NWG) provides water services to 1.5 million customers across a large part of Essex and east London, where it operates as Essex and Suffolk Water. As a vital part of Northumbrian Water’s treated water network, demand up to 55Ml/d is pumped from the Langham WTW on the Essex/Suffolk borders and forward boosted at Tiptree Pumping Station into the Layer to Danbury Aqueduct to the west. Both pumping stations were constructed in the 1930s and although they have provided reliable service for some 80 years, it had become increasingly difficult to maintain pumps, drives, diesel sets and associated equipment along with safety issues on both LV and HV electrical switchboards. Obsolescence and non-availability of spares were the critical drivers to necessitate significant investment to ensure a resilient water supply to customers.

Network overview

The Essex region is broadly supplied from four water treatment works; Chigwell to the west, Hanningfied centrally, Layer-de-la-Haye to the east and Langham to the north-east. Langham and Tiptree pumping stations are linked such that total failure of either one will result in the loss of all water produced from Langham WTW as the pressure in the main is too low to overcome the pressure in the aqueduct into which the water needs to be fed. The Layer WTW some 10 miles south can provide some short term back up but there would be a major impact on deployable output. The network would thus be very vulnerable to any issues at Layer WTW especially if its raw water supply from Abberton Reservoir is experiencing variable water quality.

Existing plant, challenges and issues

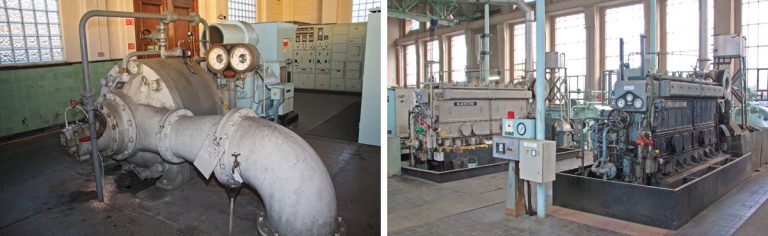

Since their original construction, the pumping stations have evolved from coal-fired to diesel to electric powered pumps, both low voltage and high voltage, and combinations of these still remained. Common challenges faced at both sites include age and condition of main assets, in particular with pumps, motors, and drives, plus the requirement of frequent and costly reactive maintenance of what is essentially obsolete equipment. The scheme offered low resilience; the sites often ran without standby pumps available due to maintenance difficulties.

(left) Electric pumps and old MCC at Tiptree PS and (right) Langham PS diesel pumps – Courtesy of NWG

Electrical equipment was non-compliant and the company’s network pumping optimisation tool Aquadapt was severely hampered by drives and pumps not running well together and with ineffective priming systems. Particular issues were:

Langham PS

- 2 (No.) HV electric pumps, motors require regular refurbishment.

- Drives are obsolete DC types, no spare parts available.

- Existing back up generator is LV hence cannot support electric pumps.

- On mains failure, manual operation of diesel pump required, also second non-compliant unit exists.

- Hydraulic interaction between pumps means a gap in flow rates between 35 and 42Ml/d.

Tiptree PS

- 3 (No.) LV electric pumps: 1 failed beyond repair, 2 requiring regular maintenance.

- Drives are obsolete DC types, no spare parts available.

- Safety and reliability issues with both HV and LV switchboards.

- Standby generator auto-changeover panel regularly fails.

Investigate and define

Critical to the performance of both pumping stations, the correct choice of pumps was the principal factor in the new design. NWG engaged their long term pump performance specialists Integrated Water Services Ltd (IWS) as principal contractor to bring the necessary expertise to the project.

For both pumping stations, the historical approach would be to have 3 (No.) pumps in duty/assist/standby arrangement to achieve the required flow rates and resilience. IWS evaluated several pump manufacturers’ proposals and it soon became clear that a two pump duty/standby regime would be capable of providing the required flow of 55Ml/d with a minimum of 40Ml/d if only one pump available. Under usual running conditions, one pump would be sufficient to meet the majority of planned operations.

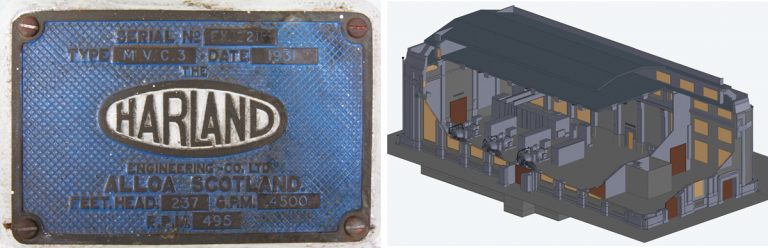

(left) Original Harland 1931 pumpsets – Courtesy of NWG and (right) Tiptree 3D model – Courtesy of IWS

Controlling the pumps by variable speed drives would also give further flexibility to provide the required flows under varying network head conditions. In addition, the proposed pumps indicated a significant OPEX efficiency saving over the old machines as well as the CAPEX saving by installing just two pumps. This approach was reviewed and agreed technically with NWG Operations and Networks.

Prior to the project, NWG was investigating the use of 3D laser scanning and modelling techniques and internal/external scans of the pumping stations were undertaken. The resulting site models were incorporated into IWS’s 3D Solidworks design package giving an instant view of the stations’ topographies and saving many hours of manual measurements and transcriptions of 1930s drawings.

The proposed solution included (per site):

- 2 (No.) new horizontal split case pumps, associated pipework and manifolds.

- ABB AC800 series variable speed drives.

- A new HV transformer.

- New motor control centre (MCC).

- New LV generator and controls at Langham and new controls for existing generator at Tiptree.

- New HV switchgear.

As well as a significant increase in reliability and safety, the proposed system will eliminate the need for operations staff to attend site to ensure correct pump starting (no priming issues) or to start/stop the generator during mains failures.

As strong synergies exist between the sites, both procurement and delivery advantages could be gained. The use of the same suppliers for MCC, pumps and generator controls, common contractors and equipment consistent with other NWG sites, means that benefits are gained both in maintenance requirements and familiarity of equipment for technicians.

Construction issues

A major factor governing construction activities was that treated water output to the distribution network had to be maintained throughout the project lifecycle. Agreement was reached to run at around 35Ml/d, the historic 5 year average, with other treatment works in the network making up additional water as required. This meant effectively that a single pump at each station could provide the required output, allowing a planned staged installation with 100% redundancy.

Unfortunately an unforeseen and unusual combination of below average rainfall and high algal blooms meant that for much of the project, required flows were much higher than predicted. Combinations of old and new pumps had to be run together often by a mix of temporary software and manual control.

Age and evolving technology also created problems. Originally being coal then diesel then electric driven, the stations, particularly Langham, contained a network of diesel pipes below floor level. Langham had an operational diesel pump, redundant diesel pump and operational diesel generator all situated within the main pump hall amongst the current electric pumps hence creating risk of fire and cross contamination.

The existing pumps were sited at pump hall ground level, allowing minimal positive suction pressures relative to the external chlorine contact tanks. The pumps had auto priming systems which were notoriously unreliable and often required operative call-outs in order to get pumps started. The solution proposed was to fit the new pumps at some 4m lower in the basement area to provide a positive suction head to eliminate the need for any priming systems.

To gain the necessary space, several large areas and several tonnes of concrete floor support had to be removed by diamond wire cutting. This had the potential to create a large amount of dust but was managed by tenting of work areas and forced air ventilation.

Langham new 40Ml/d pumps – Courtesy of NWG

Pumpsets and drives

The existing electrical pumpsets at both sites were the original 1931 units manufactured by Harland. The new units chosen are Flowserve LNNV single stage horizontal split case types, selected to provide a maximum single pump capacity of 40Ml/d at 47mHead (Tiptree) and 78mHead (Langham). The pump motors are 315kW WEG high efficiency IE4 types at Tiptree with larger 500kW units to cope with the increased head requirement at Langham.

The existing pumps were driven by 12-pulse DC drives at 480VDC. The drives had become obsolete with no source of spare parts and with no technical expertise remaining within the UK. Frequent breakdowns and maintenance intervention was required.

The new drives are ABB ACS800 series types, consistent with many other drives across NWG and hence fall under the ABB service & maintenance agreement already in place within Essex. A further advantage of common systems is the ability to ‘borrow’ parts between sites in the event of an emergency. At Langham, the drives are run super-synchronous in order to achieve the required output at the higher network heads.

All pumpsets are fitted with pressure/flow/bearing protection and monitoring. Dual axis vibration monitoring is fitted to each pump and motor which is monitored remotely via the Ethernet enabled communications system.

Electrical power supplies

Both sites are supplied by twin 11kV REC incoming supplies. The existing NWG substations were equipped with ancient switchgear which was both unreliable and difficult to maintain. These have been replaced with Schneider Premset vacuum breaker units.

At Langham, the supply was onwardly distributed via 3 (No.) ring main units (RMUs) to 3 (No.) external transformers, one to the remote ozone plant and one each to either end of the main power distribution board. The refurbishment work has simplified this to provide a new single 2000kVA transformer-fed supply to the new MCC whilst maintaining the separate ozone supply.

At Tiptree, the situation was somewhat worse with two internal 11kV transformers mounted within the same power distribution board as the LV pump controls. A new external 800kVA transformer has now been fitted which supplies the new MCC.

Arrangement of new pumps at Tiptree – Courtesy of NWG

Electrical distribution

New motor control centres have been fitted at both stations. Manufactured by TES they are of Form 4 Type 2 construction built to NWG’s engineering standards. The MCCs are symmetrically fed each end by mains incomer and generator incomer respectively with a central bus coupler to allow isolation for maintenance purposes.

The existing control software has been extensively re-written and is accessed from local HMI screen or remotely via the company’s SCADA system.

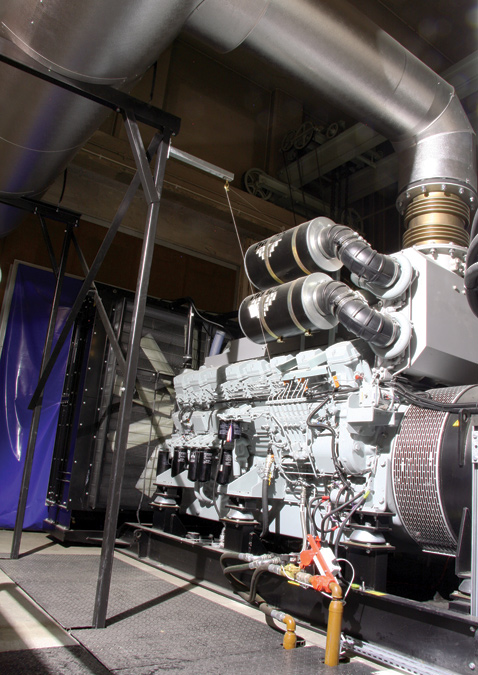

New 1736kVA standby generator at Langham PS – Courtesy of NWG

Standby generation

At Langham, standby power was supplied by an LV Blackstone generator which could only provide general site services power as the pumps were HV types. In the event of a mains power failure, manual intervention was required to start one of the two Blackstone diesel pumps which, lacking comms feedback, required manned supervision until power was restored. All old diesels have now been removed and the generator replaced with a JCB 1736kVA prime rated generating set in its own remote soundproofed room.

The set is fully automated to provide automatic start and load take-up in the event of mains failure plus a G59 synchronised no-break return to mains power on restoration of mains supply.

At Tiptree, the existing 800kVA generator is retained but has been fitted with the same automated control system features as the Langham set to provide full automatic operation. At both stations, the standby design capacity allows single pump operation to provide flows of up to 40Ml/d.

(left) Tiptree PS before construction and (right) Tiptree PS after construction – Courtesy of NWG

Conclusion

The project provides an excellent example of a collaborative approach between project team, framework partners and tier 2 suppliers to provide two modern and efficient pumping stations to meet NWG’s future needs and maintain a continuous reliable supply for our customers. The construction programme kept to plan despite unforeseen flow demand which called for some radical solutions to maintain the stations’ output.

Lessons learnt and good practice will be taken forward to a third pumping station in 2018 whereby Essex’s primary raw water pumping station at Stratford St. Mary will undergo a similar upgrade.