Tophill Low WTW (2023)

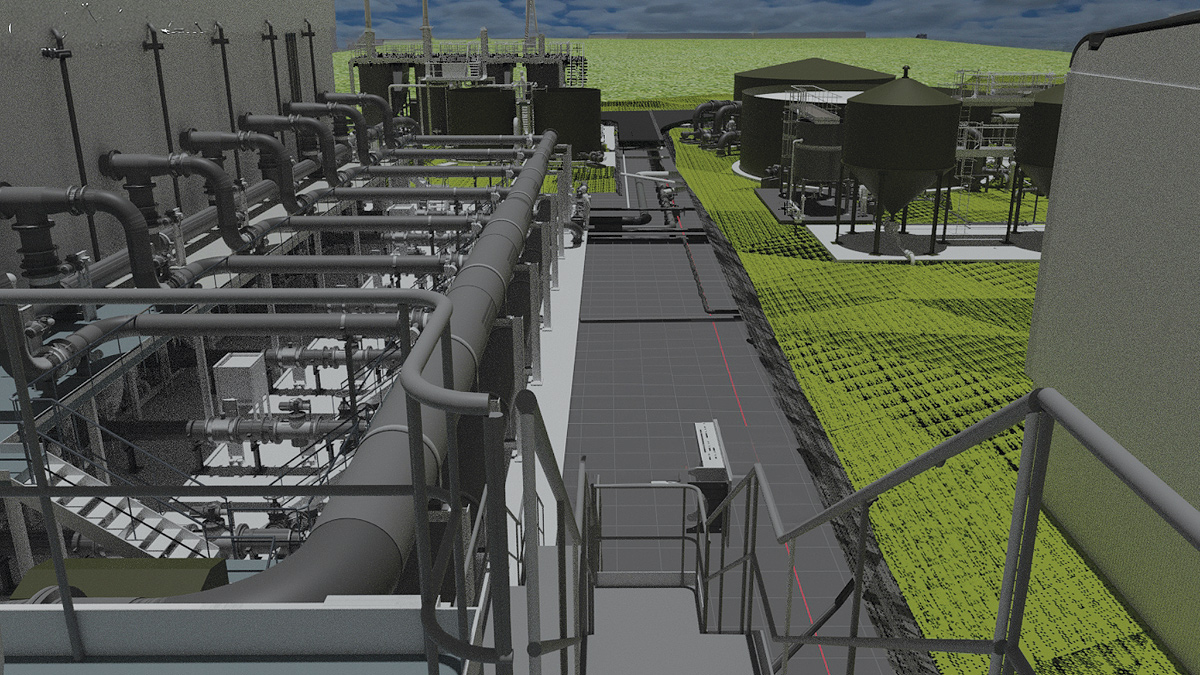

GAC adsorber gallery - Courtesy of Barhale Enpure JV

Tophill Low Water Treatment Works (WTW) is a 68 Ml/d water production plant situated in the East Riding of Yorkshire, approximately six miles from Driffield. The works was originally constructed in 1959 and upgraded in the 1990s to the current configuration. The treatment process presently includes pH correction, ozonation, coagulation, DAF clarification, rapid gravity filtration, followed by nitrate plant with bypass and disinfection with sodium hypochlorite. A seasonal dose of PAC is typically applied from February to October (inclusive) for the removal of taste and odour compounds. The works is also the site of a nature reserve, opened in 1993, which features twelve hides spread over 300 acres. The two reservoirs on the site are the heart of the reserve with a network of marshes, ponds, woodlands and grasslands around the perimeter that result in an annual observation of over 160 bird species. The key process challenges the works faces include taste and odour causing compounds.

Background

The current treatment pathway is Powdered Activated Carbon (PAC), typically dosed at 30 mg/l during the summer months when taste and odour compound levels in the raw water are at their highest. While the seasonal PAC dosing has generally been successful at removing taste and odour compounds from the water, the increased solids loading has negative impacts across the works.

The works also suffers from algal species carrying over from the dissolved air flotation system to the rapid gravity filters, limiting performance, and the current RGF sand/GAC media combination provides an insufficient degree of Cryptosporidium removal.

Tophill Low WTW: Supply chain – key participants

- Principal contractor & designer: Barhale Enpure Ltd JV

- Civils design: WSP

- Ozone design/supply: Curio Water

- Systems integration & MCCs: Total Automation & Power

- Air blowers: Aerzen Machines Ltd

- Interstage pumping station pumps: SPP Pumps Ltd

- Pumps: KSB Limited

- Lamellas: Jacopa

- Transformer: Wilson Power Solutions Ltd

- Mechanical installation: JBF Group

- Tanks: Goodwin Tanks

- Kiosks: Morgan Marine

- Kiosks: Quinshield Ltd

- GAC media: Chemviron

- Pumped tank mixing systems: Xylem Water Solutions

- HV installation: Integrated Utility Services

Project scope – main treatment process

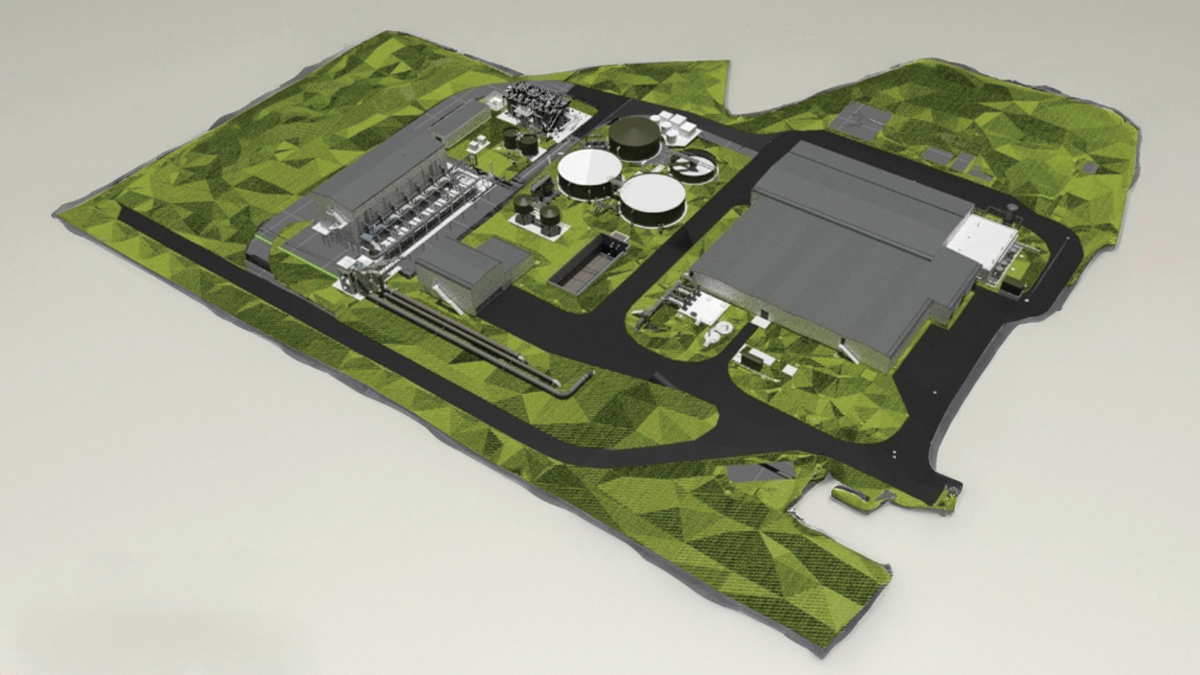

Site overview: model of upgraded Tophill Low WTW – Courtesy of Barhale Enpure Ltd JV

The Barhale Enpure Ltd Joint Venture (BEJV) are delivering the required scope in partnership with Yorkshire Water. Improvements to the main treatment process include:

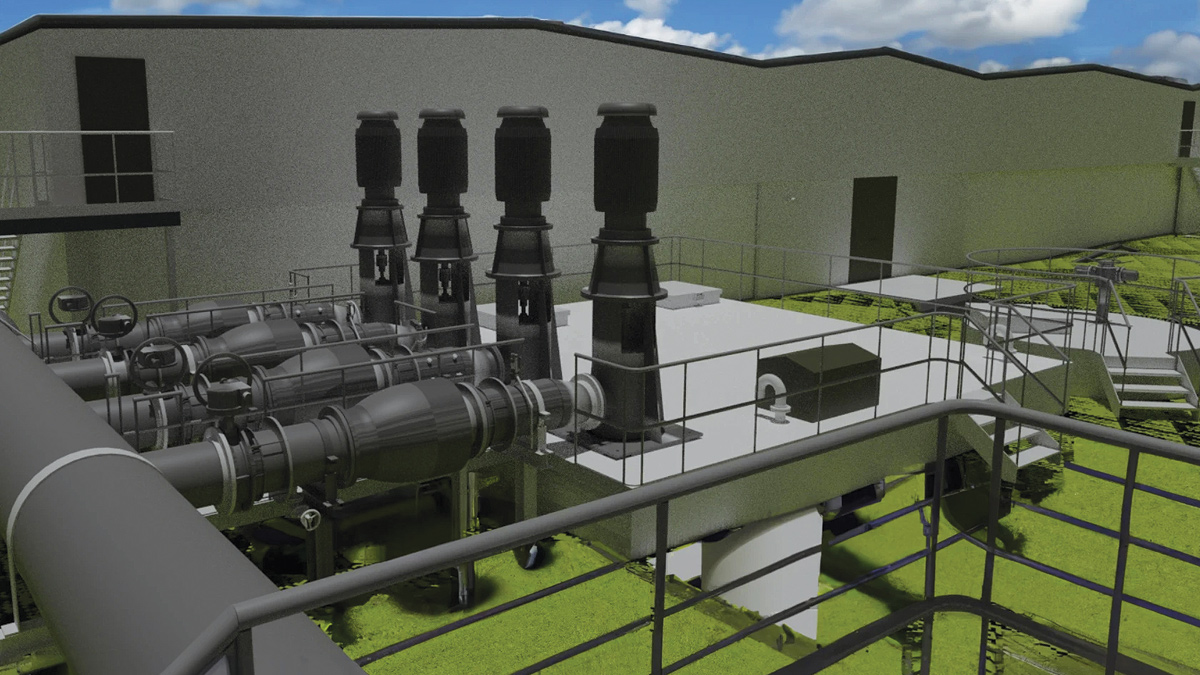

- Replacing the existing ozone generators and upgrading the dosing system from sidestream dosing to direct radial diffusion, to provide a greater ozone dose concentration.

- Refurbishment of the existing DAF installation – including replacement of the current sludge scraper systems, and improvements to the flocculation system, washdown provisions and tank access platforming.

- Conversion of the existing rapid gravity filters (RGFs) from a sand/GAC sandwich to dual media (sand and anthracite). The works includes the replacement of filter floor nozzles and upgrades to the existing control system to improve the wash regime.

- Construction of a new interstage pumping station to pump water from the RGFs to the new GAC adsorbers.

- Construction of seven new GAC adsorbers, offering a minimum of 12-minutes empty bed contact time (EBCT) with one unit in backwash and another undergoing media regeneration. Barhale Enpure have also designed a provision for an eighth adsorber to be constructed in the future if required.

- Demolition of an existing sludge thickener and construction of a new 488m3 (working volume) GAC clean backwash tank in its place, providing GAC clean wash water, and motive/carrier water for other services.

Project scope – dirty washwater process

Improvements to the existing dirty washwater systems include:

- Conversion of existing dirty washwater balance tanks to lamella balancing tanks complete with new pumped mixing system and washwater lamella feed pumps.

- Installation of four new washwater lamellas, complete with ancillary plant.

- Construction and Installation of two new sludge balancing tanks with pumped mixing system and sludge thickener feed pumps.

- Construction and installation of two new WRc style sludge thickeners and ancillary plant.

- Replacement and upgrade of the supernatant return pumping system and control system.

- Undertaking modifications to the existing building housing the sludge press and polymer make-up and dosing systems to accommodate polymer make-up systems (replacing the existing units), new polymer dosing systems and a new dry polymer powder store.

- Upgrading of the existing HV installation to provide an additional power connection to feed a new transformer supplying the new GAC and sludge treatment plant.

Other works includes construction of access roads around the new GAC plant, and upgrades to both the site drainage site security fencing.

Interstage pumping station – Courtesy of Barhale Enpure Ltd JV

Environmental management

Environmental management of any site is important, but the presence of the nature reserve makes this particularly significant on this scheme. A significant population of newts had been identified on a pre-existing spoil heap located on the north end of the site – part of which is the location of the new GAC adsorber installation.

Prior to the scheme commencement, Yorkshire Water installed newt fencing around the area, ensured that the newts were relocated, and cleared the vegetation to discourage re-population. BEJV have installed access gates in the fencing, complete with newt capture troughs which are checked daily, successfully preventing any re-population. BEJV have also investigated the potential for bringing in plant via the River Hull which runs adjacent to the site as an alternative to the narrow access road which links the site to the A614. BEJV have also committed to the nett 10% increase in biodiversity for this project, although this was not a compulsory requirement when the project commenced. Other environmental steps taken in line with good practice include installation of EV charging points, limiting work hours to control light and noise pollution, and use of PIR controlled lighting to minimise energy usage.

Tophill Low Nature Reserve – Courtesy of Barhale Enpure JV

Status

At the time of writing (September 2023), detailed design and procurement is ongoing with civils and mechanical design being undertaken in 3D within the BIM360 cloud-based environment. DfMA has been considered where applicable – although a detailed analysis undertaken during the period of supply chain volatility that occurred during 2022 demonstrated that a cast in situ solution for the GAC adsorbers provided the optimal solution both in terms of cost and programme control.

Civils works at site is well underway with site investigations, construction of temporary access roads, piling and security fencing now completed. Construction of the new GAC adsorbers is underway and excavation of the new Intermediate pump station in progress.