Brantham Pumping Station (2019)

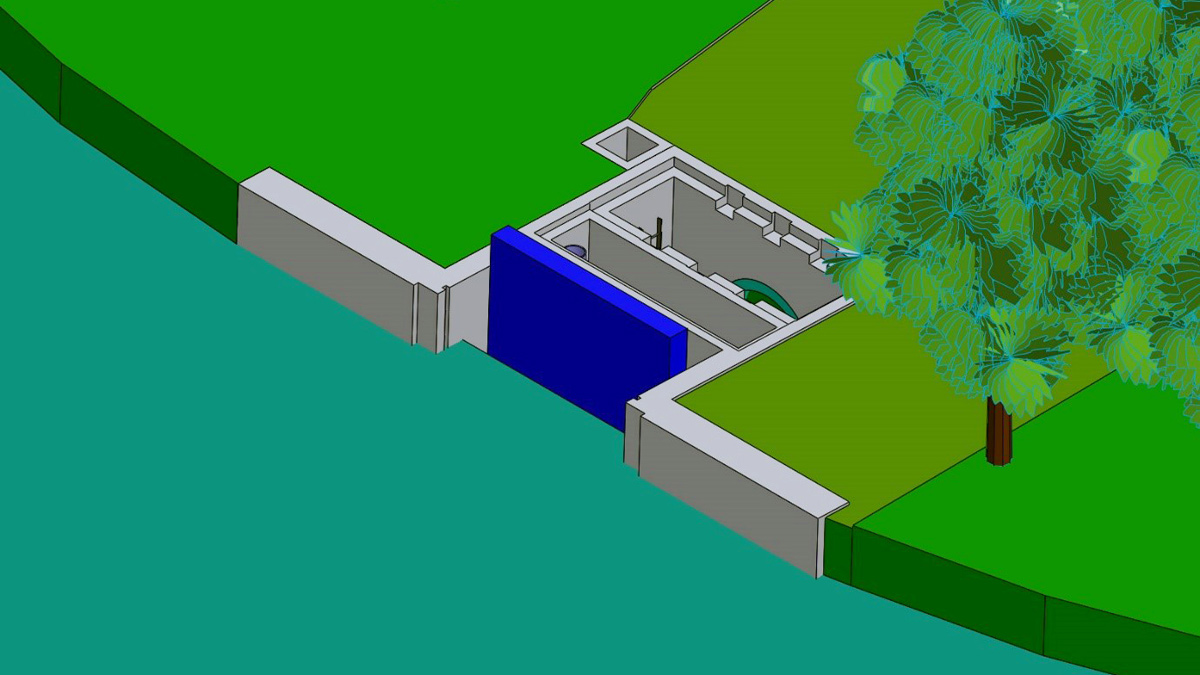

Brantham raw water intake - Courtesy of NWG

Brantham Raw Water Intake is owned and operated by Essex and Suffolk Water (ESW), part of the Northumbrian Water Group (NWG). The raw water intake, located on the banks of the River Stour north of Colchester, abstracts water from the River Stour where it is transferred under gravity to Brantham Pumping Station. The raw water is then pumped to Abberton Reservoir for onward treatment at Layer Water Treatment Works and distribution to the customer base in Essex.

The issue

The Eels (England and Wales) Regulations 2009 came into effect on 15 January 2010. Part of these Regulations set out that any structure capable of abstracting at least 20m3 of water through any one point in any 24-hour period must adequately protect the life stage of eels present at that abstraction point. Therefore the Regulations apply to a number of raw water abstraction points owned and operated by ESW.

The Brantham raw water abstraction point is located within 30km of the coast and therefore it is determined highly likely that juvenile eels (elvers) are likely to be present. To prevent this life stage of eels being drawn into the intake structure to be either killed or trapped, ESW were required under the Regulations to install appropriate screening measures as set out in the Environment Agency’s (EA) document ‘Screening at intakes and outfalls: measures to protect eels’. ESW also worked in partnership with an EA trial to determine if radio tagged eels trapped in Hanningfield Reservoir that were subsequently released in upper stretches of the Stour, would return to a migratory behaviour and whilst seeking to return to the sea, became trapped or killed in the vicinity of the Brantham intake.

Screen positioned within existing structure – Courtesy of IWS

The existing process

The abstraction point at Brantham is a raw water intake based on the banks of the River Stour in Suffolk. The river intake was constructed in the 1970s and comprises a coarse bar screen with bar spacing of approximately 100mm. The bar screens are located in front of two penstocks that can be used to isolate the river from the pumping station which is located 600m downstream. Raw water travels between the intake structure and abstraction point via a 1500mm diameter concrete pipeline. The pumping station at Brantham abstracts water at flow rates typically 32-53Ml/d via 2 (No.) variable and 1 (No.) fixed speed pumps. The existing process is controlled by the network control teams in ESW who monitor the site using the site based instrumentation including river level, sump level, differential head, salinity and abstraction flow rate.

The solution

Essex & Suffolk Water engaged Integrated Water Services (IWS) to undertake a study to investigate and define both the problem and solution, and subsequently undertake a design and construct contract to deliver the required work. The first stage of this process was to complete the EA Stage 1 evaluation sheet to determine the cost benefit ratio (CBR). The CBR calculated for the Brantham site, using the length of upstream improvement to various species delivered by investing in the site, estimated operational and capital costs and the resulting NPV indicated investment in best practice positive exclusion screening at this site.

This enabled IWS and ESW to narrow down the options to be considered at the site from the variety of measures set out in the EA document ‘Screening at intakes and outfalls: measures to protect eel’ such as behavioural measures.

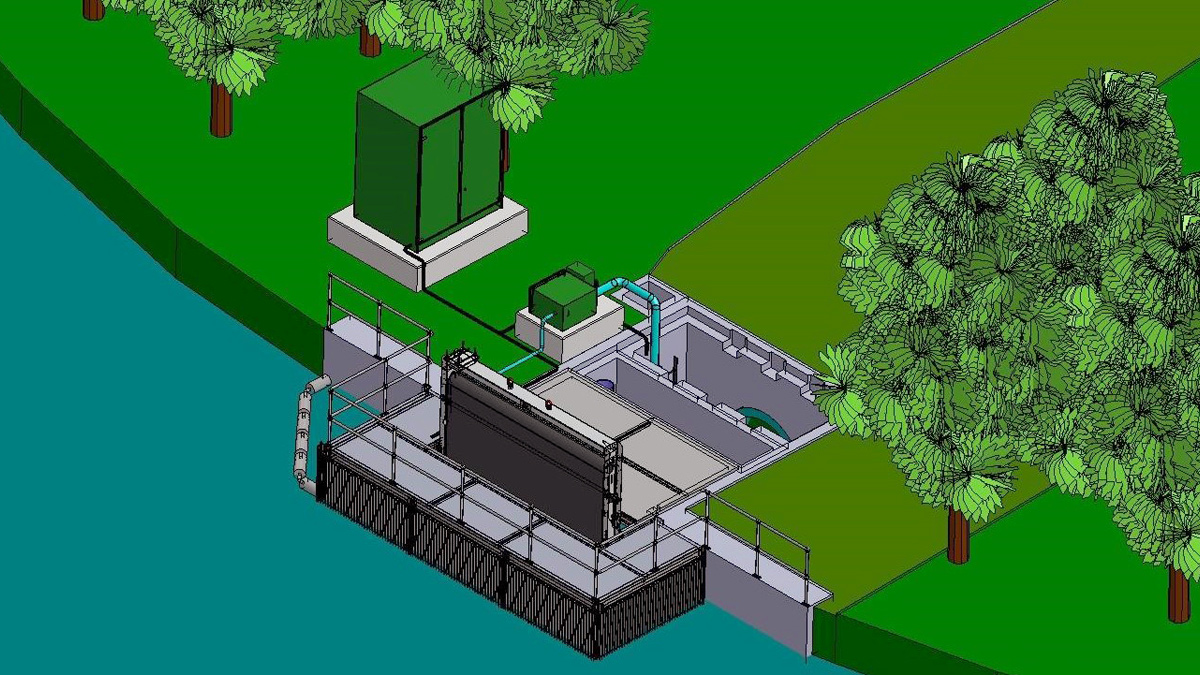

Screen positioned external to existing structure – Courtesy of NWG

Screen selection

IWS and ESW began to consider the relative merits of different positive exclusion screens principally passive wedge wire cylinders and rotating band screens. Given the life stage of eels that were to be protected, a 2mm mesh aperture was required with a maximum approach velocity of 25cm/s. The change in screen size, from coarse to 2mm was a significant one for the water supply team, who operate and maintain the structure, to accept. This prompted a number of visits by the ESW project team including site operational staff, maintenance managers and IWS to various UK sites where 2mm mesh aperture bandscreens had been fitted either passively (wedge wire) or actively (rotating). Agreement was reached within the project team to pursue a rotating bandscreen solution using a Hydrolox travelling screen built by Intralox.

IWS began to work closely with Intralox using data provided by ESW with regards to river level and abstraction flow rate to determine the screen size that would ensure the approach velocities were satisfied in all scenarios. Two principal configurations were considered, positioning the screen within the existing structure or positioning the screen on the outside of the existing structure. Design considerations with respect to approach velocities, screening area and river flow led to the design of a screen outboard of the existing structure being chosen with a single screen element of overall size 3.9m wide and 4.7m high.

Intake structure

The Hydrolox type screen requires a pre-installed support structure such that the screen can be directly lowered into position and forms a seal both at the sides and along the bottom of the screen.

The existing 1970s intake structure consisted of a submerged piled mass concrete apron extending some 5m into the river with a sheet piled front wall structure. A steel framework therefore could be designed and fabricated to fix to the existing concrete structure. A structural survey was carried out to verify condition and dimensions of the structure along with a dive survey to ensure a clear and level floor surface. The framework was manufactured off site and bolted in place by the dive team and the platform flooring fitted to give safe access for installation and future maintenance.

Screen lifted into position – Courtesy of NWG

Power supply

The remote nature of the abstraction point from the pumping station meant that there was no dedicated power supply at the intake. The power required to supply level instruments and salinity monitors prior to this project was provided via an old low capacity power cable run alongside the pipework in the 1970s. The power requirement for any new screen was significantly more than this, which required ESW to request a new power supply from the District Network Operator (DNO) rated at 400V/100A/42kVA along with a new kiosk at the site entrance. This work was commissioned directly by ESW, bypassing the supply chain in the interest of efficiency and expediency.

Design and installation

Washwater for the screen is provided by 2 (No.) duty/standby submersible 11KW canister style pumps on the downstream side of the screen to provide 11 l/s at 40mHd at the spray head. A self-cleaning in-line Y-strainer of 1mm mesh size is fitted in the washwater line to prevent debris blocking of the screen spray bars.

Power and control to the screen is provided by a Form 4, Type 2 motor control centre containing 3 (No.) variable speed drives to power the washwater pumps and screen motor. The MCC also incorporates an ICA section with PLC and interface to the company SCADA system. Various options were considered with regard to communications back to the pumping station including leased line and radio systems but it was decided to use a pair of industrial Ethernet extenders utilising cores in the original buried signal cable.

Once the structure, washwater and electrical supplies were in place, the screen was delivered to site. It then had the additional edge seals fitted and lifted into the prepared structure by crane. Basic setting up and testing was carried out by Hydrolox engineers prior to handing over to IWS staff for full operational testing and commissioning.

Brantham Pumping Station: Supply chain/key participants

- Client: Essex & Suffolk Water

- Principal contractor: Integrated Water Services

- Principal designer: Integrated Water Services

- Systems integration: OCE Systems

- Supplier of bandscreen: Hydrolox

- Motor control centre: TES Group

- Washwater pumps: Wilo Pumps

Modes of operation

The screen can be operated in several modes.

- Differential Mode: Normal operation whereby washing is initiated only if the differential level across the screen, measured by a pair of ultrasonic instruments, is above a pre-set level (say 100mm).

- Timed Mode: This can be selected to allow regular intervals and durations of wash.

- Continuous Mode: Allows the screen to run continuously if, for example, there is a prolonged period of high river debris or weed issues.

- Exercise Mode: This can be enabled to run the screen and washwater systems at pre-set intervals and durations during periods of non-running – typically in summer months where river levels prevent abstraction.

- Cold Weather Mode: In the event of potentially freezing conditions, Cold Weather Mode is automatically initiated to run the screen continuously when the ambient temperature falls below 3°C.

One year on, blending in with nature – Courtesy of NWG

Experience and performance to date

With the Brantham eel screen approaching its first year in operation, there have been no significant operating or maintenance issues. Regular visual checks on rotating parts and quarterly greasing of roller chain and bearings are undertaken and generally, the first of this type in the Essex and Suffolk operating area, has performed very well.