East Worthing WwTW (2017)

Odour control installation at East Worthing WwTW - Courtesy of Southern Water

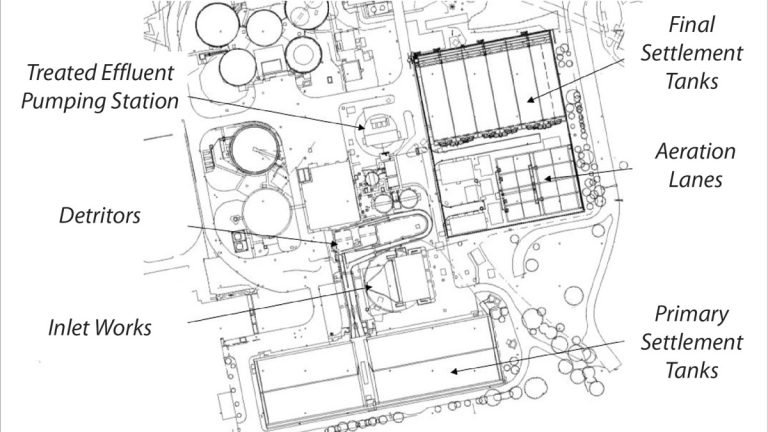

East Worthing WwTW in Lancing serves the Worthing and Sompting catchments in West Sussex, located on the south coast of England. The works provides treatment capacity to a population equivalent of 136,000, which is expected to rise to 155,000 by 2030. East Worthing WwTW is an activated sludge plant providing secondary treatment for flows up to 830 l/s. Preliminary treatment (6mm screening and grit removal) for flows up to 2,450 l/s and screening only for flows above 2,450 l/s. The site was upgraded in 2002 to comply with the Urban Waste Water Treatment Directive through a non-nitrifying contact stabilisation plant that treats settled sewage before discharge into the English Channel. The principal treatment process consists of 4 (No.) rectangular primary settlement tanks, 4 (No.) aeration lanes and 6 (No.) final settlement tanks.

Location

The site is bordered to the south by residential housing, to the west by commercial premises, and to the north and east by public recreational areas including a park, golf course and boating lake. Lancing beach is also only several hundred metres away from the works, beyond the park and lake. With such a high density of local residents with the potential to be affected by activity at the WwTW, noise, visual amenity and odour are closely controlled.

The WwTW discharges via a long sea outfall, which runs 5km off shore from Lancing beach, into the English Channel. This area is recognised as a premier destination for both surfers and kite surfers, with a number of international events held each year.

History

Screenings removal is provided by 2 (No.) 14m tall, 6mm 2D fine travelling band screens. The screens’ positioning, notably the height and angle at which the screen must operate, is somewhat different from the latest Southern Water design standards. The screens are located at the outlet of the incoming sewer.

This sewer is characterised by its large diameter and low gradient. During dry periods, when incoming flows are relatively low, the velocity within the pipe can fall below the self-cleansing threshold. Therefore, rag and grit can drop out of suspension and be deposited in the sewer. During wet periods, when flows are relatively high, self-cleansing velocities are reached, mobilising the previously deposited rag and grit and conveying it to the inlet screens. As a consequence, the site can be impacted by sudden summer storms, when preceded by long dry periods.

These particular environmental conditions contributed to a Category 1 pollution event in September 2012 for which the business was subsequently prosecuted. This event forced an emergency discharge from the short sea outfall onto the beach, generating media and public interest.

(left) Lifting the inlet screens into position and (right) lowering the 14m tall inlet screen into place – Courtesy of Southern Water

Phase 1 scope

In AMP5, Phase 1 of the East Worthing project invested almost £20m to deliver process improvements, including a site-wide programme of asset upgrade, replacement, refurbishment and to clean a 1km section of the trunk sewer main. Preliminary treatment at East Worthing WwTW is provided by 2 (No.) inlet screens, which are used to remove debris from between 500 l/s (43,200m3/d) and 4,500 l/s (388,800m3/d) of incoming flows that the site typically receives, depending on the weather.

Routine maintenance includes the refurbishment and annual rotation with a third ‘boxed spare’ inlet screen. This is required due to damage caused by significant amounts of rag coming in to the site from across the large catchment it serves. This material places additional load onto the screens, increasing both the rate at which they wear and the risk of them getting damaged. Alongside the work on site, an extensive customer focused education campaign has been carried out in the local area to try and reduce the amount of RAG, FOG and unflushables that reach the treatment works.

Scaffolding being set up to allow work on the inlet shaft – Courtesy of Southern Water

The inlet control was upgraded and the modulating flow control penstocks were installed to better control flows through the WwTW, isolate inlet channels to enable completion of maintenance work and to reduce wear on the screens, resulting in extended asset life. This is achieved by close control of pumps, penstocks and screens to optimise forward flows through to the primary process units. A new operating philosophy modelled hydraulic flows through the inlet works, taking into consideration the most efficient operation of the plant. A new PLC, together with field instrumentation, was installed to control the plant. With full SCADA integration and remote connection via telemetry, the site can be monitored and controlled remotely 24/7.

New primary settlement tank (PST) scrapers were installed to replace the existing assets. The PSTs, which are enclosed by odour control covers, are located immediately adjacent to residential housing, which required very careful management and delivery of the construction programme. The activity was scheduled to be undertaken in the spring months, when both the incoming flows and the ambient temperature were relatively low. This reduced the likelihood of odours causing a nuisance to local neighbours.

Replacement return activated sludge (RAS) valves were installed to better control the return of settled sludge from the clarifiers, back to the aeration lanes. Operating in a duty/assist/standby regimen, each RAS valve was replaced sequentially without interruption of the process.

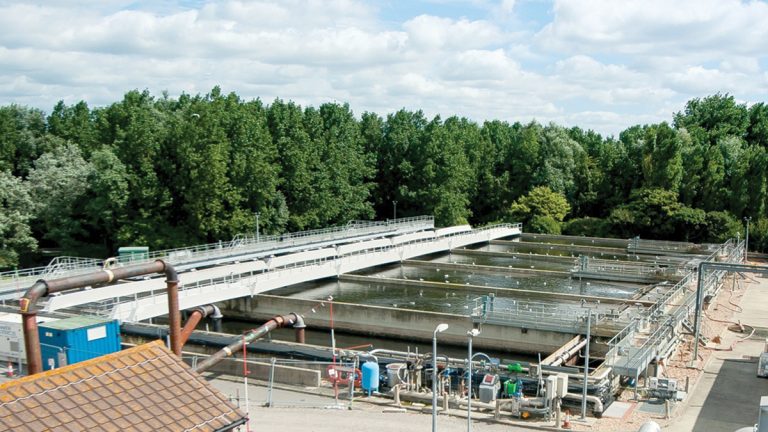

Castellated longitudinal weirs replaced the more traditional transverse weir in the FSTs to improve effluent quality.

The high-efficiency canister type treated effluent pumping station (TEPS) was affected by high flow in September 2012, with small amounts of rag which were carried over in the flows, leading to problems downstream. Using a 100 tonne mobile crane, each of the TEPS pumps were lifted, cleaned, refurbished and reinstalled.

Site overview diagram – Courtesy of Southern Water

A new TEPS motor control centre and 2000kVA transformer were installed to provide both closer control and a more stable power supply to the pumping station. Additionally, modifications were made to the TEPS valve/instrument chamber to prevent damage caused by on site flooding and build resilience into the arrangement.

A 1km section of the incoming trunk sewer near to the treatment works was jetted as part of the project. This cleared approximately 2,000 tons of rag, made up of grit and non-biodegradable debris which were clogging up the 2.2m diameter pipe. This has improved the flow of wastewater to the treatment works and increased capacity in the sewerage system for stormwater during heavy rainfall.

Phase 2 scope

In Phase 2 the project will further increase resilience at the wastewater treatment works. The benefits derived from delivering the project scope are providing the WwTW with a more stable HV power supply and a reduction in risk of inlet works failure, both of which will prevent catchment area flooding requiring the discharge of unscreened storm flows via the short sea outfall (SSO).

The site is bordered to the north and east by recreational area – Courtesy of Southern Water

The Phase 2 proposed project scope includes:

- Replacement of existing storm pumps and detritors: The existing assets require replacement and upgrade to current Southern Water design standards. This will enable higher flow rates to be achieved under storm conditions and will extend the asset life of downstream process units by reducing the wear rates following the increase in grit removal.

- Upgraded transformers, switchgear and HV power supply upgrades: The site receives two incoming power supplies connected to different parts of the network. By reconfiguring the site ring main, further resilience can be derived for the critical assets on site.

- Targeted repairs to the inlet concrete structure: Surface repairs to the inlet shaft structure are now required to extend the asset’s life.

- Continuation of the annual rotation and refurbishment of the inlet screens: A rolling programme of refurbishment and rotation maintains these critical assets and protects downstream process from rag carryover.

- Continued engagement with stakeholders and local residents.

Stakeholder engagement

Key stakeholder groups were identified early in the project, which included local residents, businesses, community groups, local councillors and the Member of Parliament for East Worthing and Shoreham. For each group, tailored engagement plans were developed, incorporating activities such as site tours, drop-in sessions and regular updates via letters and leaflets.

A dedicated webpage was created to provide live updates. These communications focused on the efforts being made to ensure that the construction programme minimised noise, odours and visual impact, particularly during the busy summer months.

In addition, the project sponsored local charities, events and a schools STEM outreach programme used to promote science technology engineering and maths subjects to secondary school students. A series of short videos was also produced to reinforce customer messaging and to provide educational resources for schools on the water treatment process.

The catchment has also seen proactive engagement with customers to reinforce what shouldn’t be disposed of in the sewer network as part of Southern Water’s ‘Unflushables’ campaign.

On the south of the site there are residential properties, so odour and noise need to be closely controlled – Courtesy of Southern Water

Conclusion

The first phase of East Worthing WwTW project was completed in September 2015. Before the second project phase could begin, a period of review was used to assess the performance following improvements made to date.

A team of in-house design engineers, including specialists from each of the disciplines of civil, electrical, mechanical and process engineering are now working on the details of how Southern Water efficiently deliver the next phase of work.