Maiden Lane Reservoir (2022)

London skyline from view at top of embankment - Courtesy of MWH Treatment

The brick-built Maiden Lane Reservoir holds 67 million litres of water and supplies a population equivalent of approximately 200,000 people in north-east London. The reservoir is located in Dartmouth Park which opened to the public in 1972 and is in the London borough of Islington. The top of the embankment gives an open semi-panorama of the London skyline, and the park has several observation points that have been installed to allow residents and visitors to enjoy the view. The park hosted one of the beacons lit nationwide on 21 April 2016 to celebrate Queen Elizabeth II’s 90th birthday and was lit again recently to mark the Queen’s Platinum Jubilee.

Description of the current facility

Water stored is already fully treated, the majority coming from the Coppermills WTW on the River Lea. Maiden Lane is a Statutory Reservoir and comes within the terms of the Reservoirs Act 1975. The top water level is 70.32m AOD and the depth when full is approximately 6.7m. The reservoir is charged at night, when pumping is more cost effective, and then depleted during the day though normal usage. The reservoir is a fully covered brick service reservoir and the brick roof arches span in two directions.

The reservoir was completed in 1855 and received its name from the lane where Dartmouth Park now stands. At the time, the surrounding area was largely undeveloped, and the reservoir was surrounded by fields. Nowadays the reservoir sits right in the heart of a bustling residential area and is accessed off the busy Dartmouth Park Hill Road.

Project need

The primary concern was the stabilisation of the operational service reservoir, the eastern embankment of which had seen gradual but accelerating movement over recent years. This was evident in large cracks in the path leading through the park surrounding the reservoir.

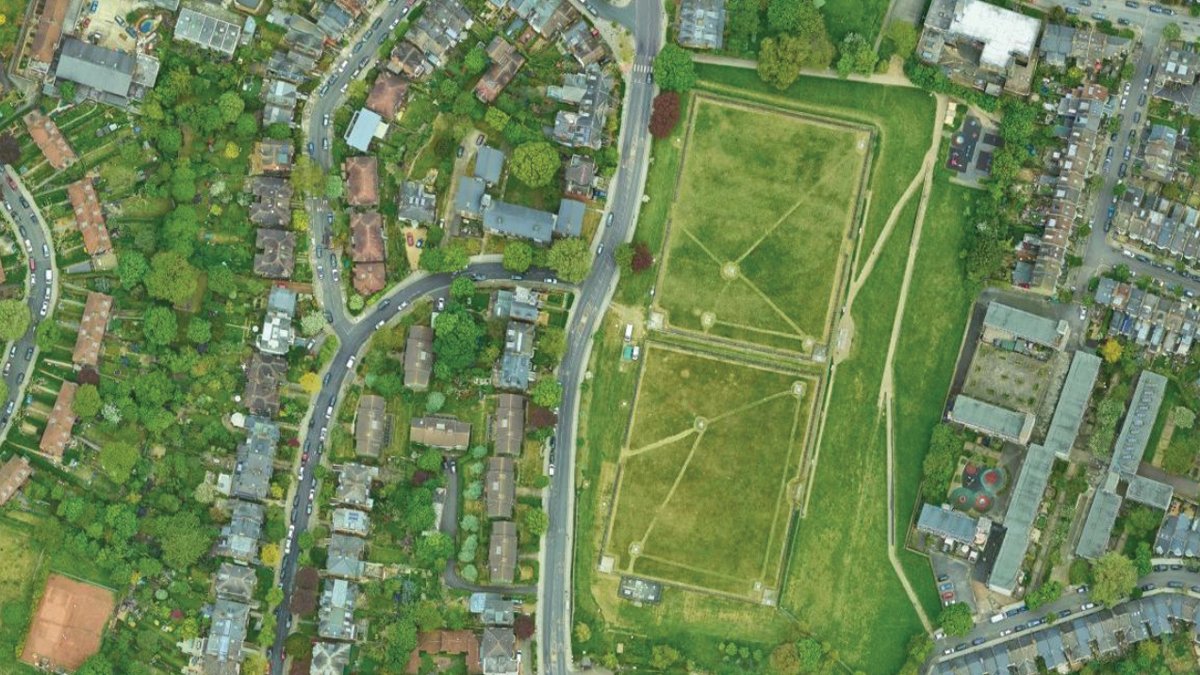

Google Maps image showing location of Maiden Lane – Courtesy of MWH Treatment

Scope of works

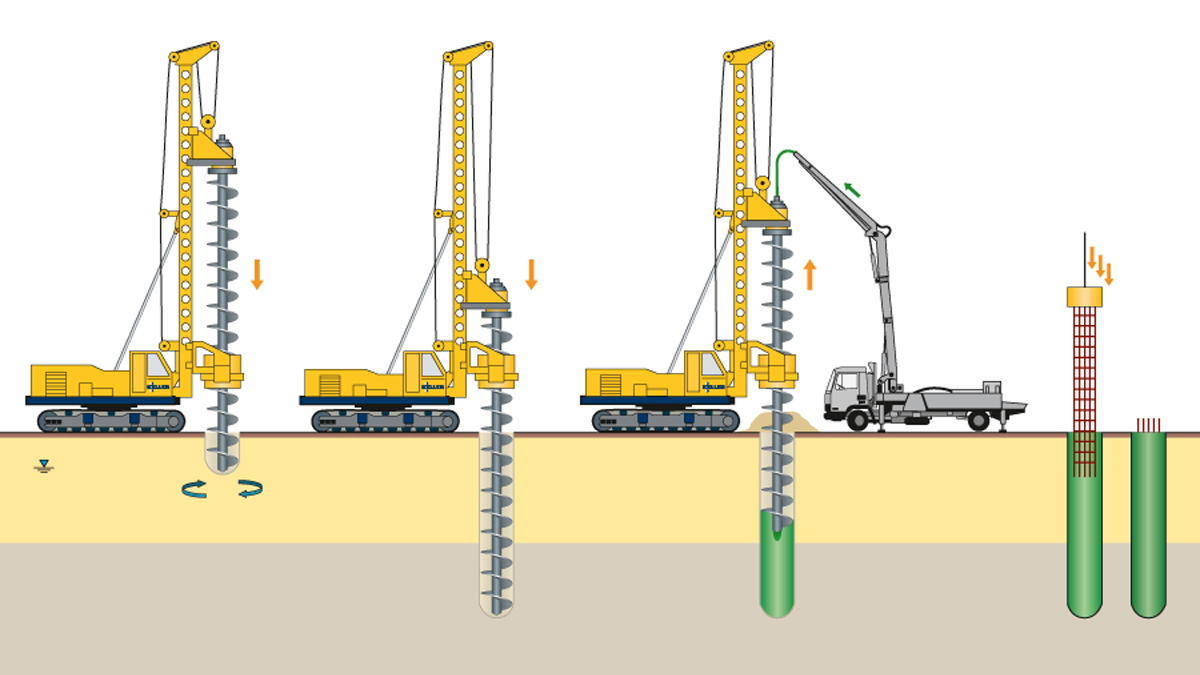

The aim of the works was to improve the overall stability of the embankment through the installation of continuous flight auger (CFA) concrete piles, along with a new drainage system.

The proposed solution was for the installation of two rows of CFA piles at appropriate locations on the embankment, with improved drainage to mitigate further ground movement. Additionally, inclinometers were planned to measure movements in the embankment, both during the works and to assess the success of the solution in the future. During the project, noise and vibration monitors were to be installed around the park, and piling would adopt a rotary bored style techniques; both to limit the noise and to minimise vibration which could potentially damage the existing structure.

MWH Treatment were allocated the project under Thames Water’s Lot 3 London Non-Infra Framework. The core scope of works included the following:

Reinforced concrete piles

The installation of 135 (No.) 600mm diameter reinforced concrete bored piles up to 11m long in the eastern embankment, arranged into two parallel rows (i) along the mid-slope line of the embankment and (ii) close to the toe and providing additional strength to the critical section of the embankment, and to intercept any potential secondary slip mechanism involving the steeper lower section.

Drainage system

The drainage system consisted of the following works:

- Topsoil strip.

- Minor slope re-grading works.

- Installation of a drainage blanket, carrier drains, and a crate-based storm water attenuation system.

- Reinstatement of the topsoil and footpaths.

(left) CFA piling rig in operation and (right) pile mat with completed piles – Courtesy of MWH Treatment

Technical description

Remedial works were undertaken on the southern embankment in 2012 at which time the eastern embankment was deemed to be less critical. Following further reviews and investigation in subsequent years, ground movement in the eastern embankment became an increasing concern. During winter months it was found that the ground swelled due to the wetter weather and shrank during the drier summer months resulting in bulk movement of the embankment.

Several solution options were considered during the initial design stage of the project. A number of factors influenced decision making including: access limitations, the height of the eastern embankment and the location of a masonry retaining wall at the toe of the embankment. These, plus increasing urgency, led to it being determined by the principal designer Mott MacDonald, in consultation with Thames Water’s Reservoir Team and Independent Panel Engineer, that the preferred solution should be reinforced concrete piles.

The permanent piles were not required to take any vertical load; their primary purpose was to stabilise the slope. The piles would be subject to lateral loads from the embankment with a design working lateral load of approximately 200kN per pile.

The proposed design of the surface drainage works would remove direct rainfall into the embankment, to reduce the swelling of the ground, thus mitigating future ground movement and improving the overall stability of the embankment.

Public consultation

Before work started on site there was a customer engagement event, where members of the public were invited to the park to meet members of the project team. Staff from Thames Water and the site team from MWH Treatment explained the purpose of the works, the duration and the measures being taken to mitigate impact to the surrounding properties during the works.

Reducing impact to the close proximity neighbours was a high priority for the project, as there are residential properties around every boundary of the park. The site hours were restricted to between 7am and 6pm Monday to Friday, to reduce the noise and impact on the surrounding areas.

Site works

Site works supervised by MWH Treatment began in July 2021, and at the peak of construction works, 30 engineers and construction staff were present on site. The reservoir is in a conservation area and whilst environmental considerations are always a priority, special attention was paid during the enabling works. Pro Landscapes MDX Ltd were employed to reduce the overhanging tree limbs and remove self-sets, to allow sufficient room for future delivery of piling plant and concrete along the existing access road. Larger limbs were retained and pruning works were kept to a minimum. Later in the same month the construction of the concrete bases for the welfare establishment was undertaken by the civils contractor, Derryard Construction Ltd. At the same time remedial and additional works to reinforce the access road were carried out in preparation for construction plant.

The site was heavily constrained from a space and logistics perspective, and a significant effort was required in the planning, design and installation of temporary works to facilitate the permanent works. The location of the proposed piles in two parallel lines meant that the piling mats and access to the piling mats had to be established on the mid-slope of the embankment at two levels.

The procedure for installation of the continuous flight auger piles by Van Elle – Courtesy of Van Elle

Space constraints and the slope of the embankment prevented the opportunity for one way traffic and turning areas, all of which resulted in the requirement for significant pre-planning to ensure safe access for the large plant and piling rig. Prior to commencement of piling, Derryard Construction Ltd constructed the piling mats for the 20-tonne rig on the slope of the reservoir. This involved removing the existing topsoil to a minimum depth of 200mm, installation of a geotextile membrane followed by layers of recycled aggregate compacted in 150mm layers.

On completion of the piling mat, Van Elle commenced installation of the 135 (No.) 600mm diameter, piles in mid-August 2021 and were on site for just over 12 weeks. The augers were lifted by an attending 13-tonne excavator to facilitate connection to the rig, thus allowing the pile to be bored to the required depth. Concrete was then pumped though the rig and down the sectional flight augers to the base of the pile using a static concrete pump and hoses. The auger sections were then removed, utilising the13-tonne excavator, and set down ready for boring the next pile.

The stormwater attenuation crates were also installed by the civils contractor. They were designed adjacent to the new piles, so that once the piles gained strength they served as lateral support for the excavation to install the drainage works.

Inclinometers were fitted at the top of each reinforced pile to measure the orientation angle of the embankment and to record any future ground movement. The inclinometers are protected by security covers in order that they remain undamaged for periodic ground movement surveys in the future. Following completion of the piling and the drainage installation the civils contractor completed the finishing works. This consisted of reinstatement of the embankment, seeding with high nutrient grass seed, installation of footpaths at mid slope and at the top of the embankment for public access. Additionally further benches were installed at the top of the embankment to allow the public to take advantage of the panoramic views across central London.

The reinstated slope of the embankment prior to hydro-seeding – Courtesy of MWH Treatment

Maiden Lane Reservoir: Supply chain – key participants

- Client: Thames Water

- Principal contractor: MWH Treatment

- Principal designer: Mott MacDonald

- Temporary works designer: Noble Works

- Landscaping and tree surgery: Pro Landscapes MDX Ltd

- UXO surveys: 6 Alpha Associates

- Laser scanning: MWH Treatment

- Civil works: Derryard Construction Ltd

- Piling: Van Elle

- Pile cropping: Kilnbridge

- Pile integrity testing: Strata Geotechnics

Conclusion

Main piling works were completed at the end of November 2021. The remaining works to complete the drainage and to reinstate the site with the additional improvements to public access and amenities, were completed in July 2022, including a second hydro-seeding of grass taking place in June 2022. When matured, this will re-establish the aesthetically pleasing natural appearance of the embankment and will be an attractive open space for the neighbouring community.

The reservoir’s stability has been secured for the next 60-100 years. Following the completion of the main heavy construction works, Thames Water and the Council are now improving the overall amenity at Dartmouth Park Hill with the installation of an upgraded children’s playground to further benefit the local community.

View from the top pf the embankment of the completed works – Courtesy of MWH Treatment

Through a collaborative approach, Thames Water, MWH Treatment and key suppliers have delivered a long-term solution to a technically and logistically challenging problem whilst maintaining excellent relations with neighbours, leaving a legacy which will enhance the local area. This was all achieved safely without any lost time or environmental incidents.

The Park was included in the Queen’s Platinum Jubilee on the bank holiday on the 2nd of June. Approximately 1,500 beacons were lit across the UK and The Commonwealth as a network of flaming tributes to the Queen, including the one in Dartmouth Park. The Mayor and other local dignitaries attended what was a very special event for the entire project team.