Matchams Riverbank Stabilisation (2022)

Matchams Raw Water Intake - Courtesy of South West Water

Matchams Raw Water Intake is located on a fast-flowing bend on the River Avon. The building was constructed c.1955, and provides a reliable source of raw water to Alderney WTW in Bournemouth. The water depths along the extraction point are typically 3-5m (relative to ‘ordinary’ water levels), with a high river flow rate, circa 3 knots, even when not in spate. Extraction is designed to deliver up to the undertaker’s abstraction licence permit agreement 63.6Ml/d. The project needed to be delivered at a time that would not affect the lapwing and redshank nesting season, both forming part of the adjoining estates high level stewardship programme to improve their chick survival rates and be completed before Salmon spawning season. The delivery requirements were (i) to stabilise the existing riverbank and prevent damage whilst providing the least amount of environmental impact, and (ii) to design and trial a temporary over pumping solution to mitigate the risk of losing the intake.

Surveys

The Matchams Raw Water Intake Station structure consisted of a steel sheet pile wall with a concrete capping beam which runs north/south along the riverside embankment on the River Avon. In May 2018 and June 2020 Teignmouth Maritime Services Ltd (TMS) were contracted by Arcadis and Bournemouth Water to carry out an in-water visual inspection of the steel sheet pile wall as well as Cygnus Underwater Ultrasonic Thickness (UT) readings of the sheet piles.

May 2018 inspection: The initial inspection was undertaken in May 2018 when some riverbank subsidence was observed. Underwater examination revealed that there were several defective clutches and exposure below the sheet piles at riverbed level. This in turn had led to riverbank washout behind the sheet pile wall. This was thought to have been caused by two issues; the first being scour along the sheet pile wall from fast water flows in the river; the second being poor pile installation.

Riverbank washout adjacent to intake prior to commencement of works Courtesy of Teignmouth Maritime Services/Bournemouth Water

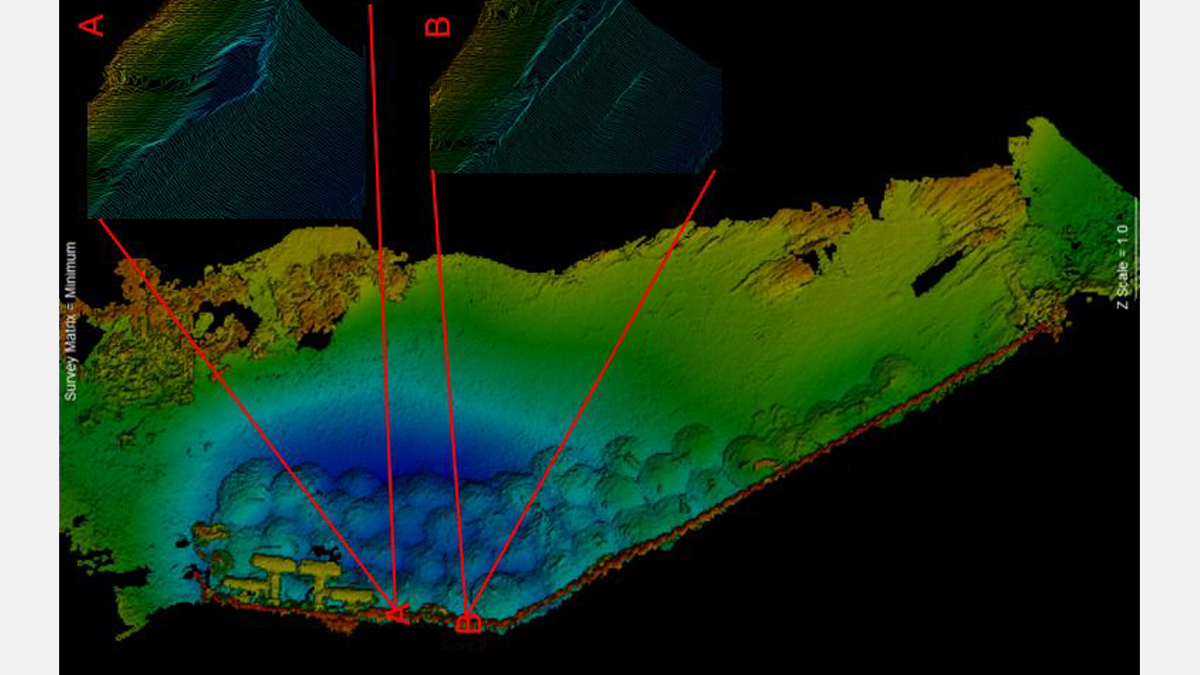

June 2020 inspection: By June 2020 the river water depth had increased along the most affected area by up to 1.2m, indicating riverbed scour. This revealed the bottom of 40 piles (an increase of 11 since May 2018) and in places formed very large voids between the pile toes and riverbed of almost 2m in height. The riverbank subsidence holes/voids had greatly increased and the material from these voids had washed out into the river underneath the piles.

Scour had also moved further upstream to the region of the pumping station and riverbed scour along the frontage had increased by a further 500mm. Whilst the piles retained adequate thickness, many were deflected with damaged and torn clutches. Due to the scour, the piles were essentially ‘floating’ and not offering any support to the riverbank and capping beam above. The scouring effect had removed all soils/fines etc from behind the sheet pile wall.

It was at this point that repair works were required. Over the next 12 months the riverbed erosion, particularly the area directly adjacent to the intake station on the south side, was regularly monitored whilst Arcadis and TMS formulated a short-term repair method package to allow for a 5-year plan to be designed for full remediation with potential intake station replacement and movement elsewhere on that stretch of the River Avon.

Planning and permits

Prior to the works commencing, numerous stakeholders required consultation; a lengthy process due to the Covid-19 lockdown.

A Habitats Regulation Assessment was carried out in addition to Natural England and Environment Agency consultation, local consultation following NEW Forest ‘sensitive wildlife areas’, a Flood Risk Activity Permit (FRAP), and finally, receipt of a bespoke EA permit.

With the above in mind TMS, acting as principal contractor, carried out the usual CDM duties as well as producing a bespoke and site-specific biodiversity policy and procedure to include the caveat that all equipment prior to and after diving operations was washed down with a specialist environmentally friendly cleaning solution ‘Virkon Aquatic’.

Prior to any site mobilisation, due to the unknown ground conditions, in situ plate loading tests were required to prove the stability of ground adjacent to riverbank to allow a 70T crawler crane access to site. The test results were favourable so the works could proceed without further ado.

(left) Chert and rock from Blashford Quarry and (right) filling the Salix AquaRockBags – Courtesy of Teignmouth Maritime Services/Bournemouth Water

Quay wall and riverbank erosion – temporary protection

Working throughout the Covid-19 lockdown, Arcadis and TMS collaborated to provide Bournemouth Water with a robust, yet temporary method of protection for the quay wall and riverbank.

Works involved the placement of AquaRockBags from Salix River and Wetland Services at the toe of the sheet piled wall using divers for positioning. The intention was for these bags to stop water from flushing under the piled wall and to give a modicum of toe support.

It should be noted that these works should not be regarded in any way as a permanent mitigation nor as fully stabilising the wall. The rock bags were not intended to infill the riverbed back to its original level as it was unknown what impact this would have on the rest of the river.

On 12 July 2021, the TMS team mobilised to site with a five man dive team, crane operator, machine operator and slinger/banksman and, following several inductions and briefs from interested stakeholders, site establishment could commence.

The local landowner was fortunately affable to the works that were required and allowed access via his land to site. A temporary access way was created through a hedgerow under some power cables. A robust ‘goal post system’ was installed as considerable plant traffic was to be expected over the short period that the works were expected to last 2 working weeks 12-23 July 2021.

Crane lifting 4T Salix AquaRockBags into position – Courtesy of Teignmouth Maritime Services/Bournemouth Water

The temporary access route for the 70T crawler crane, rock deliveries and excavator and the rock laydown area was matted out with 80 mats 5m x 1m x 150mm using the 21T excavator. The matts worked threefold, limiting damage to the ground, to local wildlife and to lift and install rock bags, filled by a 21T excavator.

A separate lay down area was created with timber mats in the adjacent field, to receive delivery of rock and to fill/assemble the rock bags.

Site security was also an important factor due to the ‘Local Forest Dwellers and River Folk’ following a few initial problems. Good site security was achieved with close collaboration with Bournemouth Water combining the use of their secure water treatment works compound and buildings as well as intelligent use and positioning of heavy plant and 4T rock bags!

Once the lay down area and access track had been established, the 70T crawler crane, dive station and jet float pontoon system (temporary diving platform) were established.

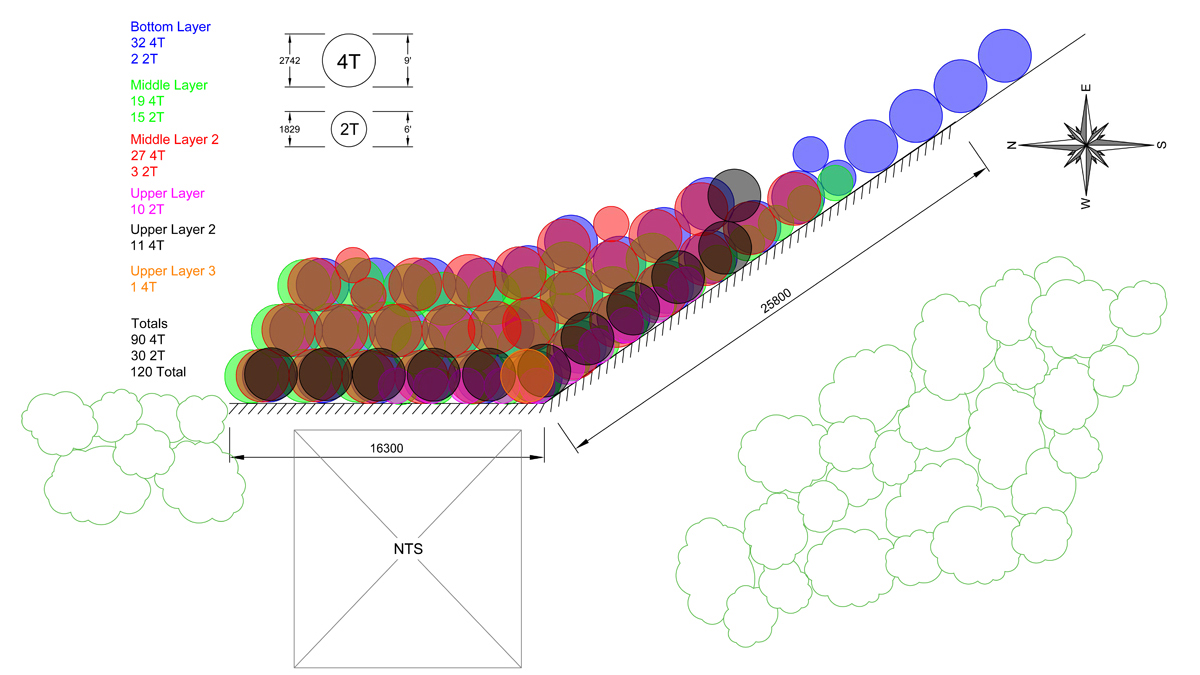

An initial dive survey on the Tuesday confirmed further scour to the quay wall. The riverbed adjacent to the wall was surveyed for scour and for any obstructions and debris. Meanwhile the topside team (non-diving) were assembling the rock bags. A total of 90 (No.) 4-tonne and 30 (No.) 2-tonne rock bags required filling, using 300 tonnes of rock.

Final position of installed rock bags – Courtesy of Teignmouth Maritime Services/Bournemouth Water

A production line was created over the following days. The rock was delivered in 20-tonne loads as per requirement from a local quarry at Blashford (5 miles away) for two reasons. Firstly to ensure that the stone for the bags was as close as physically possible to the riverbed make up and also to keep the project’s carbon footprint as low as possible. The stone used was locally sourced, consisting mainly of chert with quartz and ironstone fines.

The rock bags were filled using the 21T excavator with a bespoke-made square hopper and stacked on the laydown area. Then the 70T crane lifted the bag up and over to the river where the diver had already spotted for the crane operative as where the bag should be placed and then subsequently had moved clear to avoid any overhead lifting.

Once the bag had been placed on the riverbed the diver would guide the bag from above the load into the position as per the design drawings using communications via the dive supervisor (who in turn instructed the crane operator).

The work was arduous, particularly as it was during the hottest two weeks of the year (with temperatures in the low 30 degrees) but despite this, all 120 bags were assembled and installed by 22 July 2021 – completing this section of the works on time and on budget.

Final survey of installed rock bags – Courtesy of Teignmouth Maritime Services/Bournemouth Water

Whilst it was highly unlikely that the rock bags would move once installed and embedded into the riverbed, for additional security to ensure the temporary scour protection remained in place (if flooding/high river flows occurred) all the bags were secured/knitted together with a high quality tensile synthetic 20mm tiger rope. This rope is 50% stronger than standard nylon ropes with a breaking strain of 8T.

Matchams Riverbank Erosion Protection: Supply chain – key participants

- Main contractor: Teignmouth Maritime Services Ltd

- Riverbed surveying: Shoreline Surveys Ltd

- Overpumping: Selwood Ltd

- Overpumping materials lifting: G&M Cranes

- Rock bag layout: Arcadis

- Salix AquaRockBags: Salix River and Wetland Services

- Blashford Quarry stone: Tarmac

- Self-flushing eel screens: Rotorflush Filters Ltd

(left) Section of PN16 DN600 150m temporary overland pumped raw water delivery and (right) dualled section of temporary overland pipework discharging into the existing pumping station – Courtesy of Bournemouth Water

Trial installation of temporary emergency pumping system

Once the rock bag installation portion of the works had been completed, the jet float pontoon was relocated and reconfigured to allow trials for installation of a temporary emergency pumping system undertaken by Selwood Ltd.

Should the sheet piled wall fail, there would be a reasonable chance that the associated inlet structure would be undermined and would also fail. To mitigate this, a temporary electric powered pump was installed on the land to the west of the river. A floating hose was also installed into the river and a temporary suction hose installed into the river; this pumped system would then start abstracting water to replace the existing nearby abstraction point should it fail.

The intake was fitted with 2mm self-flushing screens from Rotorflush Filters Ltd to help protect fish, eel and other fauna from being removed from the river. This would keep it in accordance with the existing abstraction licence. The intake, screen and the floating hose were all supported by pontoons or air bags that were anchored to the bed of the river.

The exact position of the intake was identified following a detailed bathymetric survey and depth probing to identify sedimental deposits on the river bed as the intake required a critical depth of clean water to allow the screen to function.

Selwood Ltd sized the equipment to deliver 64Ml/d to the pump station in the event of the loss of the inlet on the riverbank. The 600mm rigid steel pipework rising main was laid over-ground; though was buried under the access road to four private properties and a farm. The rising main was run over a distance of approximately 150m and was designed and installed by Selwood.

Rotorflush RF1100-1000LW backwashing suction strainers – Courtesy of Bournemouth Water

Conclusion

The temporary works project ran smoothly thanks to the full cooperation of all parties involved and the expert knowledge of Teignmouth Maritime Services Ltd and Selwood Ltd.

Long term options are being explored with HR Wallingford, EA and Natural England working towards a final solution to be delivered in AMP8.