Quin WwTP (2022)

Aerial view of the upgraded Quin Wastewater Treatment Plant - Courtesy of EPS Group

Quin Wastewater Treatment Plant (WwTP) is a small works serving a rural village in County Clare in the west of Ireland. The plant has been operating with a capacity of approx. 650 population equivalent (PE) and is operated and controlled by Irish Water. It discharges into the River Rine which flows to the Shannon Estuary, which is a protected habitat under a Special Area of Conservation designation. Quin is a picturesque and historic village which attracts significant tourism in the summer months, mostly through day visitors which impose a notable hydraulic and ammonia load on the treatment plant.

Existing works

The existing wastewater treatment plant comprised of a single duty-only inlet screen, flow meter, aeration tank with vertical spindle surface aeration, twin Dortmund-type clarifiers, sludge holding tank and a motor control centre (MCC). The plant was under compliance pressure due to long-term catchment growth and seasonally high ammonia loads, and there were also operational challenges around asset reliability, energy usage, intermittent odour and noise generation.

The imposition of a new, stricter discharge consent ultimately led Irish Water to carry out a significant upgrade to the plant. Irish Water elected to carry out the project under their national Early Contractor Involvement (ECI) Framework.

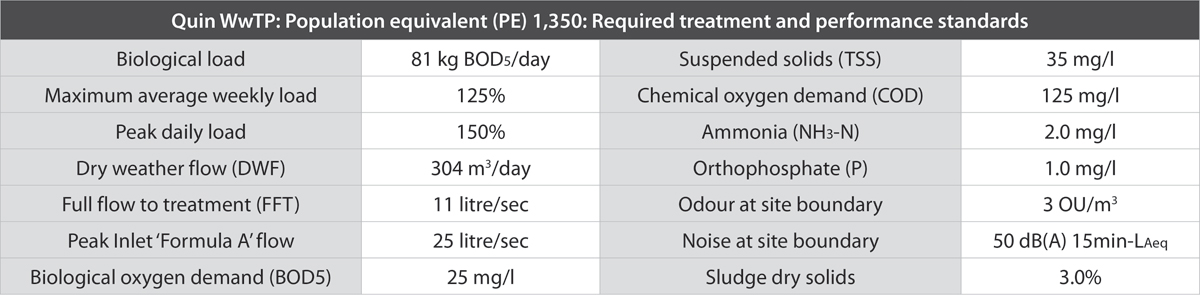

Required treatment & performance standards

Early Contractor Involvement (ECI) Framework

EPS Group was allocated the Quin WwTP Upgrade project by Irish Water, as they were the relevant regional contractor appointed under the ECI Framework. Launched in 2019, the ECI Programme represents a new capital delivery model for Irish Water, centred around contractor engagement from the start of the project lifecycle to drive collaboration and efficiency.

This leads to greater cost certainty, reduced tendering cost/effort, less wasted effort in design and increased use of innovation. The contract is expected to deliver 50+ projects valued at over €400m, and uses a commercial pain/gain incentivisation mechanisms, target cost valuations and appropriate risk allocation.

The new inlet works – Courtesy of EPS Group

Project scope

The main objectives of the Quin WwTP upgrade project were as follows:

- Upgrading of an existing brownfield site to 1350 PE.

- Delivery of compliance with a new Environmental Protection Agency (EPA) discharge licence including new, stricter ammonia and ortho-P limits to comply with the UWwT Directive.

- Replacement of end-of-life assets.

- Retention, refurbishment and integration of some existing infrastructure.

Project delivery

In order to deliver the above objectives, the following works were carried out:

- New inlet works with 6mm 2D duty/standby screen c/w screenings washing and compaction, 19mm manual bypass screen and grit removal system.

- 2 (No.) new primary settlement tanks.

- Forward feed pumping stations of FFT flows with overflow to stormwater holding tank.

- 4 (No.) rotating biological contactor (RBC) units operating in parallel with provision made for a fifth RBC to be added at a later date.

Rotating biological contactor (RBC) units at Quin WwTP supplied by KEE Process Ltd – Courtesy of EPS Group

- 2 (No.) final settlement tanks.

- Lift pumping station for final effluent discharge during periods of high river level.

- Ferric sulphate chemical dosing system for phosphorus removal.

- Sodium hydroxide chemical dosing system for low alkalinity.

- Washwater collection sump and pump set.

- Conversion of the existing aeration tank into a stormwater holding tank.

- Provision of a new administration and control kiosk with MCC.

- New instrumentation and sampling package.

- New SCADA system.

- Conversion of the existing control building to a storage facility.

- Site lighting, access road and landscaping works.

- Testing and commissioning of the new plant.

- De-commissioning, demolition and removal of redundant assets.

The design phase commenced in April 2019, with work commencing on site in March 2020 and completion of commissioning in May 2021. The out-turn project construction cost was approximately €3.0m.

(left) View of the new sludge holding and decanting tank and (right) process water (washwater) kiosk – Courtesy of EPS Group

Quin WwTP: Supply chain – key participants

- Client: Irish Water

- Main contractor: EPS Group

- Process, mechanical & electrical design: EPS Group

- Civil design: Doran Consulting Engineers

- Civil subcontractor: Balfour Beatty Ireland

- Precast concrete: Shay Murtagh Precast

- MEICA design & installation: EPS Group

- Grit classifier: Aqseptence Group GmbH (Noggerath)

- Grit trap: SAVECO Environmental Ltd

- Process pumps: Zenit Group

- Blowers: Aerzen Machines

- Rotating biological contractors: KEE Process Ltd

- Chemical dosing pumps: EMEC

- Chemical storage tank: SILOTANK

- Mixers: Xylem Water Solutions (Flygt Pumps)

- Odour control: John Cockerill Environment

- Motor control centre: Alpha Drives Ltd

- PLC/HMI & instruments: Siemens

- MCC kiosk: Industrial GRP Ltd

- Penstocks: BEFU Umwelttechnik GmbH

Constraints & challenges

The project design and delivery was impacted by a number of constraints and challenges, as follows:

- Restricted site footprint: This limited solution and design options, and restricted available areas for laydown and assembly during construction.

- Maintaining compliant treatment: The solution and construction methodology had to ensure that adequate treatment was maintained throughout the construction period.

- Influent wastewater characteristics: The site has to cater for highly variable and ‘spiking’ levels of ammonia in the inlet due to the nature of commercial businesses within the catchment.

- Elevated flood levels: The site is prone to seasonal flooding, with a defined flood level identified.

- Height restrictions: Compliance with visual impact requirements of the planning permission, particularly given the historic nature of the village.

- Proximity of residents: Ensuring that the finished plant and the construction works did not cause significant nuisance to the occupants of adjoining housing.

- Ground conditions: The site is characterised by shallow bedrock and a highly variable water table, making deep excavations costly and potentially troublesome.

- Constrained programme: Ambitious target dates to meet compliance deadlines.

- New working arrangements: This was the first project to be delivered under the ECI Programme by both EPS Group and the regional Irish Water team.

- Covid-19 controls. Limitations on in-person collaboration and site working due to the pandemic.

(left) Completed primary settlement tanks and (right) ferric sulphate chemical dosing system assembled in-house by EPS Group

Under the collaborative model, Irish Water, EPS Group and other stakeholders were able to address and mitigate the above limitations in the planning, design and execution of the project. A range of digital collaboration tools were used to deliver effective cooperative working, overcoming the impacts of Covid-19 restrictions and enabling other constraints to be addressed. Together the following solutions were agreed:

- Use of collaborative communication and data sharing tools including Teams, BIM360.

- Selection of a low-footprint treatment process that can handle ammonia spikes.

- Site layout design making efficient use of available space.

- Phasing and planning of works to ensure that adequate wastewater treatment was maintained throughout the project.

- Setting of building floors and tank walls above the defined flood level.

- Ensuring that the hydraulic profile and design were efficient without compromising flood levels or leading to deep excavations or tall structures.

- Locating the assets with greatest potential for noise/odour generation away from adjacent residences whilst using appropriate noise mitigation and odour control systems.

- Maintaining strong and effective communications with local residents.

- Careful and intelligent programming to shorten and streamline the overall construction period as much as possible.

- Adjustments to the working processes, governance and behaviours of stakeholders to suit the new commercial model.

The above methodologies, and the learnings taken during the execution of the project, were used to develop a template by which all future projects can be delivered by the respective parties under the ECI Programme.

Safety & efficiency features

The construction of Quin WwTP commenced in May 2020 at the height of the Covid-19 pandemic. As the works were deemed essential, construction of the plant was not put on hold in line with the broader government restrictions at the time. Special precautions and provisions were made in the management and delivery of the work on site to safeguard the health and well-being of all persons present without significantly impacting on the delivery programme.

A programme accelerator applied by EPS on the project was the use of bolted sectional GRP clarifiers, sourced by EPS from a trusted supplier in Europe. These units significantly reduced the time required for civil works and also offered a safety benefit by limiting the time spent working in deep excavations.

The project was delivered using construction methods and management systems focused on enhancing safety standards. This resulted in EPS achieving scores of 95% or greater on all internal and external safety inspections and audits, with prompt implementation of improvement measures wherever opportunities were identified.

Aerial view of Quin WwTP showing the proximity of the plant to village housing – Courtesy of EPS Group

Conclusion

The project was delivered on programme and within budget, and represents a successful beginning to EPS’s tranche of the Irish Water ECI Programme. It has used collaborative planning, innovative design and effective site management techniques to deliver a successful solution that meets statutory requirements and Client objectives.

The upgraded works was successfully commissioned in May 2021 and has consistently outperformed against the process design since then. It was operated by EPS under a service contract agreement until June 2022. The delivery of the enhanced treatment plant provides Irish Water and the people of Quin village with a legacy of high-quality, low-cost wastewater treatment for the long-term future.