Ynys-y-Fro Lower Reservoir (2022)

Ynys-y-Fro lower Reservoir - Courtesy of MMB

The Ynys-y-Fro Reservoir system is situated 1km north-east of High Cross, Newport. The system comprises two reservoirs in cascade: an upper ‘subsiding’ reservoir and a lower ‘old pond’ reservoir. The upper reservoir is immediately upstream of the lower reservoir. The lower reservoir was constructed as an earth embankment dam and was built for the supply of water to Newport, with construction completed circa 1848. The upper reservoir was completed circa 1884 to trap sediment upstream of the lower reservoir. The reservoirs are recreational, as they are not currently used for water supply, although they are maintained for emergency supply. Dŵr Cymru Welsh Water (DCWW) contracted Arup and Mott Macdonald Bentley (MMB) as part of the Capital Delivery Alliance to undertake the principal designer and principal contractor roles for the works.

Project drivers

Following a statutory inspection under the Reservoirs Act 1975, recommendations were made in the interest of reservoir safety (MITIOS) and measures in the interest of maintenance (MITIOM):

- MITIOS: Improve the existing overflow system to safely pass the design and safety check flood (PMF). The existing overflow comprised 3 (No.) buried pipes and refurbishing the drawdown tower/scour system would ensure the reservoir has the ability to be safely drawn down in the event of an emergency.

- MITIOM: Replace approximately 50m of the existing by-wash channel, which is in need of repair.

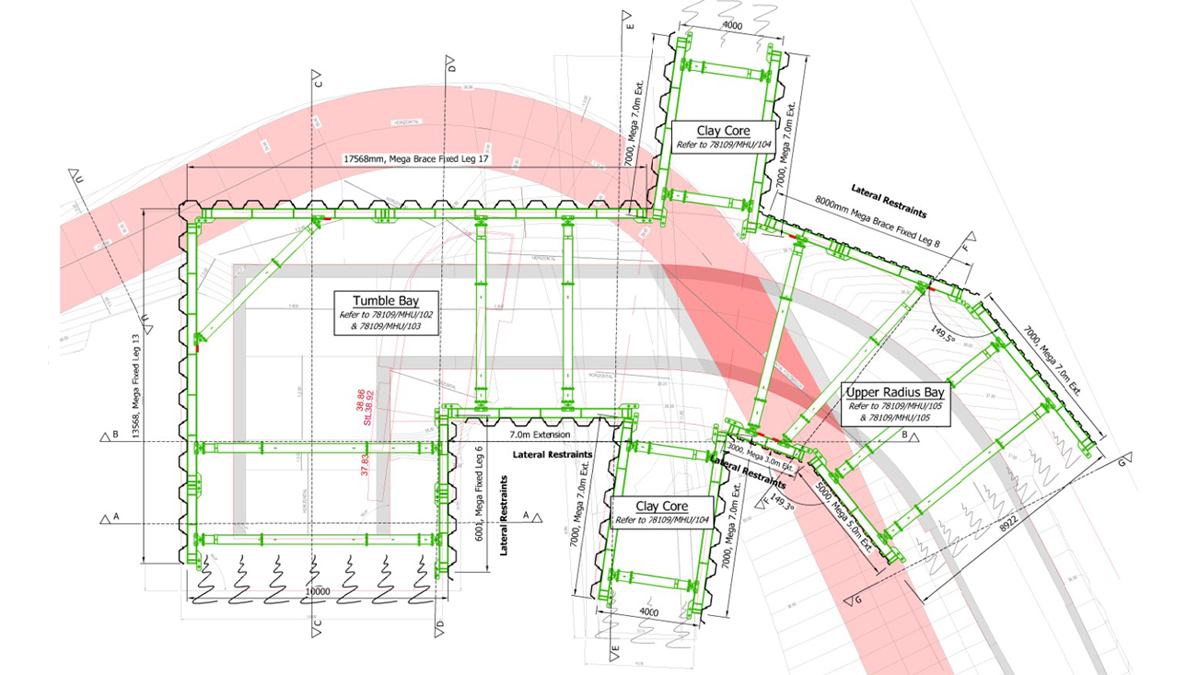

Hybrid piling design – Courtesy of MMB

Optioneering and design

Arup completed a drawdown and flood study assessment of the lower reservoir, taking into account flows from the upper reservoir during a probable maximum flood (PMF) event and proposed various options. This was to improve the drawdown capacity and meet the recently published UK guidance (‘Guide to drawdown capacity for reservoir safety and emergency planning’ (EA, 2017)).

The chosen solution was to construct a new 170m long reinforced concrete open channel spillway with the ability to contain all flood flows during a PMF event and discharge to the receiving watercourse. In addition, works also progressed to increase drawdown capacity via re-configuration of the draw-off system within the valve tower. The original draw-off system consisted of 3 (No.) 300mm diameter cast iron valves and 1 (No.) 450mm diameter scour valve. Due to the condition and operability of the draw-off valves, these were to be discontinued and a new reservoir specification DN450 valve installed to replace the existing scour valve.

In collaboration with Welsh Water and the Qualified Civil Engineer (QCE), the options considered to increase drawdown capacity and flood storage were identified by considering the technical, system resilience, construction, cost, programme, environmental, carbon, operational, and maintenance risks and impacts. The works were undertaken with a partial drawdown of the reservoir, with divers used to complete underwater works providing a cost saving to the client and reducing the construction programme. All exposed valves were accessed using a suspended scaffold with works completed in the dry.

Piling and shoring installation – Courtesy of MMB

Challenges

There were several key challenges that needed to be considered to help assist with the construction of the new fibre-reinforced concrete (FRC) spillway channel and refurbishment works to the drawdown tower:

- Environment: Due to the location of the site, dormice habitat was found to be present in several areas around the reservoir meaning that site clearance works had to be kept to a minimum, along with the requirement of planting compensatory habitat along the existing access road. These restrictions caused further logistical site constraints.

- Drawdown: Reservoir water levels needed to be maintained at the agreed drawdown level of 33.000 AoD during construction works.

- Construction sequence: Works to the spillway and draw-off tower could not run concurrently, ensuring the reservoir had the ability to be drawn down or spill during the works.

- Site access: The only access to site was via a narrow 3m wide access road.

Construction of new FRC spillway channel

The new FRC spillway construction consisted of the flowing design elements:

- Weir and tumble bay.

- Main spillway chute.

- Clay core cut off key.

- Crest access bridge/culvert.

- Cross drainage below spillway chute.

- Puddle clay core reinstatement and associated filter.

- Stilling basin.

Construction of tumble bay – Courtesy of MMB

The replacement of the existing spillway was constructed working in two locations concurrently. i.e. (tumble bay and upper radius at the top) and (open channel/stilling basin at the bottom).

A hybrid piling solution was agreed to be installed along the tumble bay and upper radius section of the chute, this allowed for the safe passing of construction vehicles and also ensured that the piles did not interfere with the clay core that would provide a potential future pathway for water.

The anti-flotation concrete was incorporated within the piling design to assist with the removal of the lower frames and whalers. On completion of the installation of the piles, whalers and frames, the cofferdam was excavated down to formation level and the anti-flotation concrete installed to support the lower section of the sheet piles.

The clay core cut off key was required to be constructed first followed by the tumble bay weir, structural slab and walls. Due to the confines of working within the cofferdam, the sequence of working was to start at the tumble bay weir and work out towards the main chute.

On completion of the tumble bay and upper radius structures, the area between the structures and the piles was backfilled to allow the safe removal of the piles and frames. Once the piles had been removed, the puddled clay core and dam shoulders were reinstated and tied into the existing core material.

Following the completion of these works, the structure was now watertight and had the ability to temporarily spill during a storm event if required.

Construction of main spillway chute and downstream channel – Courtesy of MMB

The stilling basin and main spillway chute were able to be constructed via an open cut method due to the existing ground profiles. Following excavation to formation level, the cross drainage and shear keys were first installed at each expansion joint location and the formation protected by a blinding concrete layer poured at the end of each working shift. An open channel was constructed downstream of the stilling basin to channel the flows into the existing brook and rock armour was installed between the stilling basin and downstream channel to provide further energy dissipation of the water flow.

Ynys-y-Fro Lower Reservoir: Supply chain – key participants

- Principal designer: Arup

- Principal contractor: Mott MacDonald Bentley

- Geotechnical investigation: Geotechnics Ltd

- Cofferdam design: VP Groundforce

- Formwork design: Peri UK

- Diving works: Edwards Diving Services

- Metalwork: Industrial Pipework Services

- Piling: Elite Sheet Piling Ltd

- Vegetation clearance/landscaping: AJ Butlers

- Scaffolding: Mii Engineering

- Valve supplier: Blackhall Valves

- Valve supplier: Glenfield Invicta

Refurbishment works to the drawdown tower

To provide safe access within the reservoir inlet channel and to assist with the removal of the draw-off valves and replacement of the scour valve, a suspended scaffold system was designed and installed which also included lifting gantry’s and encapsulation to assist with the works.

Double isolation of the existing draw-off arrangement needed to be carried out prior to commencement of diving works, this was achieved by installing a new DN250 gate valve within the wet tower and blanking off all other pipework downstream of the reservoir embankment. Once the isolation works were completed, the existing scour pipe was charged with water and the wet tower flooded to current reservoir water level to eliminate differential pressure risks when diving.

Tower scaffold – Courtesy of MMB

Firstly, the 3 (No.) existing draw-off valves and spindles were removed and new blanking plates installed.

On inspection of the existing scour valve, a problem that arose was that the existing scour valve had been recessed into the tower wall by 80mm, this meant that the new DN450 reservoir specification valve would not fit. To overcome this issue the team, in collaboration with DCWW Dam safety and QCE, fabricated an 800mm long steel flanged spool piece offset from the existing alignment. One flange of the spool piece was bespoke drilled to match the existing non-standard installation. The connection between the new spool piece and existing cast iron pipe flange was then encapsulated with concrete, providing additional support to the Victorian era pipe flange. The new DN450 scour valve was lowered into the water and bolted into position with an associated operating spindle.

Lifting gantry – Courtesy of MMB

New access landings and ladders were installed within the tower providing safe access for future Section 12 inspections.

A blanking plate was installed to the flange of the new DN450 scour valve and the gate close, to allow the existing scour pipe to be drained of water, this allowed works to commence downstream to modify the scour pipework arrangement to provide better flow control during drawdown operations.

Masonry by-wash channel inspection and remedial works

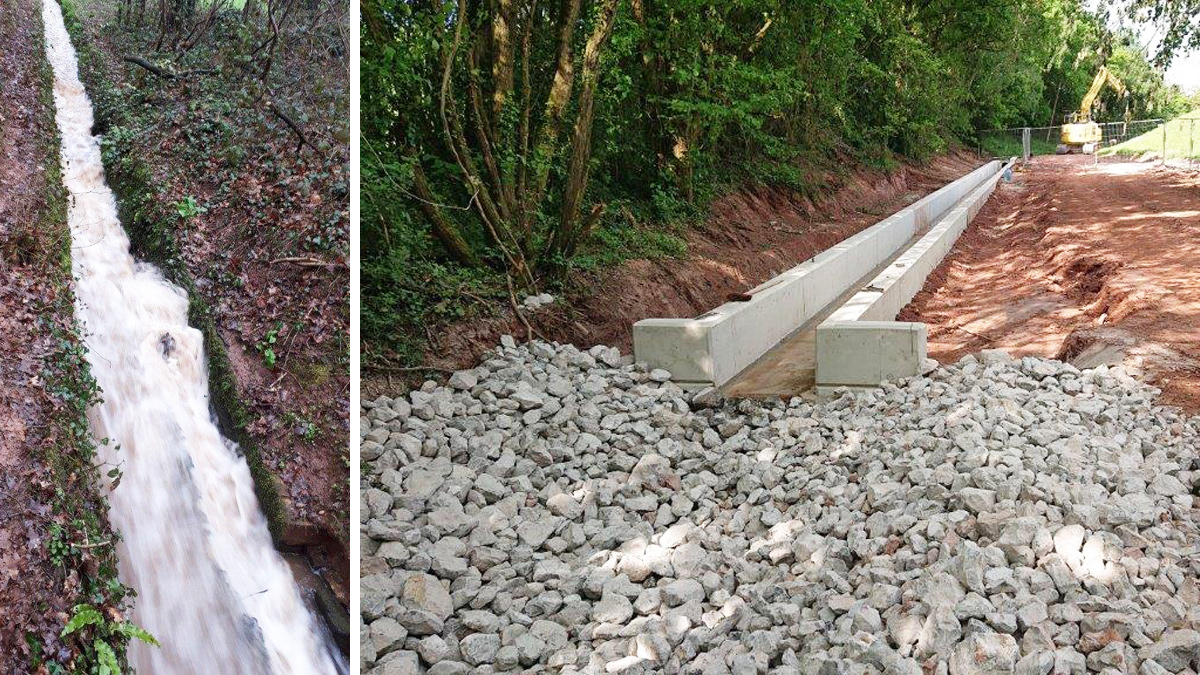

Arup completed an investigation of the condition of the masonry by-wash taking into account the Guidance for the Design and Maintenance of Stepped Masonry Spillways (Environment Agency October 2010). The inspections and intrusive investigations confirmed loss of water within spillway through continued degradation. The adopted solution was to remove the damaged section of the by-wash channel and replace it with 50m length of FRC open channel.

During the works an over pumping arrangement was installed, diverting flows from the existing by-wash channel into the lower reservoir.

(left) Existing and (right) replacement by-wash channel – Courtesy of MMB

Project timing

Works to the new spillway and refurbished draw off tower were completed in March 2021 ensuring the Ynys Y Fro Lower Reservoir met the requirements set out within the section 10 MITIOS report. The improved scour system within the draw off tower offers greater control and safer operation both for frequent tasks and infrequent or emergency situations.