Ipswich Tidal Barrier Project (2017)

The Ipswich Tidal Barrier under construction - Courtesy of Environment Agency

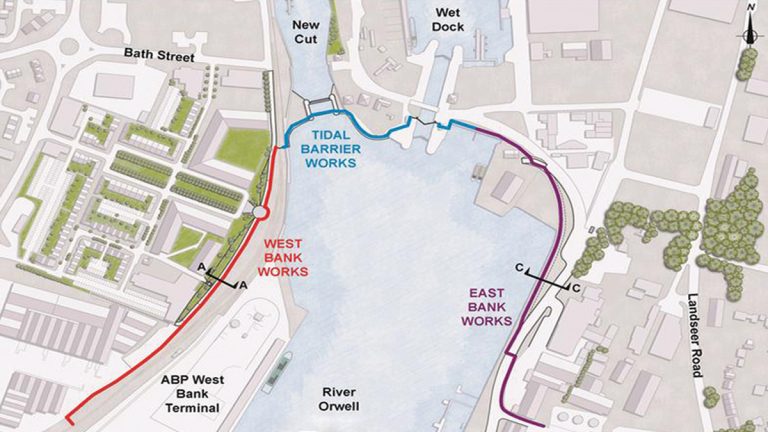

Ipswich’s position on the estuary of the River Orwell in Suffolk makes it susceptible to both fluvial and tidal flooding. The Ipswich Tidal Barrier Project is the final element of a £58m programme of work by the Environment Agency (EA), to upgrade the flood defences on the East and West bank of the tidal river and the Port of Ipswich itself. Due to the barrier permanently affecting the right of navigation through the new cut of the River Orwell, the Tidal Barrier works have required approval by the Secretary of State for the Environment, Food and Rural Affairs, via a parliamentary order under the Transport and Work Act. The Ipswich Tidal Barrier order was made in August 2012.

Background

The scheme comprises the design, construction and installation of a 20m wide, 9m high rising sector gate, associated mechanical, electrical, instrumentation and control equipment (MEICA); much of it housed in a ‘semi-iconic’ control building. (In addition, there are piled flood defence walls on either side of the barrier on the east and west banks, within the flood walls, along with smaller flood gates, one of which crosses a working rail siding). Finally the additional land created is to be landscaped, to a design agreed with the Ipswich Borough Council.

Location plan of Ipswich Tidal Barrier – Courtesy of Environment Agency

Undertakings

VBA, a joint venture comprising, VolkerStevin, Boskalis Westminster and Atkins, was awarded the contract in November 2014 following a competitive tender under the EA’s Water and Environment Management framework (WEM). When complete, the £28m element of the project awarded to VBA will provide enhanced flood protection to more than 1,500 residential and 400 commercial properties currently within the risk area. The new tidal barrier gate will prevent surge tides up the river, as well as allowing control of fluvial flow downstream.

Temporary works

Significant temporary works have being undertaken to enable construction of the main barrier structure as well as the installation and commissioning in the dry of the gate itself. The main component of this being a 30m by 30m sheet piled cofferdam, formed using 84 (No.) crimped pairs of AZ46-700N sheet piles. The sheet piled walls of the cofferdam extend to a depth of 20.6m into predominately loose weathered chalk.

Ipswich Tidal Barrier – courtesy MGF

The barrier structure reduces the existing channel width at its present location from a maximum of 55m to a minimum of 20m. The position of the barrier is offset from the centre of the channel to ensure a minimum river channel width of 15m remains throughout construction to maintain fluvial flow and river navigation. In addition to the cofferdam – two sections of deflector piles – sheet piled walls have been installed to assist in diverting the river flows and reduce the loading on the temporary cofferdam. As a result in diverting the flows through the west side of the channel; a temporary sheet piled wall has been installed to provide scour protection and dredging to the riverbed, as well as replacement of the precast concrete scour protection mattress.

VBA appointed consultant Tony Gee and Partners to design the cofferdam and primary temporary works, with input from MGF to develop the design of bespoke waling beams and props using their modular components.

Radius shutter to form recessed cell within base of structure to accept the rising sector gate – Courtesy of Environment Agency

New river walls

Tie-in river walls will be completed, extending from the new tidal barrier structure on either side of the channel both upstream and downstream, to direct flow through the barrier gate opening. The east section walls are complete and formed using a combination of 1.4m diameter steel tubes, alternated with sheet piles in varying length from 15.1m to 20.3m. The area behind these new river walls will be backfilled. Two similar walls will be installed on the west bank once the rising sector gate is commissioned.

Tidal barrier foundation piles

Ground investigation reports showed that a buried valley runs in an east to west direction across the area of the barrier structure. The buried valley is in-filled with sands and gravels, which rest upon a chalk rock head. Due to these ground conditions in the vicinity of the barrier structure being of an underlying loose chalk; 48 (No.) 1m tubular steel bearing piles have been installed of varying lengths between 36m and 56m to support the new structure. All of the piling work has been completed using a 400 tonne tracked crane situated on the adjacent land.

Concrete civil structures

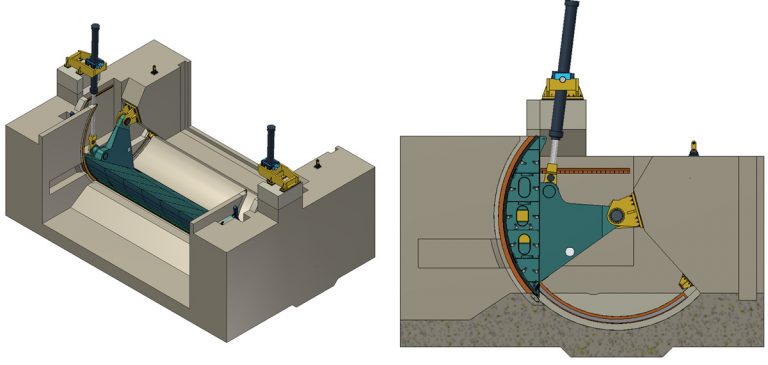

The civils structures were designed by VBA. The gate is a rising sector gate (similar to those at the Thames Barrier), which rests in a recess in the river bed when not in use. This in turn requires a substantial reinforced concrete holding structure, comprising a 1.5m thick concrete base across the 30m wide channel. On either side, the concrete walls are 5m thick, and are being cast against the sheet piled cofferdam wall, which will form part of the permanent works. A 3D BIM model has been created for the overall structure, which has allowed modelling of the complex integration of the civils, gate and MEICA designs. In particular it has allowed the team to detail the location of the large steel anchor structures needed to support the gate and avoid clashes with the reinforcing steel in the concrete.

Gate design and fabrication

The project team undertook numerous factory visits and interviews with prospective suppliers, and studied similar gate structures on projects across Europe. The gate has been designed by IRS, a German specialist firm, and is being manufactured in the Netherlands by Hollandia. It will be floated across the North Sea, fully assembled, and placed into the concrete civils structure across the river channel using a 600 tonne crane. The detailed planning and coordination of this operation will need to take account of not just the local temporary works, but weather and tidal conditions.

(left) Image of tidal barrier structure, with rising sector gate in velocity control position and (right) Cross section through structure, rising sector gate in tidal surge defence position – Courtesy of Environment Agency

The gate itself is a hollow steel structure with radial arms pivoting at each end, the gate will weigh approximately 200 tonnes. The downstream face is curved to transfer the hydrostatic load directly to the pivots and reduce the loads on the operating mechanism. The upstream face is flat, so as to offer a flush surface at sill level with the gate fully open to minimise the accumulation of silt.

The gate is to be operated either as a tidal defence gate or velocity control structure using two main hydraulic cylinders, one at each side of the gate. The cylinders will share the operational loads and will be synchronised to operate within a pre-determined tolerance band.

Factory visits to ensure quality

Hydraulics and control systems are being designed, manufactured and installed by Qualter Hall in the UK. VBA has planned a series of factory visits and acceptance tests for the gate and key MEICA equipment, to ensure comprehensive quality checks are undertaken and that components are delivered in line with design specifications.

Fabrication of rising sector gate by Hollandia Infra – Courtesy of Environment Agency

Installing the gate

A comprehensive acceptance quality test will be carried out on the gate before it is placed into the river channel and secured to the precast anchors using a 600 tonne track crane positioned on the river bank. Temporary works, including a sheet piled wall with backfill, will be constructed to provide a safe working platform for the crane.

Commissioning the gate

Classroom training will be provided to EA operatives, so they understand how to operate the system, allowing them to carry out the test under VBA’s supervision. This process acts as a ‘live’ training session. The rising sector gate will be tested in both dry and wet conditions within the temporary cofferdam. Having satisfied all parties that the tests are successful, the up and down stream cofferdam walls will be removed and the test repeated, this time in the wet and during various tidal states.

Once the testing and commissioning of the gate is complete, the river flows and navigation will be re-routed through the new structure to enable the new river walls to be installed on the west bank, closing the temporary 15m navigation channel.

Design innovation

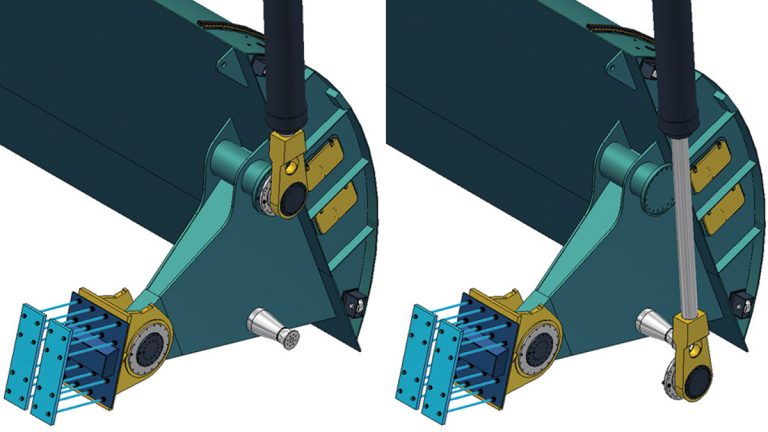

During pre-construction and design, the team developed an operating system for the gate, which allows the main hydraulic drive cylinders to lift the gate into the maintenance position i.e. horizontally above the river. This has eliminated the need for a 1000 tonne mobile crane for inspection, painting, etc. leading to long-term cost savings and safety enhancements.

Switching between main drive pin to maintenance drive – Courtesy of Environment Agency

Minimising the impact

A project of this size inevitably has some impact on the local community; however, VBA has sought to minimise impact by delivering materials by sea, whenever possible (piles and gates). This has reduced our carbon footprint, as well as minimising road traffic associated with the project.

An open terrace area has been created within the site office complex, which allows visitors to view most of the works without physically accessing the working areas. This has enabled school children and other interested local groups to visit site easily to show them what is being built and explain the benefits to the local community.

The new structure required the dredging of the riverbed and excavation of silt and gravels from within the cofferdam to create space for the new structures. Conventionally any dredged silts would be disposed of at sea; however, VBA chose to pump this material into holding areas onshore, dry it in geotextile ‘socks’, then process it for use as backfill.

As well as significantly reducing the cost of disposal and imported material, this approach provided reduced road traffic and the carbon footprint associated with using virgin aggregates.

Progress

As of May 2017, the base slab of the main structure and about 20% of the walls have been completed. The gate itself has been fabricated in Holland and is awaiting painting before final quality checks are made. Once approved, the shipment is expected to arrive in the UK in autumn. The control building has been built to ground floor level and the remaining flood walls are close to completion.