ACWA Services Ltd

AquaPyr (2024)

AquaPyr Ultra Low Waste Filter - Courtesy of ACWA Services

Tertiary Solids Removal (TSR) on small rural sites is growing in demand as phosphorus and iron consents are applied. For these smaller, remote works, additional consents, new or tightened, can lead to the overall upgrade requirements which can be difficult to execute due to economic viability and process challenges related to the low flow rates found at facilities with lower population equivalents. These challenges can include power availability and the need for site power upgrades, land availability and the need to compulsory purchase, and the hydraulic capacity of the site and the need for attenuation to cope with the backwash volumes from traditional TSR solutions.

Background

The assertion of uneconomic viability is becoming harder to argue as more sites are having ever tightening consents applied to them, meaning that the offsetting of better performance from larger sites is being negated, and these smaller sites are having to be upgraded to meet the consents and catchment area water quality targets.

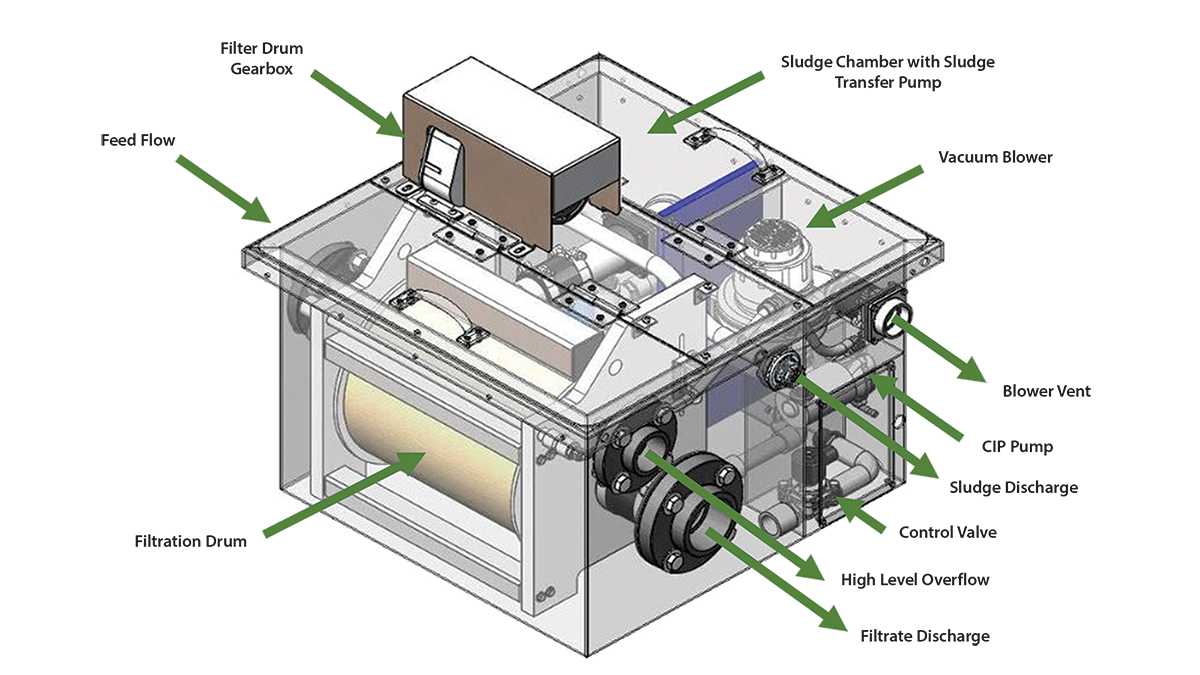

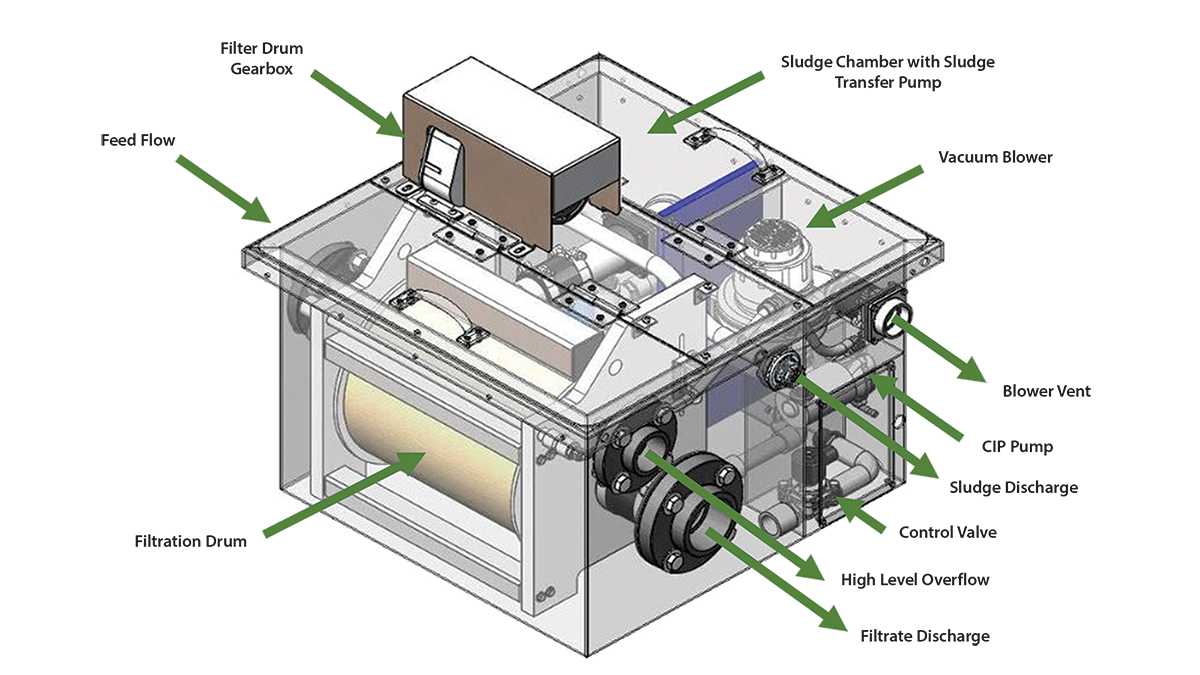

AquaPyr filter

The AquaPyr filter from ACWA Services has been designed to negate these CAPEX upgrade costs and issues as far as possible but still deliver a cost-effective, robust solution in providing tertiary solids removal for remote rural treatment works ensuring discharge consents are met.

AquaPyr Model 440 – Courtesy of ACWA Services

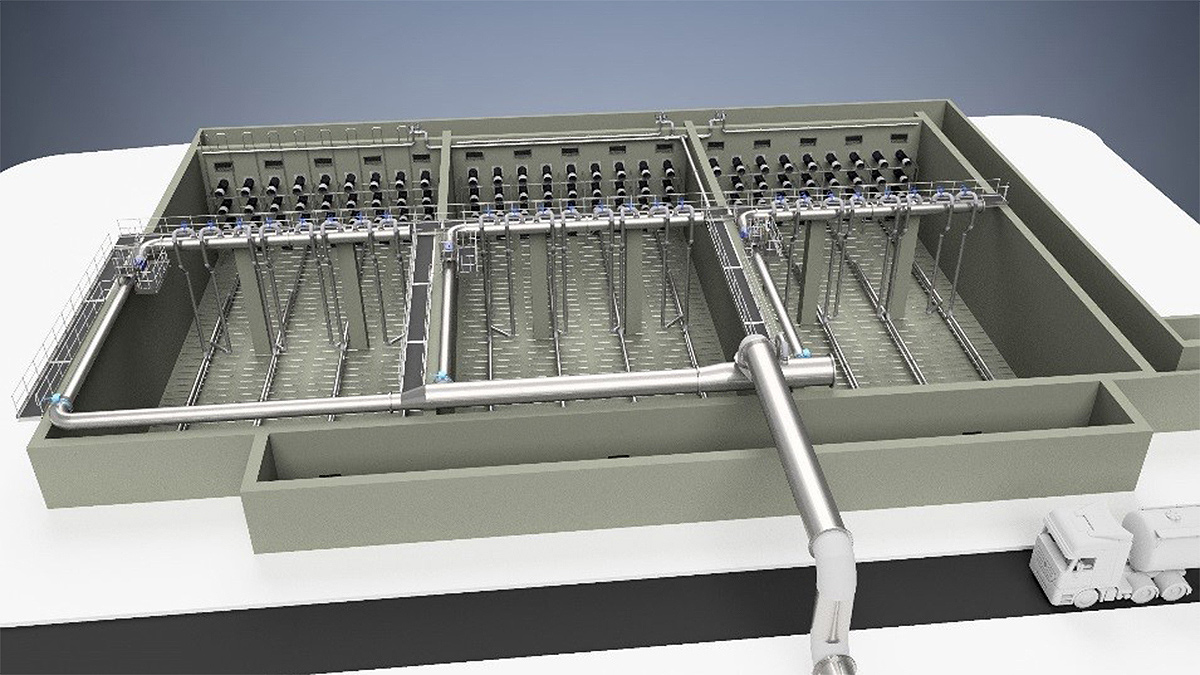

Traditional cloth media filters typically generate between 2% and 5% of forward flow volumes as backwash water according to manufacturers data. However, these figures are based on higher flow works and do not scale downward when applied to smaller WwTPs. It is not uncommon to have 15 to 20% of the forward flow utilised as backwash water and returned to the plant in smaller works or applications with higher TSS, such as filtration of chemically dosed feed for reduction of Total P. These high levels of backwash water being returned to the head of works can cause potential ‘flooding’ of the works as many are already close to their hydraulic capacity, resulting in the need for the construction of backwash balance tanks to control this additional flow being added to the works.

Low flow sites pose additional problems for traditional backwash cloth filters, as often flows are insufficient to generate the required waters for backwashing at low flow rates, such as summer months, when the need for chemical dosing for phosphorus removal is likely to be at its greatest with the resulting increase in solids that need to be removed prior to final discharge. This can result in maintenance issues for the filters or the need to build baffle tanks to hold sufficient water for the backwashing requirements during periods of low flow, again increasing CAPEX in the building of these and OPEX of the solutions with increased pumping requirements.

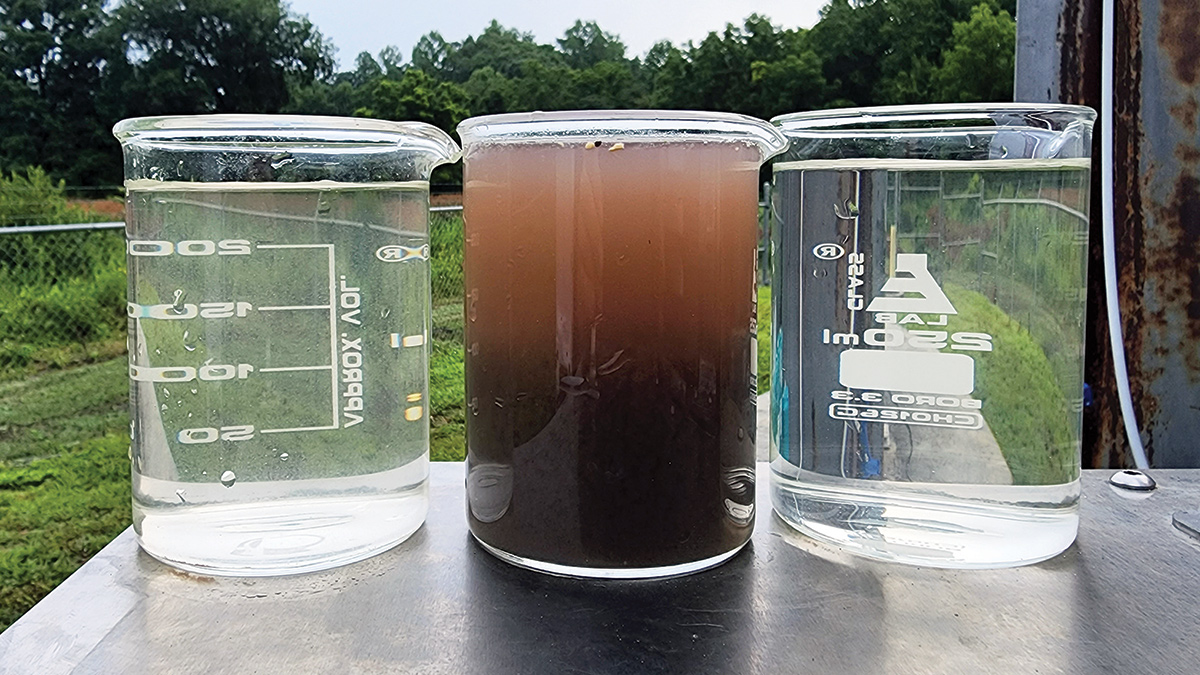

The ACWA AquaPyr filter is an innovative fully contained, deep pile cloth media filter that generates minimal waste during the filter cleaning process. This is possible as unlike traditional TSR filters, the AquaPyr filter uses a patented air driven cleaning process in place of water for backwashing the filter, thus eliminating the need to store water for backwashing and then attenuating used backwash water for return to the front of the works. Typical waste volumes per clean are between 4 litres and 50 litres depending on the size of the unit, and remain <0.25% of forward flow.

This resulting waste is of a relatively high solids concentration, as much as 2% dry solids (DS), meaning that this could be discharged to the sludge or humus tanks rather than returning to the head of works and putting extra loading stress on the works.

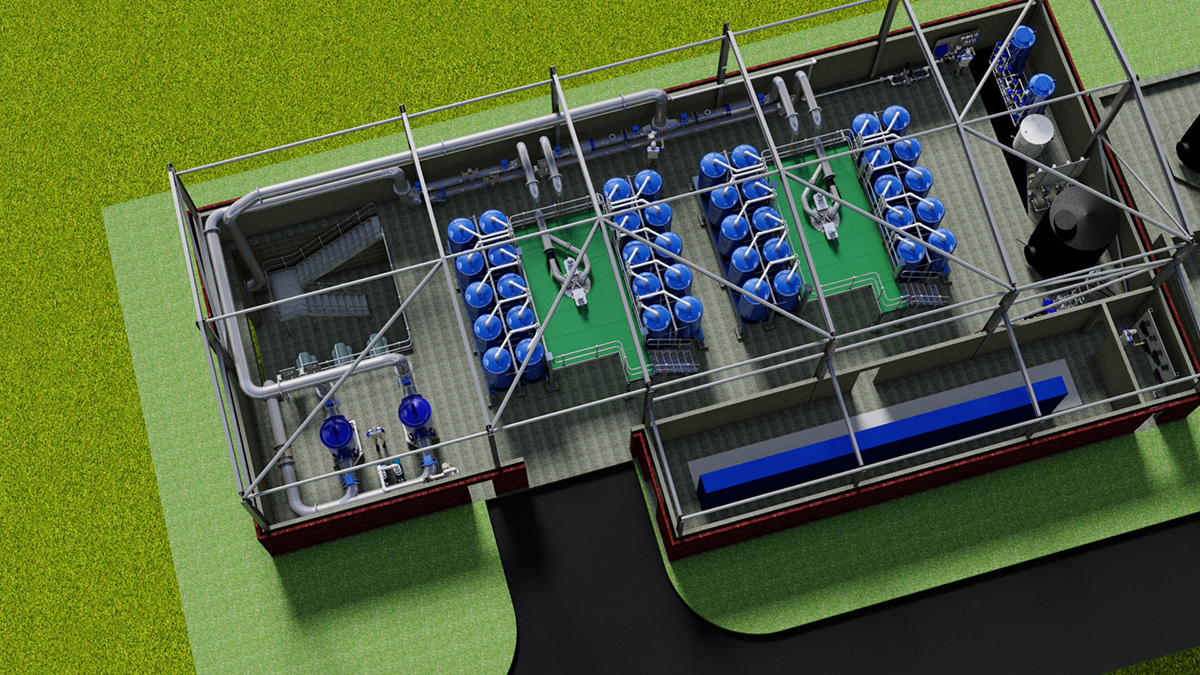

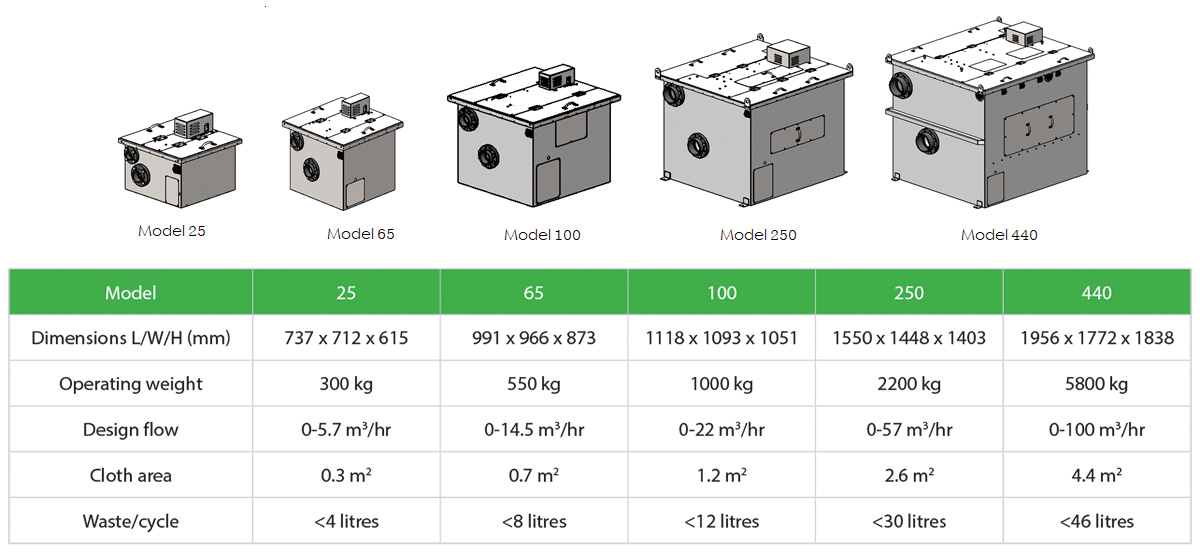

The AquaPyr filter comes in a range of sizes meaning treatment volumes of a single unit range from 0 to 2000m3/day dependent on the solids loading applied to the filter. Multiple units can be used in parallel to increase these volumes and provide duty standby resilience as required.

The AquaPyr Ultra Low Waste Filter product range – Courtesy of ACWA Services

The units are fully self contained and all the pumps, drives and vacuum motors required for the operation of the unit are fitted internally. With a footprint range of 750mm x 710mm for a Model 25 up to 1960mm x 1770mm for a Model 440, the units have a uniquely small footprint for their treatment capacity.

The units low power draw and power requirements, ranging from 11 Amps for a Model 25 to 40 Amps for the Model 440 mean that all units are single phase, with the Models 25 and 65 actually being able to be used on a domestic three pin plug. AquaPyr filters consume little power; across all models power consumption averages in the range of 7 to 10 kWh/1000m3 of feed.

Case study: Silver Lake WwTW, Indiana

AquaPyr’s compact filter size, robustness and low operational costs led to Silver Lake, a small rural community in Indiana, choosing to use the technology on their unmanned sites. The Silver Lake WwTW is an activated sludge works with a design flow of 1.6 l/s.

The effluent entering the filter had 10 mg/l total suspended solids and a BOD of 10 mg/l. The requirement was for <=0.5mg/l Total P.

Two ACWA AquaPyr Model 25 units were chosen in a duty/assist configuration, and working at a hydraulic loading rate of 12 LPM/ m2 average daily flow which was 2 x peak and a solids loading rate of 0.05 kg/m2 daily average.

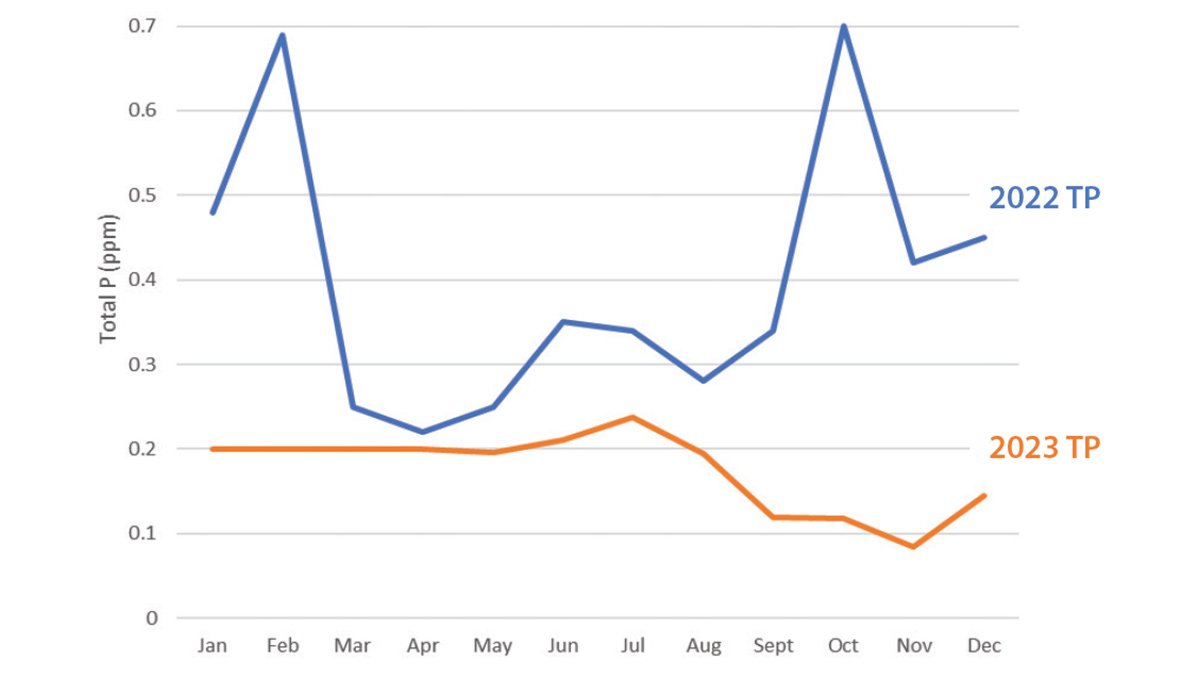

The resulting effluent quality after the filters was a Total P of <0.25 mg/l, BOD of 5 mg/l and TSS of <5 mg/l. The graph below shows the results of a 12 month period.

Silver Lake WwTP: Effluent TP before/after the installation of the ACWA AquaPyr Ultra Low Waste Filter – Courtesy of ACWA Services

Summary

The ACWA AquaPyr Ultra Low Waste Filter has proven itself to be a robust cost effective solution in industrial and municipal waste water solutions. The total cost effectiveness of the AquaPyr filter, when compared with traditional cloth filters, further increases when looked at from a project cost basis due to the reduced civils works generally required for the installation and overall scheme requirements for the AquaPyr filter.

The ACWA AquaPyr Ultra Low Waste Filter is an innovative technology providing a solution for small and low flow water treatment works, where filter waste management and the hydraulic capacity of the existing works might make the use of a traditional tertiary solids removal process inappropriate or cost prohibitive due to the civils works and costs associated with their installation.

Left to right: Feed, waste, filtrate - Courtesy of ACWA Services