iNPIPE PRODUCTS™

42″ Water Pipeline Cleaning

iNPIPE PRODUCTS™

iNPIPE PRODUCTS™ was commissioned to provide comprehensive pipeline pigging/cleaning services to a prominent civil construction firm, acting on behalf of a major client within the UK utility sector. Following a detailed review of project specifications and extensive consultation with the client, iNPIPE PRODUCTS™ executed a turnkey air pigging solution encompassing:

- Project management and engineering oversight.

- Development of pigging procedures and risk assessments.

- Provision of temporary launchers and receivers to facilitate seamless equipment.

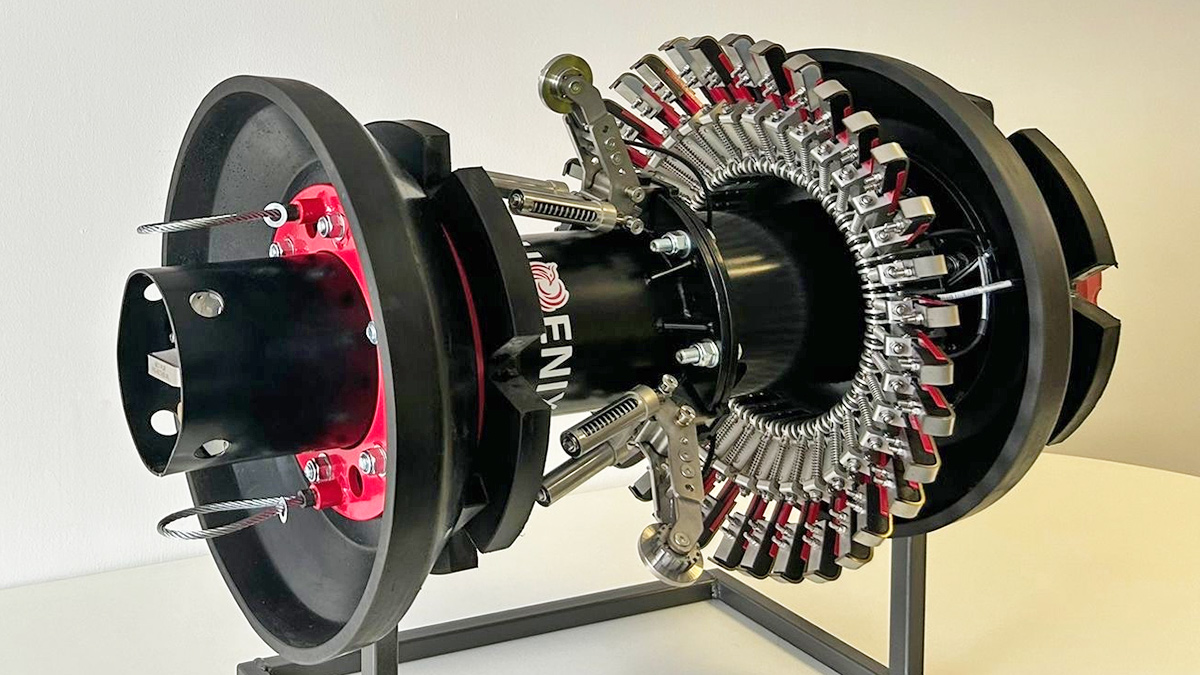

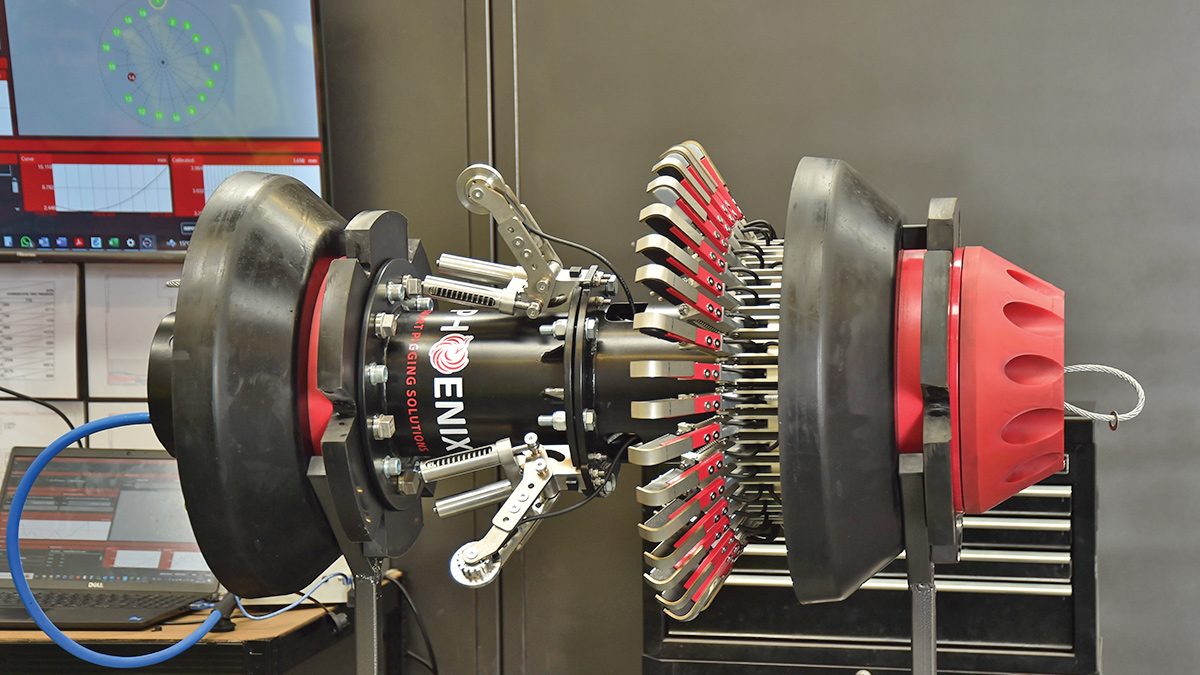

- Manufacturing of bespoke pipeline cleaning pigs equipped with advanced tracking and internal camera recording capabilities.

- Supply of cutting-edge air pigging equipment.

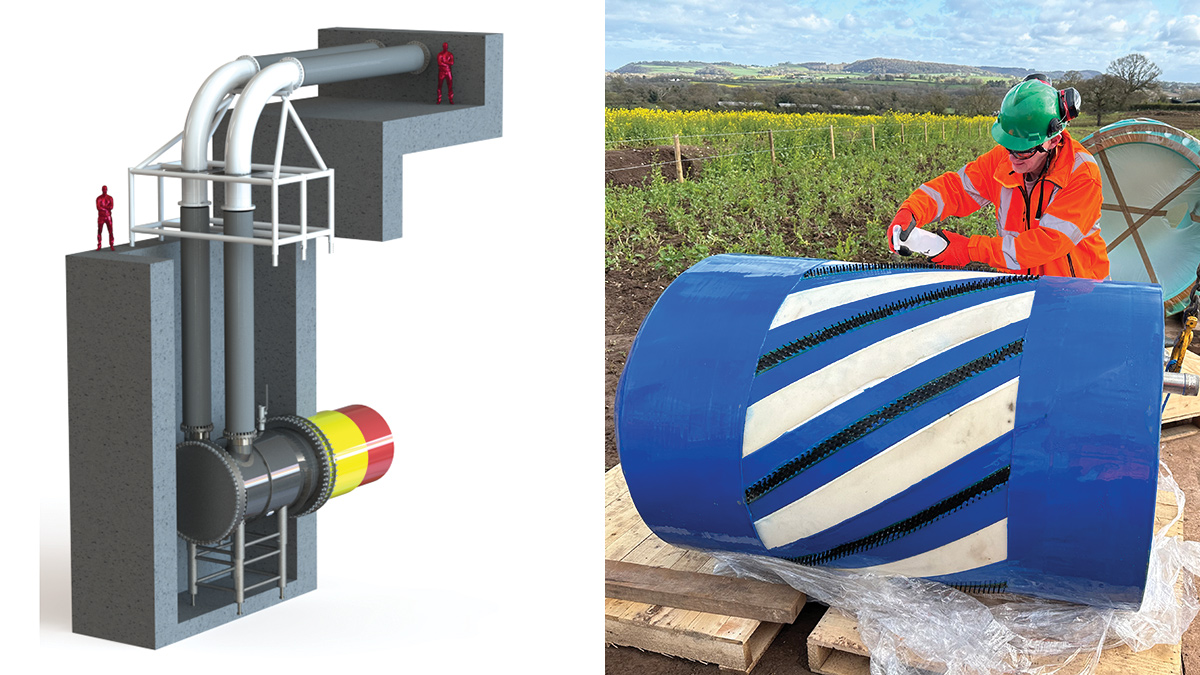

Due to the build up of manganese powder accumulated within the aged aqueduct, it became necessary to clean the pipeline. Air-propelled, tractable foam cleaning pigs were utilised to remove the sediment inside the pipe, ensuring the provision of cleaner, wholesome water for the area. The 17.5-kilometer-long, 42-inch diameter water pipeline was divided into six smaller 2 to 3 kilometer sections to manage water and air displacement. Each section was drained prior to equipment installation and pigging operations.

The project required iNPIPE PRODUCTS™ to develop a specific foam cleaning pig that would remove debris from the pipe wall without damaging the internal lining or coating of the pipeline. Quality assurance was paramount throughout the operation.

42″ pigs during pipeline cleaning operations

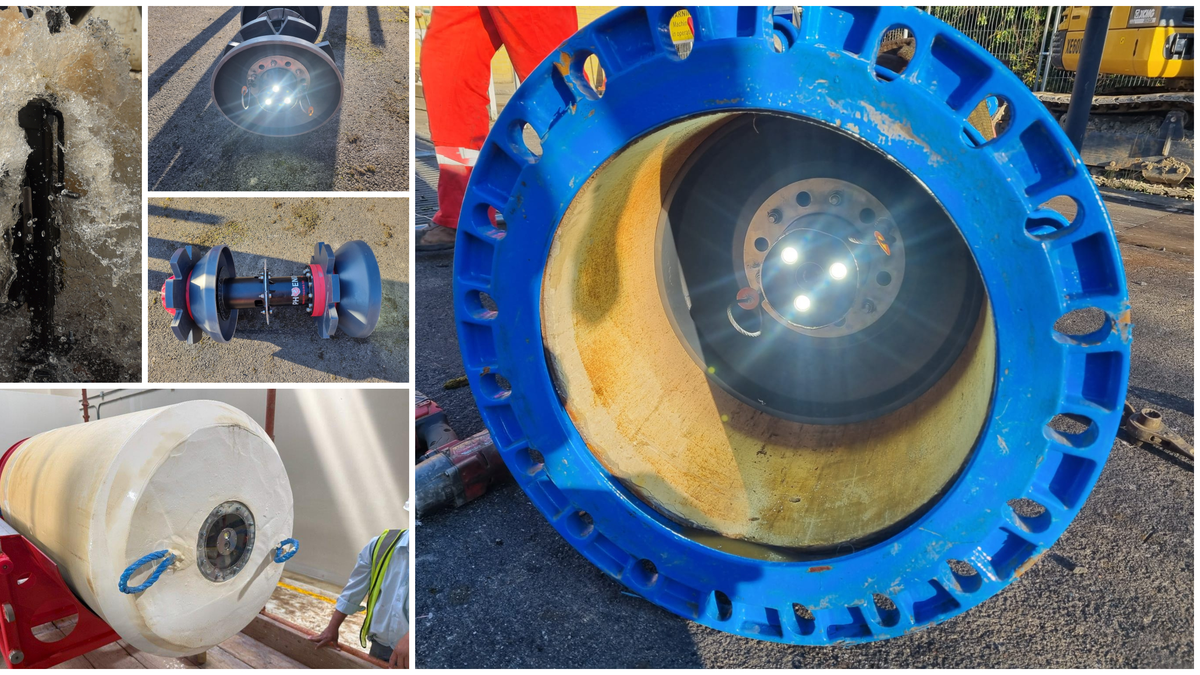

To verify the cleanliness of the pipeline in real-time, a sophisticated camera pig equipped with video recording capabilities was deployed, providing the client with unequivocal confirmation of the pipeline’s condition post cleaning.

In addition to manufacturing bespoke cleaning equipment, iNPIPE PRODUCTS™ provided a comprehensive air pigging equipment spread, including air compressors, manifolds, and silencers. Launcher and receiver pods were particularly designed and fabricated to seamlessly integrate with the cleaning process.

To ensure thorough pipeline cleaning, a series of specialised cleaning pigs were employed in succession, forming a pig train. The cleaning process began with a brush foam pig, accompanied by a 10m3 water slug, followed by a criss-cross foam pig propelled with air. Subsequently, a camera pig was utilized to meticulously verify the pipeline’s cleanliness. Each pig was equipped with a transmitter for efficient pig tracking.

Operational execution was carefully managed, with a dedicated onsite operations team, including the project manager, site supervisors, and pigging operators, overseeing every aspect of the operation.

Mobilisation of personnel and equipment was executed promptly as per schedule, with meticulous coordination between our team, the client, and the asset owner.

The project concluded successfully, surpassing expectations by completing ahead of schedule and budget, iNPIPE PRODUCTS™ commitment to excellence and expertise in pipeline cleaning delivered a pristine pipeline network, exceeding client expectations, and promoting environmental conservation and sustainability.

Air Pigging Project Benefits

|

For more information on the iNPIPE PRODUCTS™ air pigging technology, visit https://www.inpipeproducts.com/

iNPIPE PRODUCTS™, Gatherley Road, Brompton on Swale, North Yorkshire, DL10 7JH | Tel: +44 (0)1748 813270