Roperhurst Limited

Since 1976 Roperhurst has worked with a range of customers, big and small, global and local, on specialist plastic and environmental engineering projects.

Roperhurst is quality certified to ISO9001:2015, SSIP approved and a long-standing member of BESA.

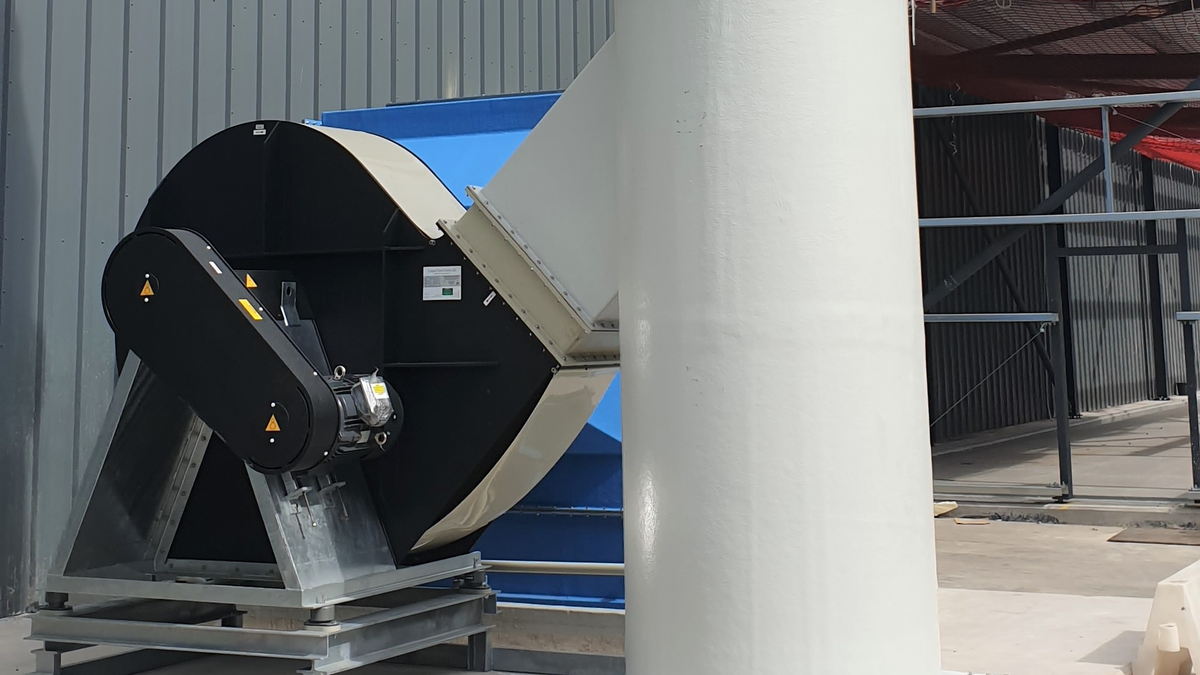

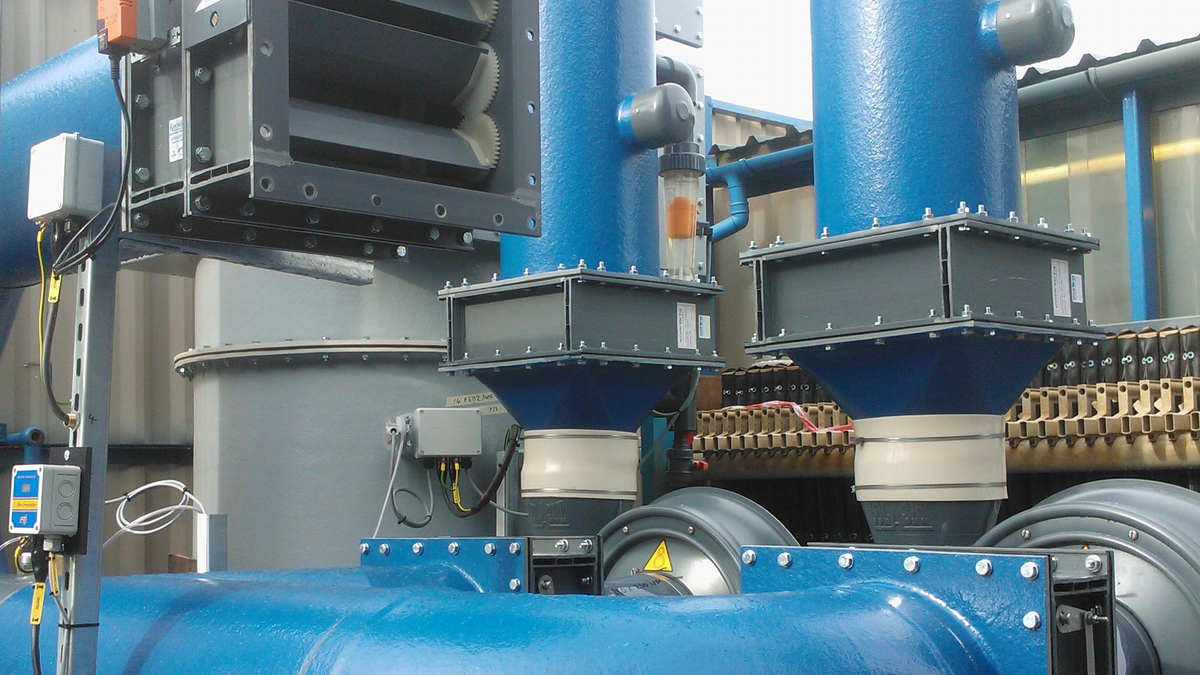

Fume/odour:

Roperhurst delivers a comprehensive proven range of solutions including catalytic iron filters, carbon absorbers, bio-filters, bio-scrubbers, biogas and chemical scrubbers. Utilising either organic or synthetic media filled units, all designed and built at our UK manufacturing facility, and each offering a green, smart and simple-to-operate solution to your fume, odour and VOC problems.

Chemical storage/dosing/delivery:

Roperhurst offers bespoke tanks and vessels for the safe long-term storage of chemicals, each specifically matched to meet your individual needs. Additionally, we fabricate and install dosing cabinets and day tanks with dual containment delivery pipework, all designed to dispense chemicals safely to the point of consumption.

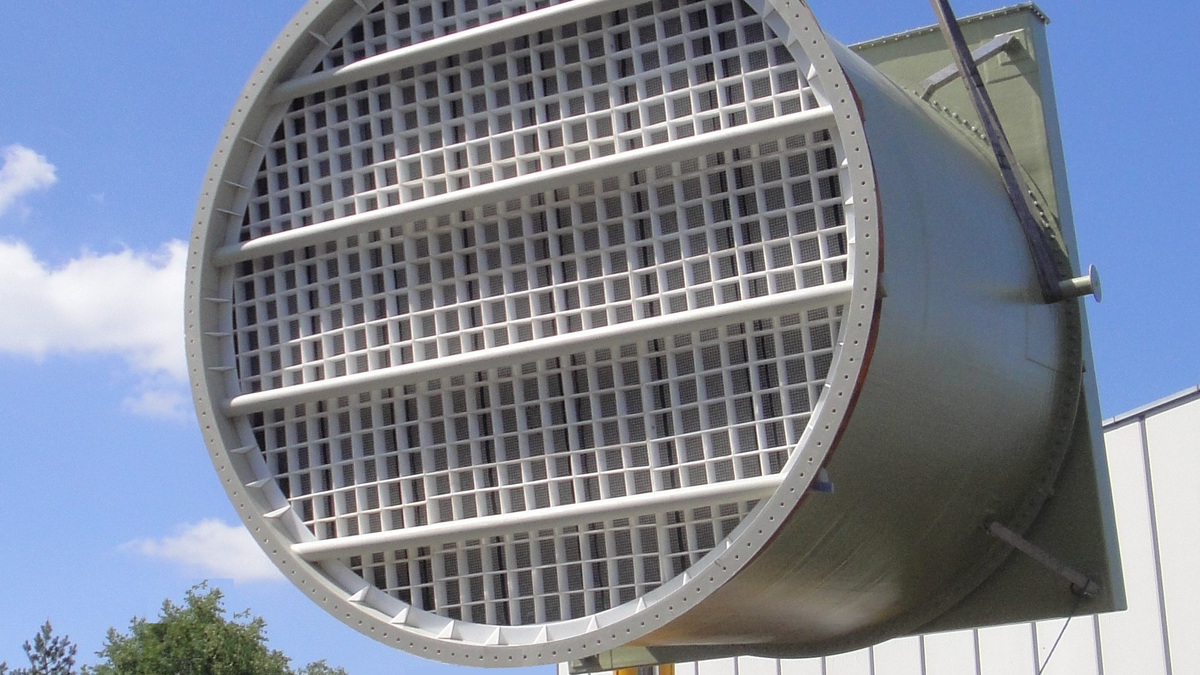

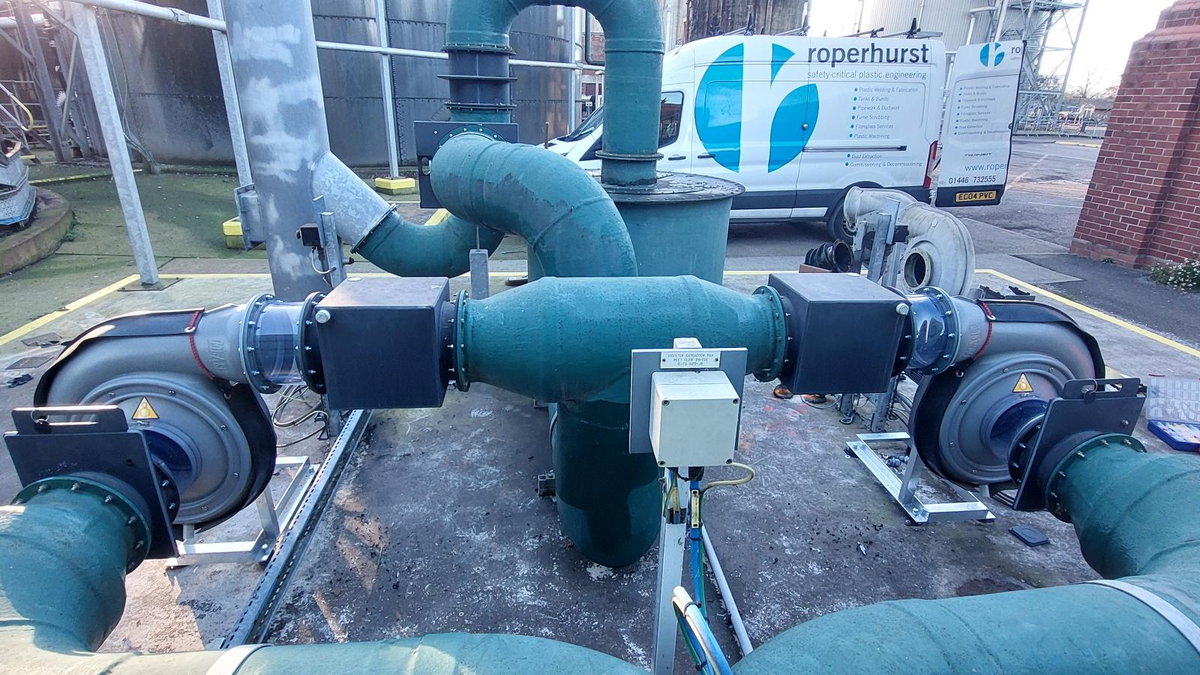

Delivery ductwork:

Plastic ductwork for dealing with fume/odours created by chemical, biological or radiological processes have a high level of inherent risk. This means that you need assurance that the ductwork will be fabricated correctly and installed competently.

The UK standard for fabrication and installation of plastic ductwork is DW154, published by BESA, the Building Engineering Services Association (formerly HVCA). Roperhurst is a UK market leader in this field:

- Roperhurst’s founder, Graham Handley, chaired the HVCA committee that wrote the 1st edition of DW154 in 2000. Roperhurst continues to work closely with BESA to improve standards.

- Roperhurst, as a BESA plastic ductwork specialist, ensures that our manufacturing and site work is regularly audited by external specialists to ensure that our work meets all current standards.

Roperhurst is one of the few plastic ductwork specialists with its own in-house fibreglass division and specialist installation and testing teams. At Roperhurst we don’t need to rely on sub-contractors to produce elements of the project, which can be a cause of quality and compliance issues. Our plastics fabricator welders are time served and certified to BS EN 13067, and our laminators have been assessed under BS 4994.