Nereda

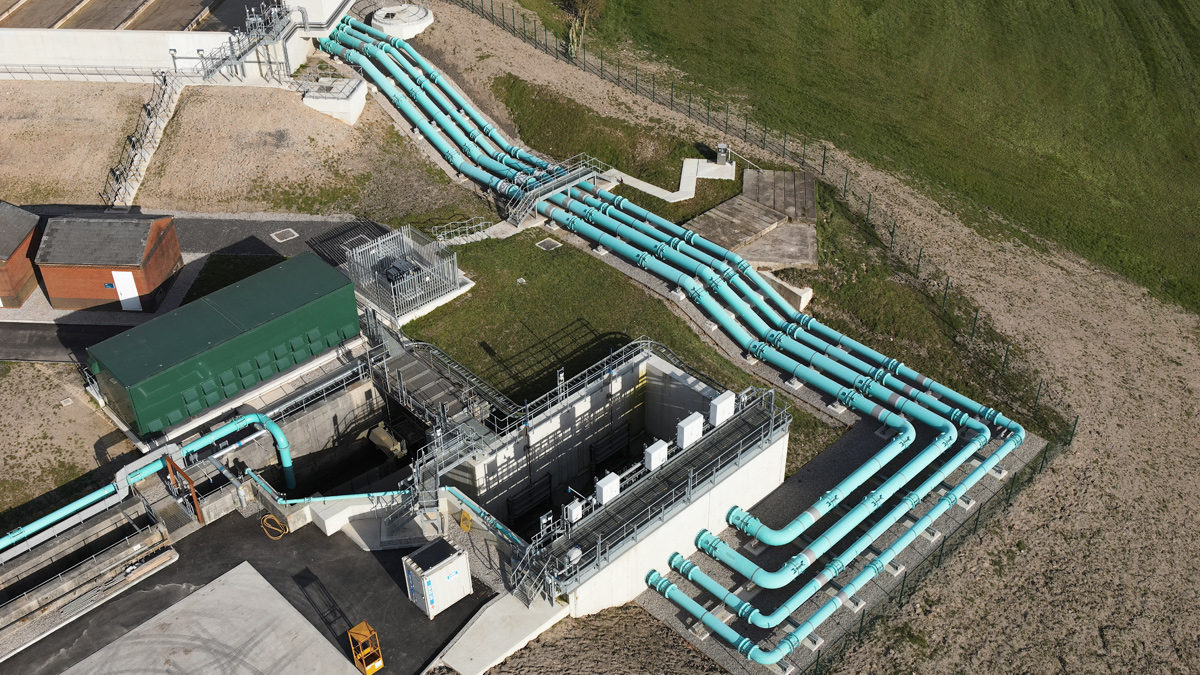

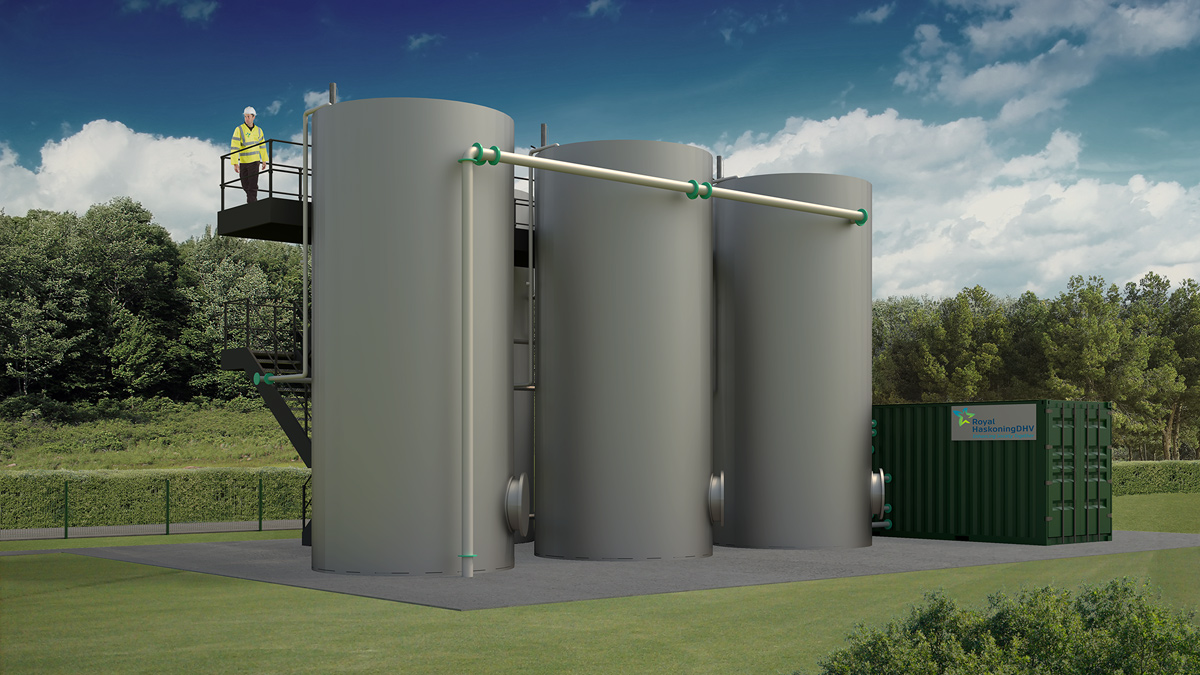

Compared to activated sludge technologies, the biological treatment power of the technology is much larger, while saving up to 50% on energy costs, delivering high quality effluent for low costs and requiring only a quarter of the area of conventional activated sludge installations.

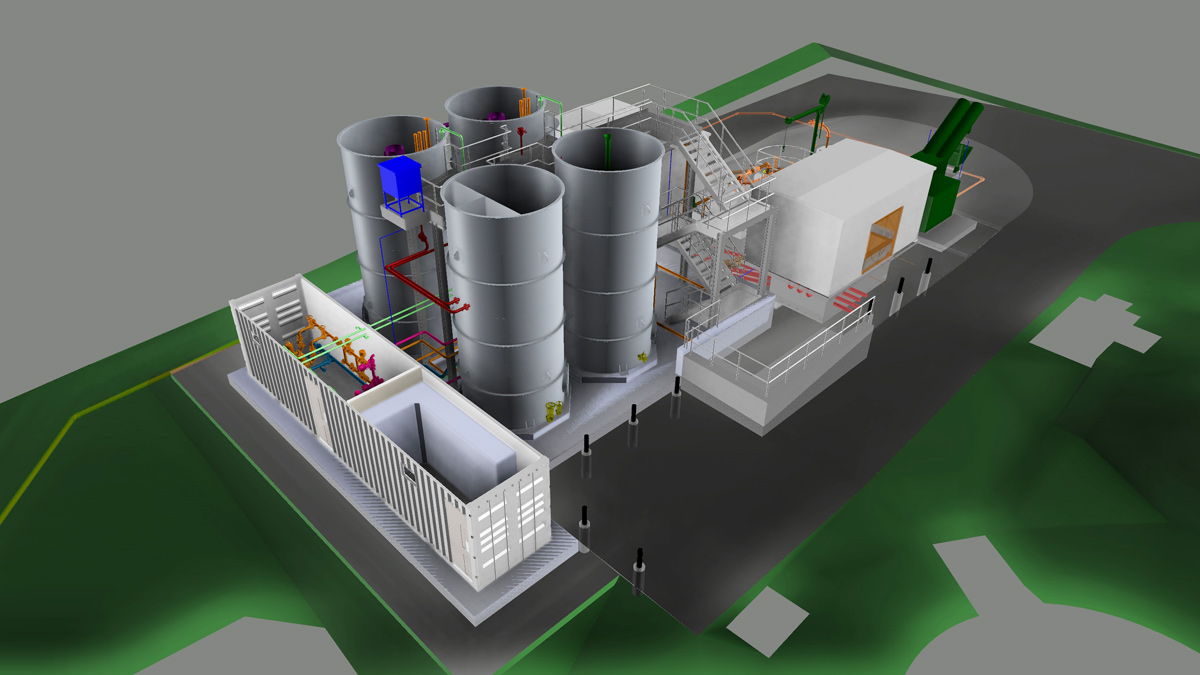

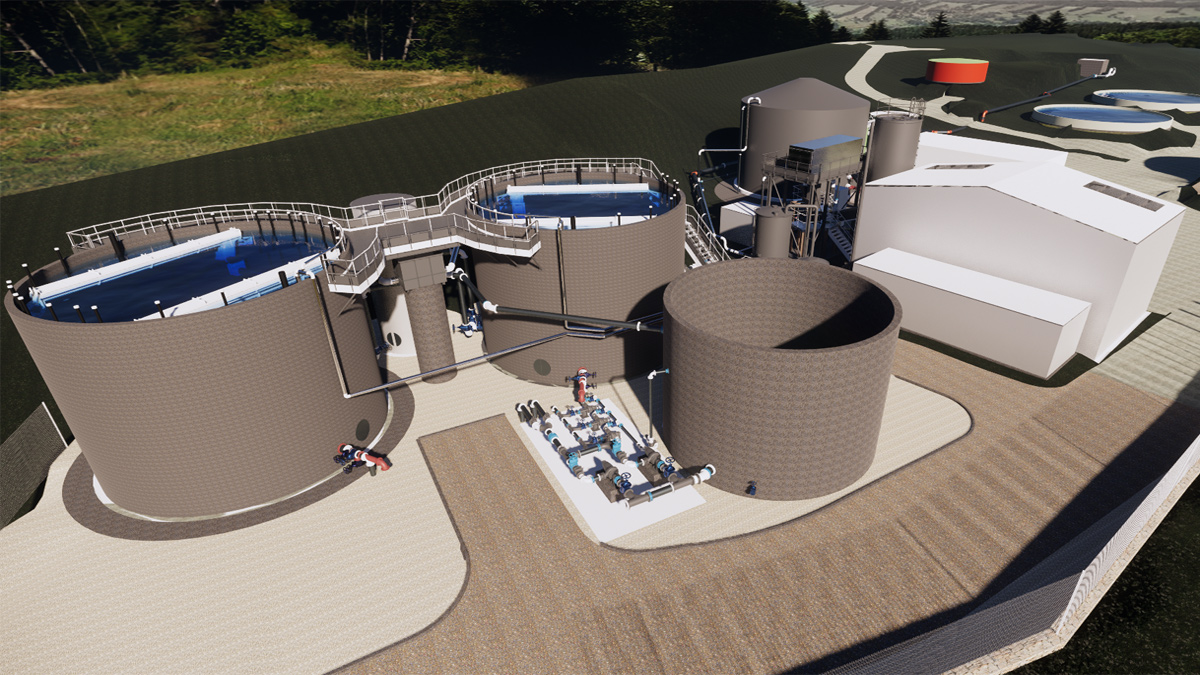

Biomass in the process develops as fast settling aerobic granular sludge. These granules have excellent settling properties, so the process does not require a separate time-consuming decant phase like conventional SBR’s. All the biological treatment processes take place simultaneously in the granules, requiring only one tank.

The technology is very versatile; it can be developed as a new build or used to retrofit existing conventional CAS or SBR plants. The benefits of the technology include:

- Excellent treatment results and settling properties: Compared to activated sludge technologies, the biological treatment power of the technology is much larger as a considerably higher concentration of biological active mass is applied that in addition has a much higher content of microorganism that are crucial for biological nitrogen and phosphate removal.

- Sustainable: Compared to conventional wastewater treatment processes, the technology not only has significantly lower energy consumption and associated greenhouse gas emission, but also produces, commonly without the use of waste generating chemicals, a remarkably high effluent quality.

- Cost effective: The technology results in construction costs that are lower than for conventional technology as for example, tank volumes are up to four times smaller and less equipment is required.

- Small physical footprint: Its footprint at sewage treatment plants is reduced due to the full nutrient removal process taking place in one single reactor.

- Easy to operate: It has proved in operation to satisfy the most stringent purification requirements. Thanks to the nature of the technology, plant operation is easy and process performance robust.

The technology is proven and applicable for even the largest applications. Currently, there are over 70 wastewater treatment plants in operation or under construction all over the world