Hamilton WwTW (2024)

Hamilton WwTW - Courtesy of Groundworks Scotland

In line with the Scottish Government’s move towards a Low Carbon Economy, Scottish Water has committed to achieving its strategic ambition of ‘Beyond Net Zero’ by 2040. Driven by this ambition, the public utility tasked its commercial subsidiary, Scottish Water Horizons, to review its asset base to identify and accelerate opportunities for renewable energy generation. Previously, most hydropower projects developed within the water industry have focused on raw and clean water sources. By adopting a different perspective, Scottish Water Horizons identified an opportunity to generate green energy via hydropower at a wastewater treatment works (WwTW).

Background to the project

This pioneering project will see Scottish Water harness hydropower from wastewater and the scheme is:

- The first mid-process wastewater hydropower install in the UK that optimises energy potential.

- The first containerised hydropower install in Scotland which not only reduces construction carbon emissions; it also saves time and costs. This solution can also be replicated on other wastewater assets as well as other applications including raw and treated water.

Design

Hydropower opportunities across Scottish Water’s estate are identified and developed through a combination of data analytics techniques (flow and pressure data in particular), GIS analysis, whilst also tapping into the first-hand knowledge of local system operators.

One of the sites with hydropower potential that emerged from this exercise was Hamilton WwTW in South Lanarkshire, near the city of Glasgow. Hamilton WwTW is a fairly typical site with the flow passing through initial 6mm inlet screening, grit removal, primary settlement, aeration tanks and final settlement unit operations before returning to the local water course which is the River Clyde.

The aeration tanks which are in operation are relatively new to the site, having been installed approximately 17 years ago with the original aeration lanes now treated as a redundant asset.

The new aeration lanes were built above-ground and therefore sit proud of the rest of the works.

Above-ground aeration lanes – Courtesy of Scottish Water Horizons

Hamilton WwTW serves a population of around 57,000 people and therefore has a high electrical consumption. Thus, any electricity generated from the hydro turbine can be utilised on site, helping to green Scottish Water operations and reduce reliance on grid electricity.

After an initial desk-based investigation into the feasibility of the site, on-site operators at Hamilton WwTW were engaged, with loggers deployed to further understand the flow and head parameters. It was determined that capturing the flow between the new aeration tanks and the final settlement would provide 10m of head which is further extended to 11.5m by use of a draft tube, and an average annual flow of 432 l/s.

Through a process of data verification, site surveys, and extensive liaison with both internal and external stakeholders, a clear opportunity was identified to develop a 48 kW hydropower scheme.

Turbine location within the WwTW

By installing the turbine mid-process this allowed Scottish Water Horizons to capture not only the flows through the WwTW but also harness the recirculating flows. This makes the turbine an integral part of the works and therefore every attempt was made to incorporate safeguards to ensure the turbine will not conflict with the overall site operations. This has been addressed by adopting several measures:

- A level sensor has been installed at the aeration tanks to ensure that the turbine does not cause the tanks to either empty or overflow.

- A bypass valve has been designed in which, should the flow be too high for the turbine to function efficiently and safely, the flow will be redirected and continue onto the final settlement tanks uninterrupted. This bypass valve also allows for safe maintenance of the system.

- If a mechanical problem was to occur on the turbine system, the bypass valve will open automatically, therefore imposing no conflict to site operations.

A secondary benefit was realised; when the effluent passes through the turbine it becomes aerated, thus aiding the treatment process. As a result, the quantity of air required to be used for aeration can be reduced on the existing asset which further reduces the energy consumption on site.

(left) The original flume and (right) container is on site with thrust restraint in progress on the left – Courtesy of Scottish Water Horizons

Varying flow rates

As Hamilton WwTW is an operational site the flow rates are largely influenced by the level of rain in the catchment. Loggers captured the average annual flow rate to be 432 l/s.

The section of the works where the turbine is located is subject to large flow fluctuations varying from 300 l/s to 1200 l/s. This prompted the incorporation of a bleed valve at the inlet to the pipework arrangement which allows excess flows to be diverted away from the turbine, allowing the turbine to continue generating at exceptionally high flow rates.

Effluent considerations

As this is Scottish Water’s first hydropower scheme to be installed on a wastewater asset, there was the aspect of using effluent to be considered. By using the flow from the gravity return pipe at the aeration tank, the effluent had been through several treatment processes such as screening, grit removal and primary settlement to remove the bulk of solids as well as through the aeration process itself. At this point in the treatment process the reactivated sludge and water combination will be denser than fully treated effluent therefore may boost the turbines power output.

Scottish Water Horizons had to consider that finer particles may find their way into the system, and it was important to understand the implications this could have on the turbine and use this knowledge to select a suitable turbine design choice.

Turbine design choice

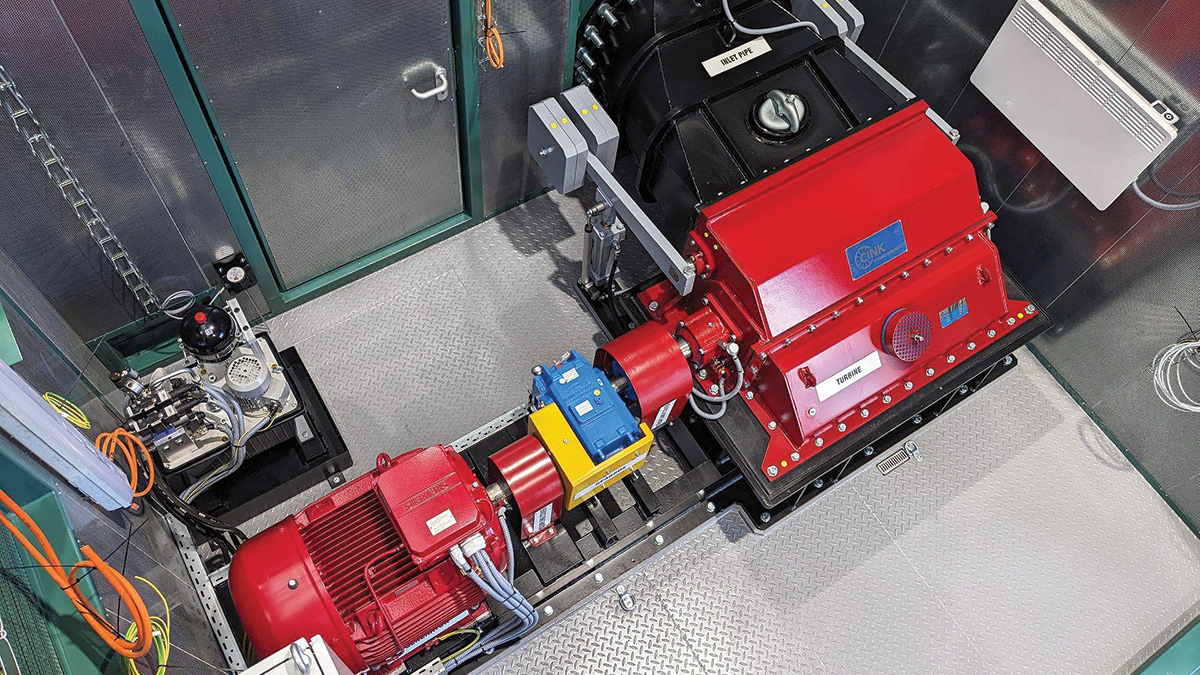

A Crossflow turbine was selected as the most suitable machine for Hamilton WwTW.

Crossflow turbine from CINK Hydro-Energy k.s. – Courtesy of Scottish Water Horizons

This cost-efficient turbine solution allows for dependable operation over a wide range of flows whilst maintaining efficiency[1]. The turbine is also capable of ‘self-cleaning’ to an extent. If debris becomes stuck on the blades, it is typically dislodged by either the outflowing water or the centrifugal force generated by the turbine rotating. This addressed concerns about using effluent to power the turbine as the maintenance risk of the turbine becoming clogged with debris such as rags has been partially mitigated against.

A Crossflow design turbine also requires lower maintenance due to the simplicity of the system with only three moving parts. It is typically only the rotor that has a bespoke design to match the hydraulic profile of the application.

Hamilton WwTW Hydropower: Supply chain – key participants

- Design & project delivery: FES Support Services Ltd

- Specialist hydro consultant: Glen Hydro

- Civil works: Calforth Construction Ltd

- Mechanical installation: Dustacco Engineering Ltd

- Turbine supplier: CINK Hydro-Energy k.s.

- Valves: Glenfield Invicta

Construction work

Construction started on site in April 2023 with the removal of the existing flume taking place in May. A temporary flume was then installed to allow the effluent to flow past the working area. This mitigated the risk of contractors encountering effluent when working.

(left) Old flume removal and (right) temporary flume in situ – Courtesy of Scottish Water Horizons

Works then started on the concrete sub-structure and tail-race upon which the turbine house is installed.

The existing pipework was retrofitted with a bespoke ‘Y’ section of pipe along with relevant bypass and bleed valves. A level sensor was installed at the outlet to the aeration tanks which communicates with the turbine control system adjusting the valves and turbine guide vanes to match the flow conditions.

A pre-fabricated containerised turbine house

Once the concrete foundations were completed the containerised turbine house was then delivered to site; the pre-fabricated unit having been assembled by CINK at their factory.

The container was crane lifted into place. Adopting off-site construction methods allowed Scottish Water to reduce its carbon footprint associated with construction and condensed time on site.

Once the container was in situ and all pipework installed, testing and commissioning began. This included pipeline stress tests and multiple mechanical and electrical tests on the equipment to prove the system functioned as the manufacturer intended.

This construction approach has an eye on standardisation which could lead to wide ranging applications within Scottish Water’s assets based on the lean principle of ‘minimum viable product’. This includes minimising capital and carbon expenditure whilst maximising energy recovery.

Bespoke ‘Y’ piece in situ showing bypass and manual isolation valves – Courtesy of Scottish Water Horizons

Conclusion

The system was connected to the grid (G99 accreditation) at the end of November 2023 and is now generating on site, providing green electricity to the works. This helps to not only reduce the reliance on importing electricity from the grid but also reduces on-site energy costs.

The scheme is estimated to generate 420,000 kWh of green electricity per year which will offset around 14% of the site’s annual energy demand. It is also projected to save around 64 tonnes of carbon emissions each year.

Re-using existing land and assets also meant a reduction in carbon emissions during construction, supporting Scottish Water’s strategic ambition of going ‘Beyond Net Zero’.

From conception to starting on site, the Hamilton Hydropower project took around 21 months, with a construction period lasting a further nine months. This shows the efficiency of the containerised methodology which will enable future similar schemes to be delivered at pace.

This project has demonstrated that hydropower generation can be achieved on a wastewater asset and can offset the heavy cost of electricity on wastewater sites. There are many similar opportunities available across other wastewater sites and other industries such as petrochemical and outfalls from power plants. This would drive down the carbon associated with capital investment and operational activities.

References

[1] CINK Hydro Energy, “Crossflow Turbines,” [Online]. Available: https://www.cink-hydro-energy.com/crossflow-turbines.

CINK Crossflow turbine installed at Hamilton WwTW - Courtesy of Scottish Water Horizons