Offwell Storm Tank (2024)

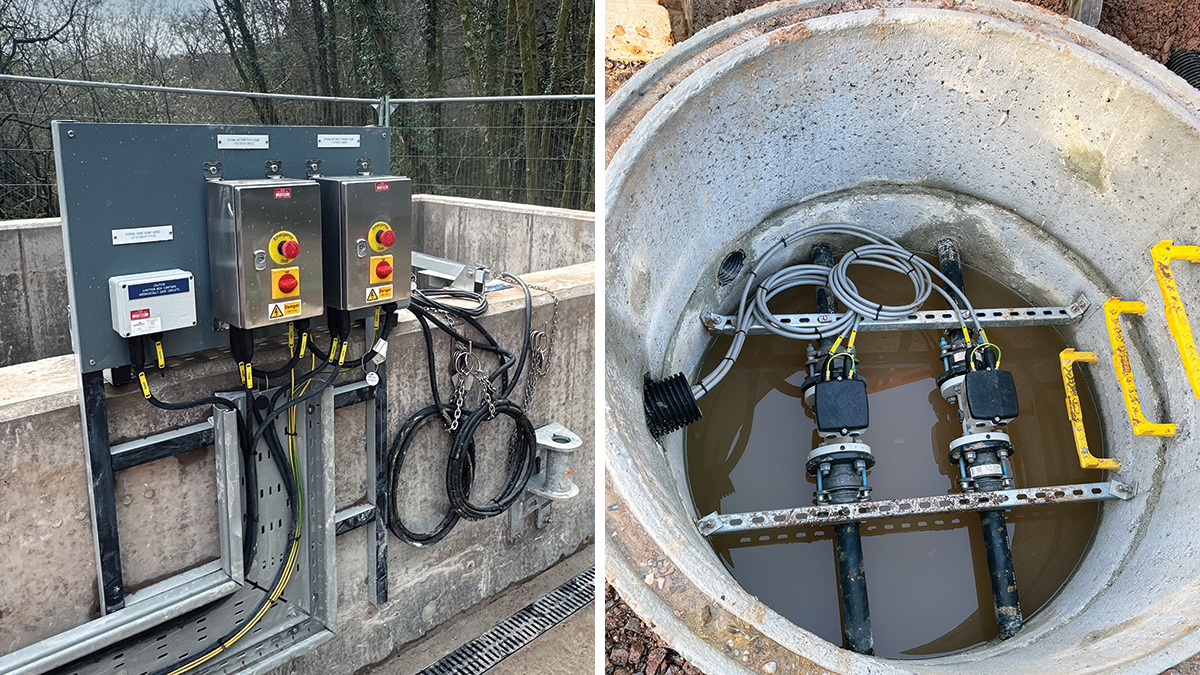

(left) Isolators and (right) new flow meters within chamber - Courtesy of Galliford Try

Offwell is a small village on the outskirts of Honiton just off the A35. The existing sewage treatment works was constructed in the 1980s and serves a population of around 350. It was typical of the era, with an old style Dortmund tank with percolating filter and humus tank off the back end. Final effluent from here gravitates out from the site to Offwell Brook. The driver for the scheme was to reduce the number of unconsented spills to the environment by providing a capacity of 30m3 storm storage (exceeding the EA’s required storage volume of 25m3).

Project scope

At the scoping stage, Galliford Try worked closely with South West Water to establish the most cost-efficient solution when considering both operational expenditure (OPEX) and capital expenditure (CAPEX) to ensure South West Water achieved the best whole life costs. From this exercise it was established that the scope outlined below was to be included for construction on site:

- One new part buried concrete rectangular stormwater storage tank with capacity of 30m3.

- New LCP for the control of duty/standby pump for return of effluent within the storm tank.

- Relocate the existing MCERTS final effluent flow meter and re-test.

- New pipelines between existing equipment and new storm tank.

Storm tank construction: (left) steelwork framework and (right) shuttering – Courtesy of Galliford Try

Stormwater storage tank

Being a part-buried tank, a significant excavation was undertaken with appropriate temporary works associated to the angle of repose. Once completed, a blinding layer was installed at an appropriate level for the steelwork to be built up from.

The steel for the base was installed, shuttered, and poured in two due to a sump for the install of return pumps. Wall steelwork was then installed up to 2.5m above ground and shutter pans used for the concrete pour. The overflow from this then spills to an existing chamber on site and then to Offwell Brook.

MEICA

To enable on-site efficiencies, the majority of the LCP and kiosk were fitted out off-site in Galliford Try’s local depot, with the LCP being constructed in Plymouth and the kiosk being fitted out with the LCP and services within the same workshop.

Once completed and tested, this was transported directly to site where Galliford Try’s electrical team connected the LCP into the site network for both power and communications. Once on site, all that remained was to install the already put together framework and brackets for the isolators and ultrasonic junction box and install the pre-wired flow meters back to the already mounted heads within the kiosk.

This in turn lead to betterment of the programme and benefited by undertaking the off-site build in a controlled environment.

Site access

Access to site was challenging. The site was only accessible for construction vehicles through one road, which was a narrow, single lane track with a steep drop off on one side and tall hedge banks on the other, and there were infrequent passing places for larger construction type vehicles. It was difficult for the site team to manage construction activities and getting plant and materials to site.

After the first week of mobilising to site, Galliford Try found that the road with the verge was starting to degrade and potentially become unsafe. This was reported back to the Highways Commission. While waiting for further consultation, several other routes were identified and the project team looked at each of these routes to identify which was best suited. After the Highways Commission responded, it was finally decided that to ease further degradation of the road that a handling/staging area was to be found in a local farmer’s yard and smaller vehicles were to be used to transport plant and materials to site. This had an effect on programme and cost but was more manageable and safer to undertake, but left Galliford Try with one inevitable issue; concrete deliveries for the storm tank.

Galliford Try’s Client Liaison Officer notified residents on the few occasions that the concrete had to be transported through the village. Deliveries were restricted in size and were escorted through the village to prevent damage to any of the dwellings. This was undertaken for the base pour and the wall pours; with multiple wagons on each of the days.

Confined site

The footprint of the working area was confined to the site boundaries, only providing 950m2 of space, of which only 180m2 was usable for construction activities. Alongside this, there were some enabling works that required undertaking first to enable access into the construction zone, this consisted of:

- New final effluent flow meter chamber.

- Relocation of turbidity sensor.

- New sample chamber with weir plate.

Offwell Stormwater Storage: Supply chain – key participants

- Client: South West Water

- Project delivery, civils & MEICA: Galliford Try

- Civil design: Eastwood & Partners

- Tank construction: D Wall Construction Services

- Pumps: Xylem Water Solutions

- Metalwork: GT Fabrications

- Flow meter: Siemens

- Pipework: Saint Gobain PAM UK

- Kiosk: GR PRO Precision Manufacturing

- Instrumentation: Pulsar Measurement

- Aggregates: Steve Wills Haulage

Regraded operational land – Courtesy of Galliford Try

Carbon savings & in-house capability

Local resources and materials were used where possible including subcontractors, which as a result provided the local economy with a financial boost during the construction phase.

Where local suppliers were not available, Galliford Try strived to use off-site build solutions where possible to minimise commuting. Contractors from Exeter were used for the construction of the storm tank, all concrete for the project also came from Exeter, and local suppliers were used for aggregates from local quarries.

In-house resources that were utilised included project management, electrical design, LCP design/build, process control, and commissioning. The in-house workforce undertook the site establishment, civil engineering, landscaping, MEICA works, and finally the demobilising the site.

Stakeholder management

At pre-construction phase, all third-party stakeholders were identified and entered onto a management plan. Galliford Try’s Customer Liaison Officer contacted all stakeholders prior to commencement to provide them with the appropriate project contacts should they have questions, queries, or complaints and to establish their requirements and desires throughout the construction phase of the works. As part of the management plan all communications where complaints or agreements are made are formally recorded, resolved, and closed out.

Conclusion

Initial progress on site was good with setting up site and setting the project up for an efficient delivery until the road issues occurred.

Once this was managed and materials and plant were getting to site the remainder of the project ran through a smooth transition and was delivered by the regulation date of 31 March 2024.