Whittle Dene WTW (2025)

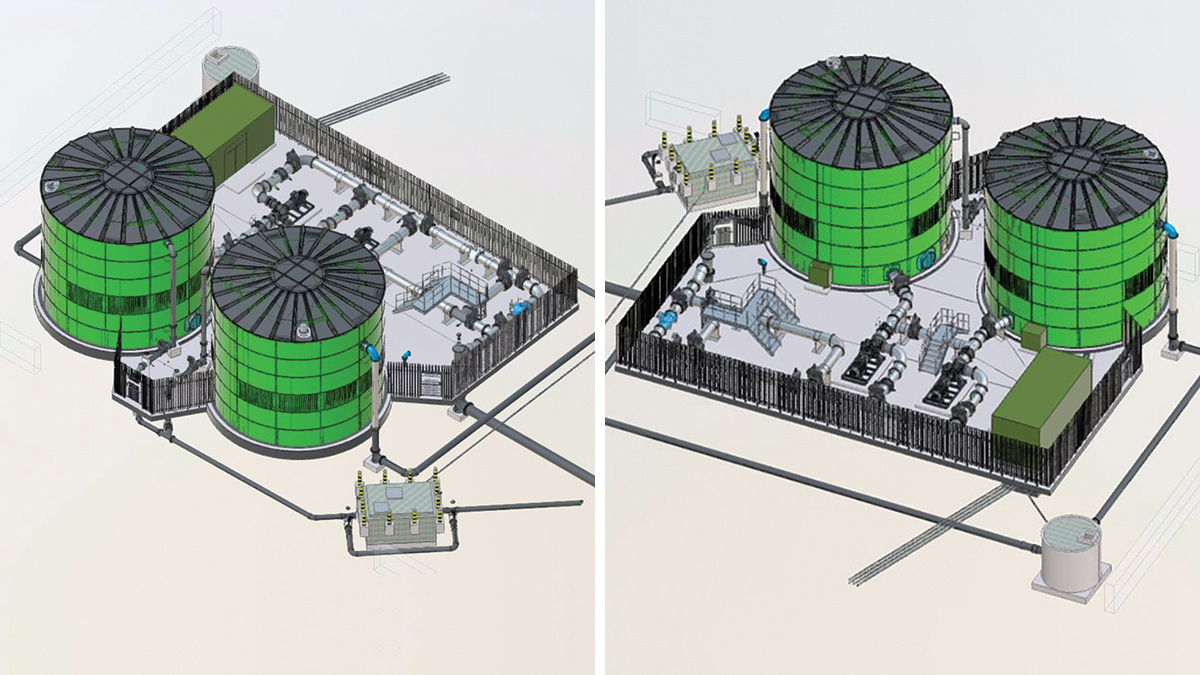

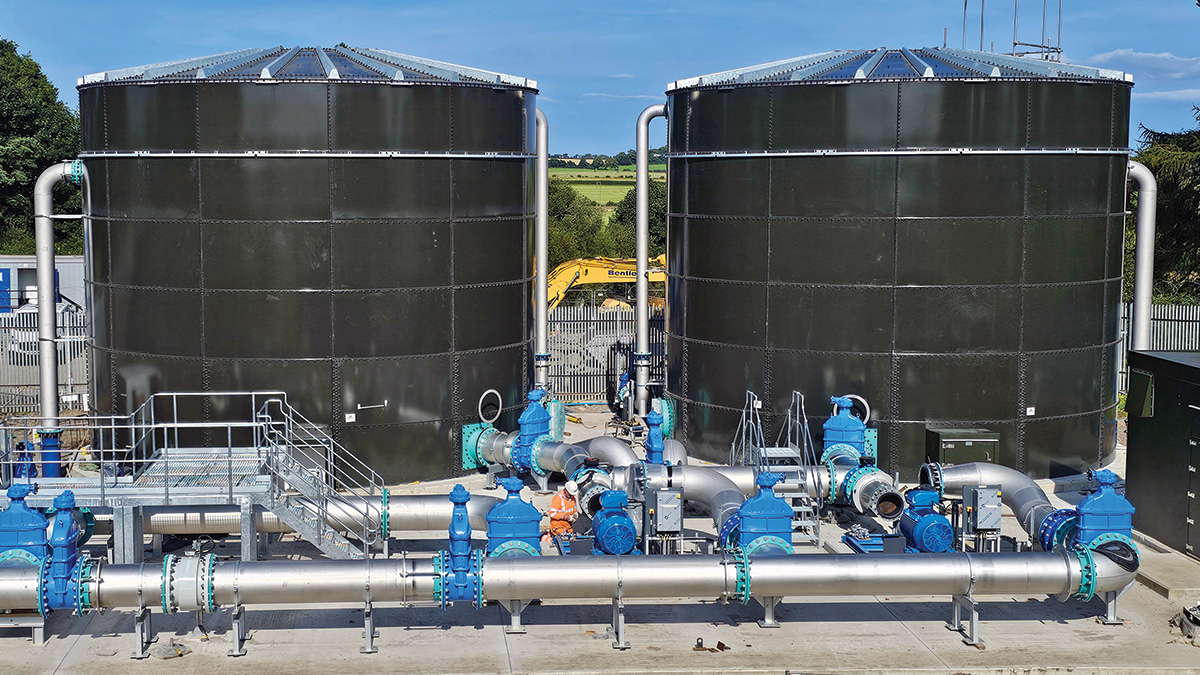

Finished site arrangement - Courtesy of MMB

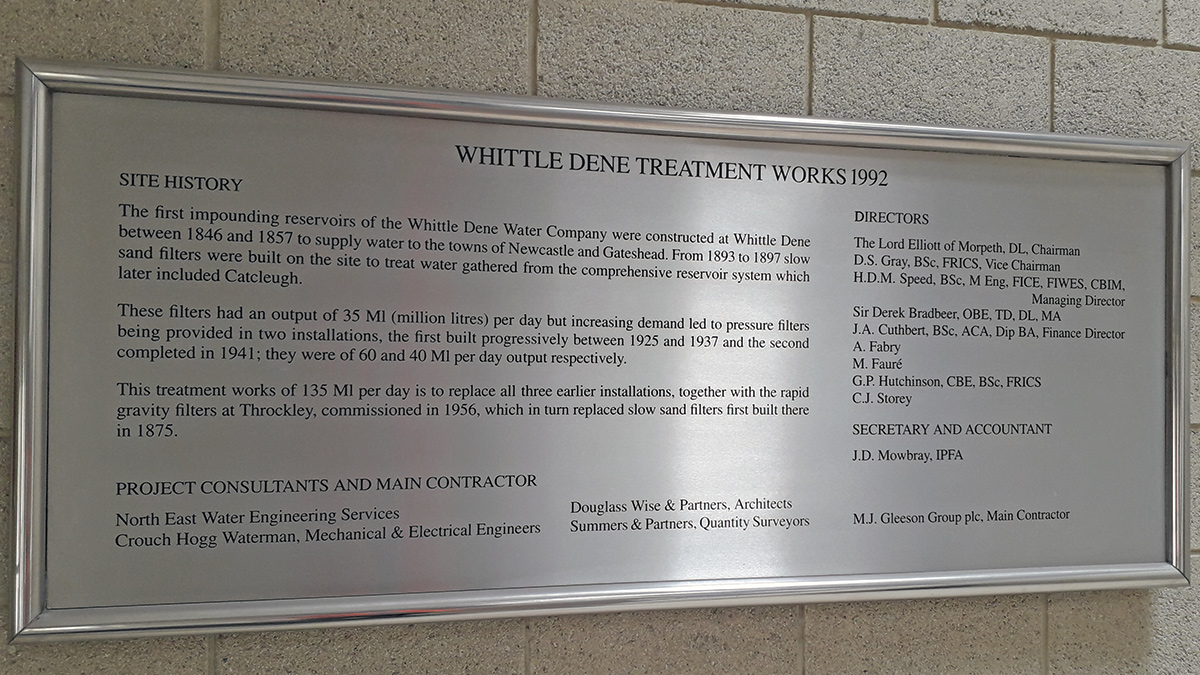

Since the mid-1800s, Whittle Dene has served Newcastle-upon-Tyne and surrounding areas with potable water, and continues do so, albeit with more modern processes and technology. When constructed in 1992, the current water treatment works replaced slow sand filters with sedimentation tanks, rapid gravity filters (RGFs) and chemical dosing, alongside provision of further on-site single cell service reservoir storage to compliment the two pre-existing reservoirs associated with the original works. A scheme followed soon after in the mid to late 1990s to add additional treatment processes by way of granular activated carbon filtration, contact tanks, and abandonment of the two original service reservoirs (likely due to their construction being no longer acceptable for modern water treatment and storage standards), leaving the new reservoir as the sole storage facility on the site.

Project drivers

The main objective of the project was to allow an existing asset, the remaining operational service reservoir, to be taken out of service and inspected, whilst maintaining the treatment works output to the network.

Backwashing of the rapid gravity filters, approximately every 48 hours, requires a significant volume and source of stored water, hence the use of the sole remaining on-site 17 ML in-service reservoir. However, a single source of stored water represented a operational and maintenance bottleneck for Northumbrian Water as no other structure on site was available to store treated water for supply or backwash during maintenance or repairs without disruption.

3D Revit model: (left) Looking west and (right) looking east – Courtesy of MMB

The site faced the following issues:

- Existing backwash pumps, associated drives and MCC were aged.

- The last remaining reservoir in service was the only significant body of stored potable water.

- Limited availability of spare land or unused structures that could be re-purposed on the site to construct new assets.

- Finite spare capacity for power available for new additional assets.

- Lack of spare compartments on existing MCCs from which to take a power supply and install new drives.

- Integration with an on-going, site-wide, fibre optic upgrade project undertaken by others.

Project summary

Northumbrian Water awarded Mott MacDonald Bentley (MMB) a Concept & Define (C&D) contract to review potential solutions, followed by a Design & Construction (D&C) contract, latter valued at £3.1m. The scope of works included:

- Installation of 1,050m3 workable volume of water storage by way of twin glass fused to steel tanks, 525m3 each.

- Installation of two new duty/assist 11 kW storage tank feed pumps each delivering 70 l/s.

- Installation of two new duty/standby 110 kW backwash pumps to deliver 600 l/s.

- Associated buried and above-ground pipework including provision of block and bleed valving for double isolation, flow monitoring and pressure regulation.

- Modification of the existing MCC to add additional tier for new drives.

- MCC, PLC and system integration into existing site-wide SCADA.

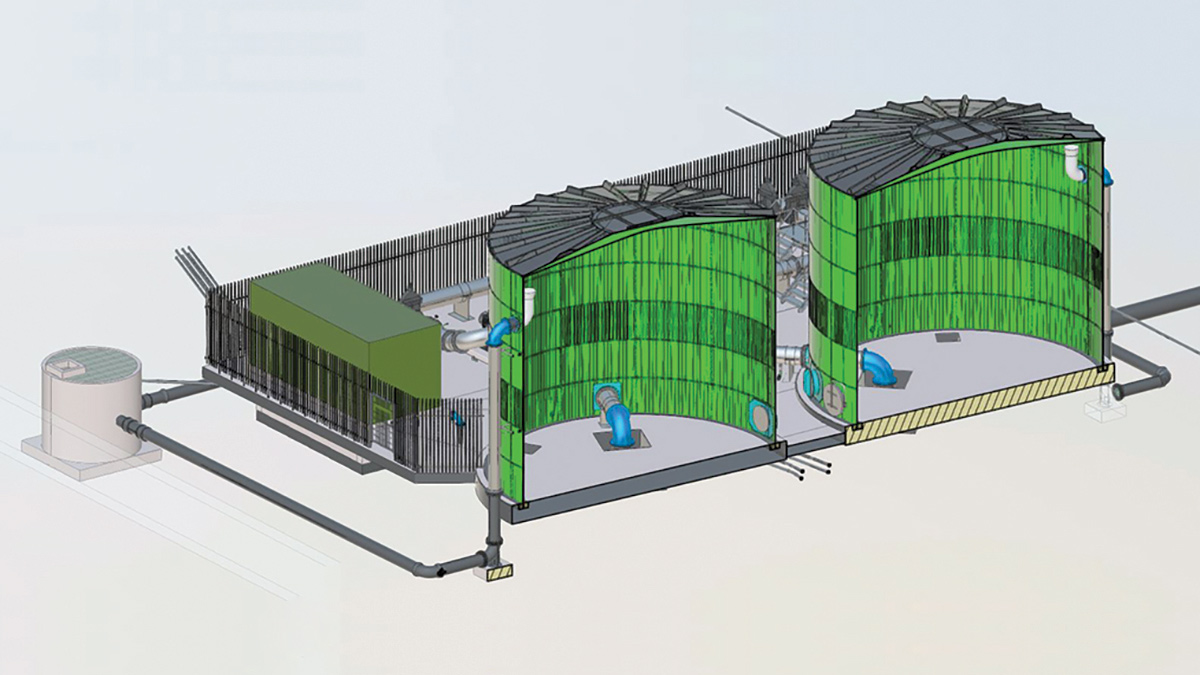

3D Revit model: Section through tanks – Courtesy of MMB

Throughout the project, Mott MacDonald Bentley worked with Northumbrian Water to find solutions that would benefit the project, realising CAPEX, OPEX and carbon savings by replacing the pre-existing backwash system which was fed from the existing reservoir.

Consideration for upgrading the existing fixed flow backwash to a temperature compensated flow rate (to ensure consistent levels of filter bed expansion) was given, however would have required upsizing the existing distribution header pipework. These works would have resulted in significant disruption to the treatment site and was unfortunately ruled out.

Seeking an alternative source of water was a key theme to the success of the project.

Whittle Dene WTW – Backwash System: Supply chain: key participants

- Client: Northumbrian Water

- Principal designer & contractor: Mott Macdonald Bentley

- Flow surveys: Hydraulic Analysis Ltd

- Topographical/GRP surveys: Castle Keep Surveys Ltd

- Contaminated land & asbestos survey: Lucion Environmental

- LV & ICA cabling: Intelect (UK) Ltd

- Backwash switchboard: Blackburn Starling Ltd

- Additional tier to main switchboard: Technical Control Systems

- Systems integration: March Engineering (formerly EJ Peak)

- Cleaning, swabbing & disinfection: Excel Pipelines Ltd

- Coring: NML (Diamond Drilling) Ltd

- Coating works: RAM Services

- Above-ground pipework: Fluid Sealing & Engineering (FSE)

- Under pressure tappings: UTS Engineering Ltd

- Feed pumps: Xylem Water Solutions

- Backwash pumps: SPP Pumps Ltd

- Permastore Trifusion tanks: Goodwin Tanks Limited

- Valves: AVK UK Ltd

- Valves: Affco Flow Control (UK) Ltd

- Pressure sustaining valve: Cla-Val UK Limited

- Pipework: Electrosteel Castings (UK) Ltd

- Pipework: North East Pipeline Solutions Ltd

- Pipework: Saint Gobain PAM UK

- Pipework: EGEPLAST (UK)

- Kiosks: NPS Engineering Group

- Instrumentation: SWAN Analytical UK Ltd

- Instrumentation: Siemens

- Instrumentation: Endress+Hauser Group

- Metalwork & covers: Steelway Fensecure Ltd

- Security covers: Technocover Ltd

- Security fencing: Middleton Forge Ltd

- Scaffolding: SWL Scaffolding Ltd

Above-ground backwash pumps, stainless steel pipework and valves – Courtesy of MMB

Alternative source of water

The original brief was to source potable water by alternative means. This led to a review of options for intercepting fully treated water before it left the site, or if available, from the local distribution network utilising storage capacity at an existing service reservoir approximately 1 mile away. The latter was soon ruled out due to cost and programme considering the length of new mains pipework required to be laid, in third party land.

Focusing on intercepting potable water from within the site, MMB worked collaboratively with our client to review locations to construct new storage and investigated how this could be filled and returned via new backwash pumps to the RGFs for backwashing.

Whilst tees and tappings to divert potable water from existing transfer pipelines within the site were achievable, the ability to create new storage proved more challenging.

The disused original two service reservoirs were early candidates in which to construct storage using modern materials to current potable water quality standards, but the structures lacked:

- As-built records accurately representing their construction.

- Details of foundation to determine re-use to sustain a new loading regime.

- The structures were buried and risked accumulation of surface water and hence required additional pumping CAPEX and OPEX.

- Combined with demolition to remove the existing roofs, the access issues to construct and then maintain new plant represented significant cost.

An area of land immediately adjacent to the existing in-service reservoir and backwash system looked available upon initial walkover, but further investigation revealed extensive made ground with low bearing strength which contained a complex network of services.

The extent of disruptive ground modification necessary to avoid extensive surcharge loading on adjacent structures and service infrastructure rendered this location unfavourable.

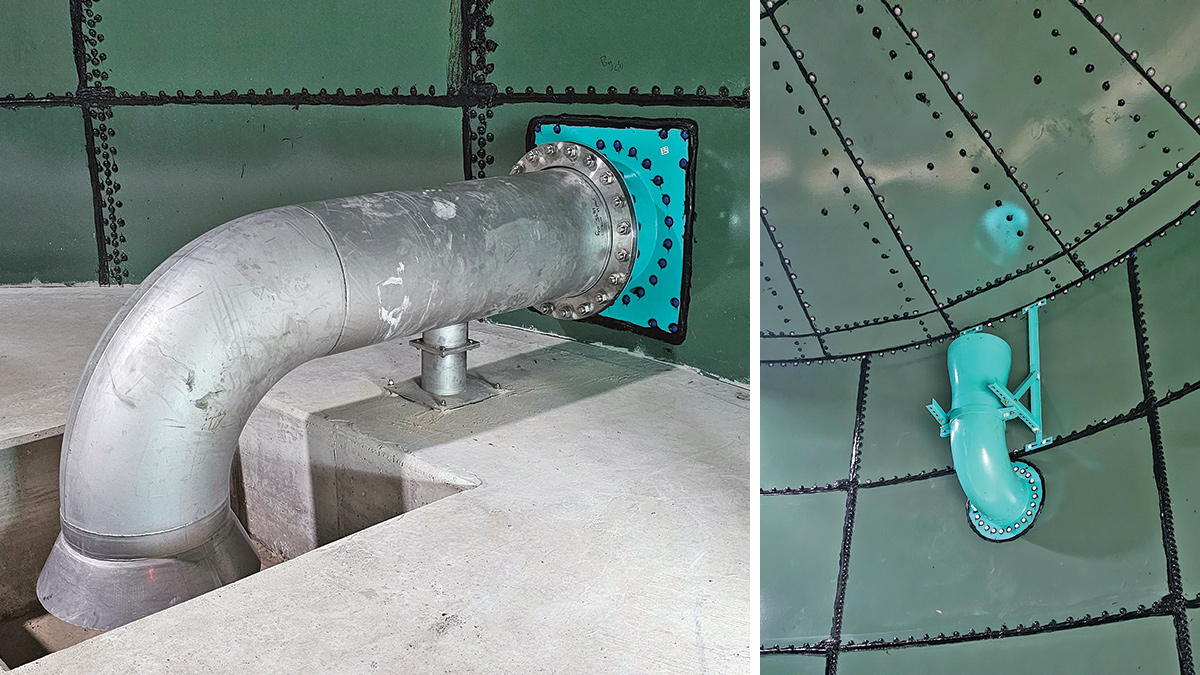

(left) Tank internal view on draw off pipe and (right) tank internal view on overflow pipe – Courtesy of MMB

Due to the need to locate the storage vessels further from the planned source, Mott MacDonald Bentley challenged Northumbrian Water’s requirement that washwater from the rapid gravity filters needed to be potable, and whether partially treated water (pre-final chlorination) i.e. filtered water from the RGFs, could be sourced and re-circulated as RGF backwash water. Northumbrian Water confirmed that this would be an acceptable arrangement not affecting downstream processes.

Thus a solution based upon this philosophy was developed and proposed, requiring buried pipework of the order 100m to connect RGF outlet, new feed pumps, new storage tanks, new backwash pumps and back to the RGF backwash inlet manifold. The tanks and backwash pumps were designed at ground level resulting in low static head and hence low pumping OPEX.

Civils consideration

The material forming the stored water structure was greatly debated for suitability for purpose, ease of construction, programme duration, Regulation 31 compliance, and embedded carbon. Historically the material of choice would have been concrete, whether cast in situ or semi-precast, but other materials were considered, including HDPE, stainless steel, and glass fused to steel (GFS), along with exploration of opportunities for DfMA for off-site fabrication and assembly on site.

Ultimately, despite no precedence within Northumbrian Water’s portfolio of assets whereby GFS has been used to store potable or partially treated water, GFS nonetheless succeeded as the preferred solution, scoring highly in nearly every category considered.

Electrical consideration

Through careful and detailed planning, full works shutdowns were limited to one half day loss of production, to confirm the condition of the main works distribution switchboard busbars for continued use, but equally importantly, for checking the ability to connect the additional tier to supply power to support the new backwash pumps MCC.

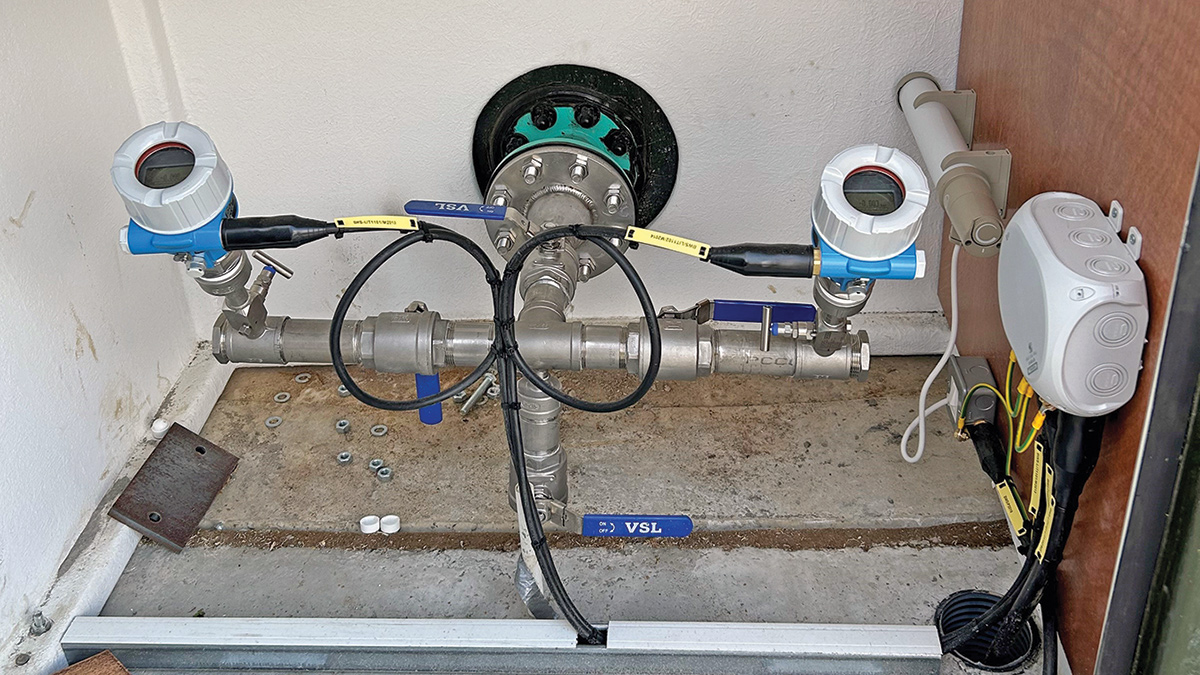

New backwash MCC in kiosk to power and control new plant and equipment – Courtesy of MMB

A harmonic survey was also undertaken to provide a representative profile of the background harmonic distortion in order to demonstrate that the equipment incorporated within the new MCC would conform with the requirements of the Energy Networks Association document Engineering Recommendation G5/5.

Whilst a shutdown was granted to expediently check the main switchboard busbars, a full board condition survey would have required much longer to have informed an outline design and enquiry with suppliers for the detailed design, manufacture and installation subcontract package for the additional tier. To mitigate risk, MMB engaged with the original panel supplier for provision and installation of the new tier to benefit from their knowledge of the original panel design, which proved highly successful upon site acceptance testing and commissioning.

Mechanical consideration

To ensure no loss in RGF backwash performance, Hydraulic Analysis Ltd was engaged to survey the flow and pressure seen at each of the various filters. The pumps were then sized to be able to provide a constant flow of 600 l/s to each of the filters independently, regardless of which filter in the 130m long gallery was to be washed.

The varying discharge head requirements was compounded by sizing the pumps for maximum to minimum suction head variation of 8m in the storage tanks. This required the use of a pressure sustaining valve and variable speed pumps to provide the required flow and pressure irrespective of the discharge and suction conditions.

Hydrostatic pressure transmitters – Courtesy of MMB

Digital delivery

Following site surveys and collation of information physically held on site and in digital format e.g. as-builts, a 3D Revit model was developed showing all known assets above and below ground including services. This was fully utilised throughout design development for siting the new structures avoiding construction over known assets, and for routing new pipelines and cables through the myriad of pre-existing services.

All stakeholders were invited to an access, lifting and maintenance (ALM) review whereby the model was viewed on screen, but also through a VR headset, where a walk-through simulation identified several ALM issues including access to valve handwheels to operate them, resulting in chains being provided, and hop-over stairs and platforms where above-ground pipework prevented access to all areas.

The model was linked to the construction programme through Syncro, creating a 4D planning and project management resource for all stakeholders to visually understand sequencing and interfaces throughout the construction phase.

Collaboration and proactive management

The project was a complex multidisciplinary replacement of assets requiring integration to a strategically important treatment works.

This required proactive management of work-faces to achieve its implementation combined with adaptable planning to meet changing constraints evolving through daily management of the treatment works. To achieve this, MMB employed regular collaborative planning sessions to look ahead and plan out forthcoming work activities and management of interfaces.

The collaborative planning sessions brought all parties together including client capital delivery team, treatment works operators, and key subcontractors.

The sessions aimed to highlight opportunities, identify blockers and agree a collaborative plan for not only upcoming tasks, but to map the route to ensure efficient and seamless delivery of the scheme to completion. Held every month, and coupled with buildability reviews on the practicality of the developing methodology, MMB enabled a clear plan to be developed which was bought into by all stakeholders.

Installation of new tanks, backwash pumps, stainless steel pipework and valves – Courtesy of

Summary

Whittle Dene WTW’s status as a key asset within Northumbrian Water’s portfolio means that the community benefit it currently provides, in terms of safeguarding water supply for major parts of the north east, cannot be understated.

After over 100 years of service, the scheme implemented as a part of this project will mean that the treatment works can continue to operate for decades to come, with less demand on multiple electrical and mechanical upgrades of aging assets, and by having a more serviceable and maintainable reservoir.

Overall use of collaborative planning enabled the site team to ensure our client and their operations team were fully briefed of the forthcoming works and interfaces, and as a tool to engage with subcontractors and suppliers for sufficient notice of the optimal time to attend site to undertake their works. In total, the project had over 50 personnel on site and involved over 25 different sub-contractor organisations.

Whittle Dene WTW site history - Courtesy of MMB