WISP Global Limited

PFAS Treatment Pilot Plants (2025)

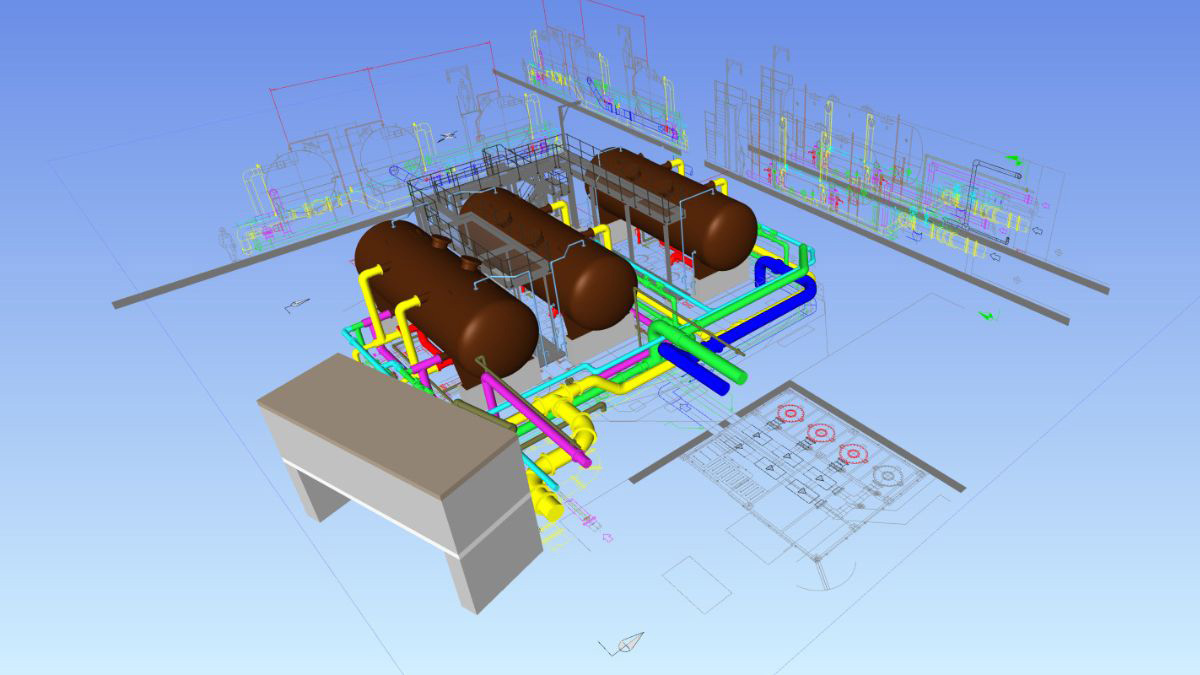

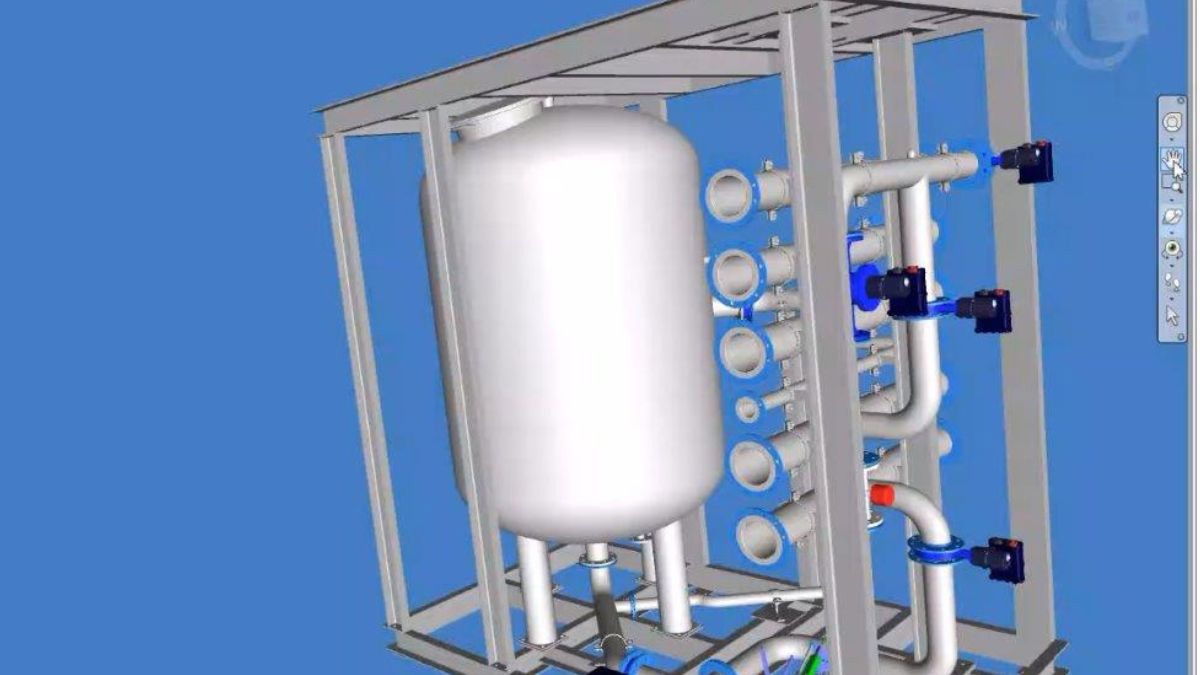

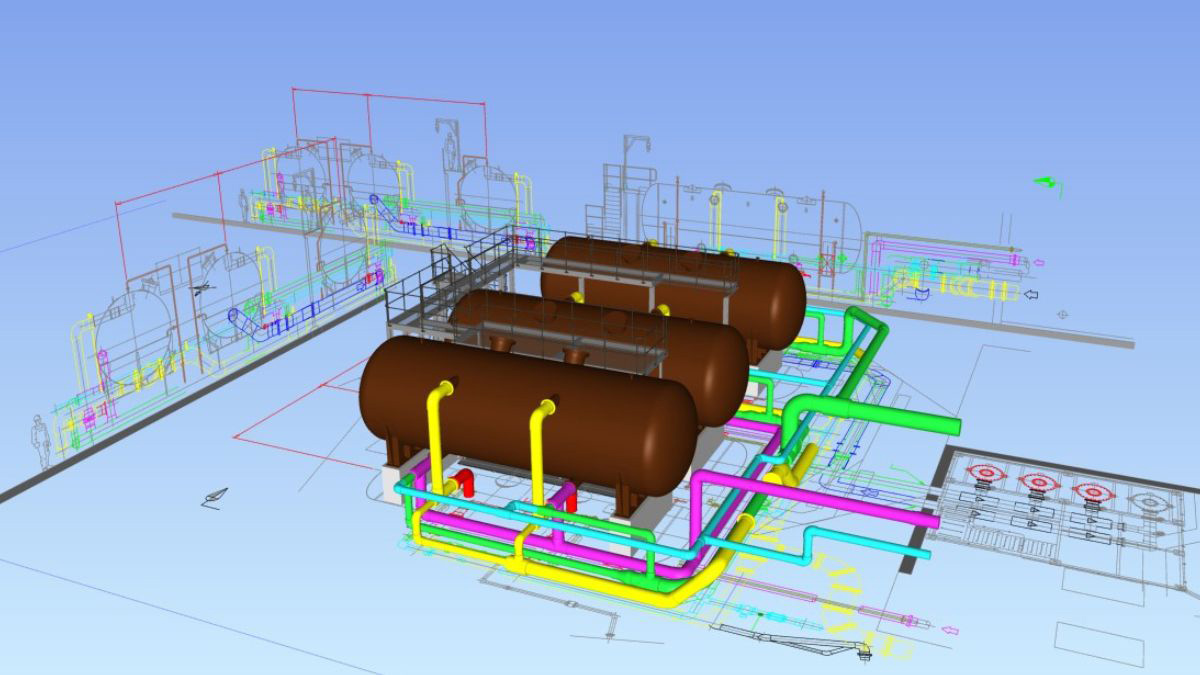

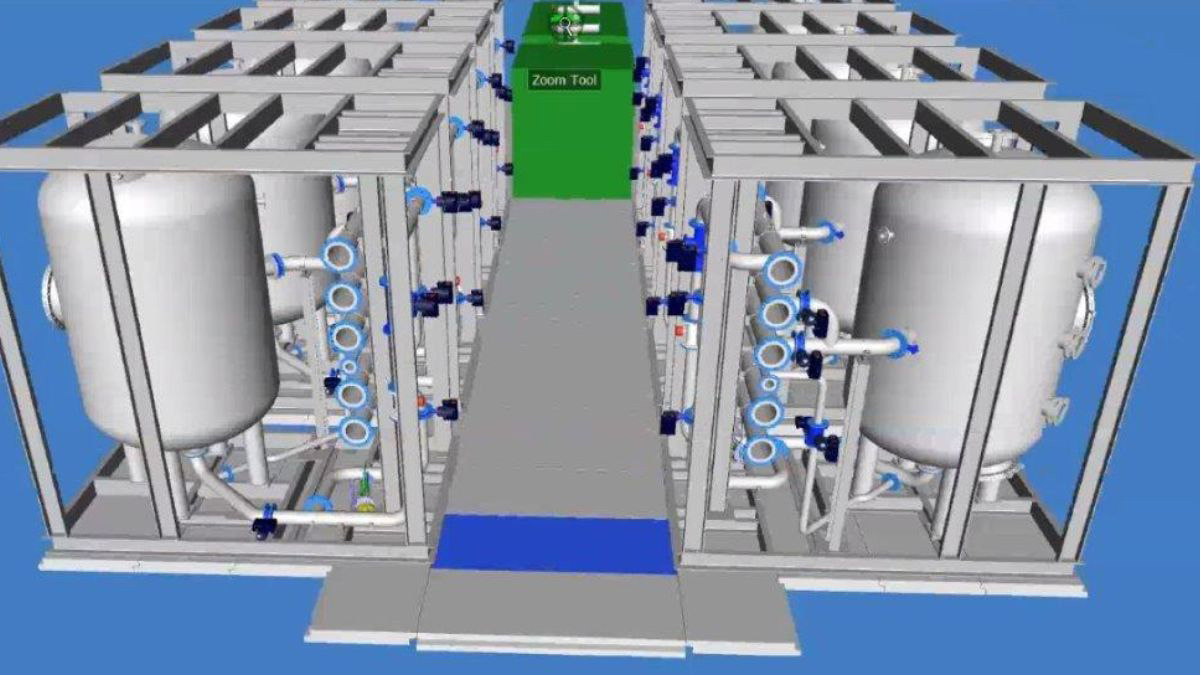

Witches Oak WTW: (left) CeraMac vessel towards the end of installation, (top right) backwash vessel in the foreground and CeraMac vessels in the background, and (bottom right) view of the air-spring manifold - Courtesy of Severn Trent/Nijhaus/PWNT

Across the global water industry, the challenge of emerging contaminants is becoming increasingly urgent. Among these, per- and polyfluoroalkyl substances (PFAS) represent one of the most difficult groups of compounds to manage. Often described as forever chemicals, PFAS are widely used in industrial and consumer products, from firefighting foams to textiles, and are characterised by their resistance to degradation and ability to simultaneously repel water and oil substances. This persistence results in long-term accumulation in the environment and water sources, raising concerns about their potential impacts on human health and ecosystems.

Witches Oak WTW

Severn Trent has constructed a new water treatment works, specifically to treat raw water supplied from the River Trent, a major surface water source in the East Midlands, which contains elevated concentrations of PFAS, presenting a significant challenge.

With growing regulatory attention on PFAS levels in drinking water, Severn Trent prioritised the development of a robust solution to protect consumers and comply with DWI Regulation 15 for the introduction of a new water source, and with anticipated future regulatory standards.

To address this challenge, Severn Trent employed WISP Global to help develop, design, and commission an innovative PFAS treatment solution at the newly constructed Witches Oak WTW. At the heart of this collaboration was a comprehensive pilot programme, led by WISP Global, that tested and validated advanced technologies capable not only of removing PFAS from drinking water, but also of breaking down the notoriously strong carbon–fluorine bond; enabling safe, permanent disposal.

Technical approach

Traditional water treatment methods, including granular activated carbon (GAC) and ion exchange resins, are effective at capturing PFAS from raw water. However, these approaches do not address the underlying issue of safe waste management. Spent media containing PFAS must be replaced and disposed of, typically via incineration or landfill, shifting rather than solving the environmental burden.

Recognising this limitation, WISP Global’s pilot programme explored and optimised technologies that go beyond just capture but also the destruction of PFAS compounds. This capability represents a step change in water industry practice, offering a sustainable and long-term solution.

The pilot programme included a number of conventional and novel technologies, targeting both removal and destruction of PFAS compounds.

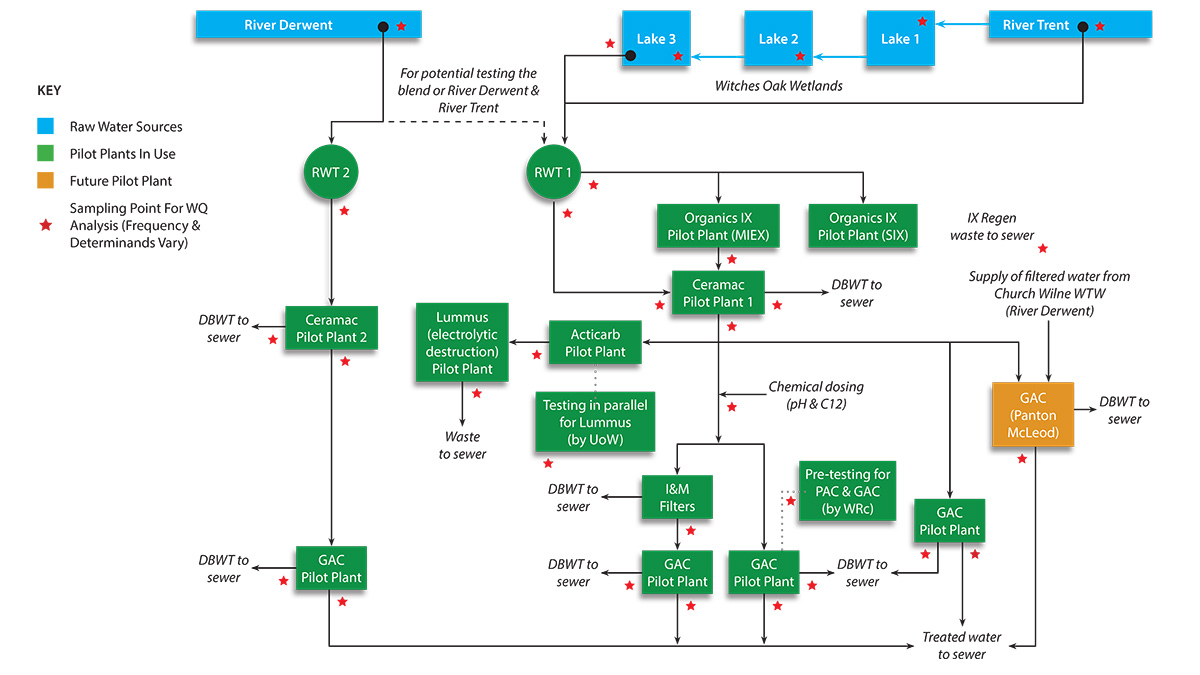

Overall pilot plant schematic – Courtesy of WISP Global

The pilot plants involved different suppliers, forms and grades of activated carbons, plus comparative virgin and regenerated media, impact of iron and manganese on removal, ceramic membranes, ion exchangers, passive sampling systems, plus electrolytic oxidation destruction.

Each technology was evaluated for:

- Removal efficiency across short-chain and long-chain PFAS compounds.

- By-product management, ensuring breakdown products are safe and non-toxic.

- Energy demand and operational footprint, critical to long-term affordability and carbon impact.

- Integration potential within a large-scale treatment works.

The pilot programme provided Severn Trent with robust, site-specific performance data, to inform the design of the Witches Oak WTW, and ensured it is equipped with a PFAS-resilient treatment train capable of meeting both current and emerging regulatory requirements.

Case studies & pilot results

Pilot units were deployed at abstraction points along the River Trent, to process representative flows of raw water under real-world conditions. Data from these trials was central to validating performance of the technologies and feasibility for scale-up.

Key findings included:

- High removal rates: Several treatment trains achieved reductions of PFAS concentrations to below 10 ng/l, aligning with the most stringent international regulatory standards.

- PFAS destruction: The trials demonstrated measurable cleavage of the carbon–fluorine bond, with residual fluorine captured as stable inorganic by-products, suitable for safe disposal.

- Operational stability: Pilot units were operated continuously over extended periods, providing insight into maintenance requirements, resilience to fluctuating raw water quality, and energy use.

- Waste minimisation: Destructive processes reduced the volume of PFAS-laden residuals that required off-site disposal, decreasing both environmental risk and lifecycle costs.

These results gave Severn Trent Water the confidence to adapt the design of the newly constructed Witches Oak WTW, integrating an optimised PFAS treatment capability directly into its operational framework.

View of the air-spring manifold – Courtesy of Severn Trent/Nijhaus/PWNT

Impact & benefits

The WISP Global–Severn Trent initiative represented one of the first UK-based programmes to demonstrate combined PFAS removal and destruction at pilot scale. The outcomes provide a model for utilities across the sector.

Key impacts included:

- Innovation in treatment design: By adding an ion-exchange raw water pre-treatment, this allowed the conventional adsorptive methods to be optimised for PFAS removal. Severn Trent had positioned Witches Oak WTW as a next-generation facility capable of addressing not only today’s challenges but also future contaminants of concern.

- Cost efficiencies: Despite the step change in treatment cost, the pilot trials enabled lifecycle data analysis, which suggested long-term cost savings through the potential for prolonging media replacement and the possibility for media regeneration [still under investigation], transport, and disposal requirements.

- Carbon reduction: Minimising the need for frequent media regeneration and off-site disposal directly lowers the carbon footprint of treatment operations.

- Environmental stewardship: Severn Trent ensured its supply chain could apply destructive processes to mitigate the risks associated with PFAS-laden waste streams, reducing reliance on landfill while eliminating the possibility of re-release into the environment.

- Consumer protection: Customers of Severn Trent will benefit from enhanced drinking water quality and assurance, with them taking a proactive stance on an emerging health risks.

In addition, the project provides a scalable framework for addressing PFAS contamination in other surface water sources across the Severn Tent portfolio, other water companies in the UK and internationally.

Conclusion & future outlook

PFAS represent one of the defining water quality challenges of the coming decade. Their chemical persistence, widespread occurrence, and potential health risks demand solutions that are both technically robust and environmentally sustainable.

Through collaboration with WISP Global, Severn Trent Water is demonstrating leadership in addressing this challenge head-on. The pilot trials on the River Trent delivered the data and insights needed to commission the Witches Oak WTW as a facility capable of removing PFAS from drinking water cycle, which is a step change in industry practice.

The success of this initiative will inform wider application of PFAS treatment technologies across Severn Trent’s network and provide a benchmark for other utilities facing similar challenges. Future research will continue to optimise energy efficiency, explore hybrid treatment trains, and extend PFAS destruction methods to address a wider suite of persistent contaminants.

By investing in innovation today, Severn Trent Water, with WISP Global, are laying the foundation for a resilient, future-proofed water supply that protects both public health and the environment.

Witches Oak WTW design & construction case studies

You can read the Witches Oak WTW design and construction case studies here:

- 2023: Witches Oak WTW – Case study 1

- 2024: Witches Oak WTW – Case study 2

- 2025: Witches Oak WTW – Case study 3

CeraMac inlet pipework - Courtesy of Severn Trent/Nijhaus/PWNT