Wem STW (2025)

Oxibox aeration tanks - Courtesy of Mott MacDonald Bentley

Wem (Aston Road) STW is a medium-sized sewage treatment works located in Shropshire. The objective of the AMP7 scheme is to improve the quality of the final effluent in line with the Water Framework Directive (WFD) requirements set out in the National Environment Programme (NEP). The current connected population is 5,786 and is due to increase by 26% to 7,301 by 2033 design horizon. As part of the WFD, the site was identified for a new Total Phosphorus (P) permit of 0.6 mg/l and a tightening in ammonia (NH3) from 5mg/l to 4mg/l. The pDWF increased from 1570m3/d (18.2 l/s) to l,900m3/d (22 l/s) triggering a major rise in the permitted full flow to treatment (pFFT) from 38.2 l/s to 64 l/s.

Scheme development

This £10.4m capital investment project pushed the design and build team to the limit due to the enormous task of increasing the capacity of the sewage treatment works by 70% with the introduction of a 0.6 mg/l Total P permit and tightening of the ammonia permit, in an already spatially constrained site. Due to planning restrictions, no additional land purchase was feasible and therefore all upgrades were confined to the existing site boundary.

The existing site consisted of an inlet works, two PSTs, primary stone media filters with HSTs, secondary plastic media filters with HSTs and finally a TSR. Due to hydraulic and process incapacities the scope was to carry out a major overhaul by providing a new treatment process. The scope of works comprised of a new FFT PS, crude Oxibox ASP system, two FSTs, RAS/SAS complete with sludge thickening and new sludge holding tank, chemical dosing system and increased storm storage.

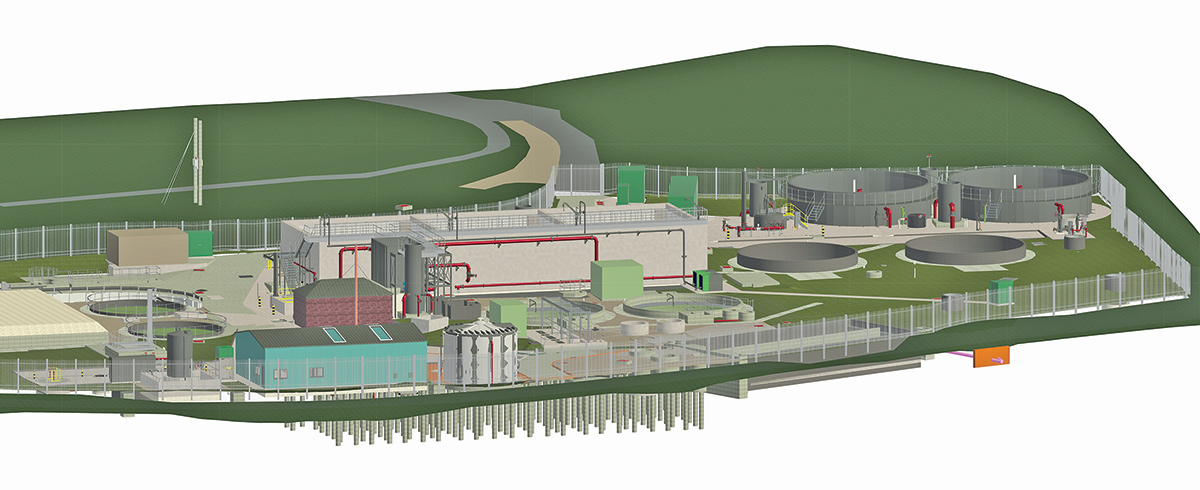

Model of WEM STW – Courtesy of Mott MacDonald Bentley

MMB carried out design sprints and buildability reviews with Severn Trent to highlight areas that carried significant risk to the programme and treatment process. In doing so, MMB restructured the outline design and optimised the installation sequence to provide a robust programme. Two key opportunities were identified.

- Relocating the Oxibox outside the overhead electrical cables, that were due to be relocated later in the project alongside a power upgrade to the site. This allowed the construction of the Oxibox to be removed from the critical path helping to maintain the permit regulation date. The change of location also unlocked a design efficiency by optimising the dimensions, while maintaining the process requirements which reduced the volume of concrete and tonnage of steel by 15%.

- It became apparent as the scheme progressed and additional structures were built, that the working room to install the cross-site pipework, ducting and other ancillaries would foul access for construction works and Severn Trent Water Operations. The decision was therefore made to accelerate works and start ahead of the main construction works, facilitating multiple working fronts and maintaining access for Severn Trent Operations throughout the scheme.

To create space on site, the existing two 20m diameter plastic media filters, along with other assets, needed to be demolished to make way for the new structures. The team adjusted the existing process, which involved extensive site-wide quality monitoring, to allow for no detrimental effect to the effluent quality, mitigating the need to provide temporary treatment throughout the construction works.

Wem STW: Supply chain – key participants

- Main designer/contractor: Mott Macdonald Bentley | MMB

- Civils: DS Construction Services ltd

- Piling: Ivor King The Piling People

- Geogrid reinforced piling mat: Tensar

- Core drilling: Optima DS

- Oxibox FRC: Offa-fix Formwork Ltd

- Oxibox aeration system: Suprafilt Ltd

- Aeration system blowers: AERZEN Machines Ltd

- FST tanks: FLI Precast Solutions

- FST half-bridge scrapers: EPS Water

- Access platforms: KG Site Services Ltd

- Electrical: Protocol Control Services Ltd (PCS)

- ICA: BGEN Ltd

- Control panels: CEMA Group

- Generator: A&M Generators Limited

- Sludge thickening building: LGSF

- Screening/sludge thickening: Huber Technology Ltd

- Sludge tank: Goodwin Tanks Limited

- Mechanical installation: Pruce Newman Pipework Ltd

- Auto strainer: Bollfilter UK Ltd

- Chemical dosing: Colloide

- MDPE package PS & distribution chambers: SDS Limited

- Pumps: SEEPEX UK Ltd

- Pumps/mixers: Xylem Water Solutions

- Pumps: Grundfos Pumps Ltd

- Pipework: Saint Gobain PAM UK

- Valves/couplings: AVK UK Ltd

- Trace heating & lagging: Waste Water Manufacturing (WWM)

- Storm tank cleaning: Spray Nozzle People

- Flow controls: Rotork

- FE monitoring: Servitech International Ltd

- Crane lifts: Q Crane & Plant Hire Ltd

- Crane lifts: Dewsbury & Proud Ltd

- Lifting: T Allen Engineering Services Ltd

- Lightening protection: BEST Services Ltd

- Security fencing: Town & Country Fencing (Midlands) Ltd

(left) Screening channel modifications and ROK1 scree and (right) FFT pumping station – Courtesy of Mott MacDonald Bentley

Oxibox design/control development

The Oxibox solution at Wem approximates a traditional pocket activated sludge plant (ASP) into three cells, which operate independently, taking a third of the flow each. This allows for a reduced footprint secondary treatment process, ideal for a site with such space constraints, and allowing for future-proofing of the community’s wastewater treatment.

Crude flows are sent to the Oxibox in order to provide sufficient load from the catchment to the process, which are pumped via the new 4m diameter 5m deep full flow to treatment pumping station up to a MDPE selector zone, which is ferric dosed and mixed, providing 20 minutes of retention at average flow, promoting beneficial microorganism growth over that of filamentous bacteria, improving settleability in subsequent final settlement tanks.

Flow is split equally into one of the three Oxibox cells. Here, a fine bubble diffused aeration system from Suprafilt Ltd is supplied by two D/S blowers from AERZEN Machines, providing aeration to the load and allowing for nitrification. The 12m x 12m x 4.5m deep cells are fitted with individual dissolved oxygen monitors, with PID control maintaining a DO setpoint of 1.5mg/l through altering air volumetric flow rate.

Twenty-minute anoxic periods are triggered via a peg timer, which is adjustable via the human machine interface (HMI), and can act sequentially for each cell, or simultaneously. The aeration alters equally between anoxic and minimum aeration for mixing. Mixers from Xylem Water Solutions in each cell are triggered via air flow reaching a minimum aeration for mixing set-point, or anoxic period being triggered.

Flow spends, on average, eight-hours within the Oxibox before passing to the FSTs, which is the first settlement stage, where the majority of flocs formed by the secondary process and suspended solids are removed.

(left) Fine bubble aeration system in the Oxibox cell and (right) aeration system leak and pattern test – Courtesy of MMB

Oxibox construction

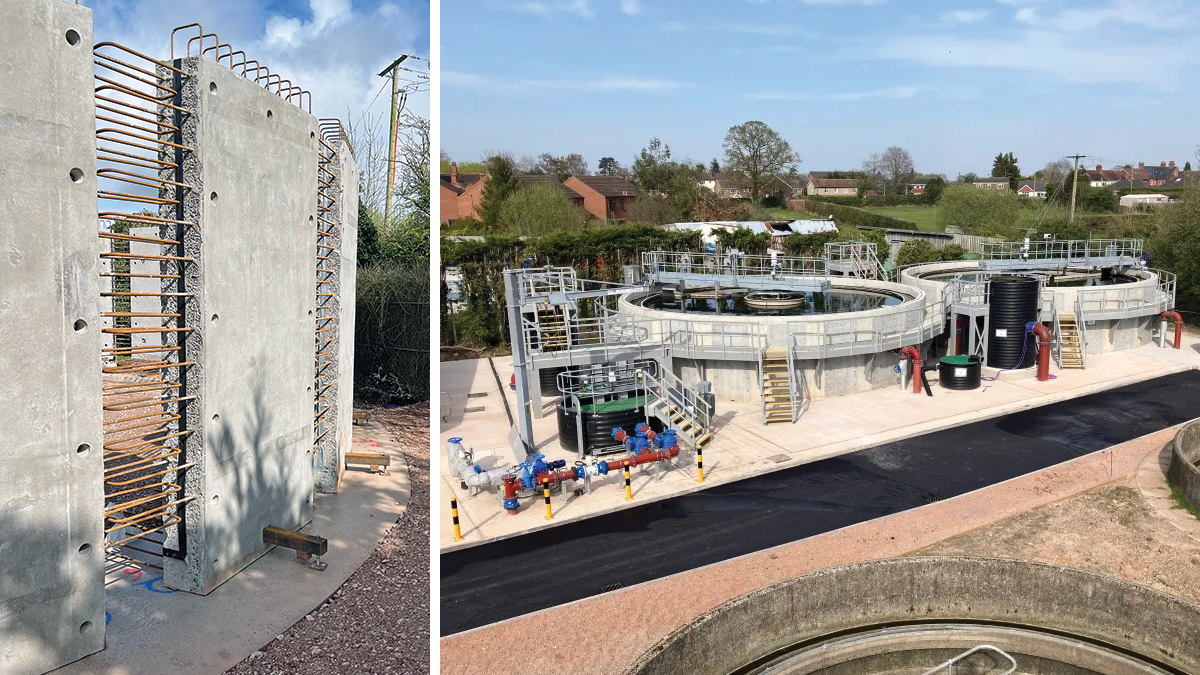

Historic mapping highlighted that the River Roden was channelled outside the site to make way for major expansion in the 1940s. The ground investigation review concluded that the Oxibox needed to be founded on 131 CFA piles, extending 15m below ground.

To facilitate the piles, historic abandoned assets needed to be removed from the ground; with 580t of hardcore material being processed into 6f5 grade. This was then used as a suitable backfill material to stabilise the ground ahead of the planned construction works. This operation reduced the number of lorry movements through the neighbouring housing estate and it was calculated that the processing of this material had a reduction of embodied carbon of 24,132kg CO2e.

Due to the spatial constraint and programme pressure to meet the obligation date, MMB worked with piling subcontractor (Ivor King The Piling People) to engineer a unique pile head design which finished below the pile mat for two reasons.

- It allowed for the use of couplings to tie the structure into the piles which mitigated the need to remove the pile mat and crop the pile head.

- It allowed for the crane to be cited on the footprint of Cell 3 of the Oxibox to construct cell 1 and 2; allowing access to be maintained.

Due to the low Cu value of the soils, MMB worked with Geogrid suppliers, Tensar, to design the reinforced pile mat. This collaboration led to a reduction in thickness from 1200mm to 560mm, which significantly decreased both the quantity of materials used and the number of compaction passes required. After integrity tests on the piles were complete, Offa-Fix Formwork Ltd started construction of Cells 1 and 2 of the in situ Oxibox in early March 2024.

A crane coordinator was employed throughout the scheme to oversee the multiple complex lifts that occurred daily within the spatially constrained site.

(left) Piling operation underway and (right) Oxibox construction – Courtesy of Mott MacDonald Bentley

Final settlement tanks

Flows from the Oxibox cells will be transferred to an MDPE above-ground distribution chamber from SDS Limited; splitting the flow to the two new 12.8m diameter final settlement tanks.

A precast concrete option was chosen for the final settlement tanks, with FLI Precast Solutions bought into the scheme, understanding the nature of the programme, for which they proposed an innovative removable toe design allowing for the casting time in the factory to be halved with only one mould required. This design also allowed for additional units to be added to the transportation, reducing the logistical time and keeping the scheme on programme.

The removable toe allowed for the site team to set each panel with precision due to the simple addition of a M20 bolt which allowed for a wrench to provide precise placement.

Half bridge scrapers and hanging launders were provided for each tank by EPS Water. The bridges were complete with EDIs and McKinney baffles. Both contractors worked seamlessly within MMB’s CDE, providing 3D models and allowing for clash detection reviews to be undertaken.

GRP access platforms were used throughout the scheme; fabricated and installed by KG Site Services Ltd (KGSS). The use of GRP allowed for the FST access platforms to be installed by hand, reducing the need for craneage and allowing for additional activities in the area to occur.

(left) FST removable toes and (right) the completed precast FSTs – Courtesy of Mott MacDonald Bentley

Storm screenings

Due to the increase in FFT, the 3PG weir was made redundant. A mechanical ROK1 screen from Huber Technology was installed on the 6PG weir to screen all flows and return the solids into the inlet channel.

Increased storage

The existing site comprised two rectangular tanks totalling 250m3 of storage. Once the new site was operational, the existing two PSTs were re-purposed into additional storm storage. Each PST added an addition storage volume of 220m3.

The team was challenged with the interface of combining old assets with new and worked collaboratively with Severn Trent to facilitate clever engineering to re-use the HST tanks, which were due to be demolished for additional storm storage.

Adding these four tanks to the existing storm storage provided an increase of over 500% of additional capacity. Storm tank cleaning was introduced with a new washwater pumping station connected to 360° spray nozzles fitted in specific locations providing automatic cleaning post a storm event.

RAS/SAS & sludge storage

The new process required the introduction of a sludge handling facility. A MDPE pre-package RAS/SAS pumping station from SDS Limited was selected which provided much needed programme savings. A new sludge handling building was installed by LGSF to house an S-DISC sludge thickening plant from Huber Technology.

A single 124m3 sludge storage tank was proposed to replace the existing tanks. By obtaining the original as-built drawings, MMB worked closely with Goodwin Tanks Ltd to design the same diameter tank and slab mounting detail, which allowed the old tank to be removed and the existing concrete base slab and ancillary pipework to be reused. This enabled the sludge storage to be brought into operation two weeks earlier than programmed, reducing client tanker operations.

Having detailed as-built drawings that dated from 1908, MMB was able to structurally assess and reuse tanks that had been abandoned to enable the construction of the inlet works and temporary bypass. Furthermore, three existing pumping stations were re-purposed by retaining the structures and retrofitting them with new mechanical assets making them compliant with the latest standards.

Stuart Page, Senior Project Manager with Severn Trent explains the investment at Wem STW that will help protect rivers in Shropshire

Successes

The scheme successfully met the obligation permit date in December 2024. With 76,974 hours worked without a LTI or RIDDOR while maintaining access throughout the scheme to the operational sewage treatment works without impacting effluent quality performance.

Since the site has become operational, flows are being retained on site during storm events, which has improved the overall environmental impact.

With the Oxibox being only the second of this type of ASP within Severn Trent’s region, a low process risk remained to the site achieving it the tightened Total P permit and a phased TSR approach is scheduled in future AMPs. However, due to the performance of this reactor, the site has been consistently achieving low phosphorus levels with only front-end chemical dosing. This has reduced chemical usage as well as the scope of future tertiary solids removal plants.

Given the complex control for this application, combining several of Severn Trent aeration control design manuals, Wem STW is being used as a basis for a several more projects across the Severn Trent Water region.

Wem STW: Panoramic view of the site - Courtesy of Mott MacDonald Bentley